| Citation: |

Wei Pan, Yunfei Han, Zhenguo Wang, Qun Luo, Changqi Ma, Liming Ding. Over 1 cm2 flexible organic solar cells[J]. Journal of Semiconductors, 2021, 42(5): 050301. doi: 10.1088/1674-4926/42/5/050301

W Pan, Y F Han, Z G Wang, Q Luo, C Q Ma, L M Ding, Over 1 cm2 flexible organic solar cells[J]. J. Semicond., 2021, 42(5): 050301. doi: 10.1088/1674-4926/42/5/050301.

Export: BibTex EndNote

|

-

References

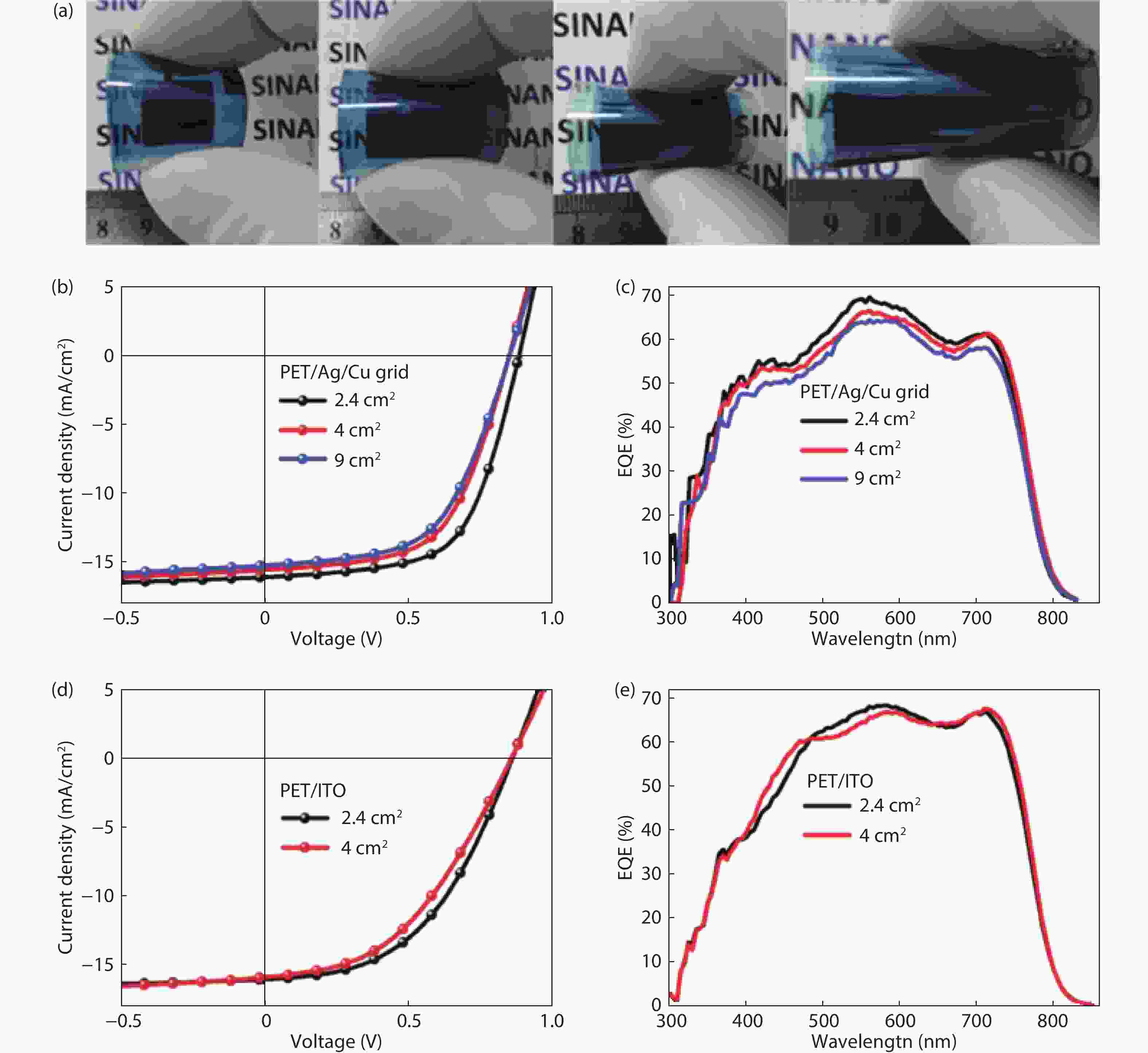

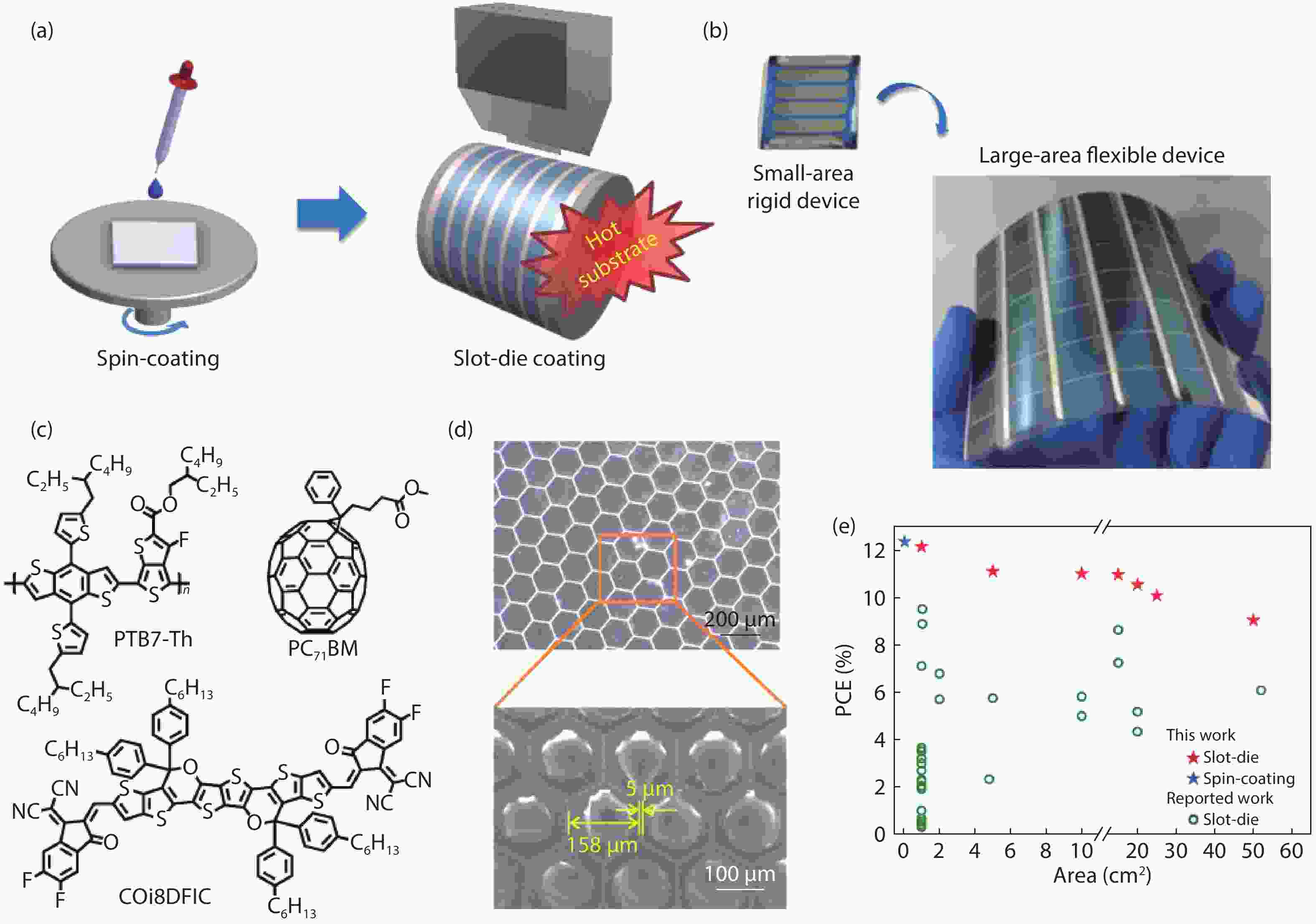

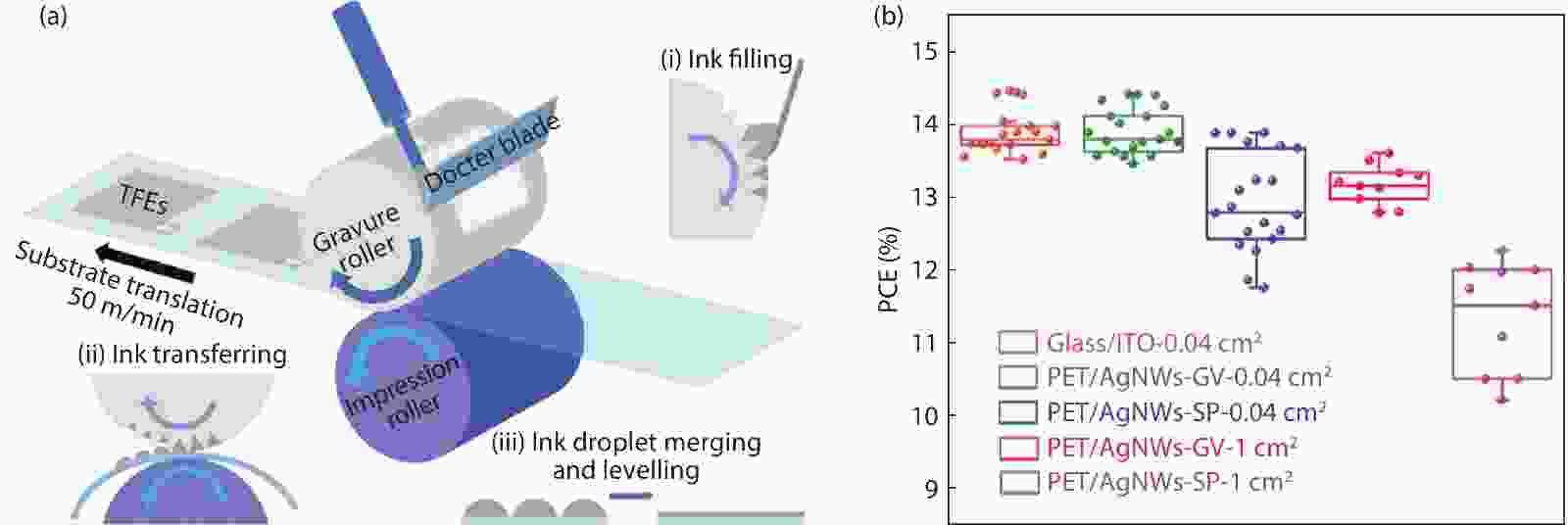

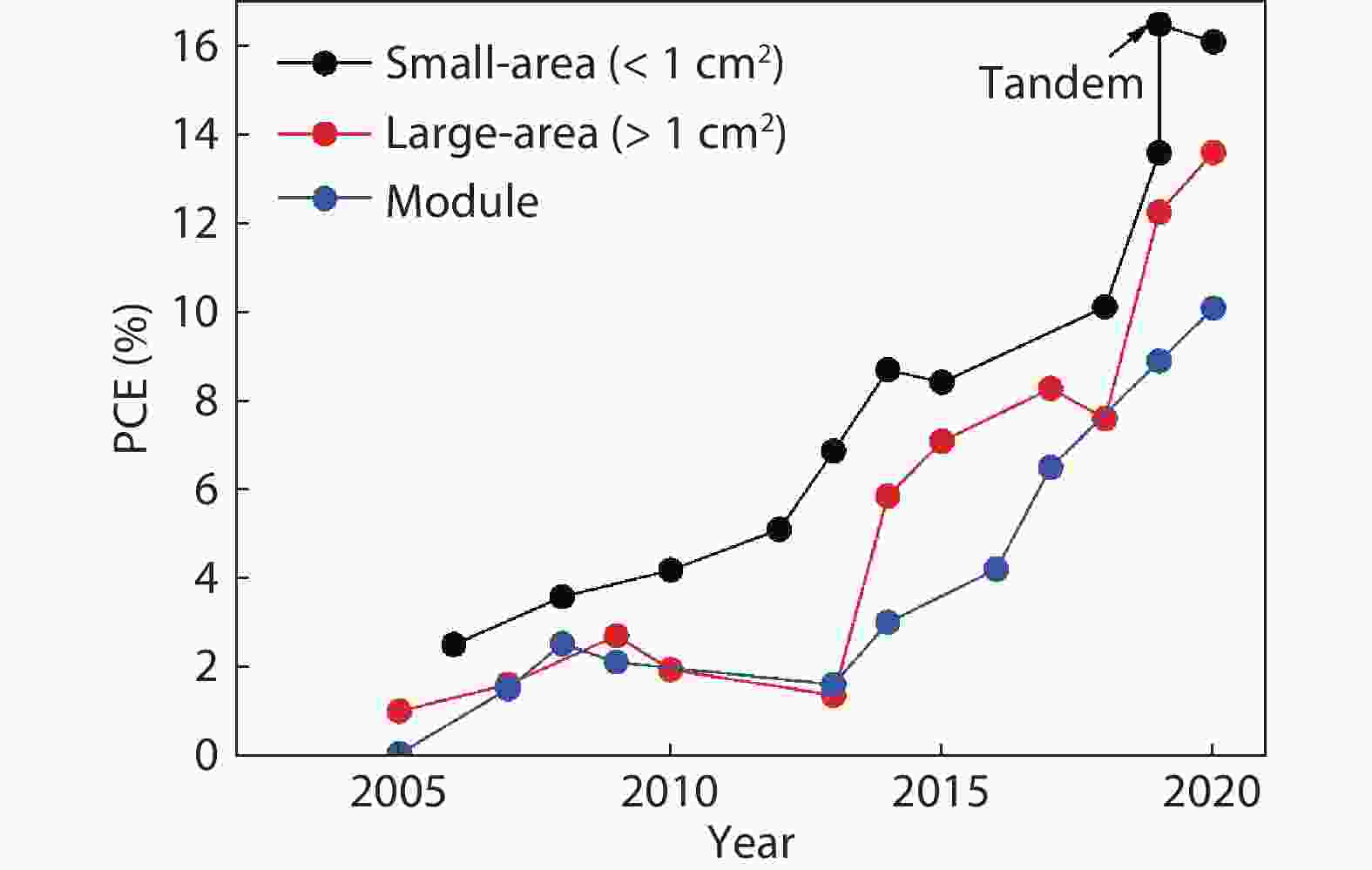

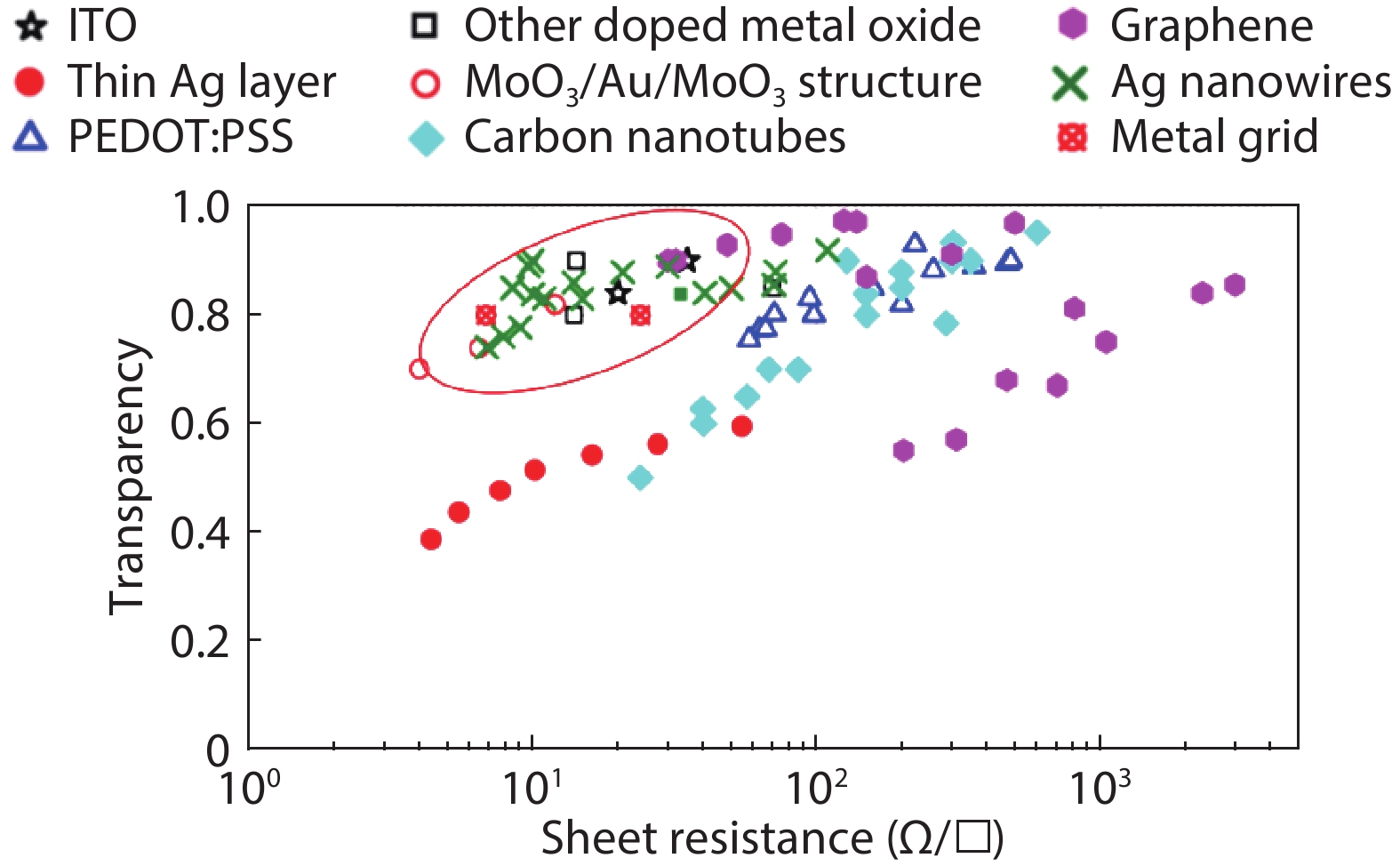

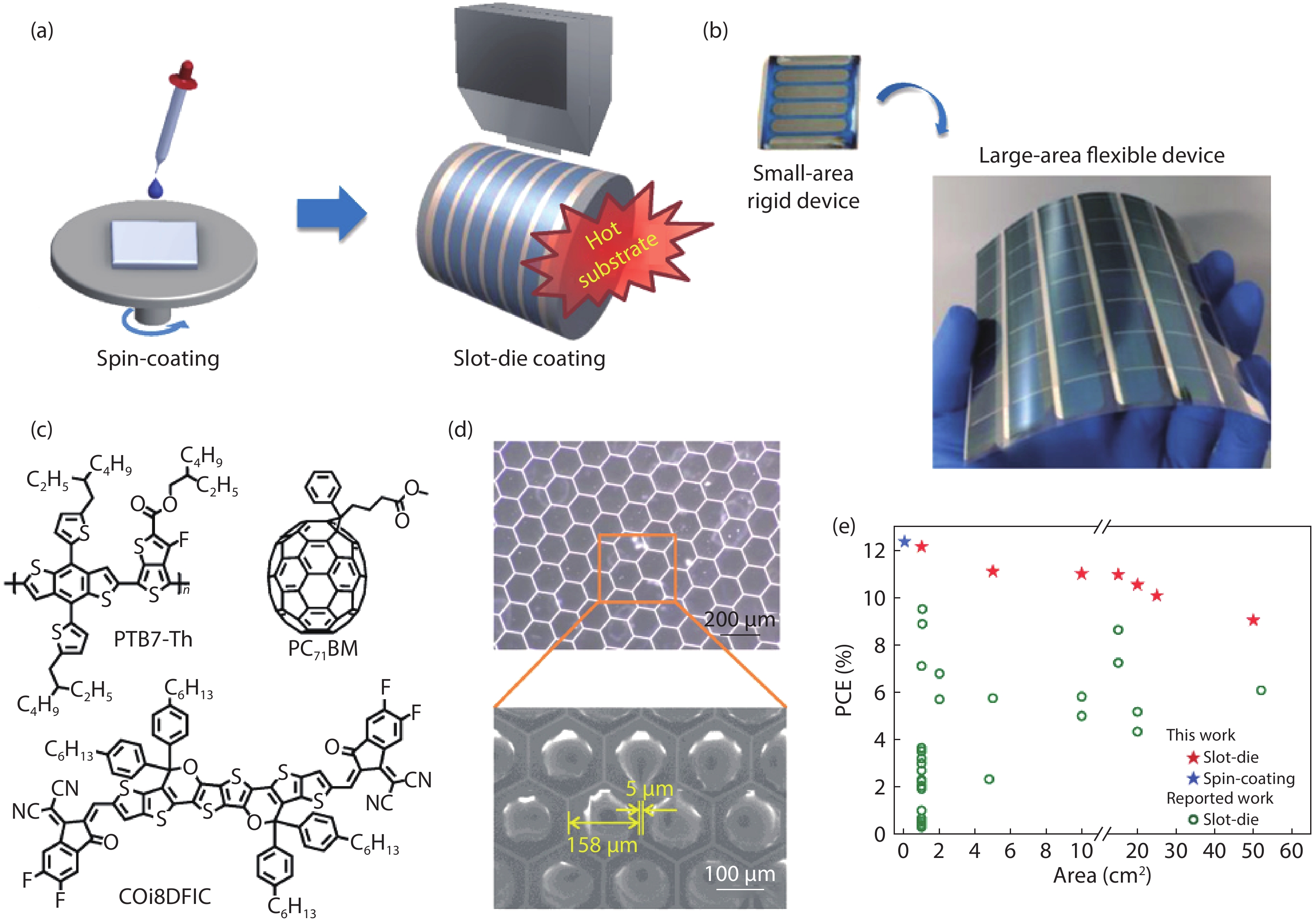

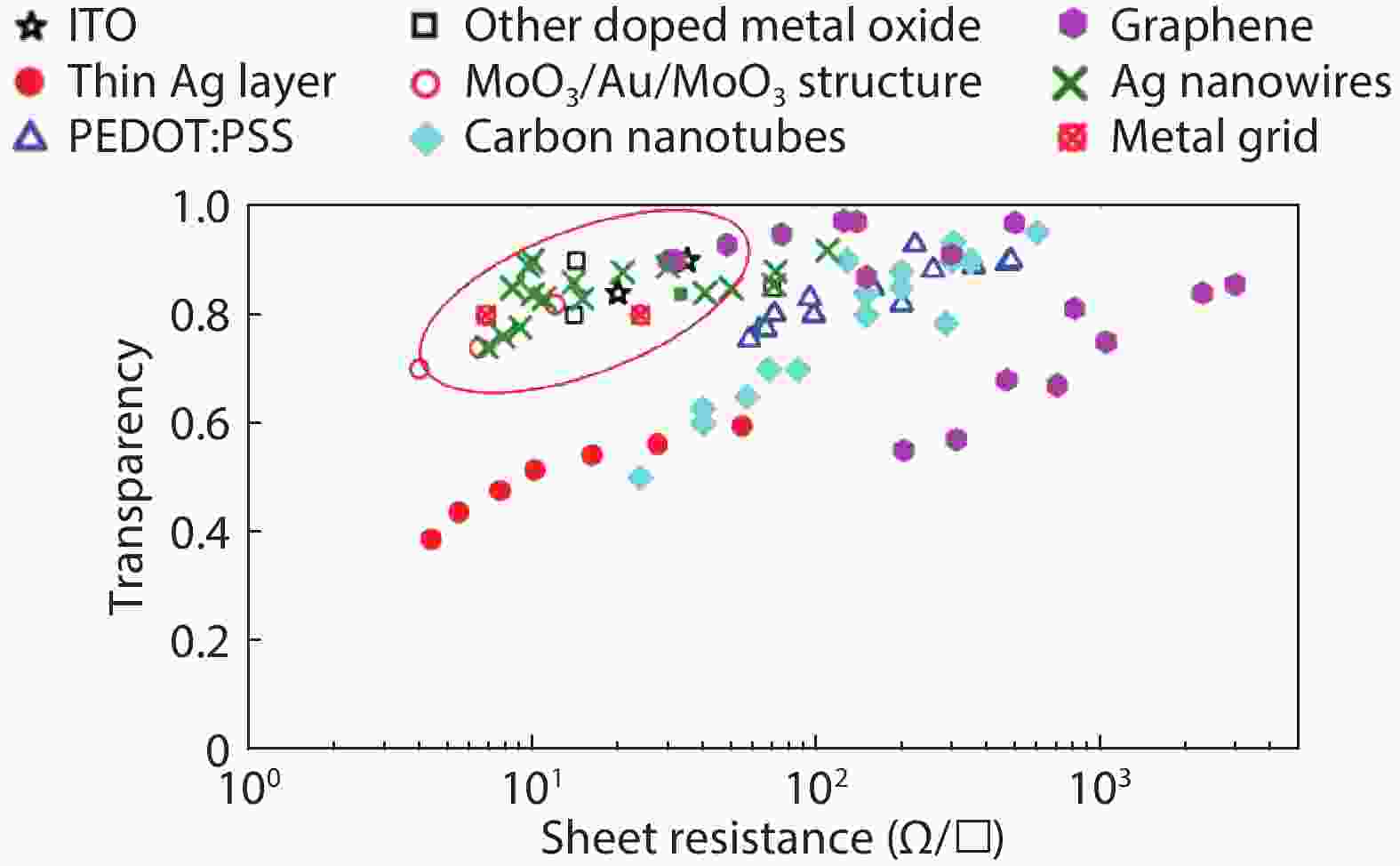

[1] Qu T Y, Zuo L J, Chen J D, et al. Biomimetic electrodes for flexible organic solar cells with efficiencies over 16%. Adv Opt Mater, 2020, 8, 2000669 doi: 10.1002/adom.202000669[2] Sun Y N, Chang M J, Meng L X, et al. Flexible organic photovoltaics based on water-processed silver nanowire electrodes. Nat Electron, 2019, 2, 513 doi: 10.1038/s41928-019-0315-1[3] Wang Z, Han Y, Yan L, et al. High power conversion efficiency of 13.61% for 1 cm2 flexible polymer solar cells based on patternable and mass-producible gravure-printed silver nanowire electrodes. Adv Funct Mater, 2020, 2007276 doi: 10.1002/adfm.202007276[4] Wang G D, Zhang J Q, Yang C, et al. Synergistic optimization enables large-area flexible organic solar cells to maintain over 98% PCE of the small-area rigid devices. Adv Mater, 2020, 32, 2005153 doi: 10.1002/adma.202005153[5] Chen Z, Cotterell B, Wang W. The fracture of brittle thin films on compliant substrates in flexible displays. Eng Fract Mech, 2002, 69, 597 doi: 10.1016/S0013-7944(01)00104-7[6] Cao W R, Li J, Chen H Z, et al. Transparent electrodes for organic photoelectronic devices: A review. J Photonics Energy, 2014, 4, 040990 doi: 10.1117/1.JPE.4.040990[7] Galagan Y, Zimmermann B, Coenen E W C, et al. Current collecting grids for ITO-free solar cells. Adv Energy Mater, 2012, 2, 103 doi: 10.1002/aenm.201100552[8] Andersen T R, Dam H F, Hosel M, et al. Scalable, ambient atmosphere roll-to-roll manufacture of encapsulated large area, flexible organic tandem solar cell modules. Energy Environ Sci, 2014, 7, 2925 doi: 10.1039/C4EE01223B[9] Galagan Y, Coenen E W C, Sabik S, et al. Evaluation of ink-jet printed current collecting grids and busbars for ITO-free organic solar cells. Sol Energy Mater Sol Cells, 2012, 104, 32 doi: 10.1016/j.solmat.2012.04.039[10] Mao L, Chen Q, Li Y W, et al. Flexible silver grid/PEDOT:PSS hybrid electrodes for large area inverted polymer solar cells. Nano Energy, 2014, 10, 259 doi: 10.1016/j.nanoen.2014.09.007[11] Li Y W, Mao L, Gao Y L, et al. ITO-free photovoltaic cell utilizing a high-resolution silver grid current collecting layer. Sol Energy Mater Sol Cells, 2013, 113, 85 doi: 10.1016/j.solmat.2013.01.043[12] Tan L C, Wang Y L, Zhang J W, et al. Highly efficient flexible polymer solar cells with robust mechanical stability. Adv Sci, 2019, 6, 1801180 doi: 10.1002/advs.201801180[13] Wu Q, Guo J, Sun R, et al. Slot-die printed non-fullerene organic solar cells with the highest efficiency of 12.9% for low-cost pv-driven water splitting. Nano Energy, 2019, 61, 559 doi: 10.1016/j.nanoen.2019.04.091[14] Chen X L, Guo W R, Xie L M, et al. Embedded Ag/Ni metal-mesh with low surface roughness as transparent conductive electrode for optoelectronic applications. ACS Appl Mater Interfaces, 2017, 9, 37048 doi: 10.1021/acsami.7b11779[15] Chen X L, Nie S H, Guo W R, et al. Printable high-aspect ratio and high-resolution Cu grid flexible transparent conductive film with figure of merit over 80000. Adv Electron Mater, 2019, 5, 1800991 doi: 10.1002/aelm.201800991[16] Han Y, Chen X, Wei J, et al. Efficiency above 12% for 1 cm2 flexible organic solar cells with Ag/Cu grid transparent conducting electrode. Adv Sci, 2019, 6, 1901490 doi: 10.1002/advs.201901490[17] Tang H H, Feng H R, Wang H K, et al. Highly conducting mxene-silver nanowire transparent electrodes for flexible organic solar cells. ACS Appl Mater Interfaces, 2019, 11, 25330 doi: 10.1021/acsami.9b04113[18] Chen X B, Xu G Y, Zeng G, et al. Realizing ultrahigh mechanical flexibility and > 15% efficiency of flexible organic solar cells via a "welding" flexible transparent electrode. Adv Mater, 2020, 32, 198478 doi: 10.1002/adma.201908478[19] Dong X Y, Shi P, Sun L L, et al. Flexible nonfullerene organic solar cells based on embedded silver nanowires with an efficiency up to 11.6%. J Mater Chem A, 2019, 7, 1989 doi: 10.1039/C8TA11378E[20] Zhang Y X, Fang J, Li W, et al. Synergetic transparent electrode architecture for efficient non-fullerene flexible organic solar cells with >12% efficiency. ACS Nano, 2019, 13, 4686 doi: 10.1021/acsnano.9b00970[21] Kang S B, Noh Y J, Na S I, et al. Brush-painted flexible organic solar cells using highly transparent and flexible Ag nanowire network electrodes. Sol Energy Mater Sol Cells, 2014, 122, 152 doi: 10.1016/j.solmat.2013.11.036[22] Lu H F, Ren X G, Ouyang D, et al. Emerging novel metal electrodes for photovoltaic applications. Small, 2018, 14, 1703140 doi: 10.1002/smll.201703140[23] Kim J, Ouyang D, Lu H F, et al. High performance flexible transparent electrode via one-step multifunctional treatment for Ag nanonetwork composites semi-embedded in low-temperature-processed substrate for highly performed organic photovoltaics. Adv Energy Mater, 2020, 10, 1903919 doi: 10.1002/aenm.201903919[24] Han Y W, Jeon S J, Lee H S, et al. Evaporation-free nonfullerene flexible organic solar cell modules manufactured by an all-solution process. Adv Energy Mater, 2019, 9, 1902065 doi: 10.1002/aenm.201902065[25] Zhao W C, Li S S, Yao H F, et al. Molecular optimization enables over 13% efficiency in organic solar cells. J Am Chem Soc, 2017, 139, 7148 doi: 10.1021/jacs.7b02677[26] Yuan J, Zhang Y Q, Zhou L Y, et al. Single-junction organic solar cell with over 15% efficiency using fused-ring acceptor with electron-deficient core. Joule, 2019, 3, 1140 doi: 10.1016/j.joule.2019.01.004[27] Meng X, Zhang L, Xie Y, et al. A general approach for lab-to-manufacturing translation on flexible organic solar cells. Adv Mater, 2019, 31, 1903649 doi: 10.1002/adma.201903649[28] Huang J, Wang X, Kim Y, et al. High efficiency flexible ITO-free polymer/fullerene photodiodes. Phys Chem Chem Phys, 2006, 8, 3904 doi: 10.1039/b607016g[29] Hau S K, Yip H L, Baek N S, et al. Air-stable inverted flexible polymer solar cells using zinc oxide nanoparticles as an electron selective layer. Appl Phys Lett, 2008, 92, 253301 doi: 10.1063/1.2945281[30] Wang J C, Weng W T, Tsai M Y, et al. Highly efficient flexible inverted organic solar cells using atomic layer deposited ZnO as electron selective layer. J Mater Chem, 2010, 20, 862 doi: 10.1039/B921396A[31] Stec H M, Hatton R A. Plasmon-active nano-aperture window electrodes for organic photovoltaics. Adv Energy Mater, 2013, 3, 193 doi: 10.1002/aenm.201200502[32] Jose da Silva W, Kim H P, Rashid bin Mohd Yusoff A, et al. Transparent flexible organic solar cells with 6.87% efficiency manufactured by an all-solution process. Nanoscale, 2013, 5, 9324 doi: 10.1039/c3nr03011c[33] Zhao B, He Z, Cheng X, et al. Flexible polymer solar cells with power conversion efficiency of 8.7%. J Mater Chem C, 2014, 2, 5077 doi: 10.1039/c3tc32520b[34] Zuo L, Zhang S, Li H, et al. Toward highly efficient large-area ITO-free organic solar cells with a conductance-gradient transparent electrode. Adv Mater, 2015, 27, 6983 doi: 10.1002/adma.201502827[35] Song W, Fan X, Xu B, et al. All-solution-processed metal-oxide-free flexible organic solar cells with over 10% efficiency. Adv Mater, 2018, 30, 1800075 doi: 10.1002/adma.201800075[36] Kushto G P, Kim W, Kafafi Z H. Flexible organic photovoltaics using conducting polymer electrodes. Appl Phys Lett, 2005, 86, 093502 doi: 10.1063/1.1867568[37] Lungenschmied C, Dennler G, Neugebauer H, et al. Flexible, long-lived, large-area, organic solar cells. Sol Energy Mater Sol Cells, 2007, 91, 379 doi: 10.1016/j.solmat.2006.10.013[38] Krebs F C, Gevorgyan S A, Alstrup J. A roll-to-roll process to flexible polymer solar cells: Model studies, manufacture and operational stability studies. J Mater Chem, 2009, 19, 5442 doi: 10.1039/b823001c[39] Galagan Y, Rubingh J E, Andriessen R, et al. ITO-free flexible organic solar cells with printed current collecting grids. Sol Energy Mater Sol Cells, 2011, 95, 1339 doi: 10.1016/j.solmat.2010.08.011[40] Zhang J, Zhao Y, Fang J, et al. Enhancing performance of large-area organic solar cells with thick film via ternary strategy. Small, 2017, 13, 1700388 doi: 10.1002/smll.201700388[41] Lin Y, Jin Y, Dong S, et al. Printed nonfullerene organic solar cells with the highest efficiency of 9.5%. Adv Energy Mater, 2018, 8, 1701942 doi: 10.1002/aenm.201701942[42] Dennler G, Lungenschmied C, Neugebauer H, et al. Flexible, conjugated polymer-fullerene-based bulk-heterojunction solar cells: basics, encapsulation, and integration. J Mater Res, 2005, 20, 3224 doi: 10.1557/jmr.2005.0399[43] Tsakalakos L, Lemaitre N, de Bettignies R, et al. High-efficiency large area flexible organic solar cells. 2008, 7047, 70470K doi: 10.1117/12.795036[44] Hösel M, Søndergaard R R, Jørgensen M, et al. Fast inline roll-to-roll printing for indium-tin-oxide-free polymer solar cells using automatic registration. Energy Technol, 2013, 1, 102 doi: 10.1002/ente.201200029[45] Carlé J E, Helgesen M, Madsen M V, et al. Upscaling from single cells to modules – fabrication of vacuum- and ITO-free polymer solar cells on flexible substrates with long lifetime. J Mater Chem C, 2014, 2, 1290 doi: 10.1039/C3TC31859A[46] Lucera L, Machui F, Kubis P, et al. Highly efficient, large area, roll coated flexible and rigid opv modules with geometric fill factors up to 98.5% processed with commercially available materials. Energy Environ Sci, 2016, 9, 89 doi: 10.1039/C5EE03315B[47] Mao L, Tong J H, Xiong S X, et al. Flexible large-area organic tandem solar cells with high defect tolerance and device yield. J Mater Chem A, 2017, 5, 3186 doi: 10.1039/C6TA10106B[48] Dong S, Zhang K, Xie B M, et al. High-performance large-area organic solar cells enabled by sequential bilayer processing via nonhalogenated solvents. Adv Energy Mater, 2019, 9, 1802832 doi: 10.1002/aenm.201802832[49] Zhao H, Naveed H B, Lin B J, et al. Hot hydrocarbon-solvent slot-die coating enables high-efficiency organic solar cells with temperature-dependent aggregation behavior. Adv Mater, 2020, 32, 2002302 doi: 10.1002/adma.202002302[50] Ji G Q, Zhao W C, Wei J F, et al. 12.88% efficiency in doctor-blade coated organic solar cells through optimizing the surface morphology of a ZnO cathode buffer layer. J Mater Chem A, 2019, 7, 212 doi: 10.1039/C8TA08873J[51] Kim Y Y, Yang T Y, Suhonen R, et al. Gravure-printed flexible perovskite solar cells: Toward roll-to-roll manufacturing. Adv Sci, 2019, 6, 1802094 doi: 10.1002/advs.201802094 -

Proportional views

DownLoad:

DownLoad: