| Citation: |

Jongwoon Yoon, Kwangsoo Kim. A 3.3 kV 4H-SiC split gate MOSFET with a central implant region for superior trade-off between static and switching performance[J]. Journal of Semiconductors, 2021, 42(6): 062803. doi: 10.1088/1674-4926/42/6/062803

J Yoon, K Kim, A 3.3 kV 4H-SiC split gate MOSFET with a central implant region for superior trade-off between static and switching performance[J]. J. Semicond., 2021, 42(6): 062803. doi: 10.1088/1674-4926/42/6/062803.

Export: BibTex EndNote

|

A 3.3 kV 4H-SiC split gate MOSFET with a central implant region for superior trade-off between static and switching performance

doi: 10.1088/1674-4926/42/6/062803

More Information-

Abstract

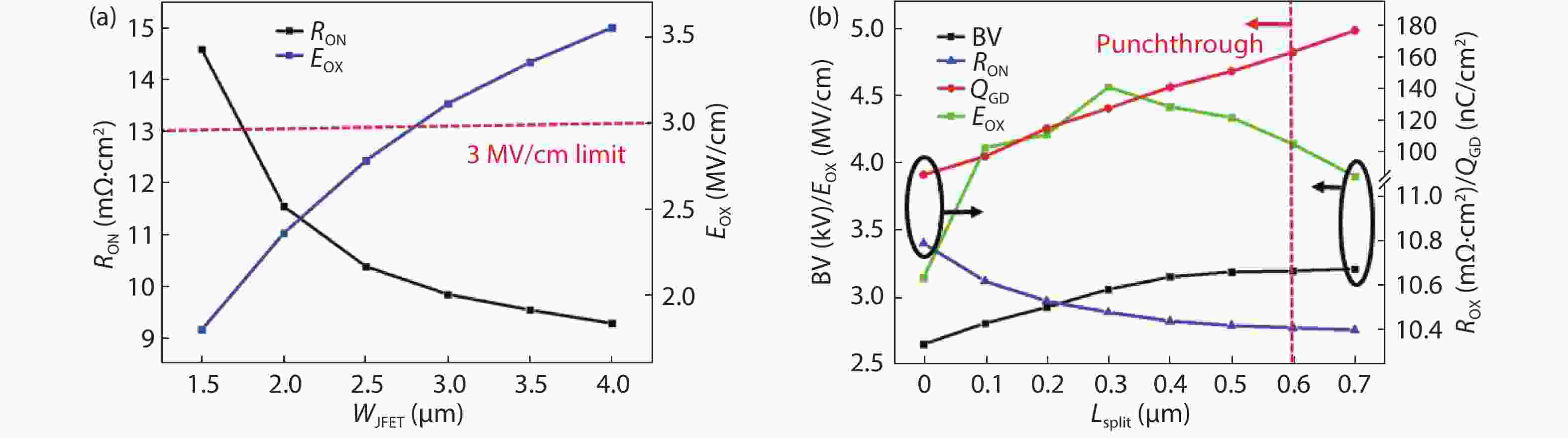

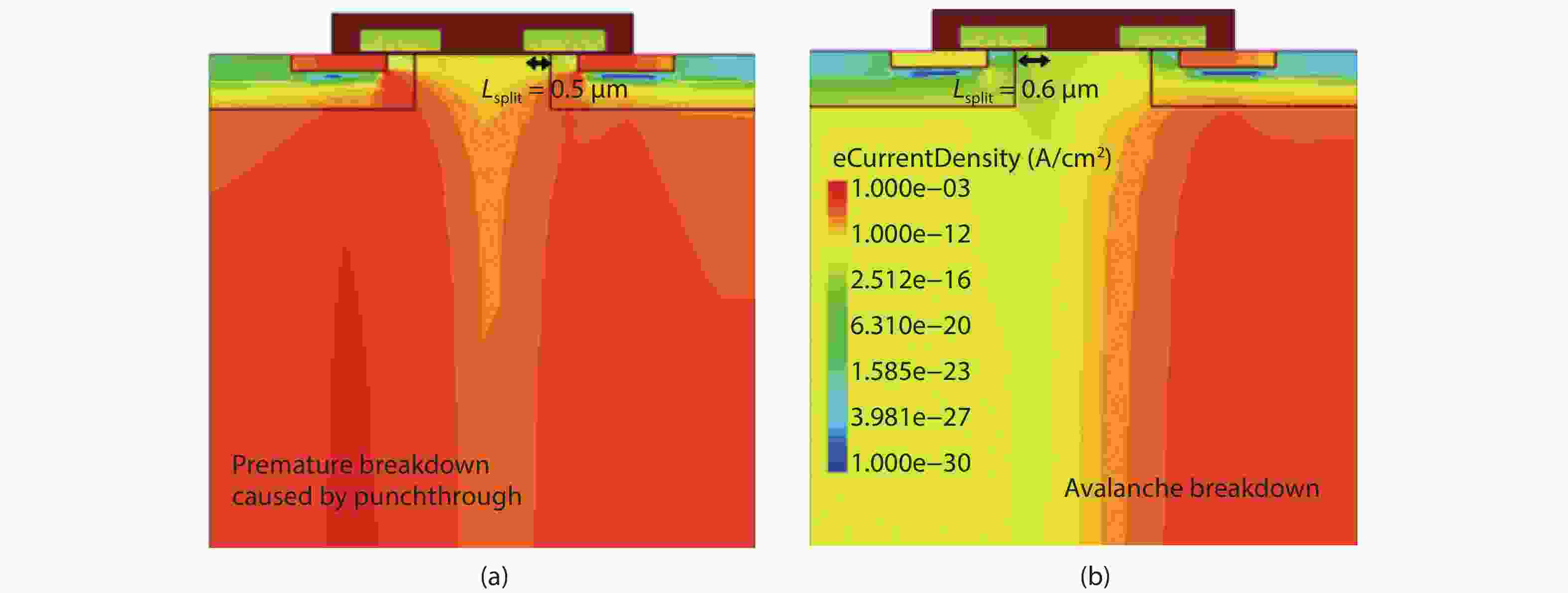

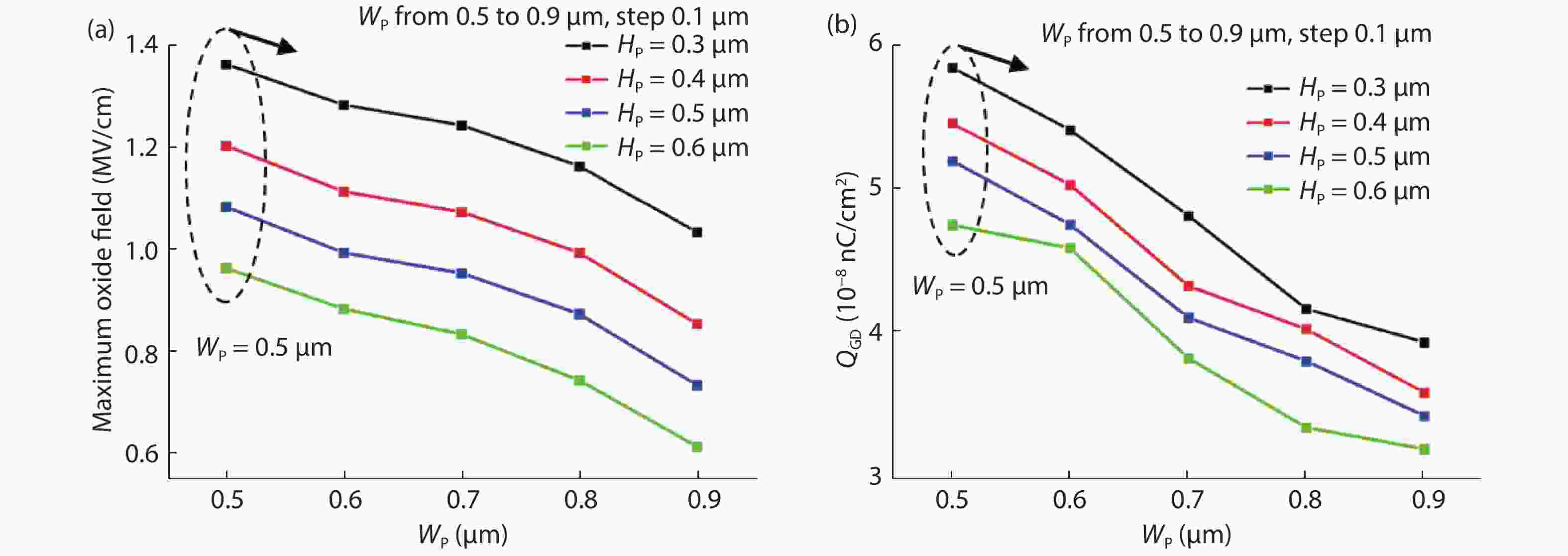

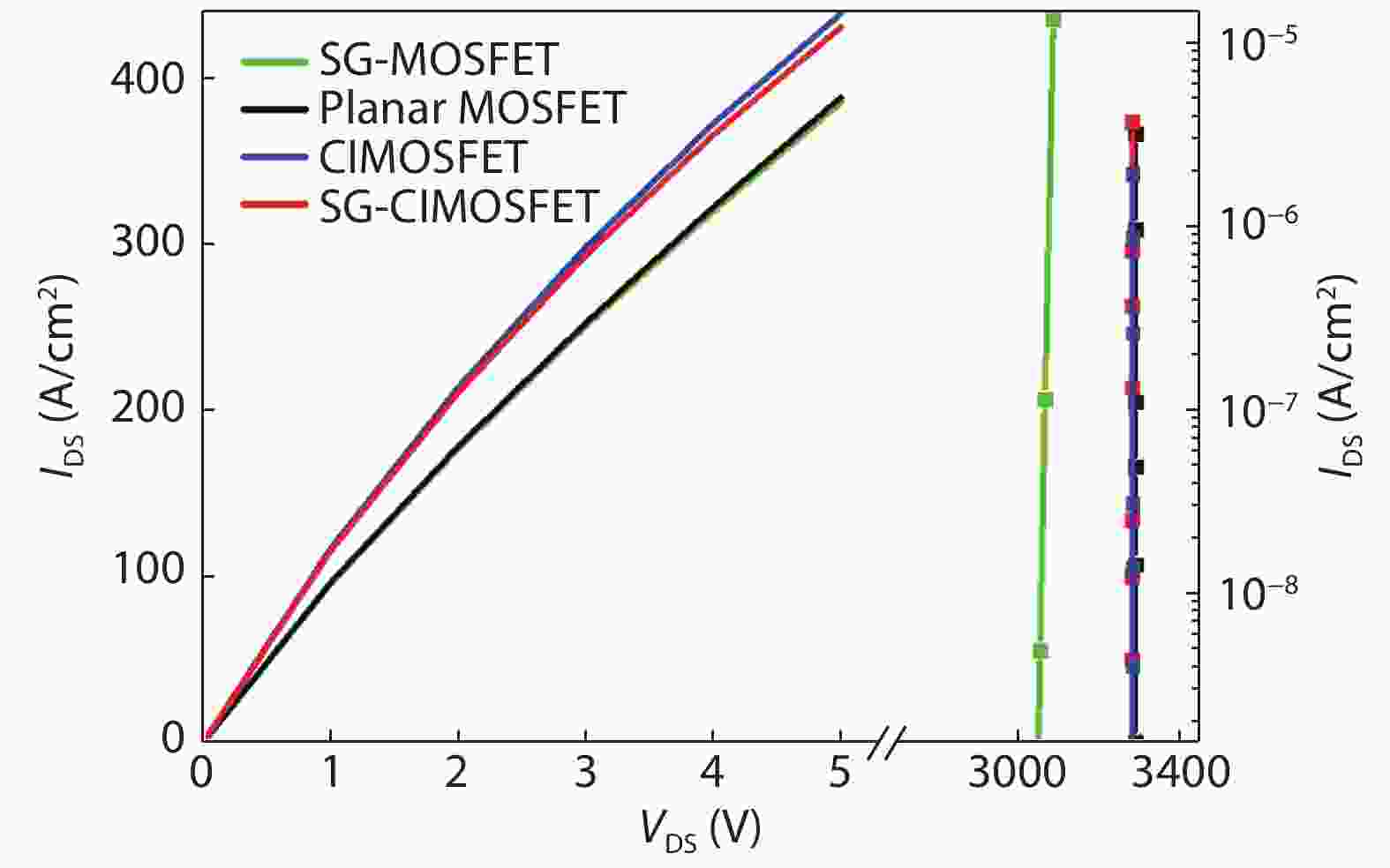

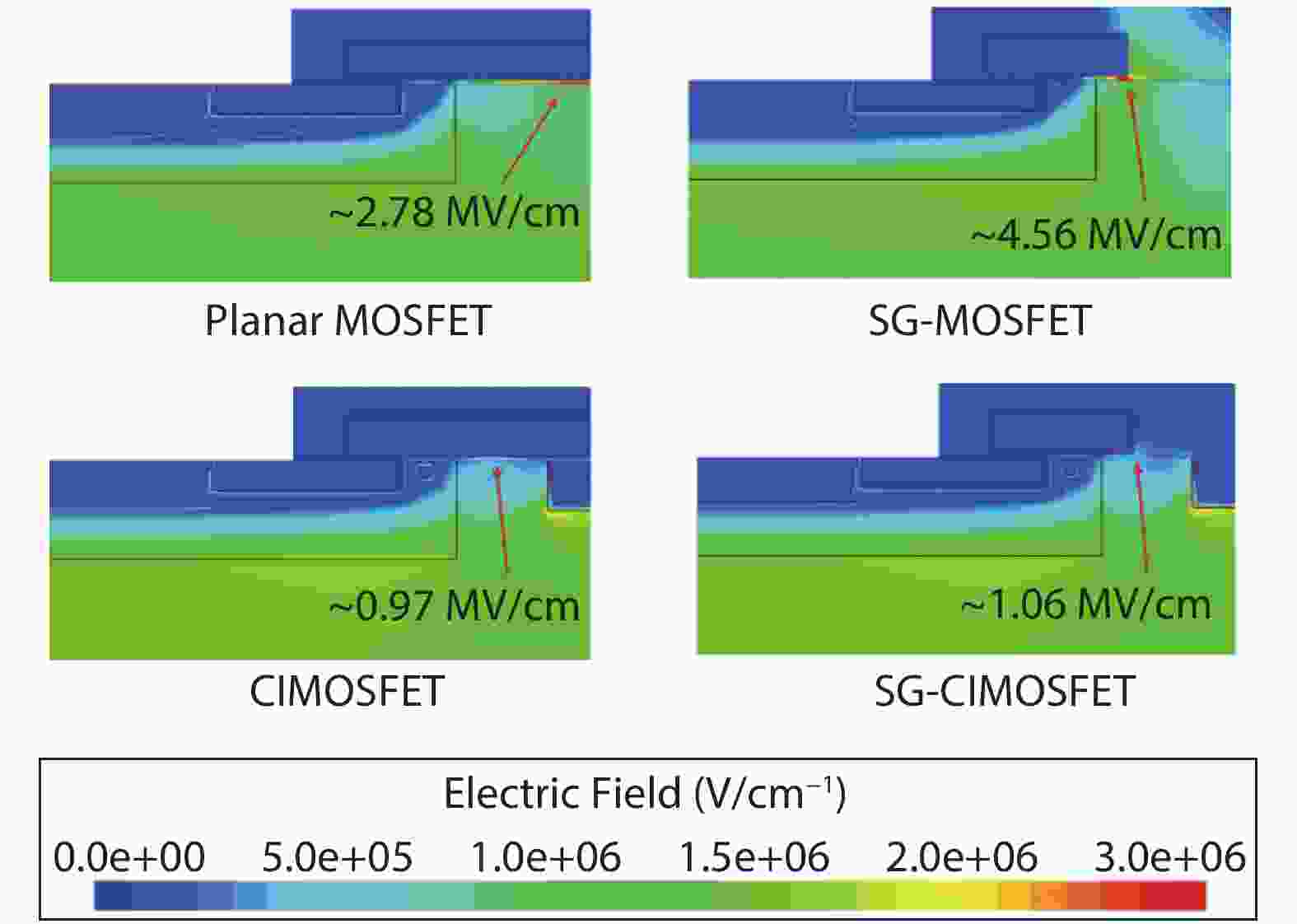

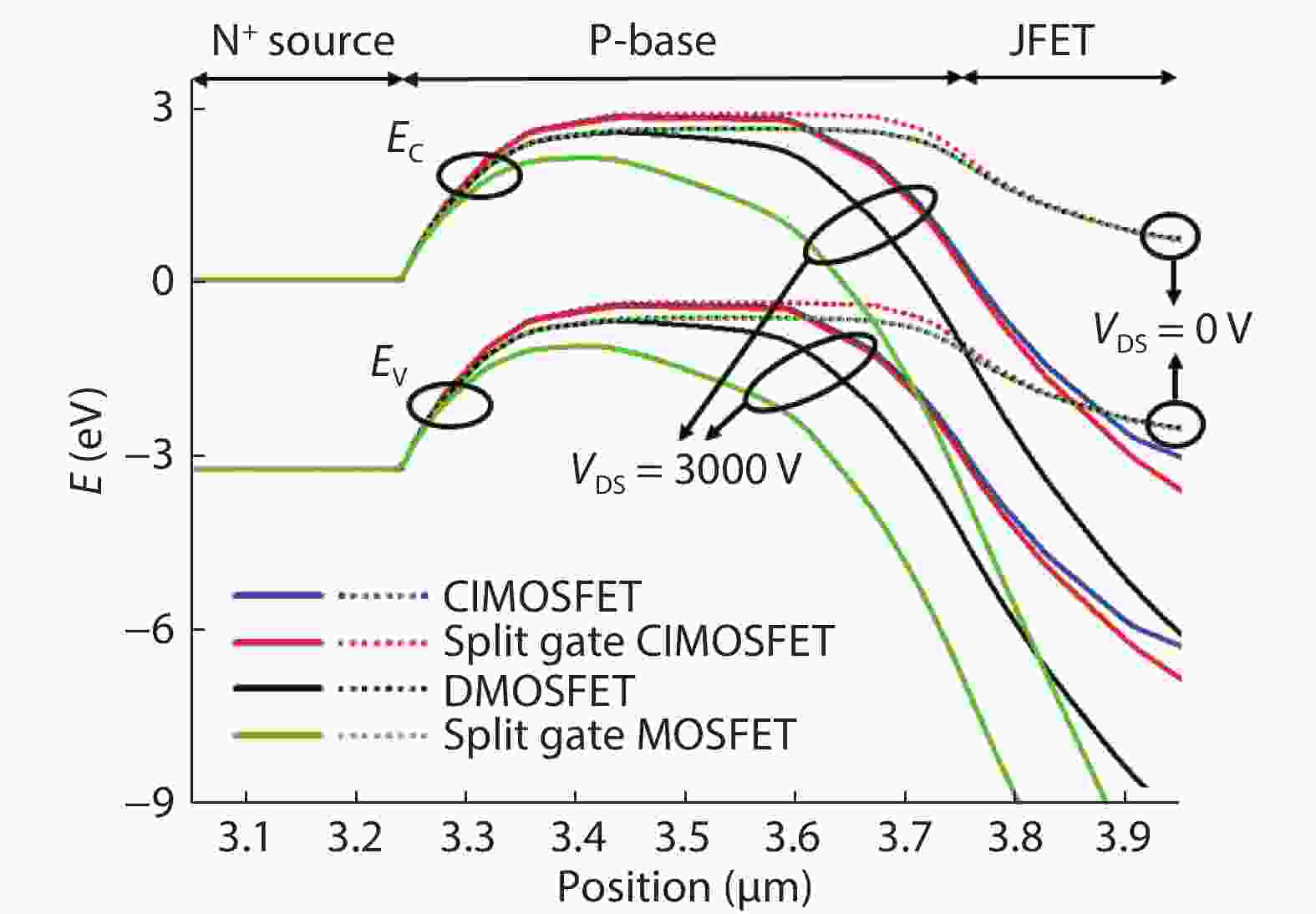

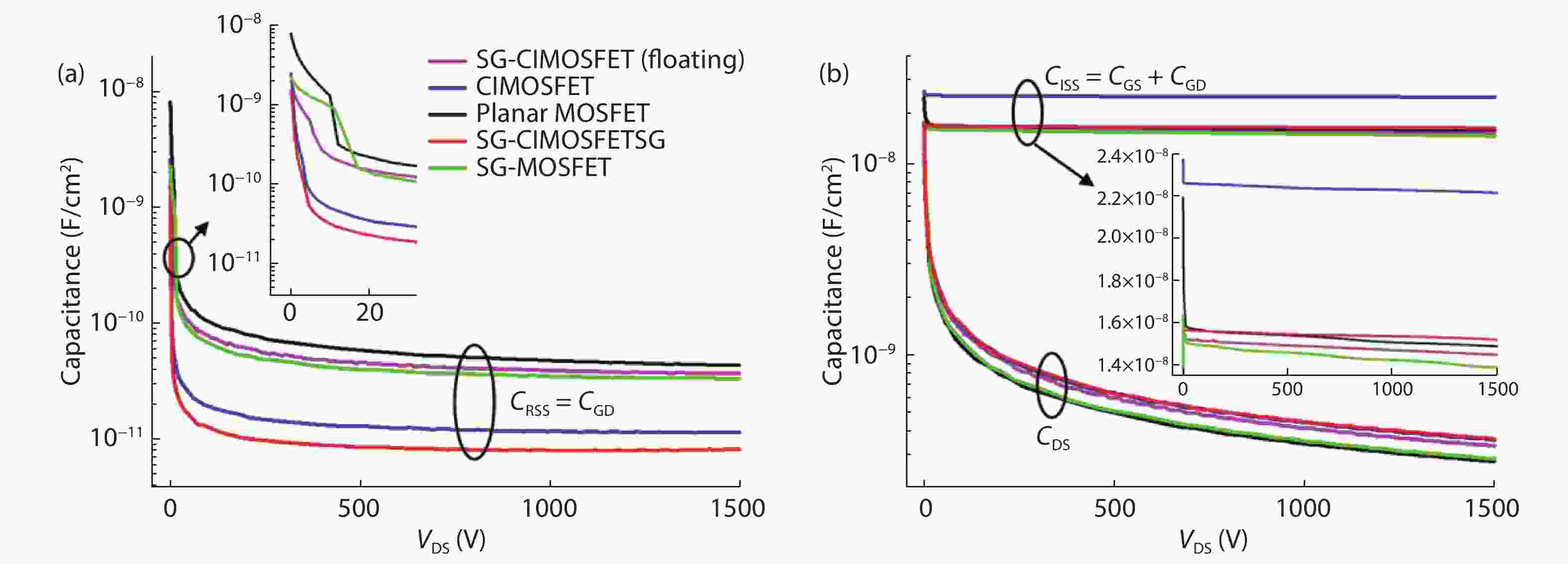

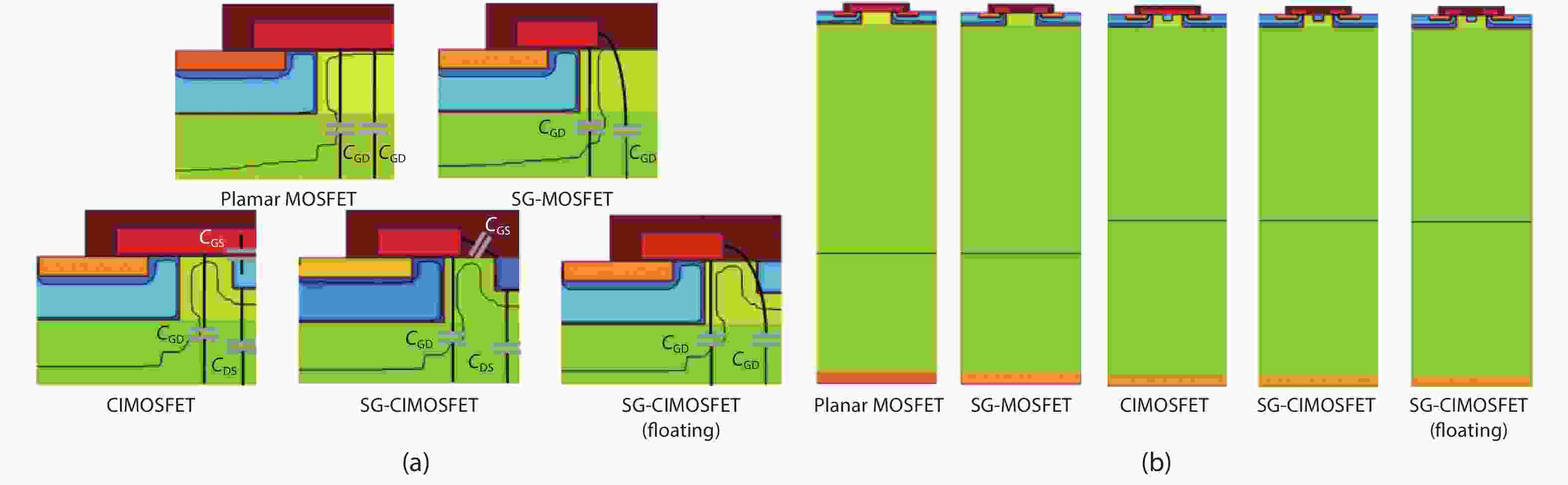

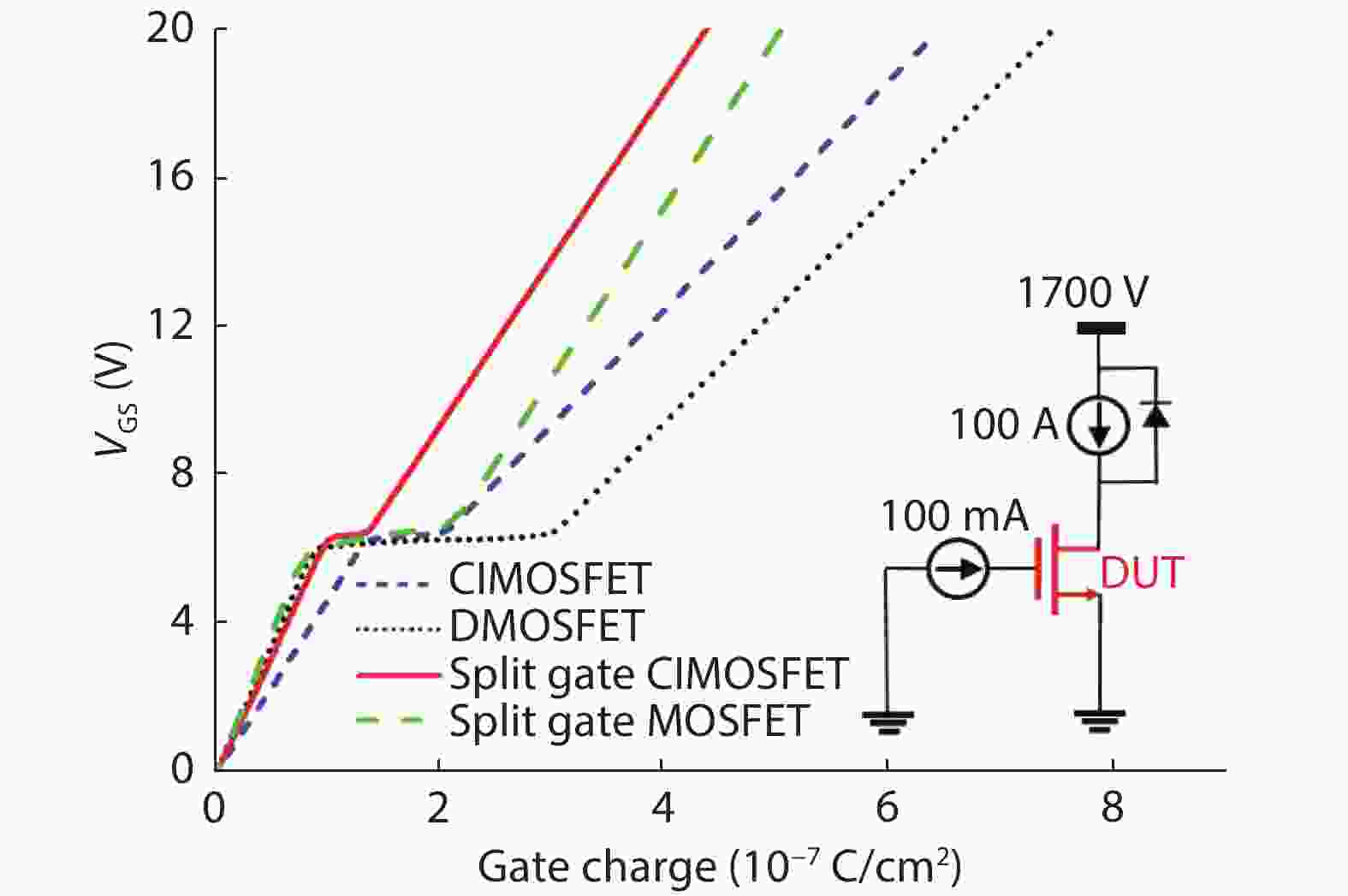

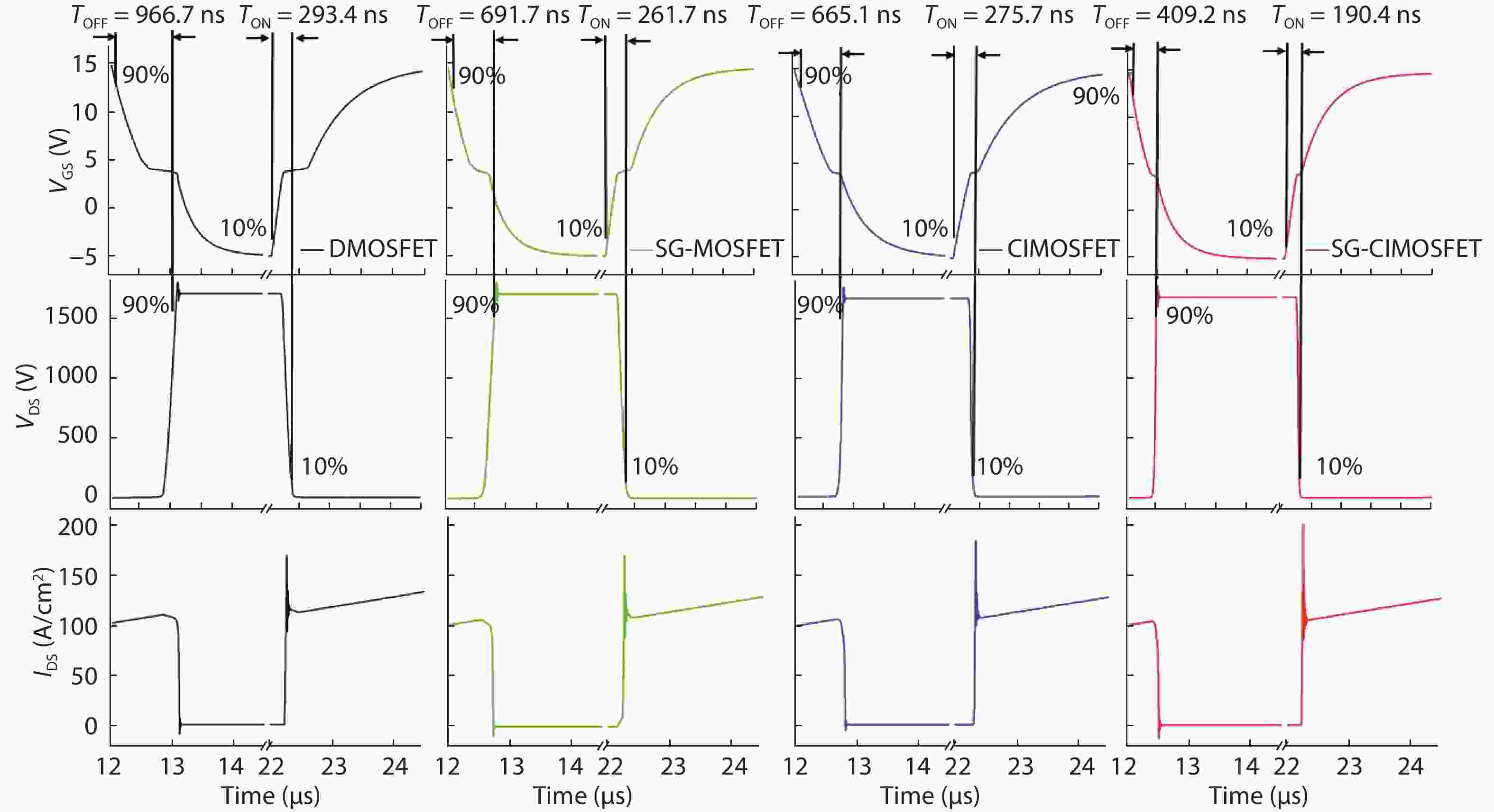

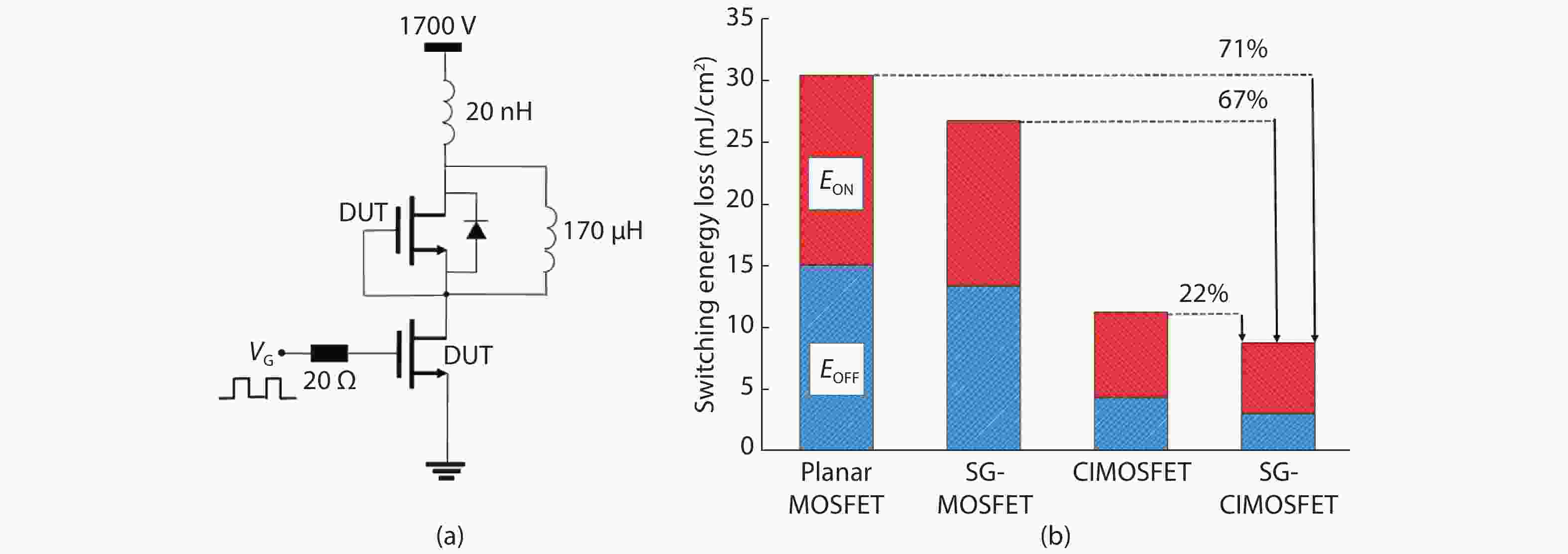

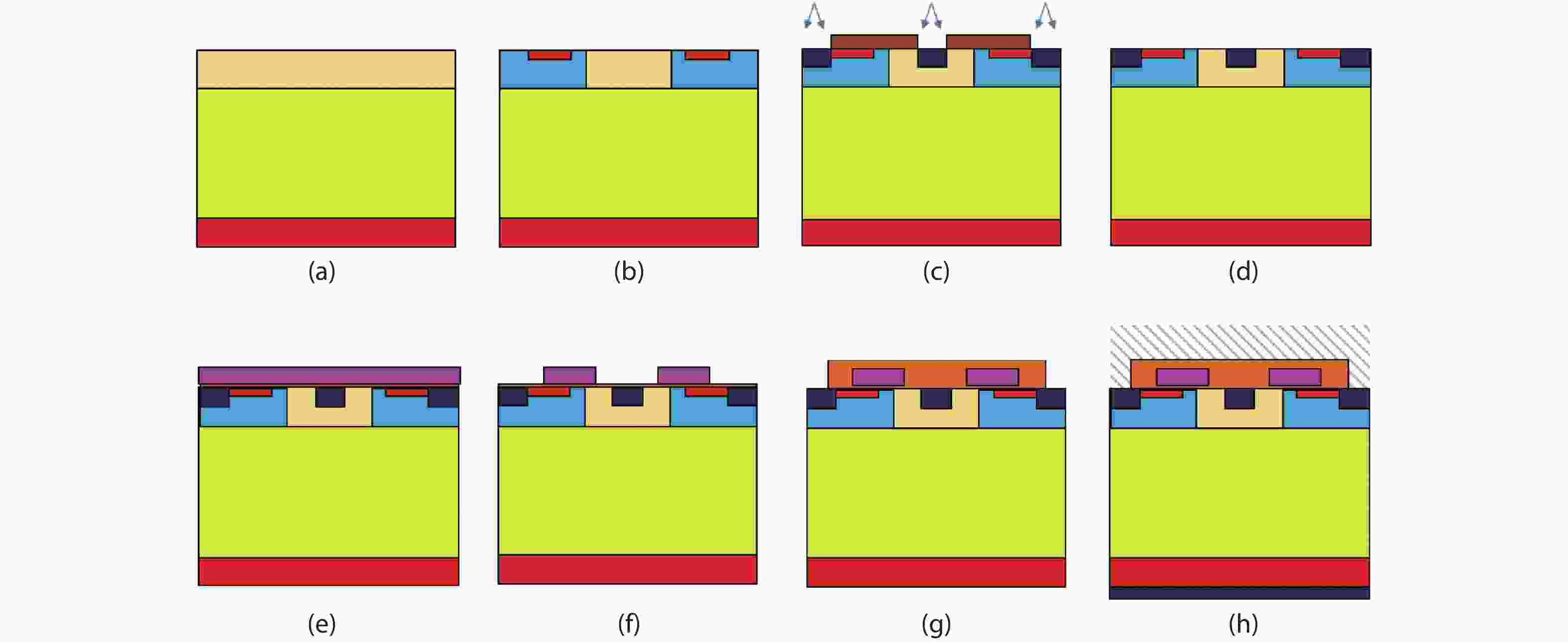

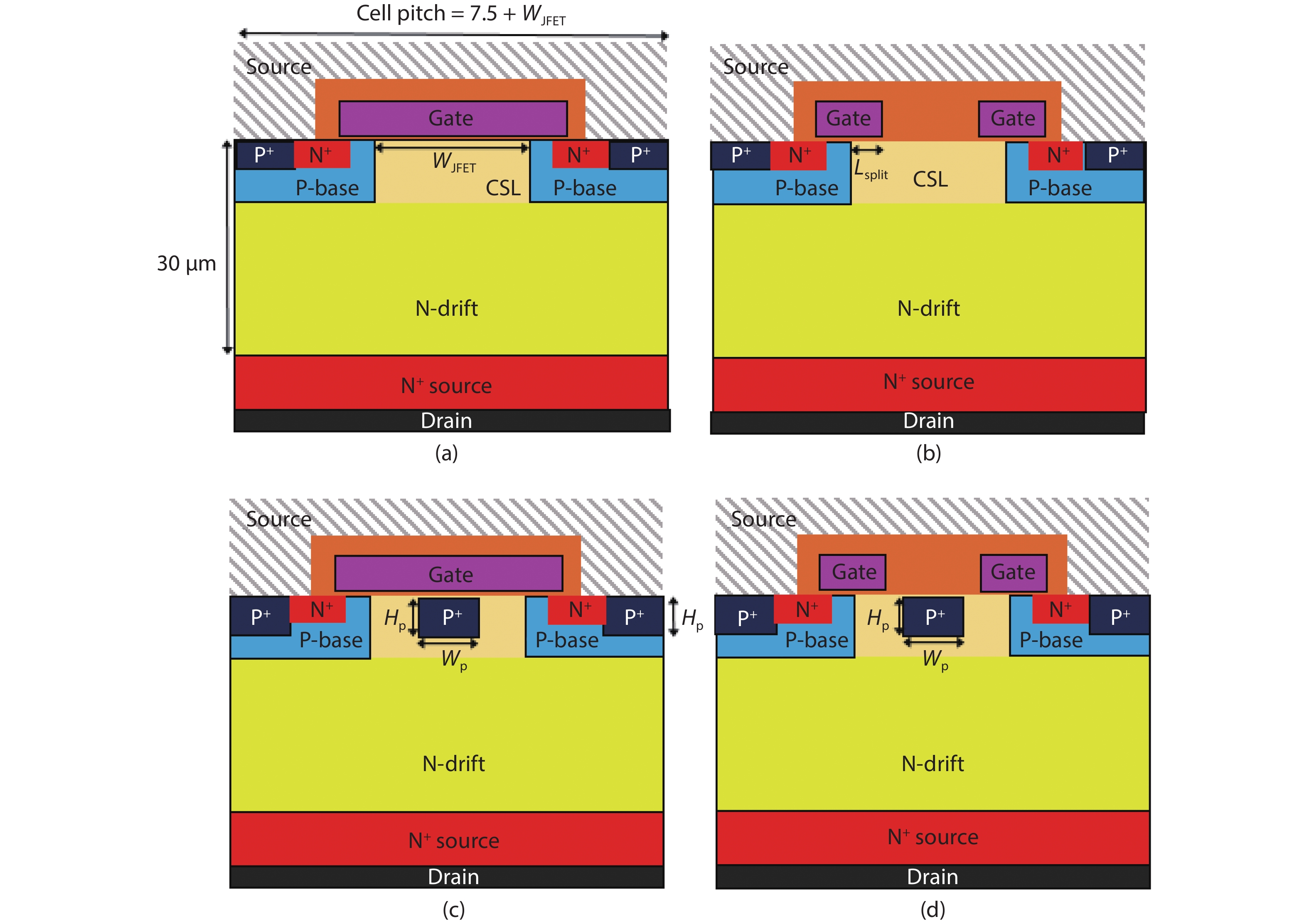

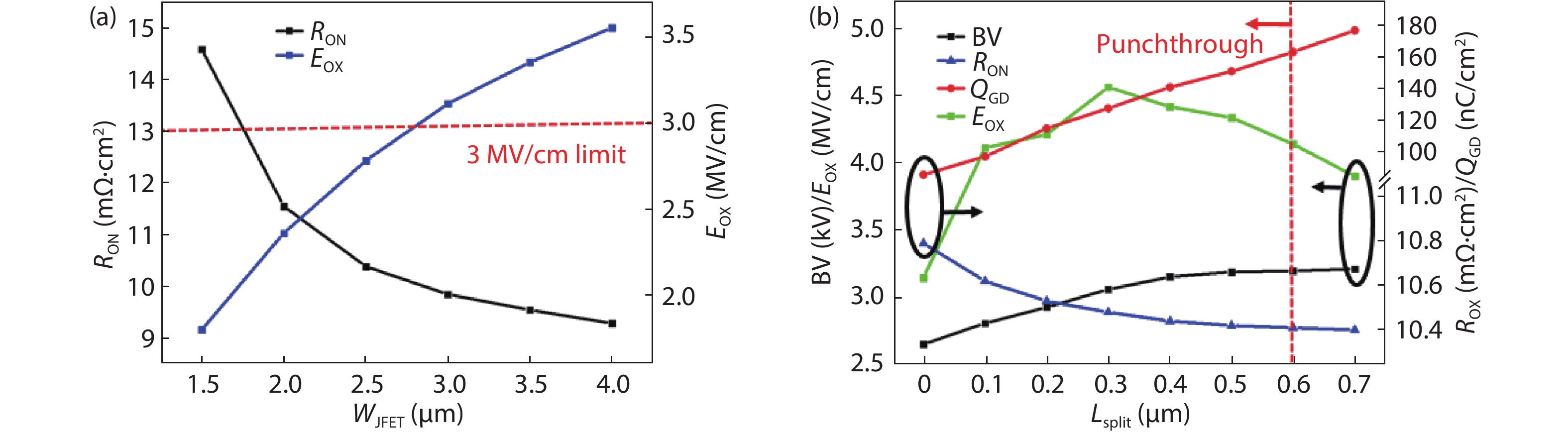

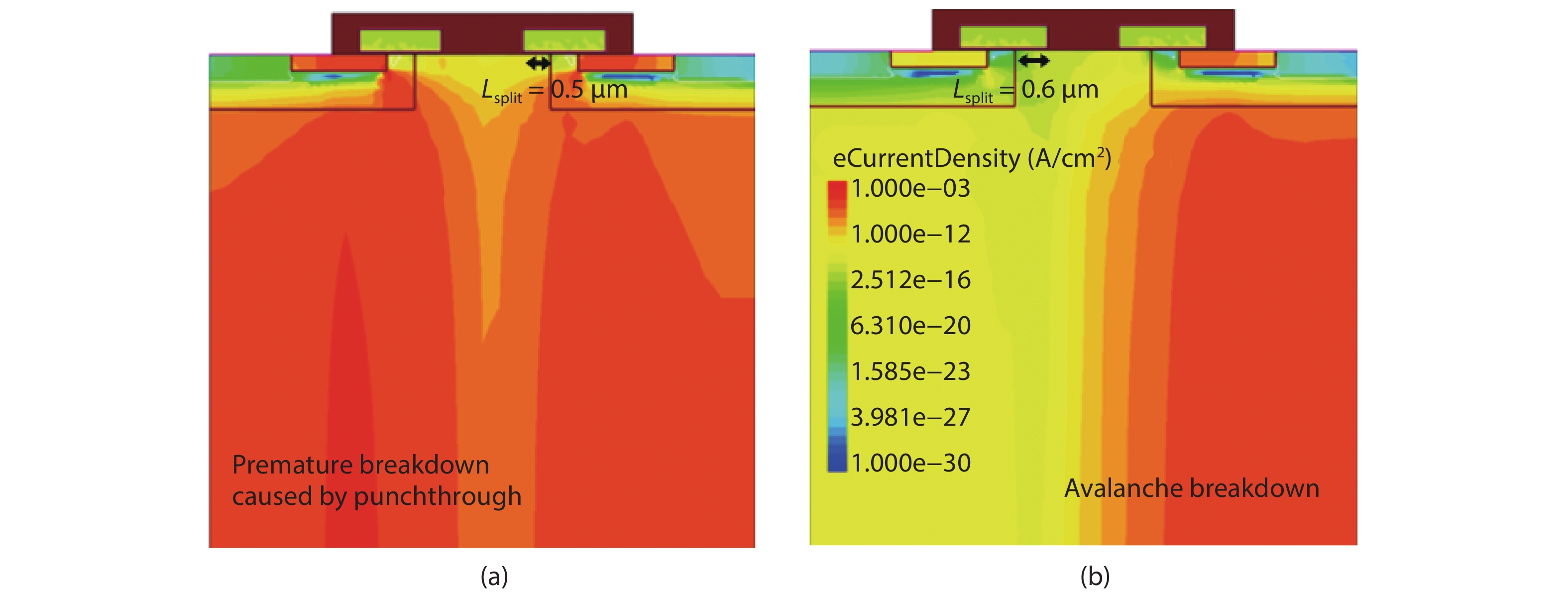

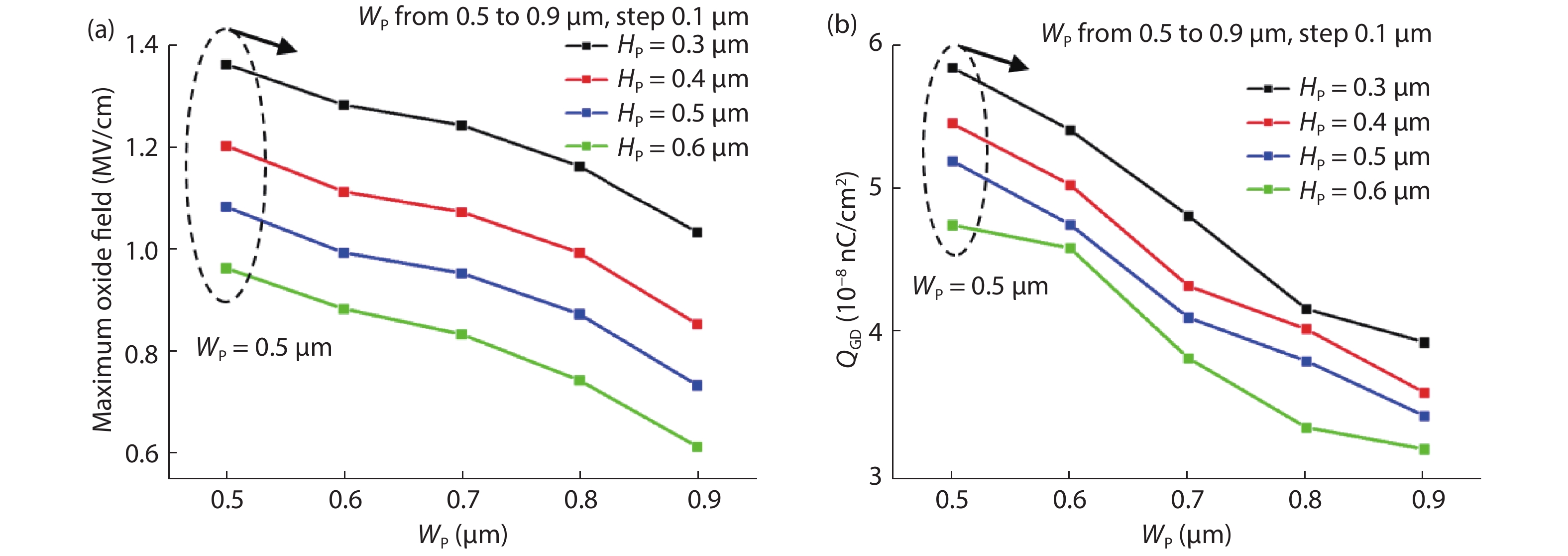

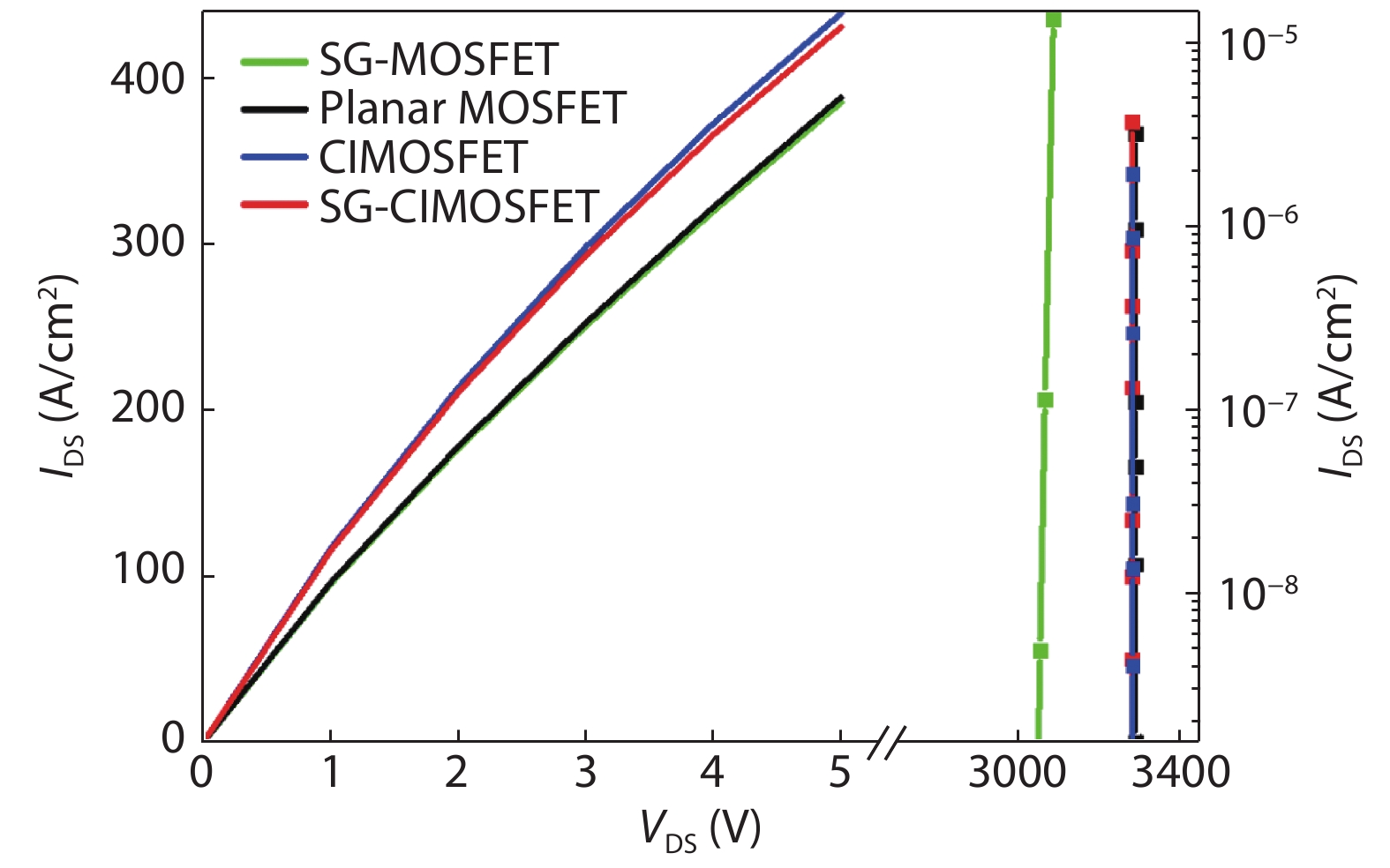

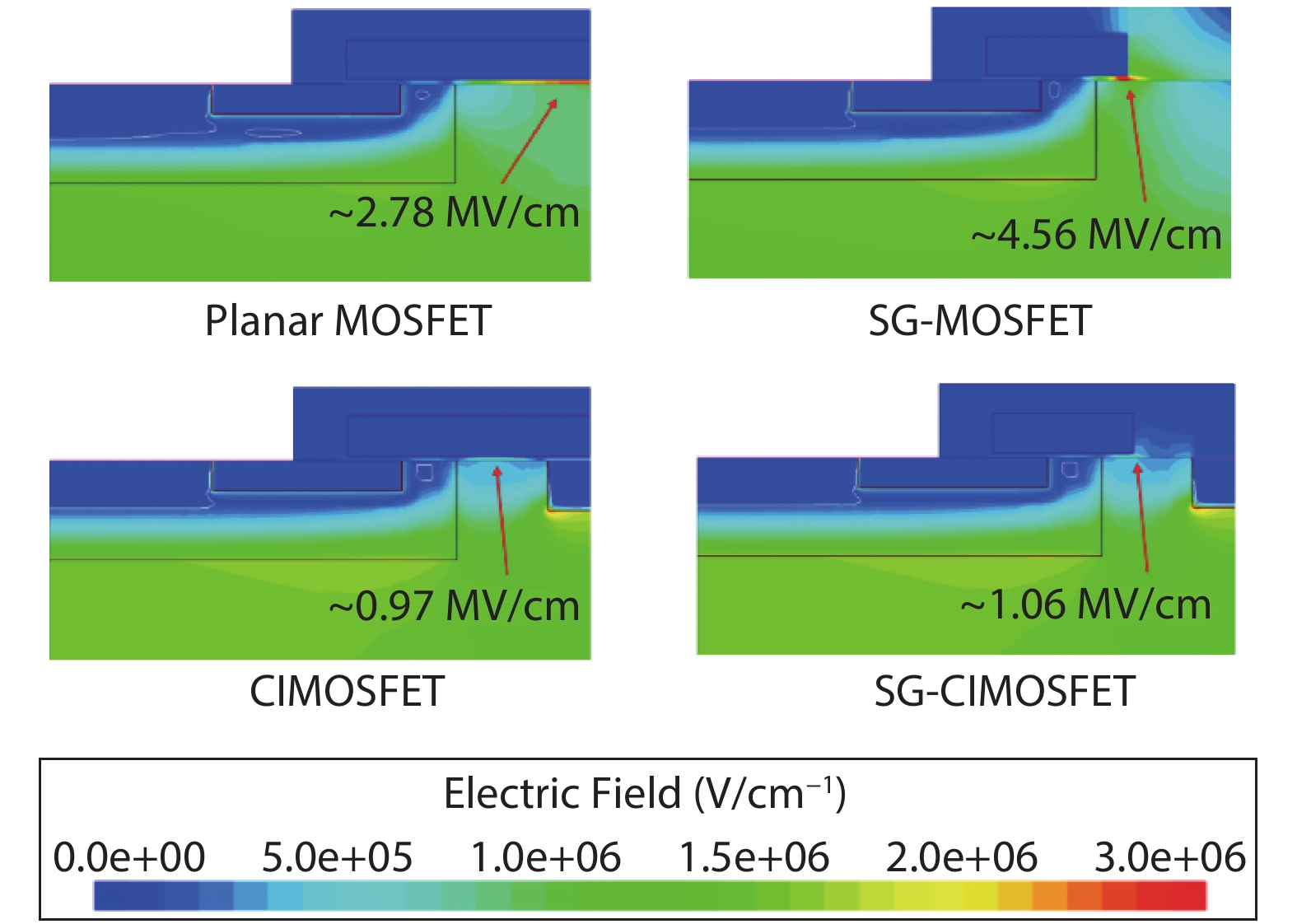

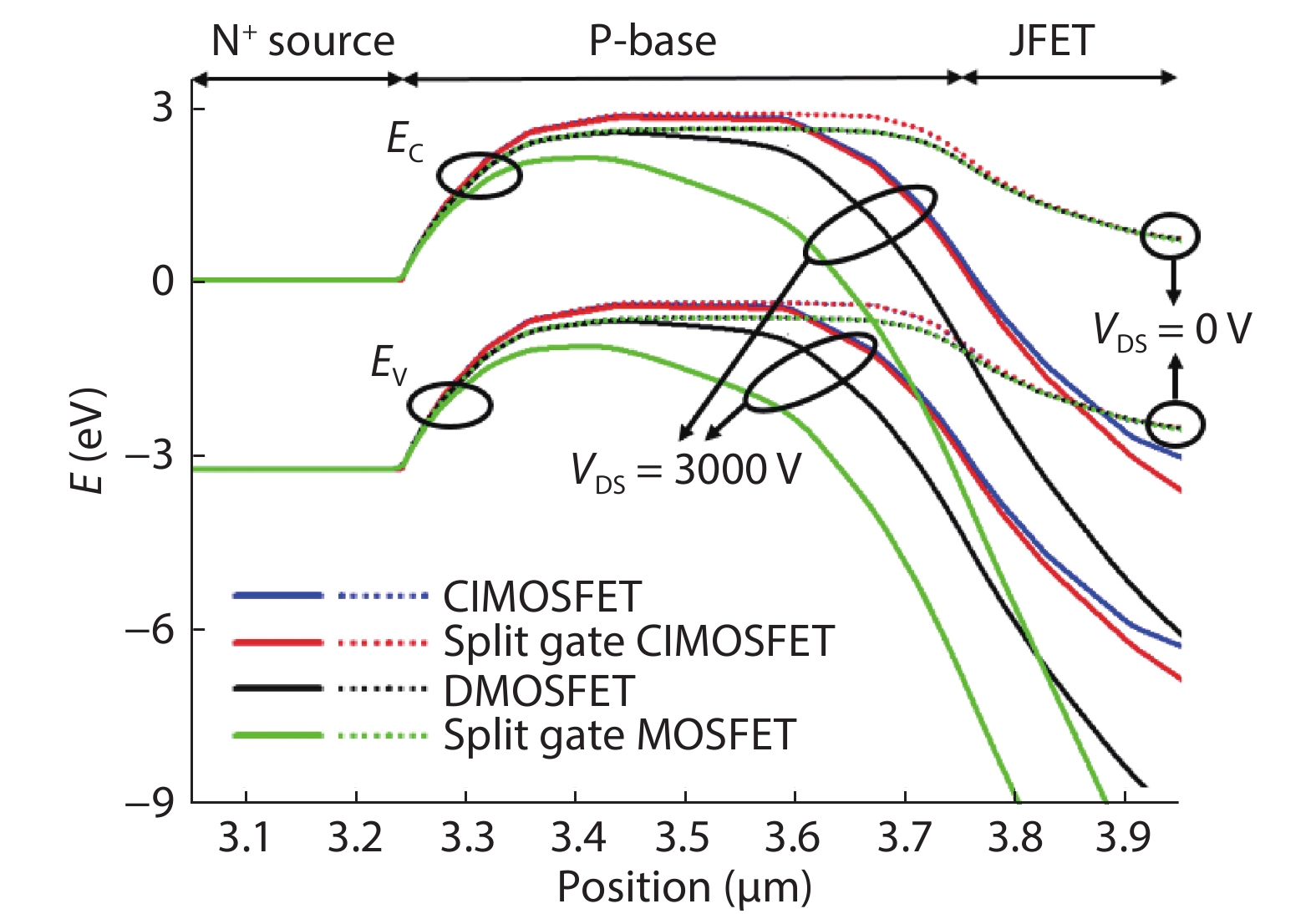

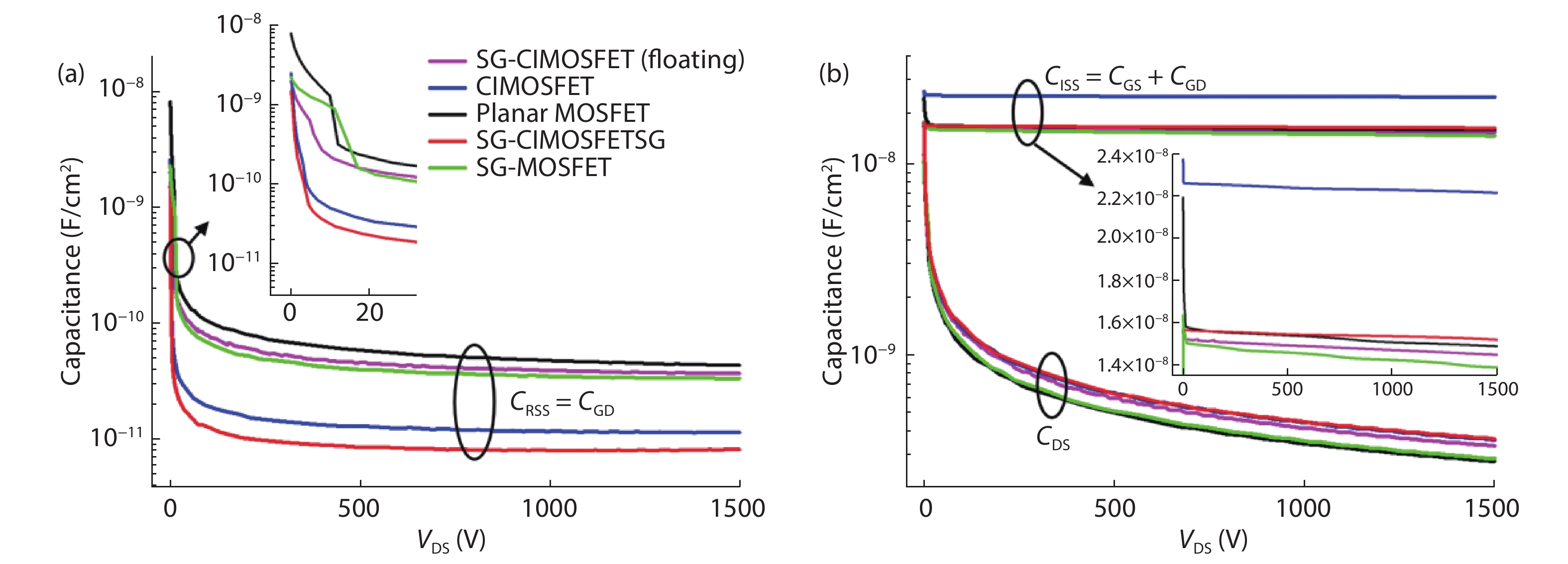

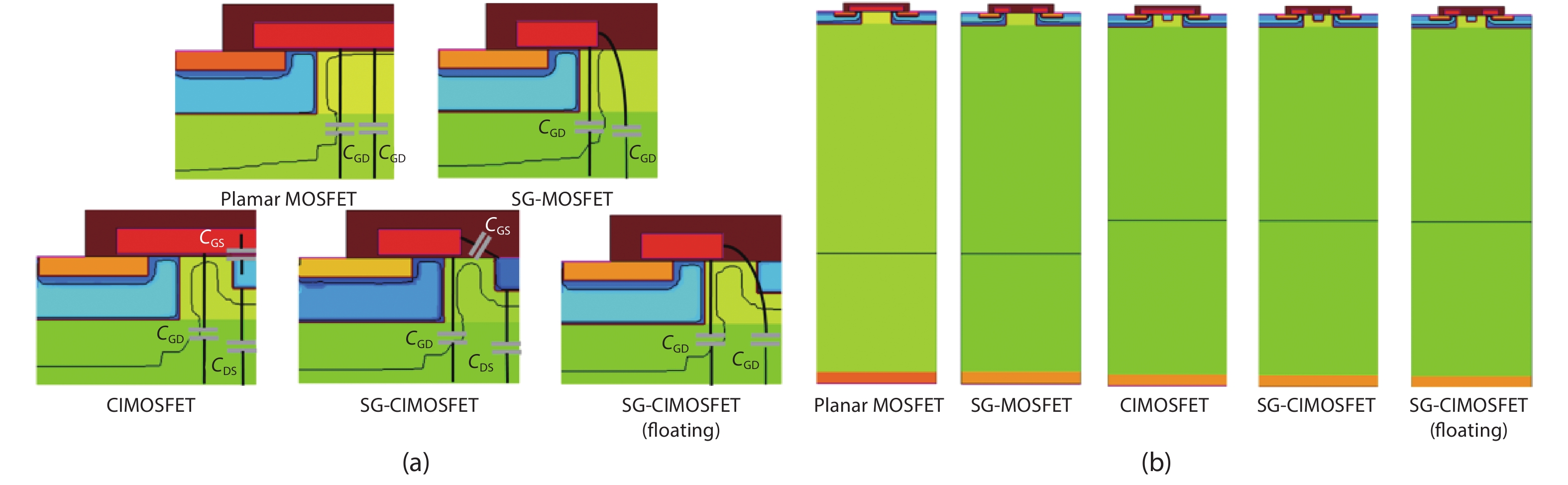

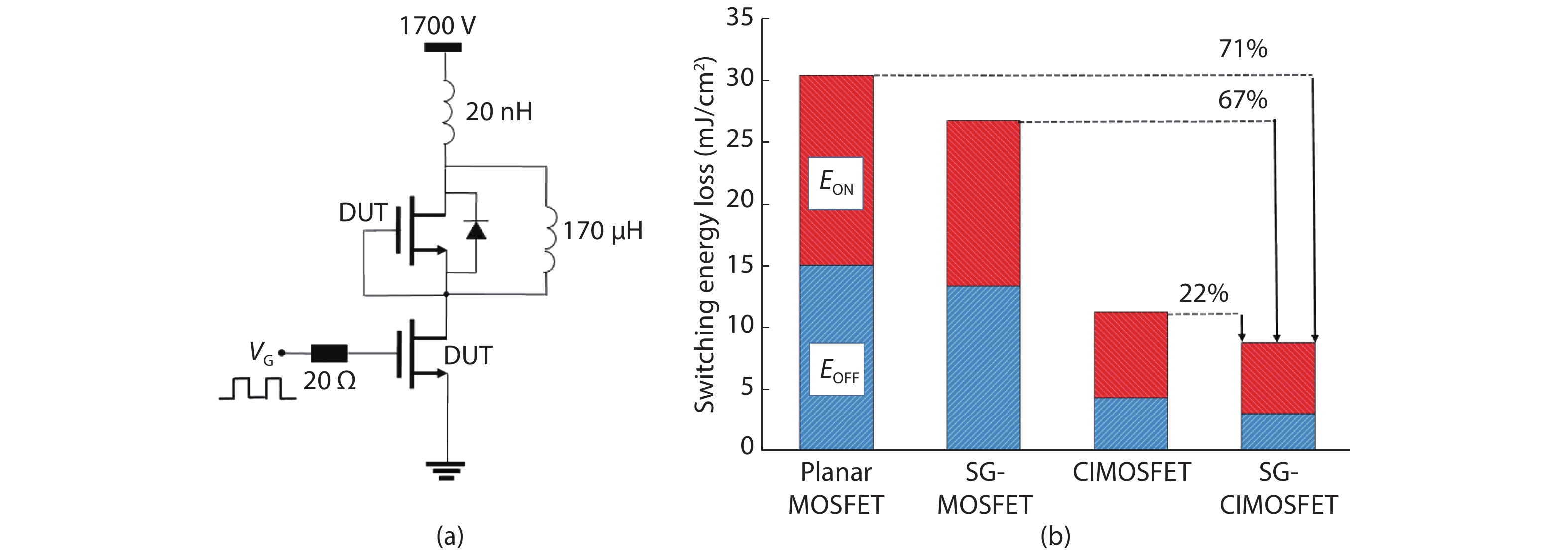

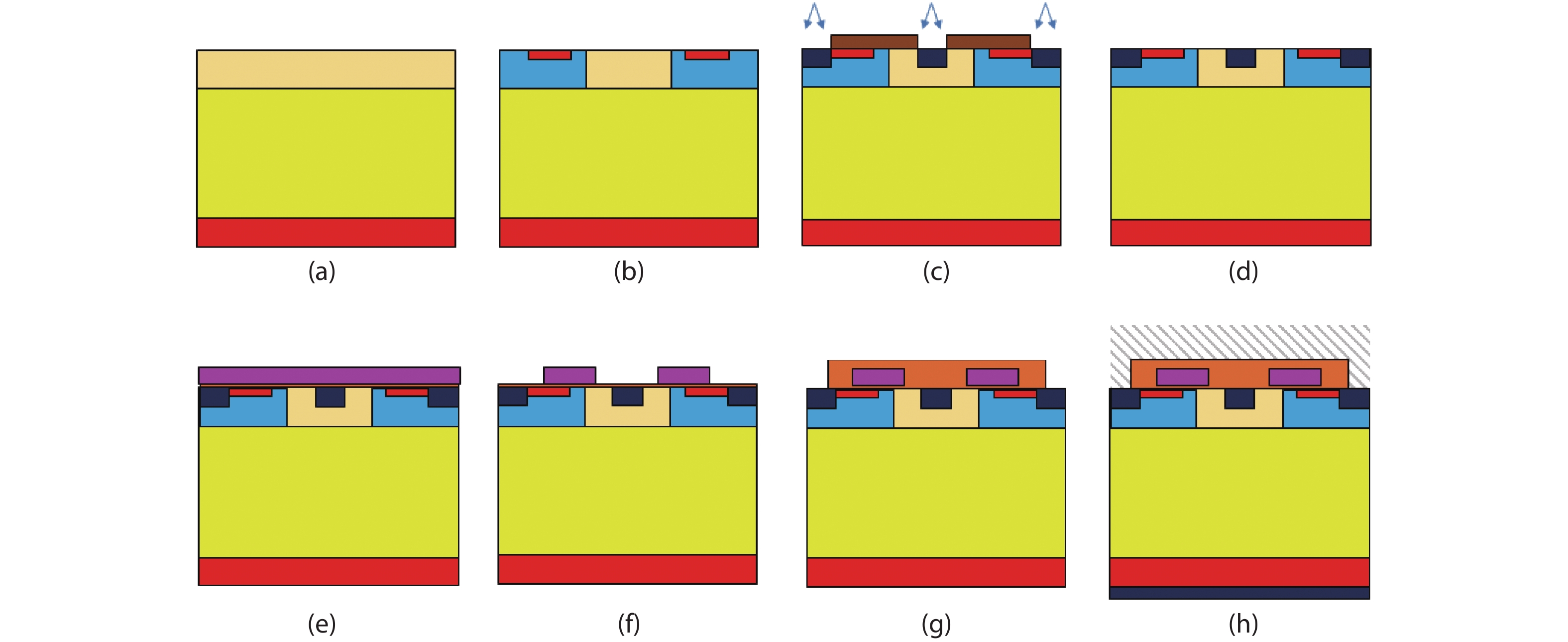

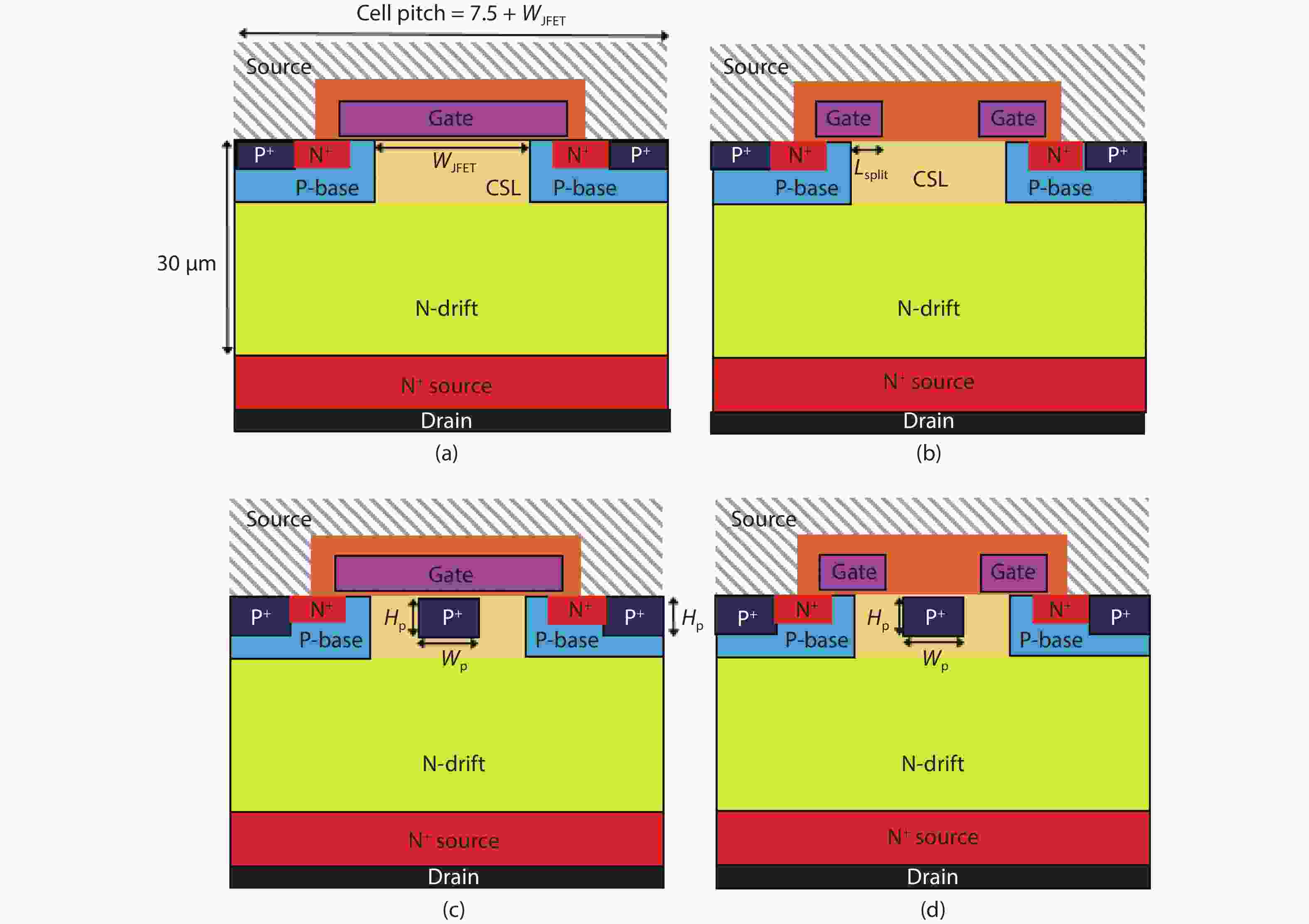

A split gate MOSFET (SG-MOSFET) is widely known for reducing the reverse transfer capacitance (CRSS). In a 3.3 kV class, the SG-MOSFET does not provide reliable operation due to the high gate oxide electric field. In addition to the poor static performance, the SG-MOSFET has issues such as the punch through and drain-induced barrier lowering (DIBL) caused by the high gate oxide electric field. As such, a 3.3 kV 4H-SiC split gate MOSFET with a grounded central implant region (SG-CIMOSFET) is proposed to resolve these issues and for achieving a superior trade-off between the static and switching performance. The SG-CIMOSFET has a significantly low on-resistance (RON) and maximum gate oxide field (EOX) due to the central implant region. A grounded central implant region significantly reduces the CRSS and gate drain charge (QGD) by partially screening the gate-to-drain capacitive coupling. Compared to a planar MOSFET, the SG MOSFET, central implant MOSFET (CIMOSFET), the SG-CIMOSFET improve the RON×QGD by 83.7%, 72.4% and 44.5%, respectively. The results show that the device features not only the smallest switching energy loss but also the fastest switching time. -

References

[1] Baliga B J. Power MOSFETs Fundamentals of power semiconductor devices. Boston, MA: Springer US, 2008, 276[2] Ji S Q, Zhang Z Y, Wang F. Overview of high voltage sic power semiconductor devices: Development and application. CES Trans Electr Mach Syst, 2017, 1, 254 doi: 10.23919/TEMS.2017.8086104[3] Cooper J A, Agarwal A. SiC power-switching devices-the second electronics revolution. Proc IEEE, 2002, 90, 956 doi: 10.1109/JPROC.2002.1021561[4] Wang G Y, Wang F, Magai G R, et al. Performance comparison of 1200V 100A SiC MOSFET and 1200V 100A silicon IGBT. 2013 IEEE Energy Convers Congr Expo, 2013, 3230[5] Nakamura T, Nakano Y, Aketa M, et al. High performance SiC trench devices with ultra-low Ron. 2011 International Electron Devices Meeting, 2011, 26.5.1[6] Sampath M, Morisette D T, Cooper J A. Comparison of single- and double-trench UMOSFETs in 4H-SiC. Mater Sci Forum, 2018, 924, 752 doi: 10.4028/www.scientific.net/MSF.924.752[7] Krishnaswami S, Das M, Hull B, et al. Gate oxide reliability of 4H-SiC MOS devices. 2005 IEEE International Reliability Physics Symposium, 2005, 592[8] Xu S M, Ren C H, Liang Y C, et al. Theoretical analysis and experimental characterization of the dummy-gated VDMOSFET. IEEE Trans Electron Devices, 2001, 48, 2168 doi: 10.1109/16.944212[9] Agarwal A, Han K, Baliga B J. 2.3 kV 4H-SiC accumulation-channel split-gate planar power MOSFETs with reduced gate charge. IEEE J Electron Devices Soc, 2020, 8, 499 doi: 10.1109/JEDS.2020.2991355[10] Han K, Baliga B J, Sung W. A novel 1.2 kV 4H-SiC buffered-gate (BG) MOSFET: Analysis and experimental results. IEEE Electron Device Lett, 2018, 39, 248 doi: 10.1109/LED.2017.2785771[11] Vudumula P, Kotamraju S. Design and optimization of 1.2-kV SiC planar inversion MOSFET using split dummy gate concept for high-frequency applications. IEEE Trans Electron Devices, 2019, 66, 5266 doi: 10.1109/TED.2019.2949459[12] Zhang Q C J, Duc J, Hull B, et al. CIMOSFET: A new MOSFET on SiC with a superior Ron·Qgd figure of merit. Mater Sci Forum, 2015, 821–823, 765[13] Zhang Q J, Wang G Y, Doan H, et al. Latest results on 1200 V 4H-SiC CIMOSFETs with Rsp, on of 3.9 mΩ·cm2 at 150 °C. 2015 IEEE 27th International Symposium on Power Semiconductor Devices & IC's (ISPSD), 2015, 89[14] TCAD Sentaurus Device Manual, Synopsys. 2016, Inc., Mountain View, CA, USA[15] Darwish M N, Lentz J L, Pinto M R, et al. An improved electron and hole mobility model for general purpose device simulation. IEEE Trans Electron Devices, 1997, 44, 1529 doi: 10.1109/16.622611[16] Mujtaba S A. Advanced mobility models for design and simulation of deep submicrometer MOSFETs. PhD Dissertation, Stanford University, 1995[17] Han K, Baliga B J, Sung W. Split-gate 1.2-kV 4H-SiC MOSFET: Analysis and experimental validation. IEEE Electron Device Lett, 2017, 38, 1437 doi: 10.1109/LED.2017.2738616[18] Wei J, Zhang M, Jiang H P, et al. Low ON-resistance SiC trench/planar MOSFET with reduced OFF-state oxide field and low gate charges. IEEE Electron Device Lett, 2016, 37, 1458 doi: 10.1109/LED.2016.2609599[19] Wei J, Zhang M, Jiang H P, et al. Dynamic degradation in SiC trench MOSFET with a floating p-shield revealed with numerical simulations. IEEE Trans Electron Devices, 2017, 64, 2592 doi: 10.1109/TED.2017.2697763[20] Ren M, Chen Z, Niu B, et al. A low miller capacitance VDMOS with shield gate and oxide trench. 2016 IEEE International Nanoelectronics Conference (INEC), 2016, 1[21] Basler T, Heer D, Peters D, et al. Practical aspects and body diode robustness of a 1200 V SiC trench MOSFET. International Exhibition and Conference for Power Electronics, Intelligent Motion, Renewable Energy and Energy Management, 2018, 1[22] Maerz A, Bertelshofer T, Bakran M, et al. A novel gate drive concept to eliminate parasitic turn-on of SiC MOSFET in low inductance power modules. International Exhibition and Conference for Power Electronics, Intelligent Motion, Renewable Energy and Energy Management, 2017, 1[23] Tian K, Hallén A, Qi J W, et al. An improved 4H-SiC trench-gate MOSFET with low ON-resistance and switching loss. IEEE Trans Electron Devices, 2019, 66, 2307 doi: 10.1109/TED.2019.2905636[24] Morikawa T, Ishigaki T, Shima A. Device design consideration for robust SiC VDMOSFET with self-aligned channels formed by tilted implantation. IEEE Trans Electron Devices, 2019, 66, 3447 doi: 10.1109/TED.2019.2924969[25] Zhou X T, Yue R F, Zhang J, et al. 4H-SiC trench MOSFET with floating/grounded junction barrier-controlled gate structure. IEEE Trans Electron Devices, 2017, 64, 4568 doi: 10.1109/TED.2017.2755721 -

Proportional views

DownLoad:

DownLoad: