| Citation: |

Qi Liu, Seeram Ramakrishna, Yun-Ze Long. Electrospun flexible sensor[J]. Journal of Semiconductors, 2019, 40(11): 111603. doi: 10.1088/1674-4926/40/11/111603

Q Liu, S Ramakrishna, Y Z Long, Electrospun flexible sensor[J]. J. Semicond., 2019, 40(11): 111603. doi: 10.1088/1674-4926/40/11/111603.

Export: BibTex EndNote

|

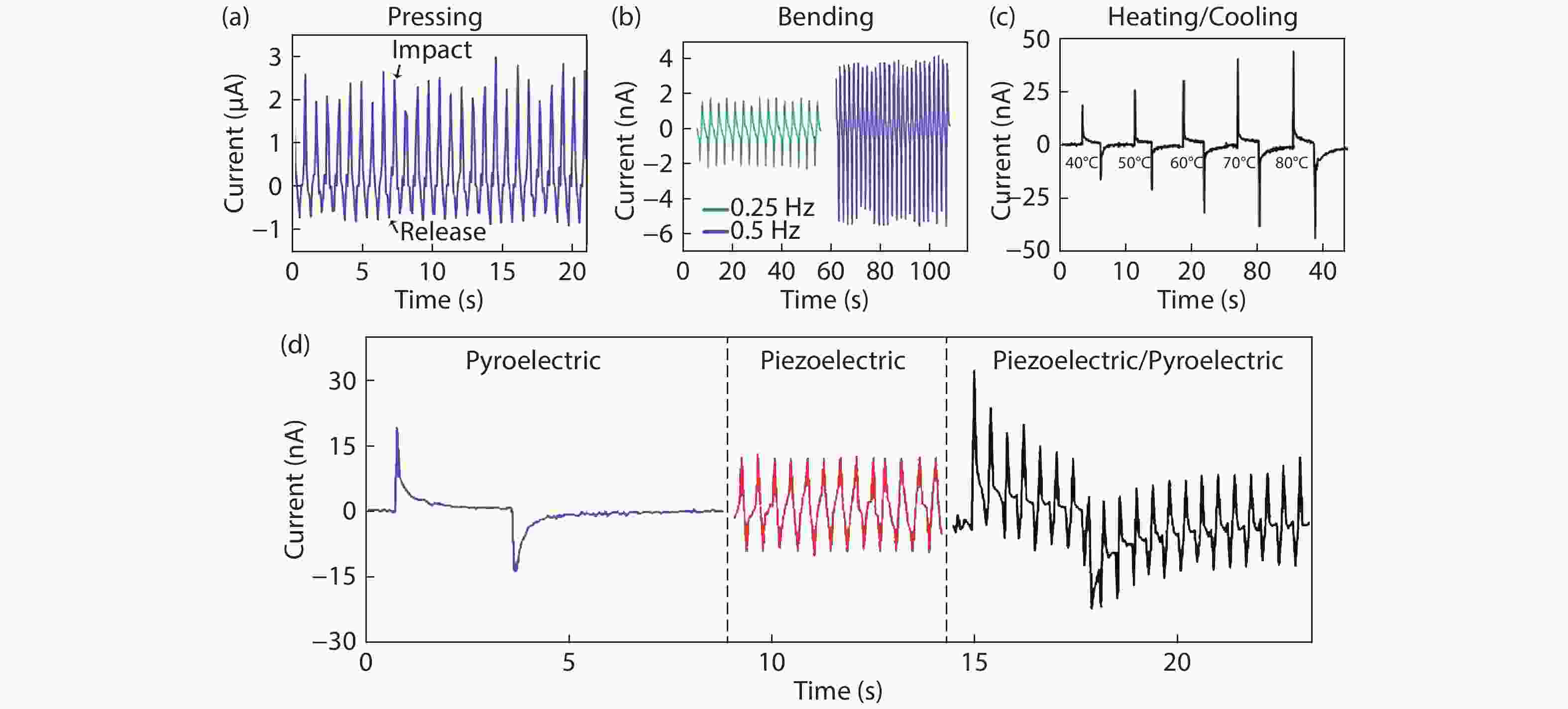

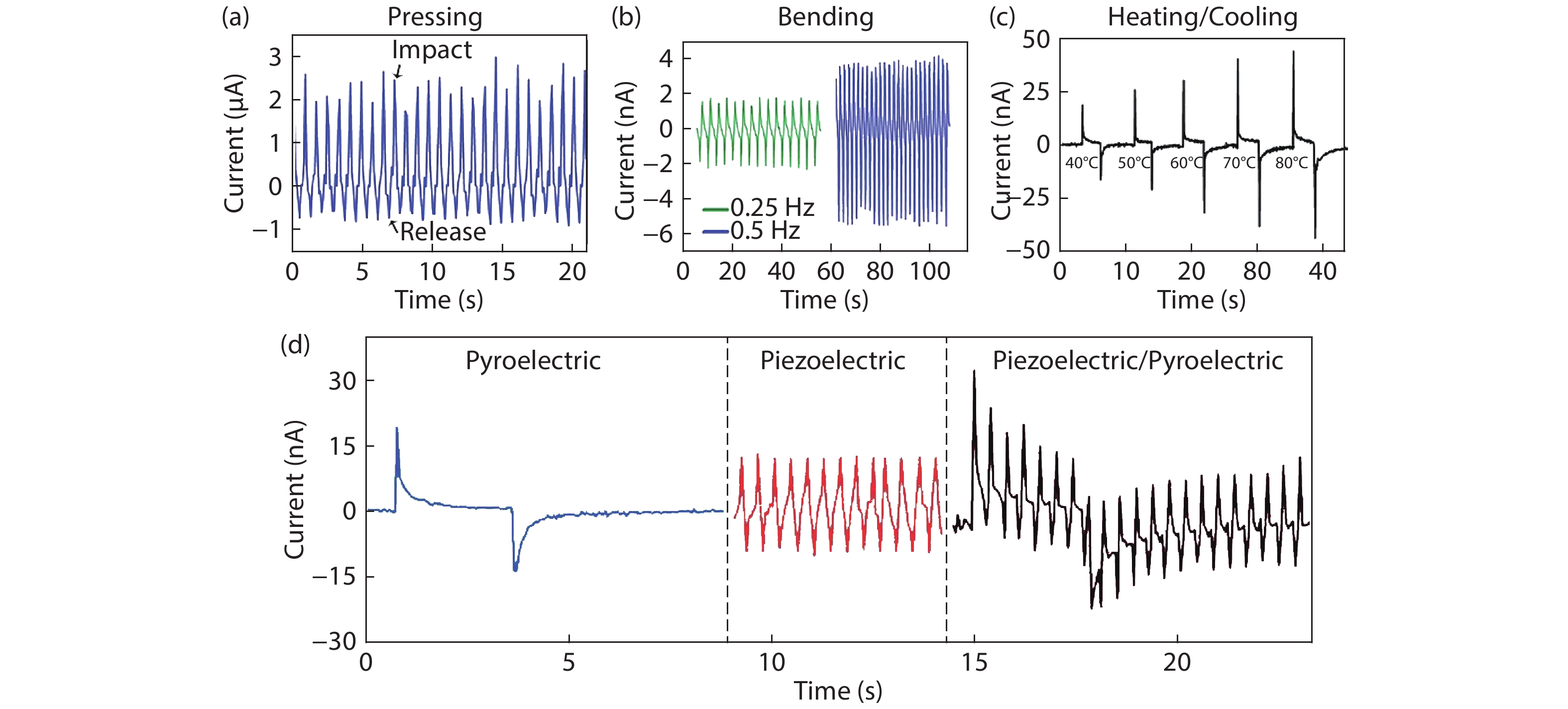

-

Abstract

Flexible sensors have received wide attention because of their ability to adapt to a variety of complex environments. Electrospinning technology has significant advantages in the preparation of flexible sensors. This paper summarizes the progress in the preparation of flexible sensors by electrospinning. Sensors that respond to light, stress, and gas are presented separately. Finally, some directions for electrospinning and flexible sensors are discussed.-

Keywords:

- electrospinning,

- sensor,

- nanofibers

-

References

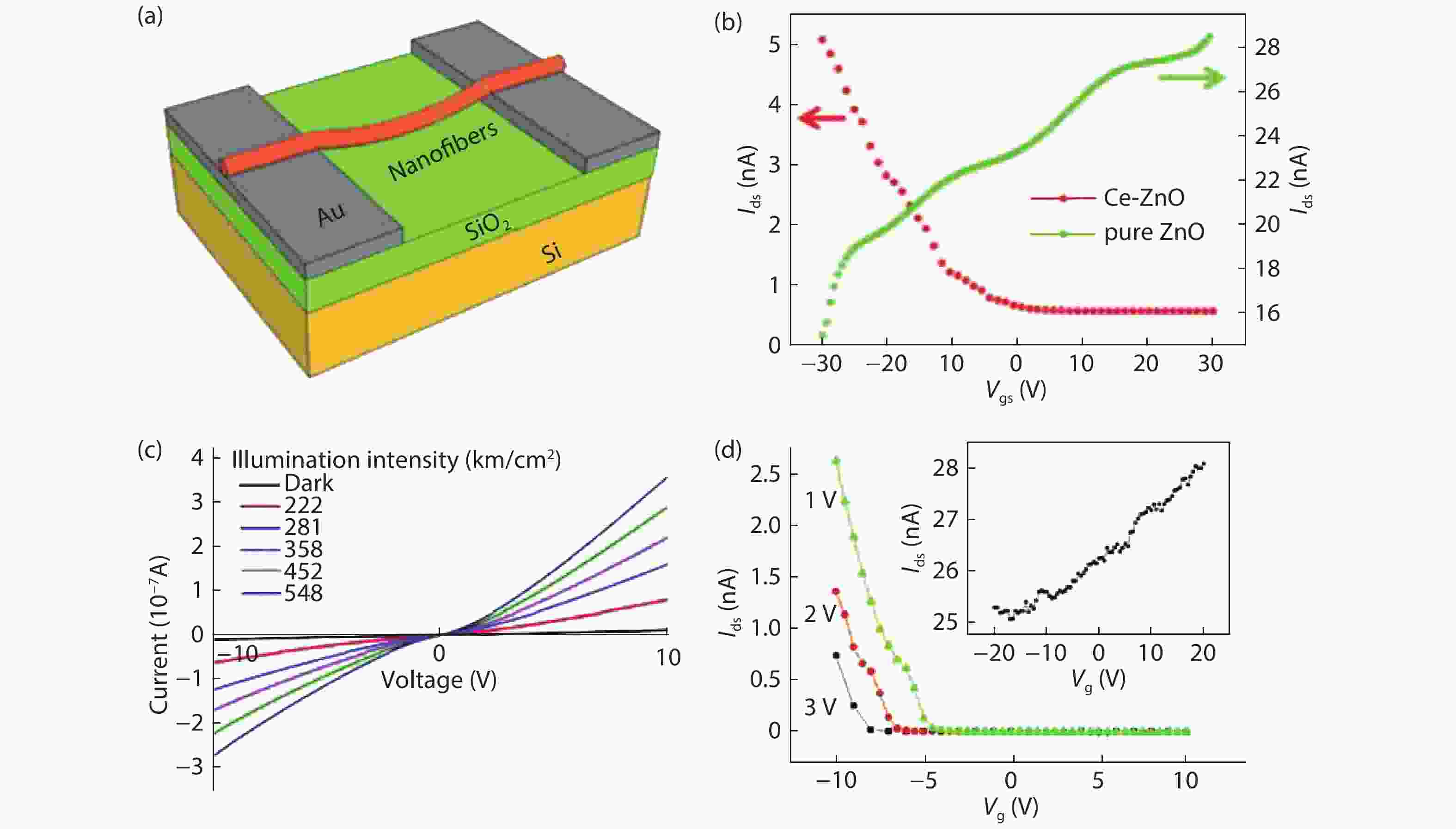

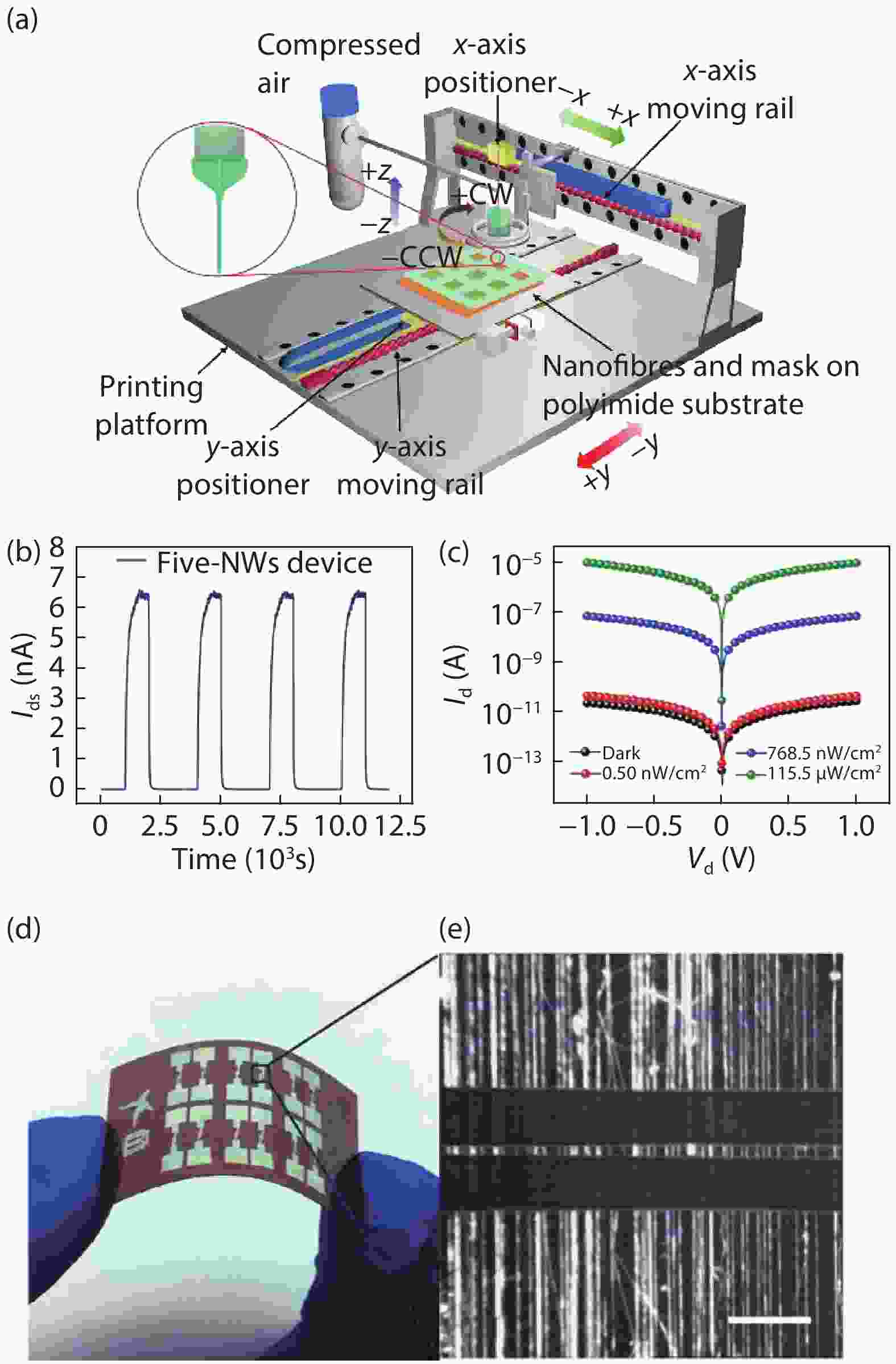

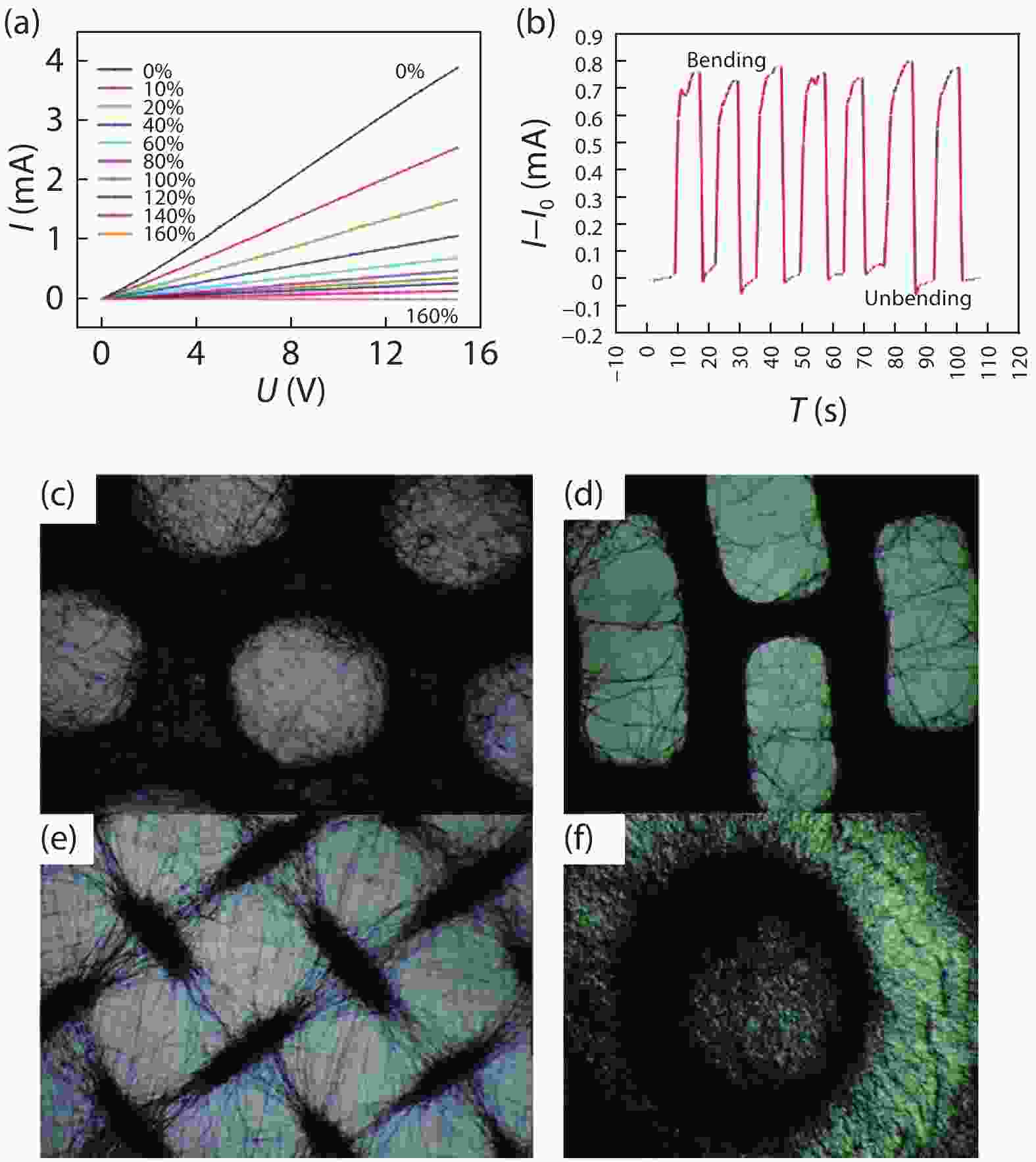

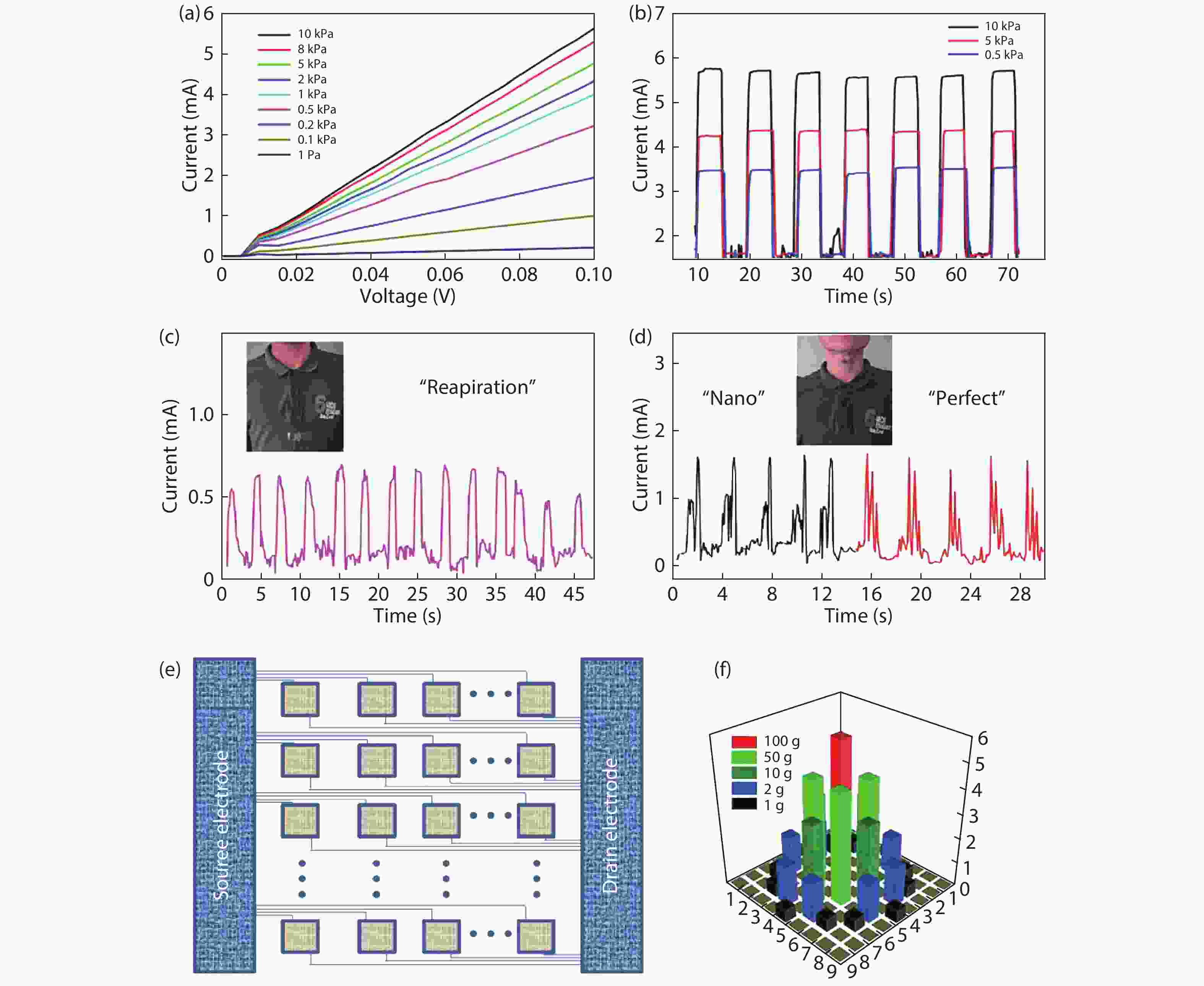

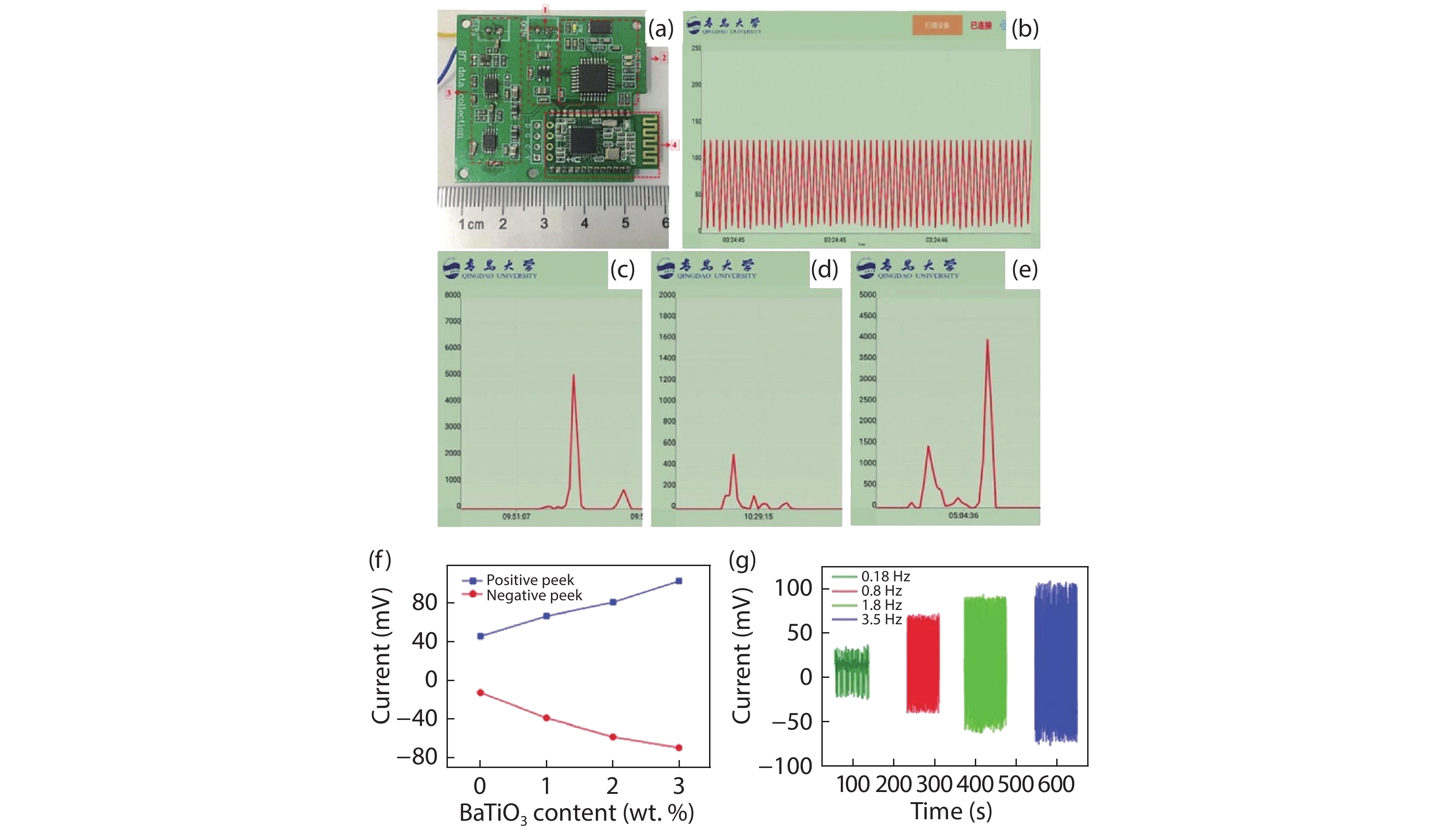

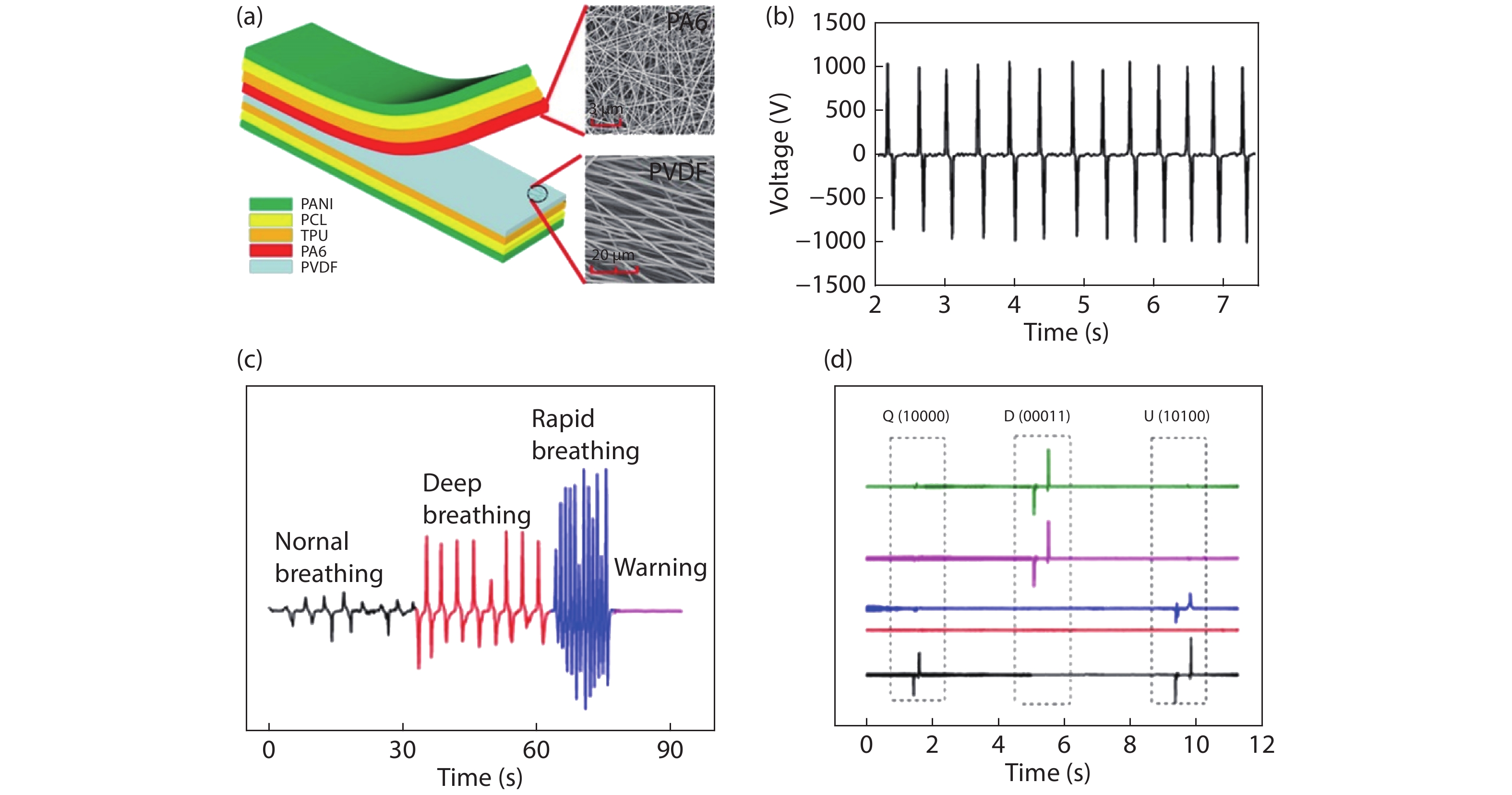

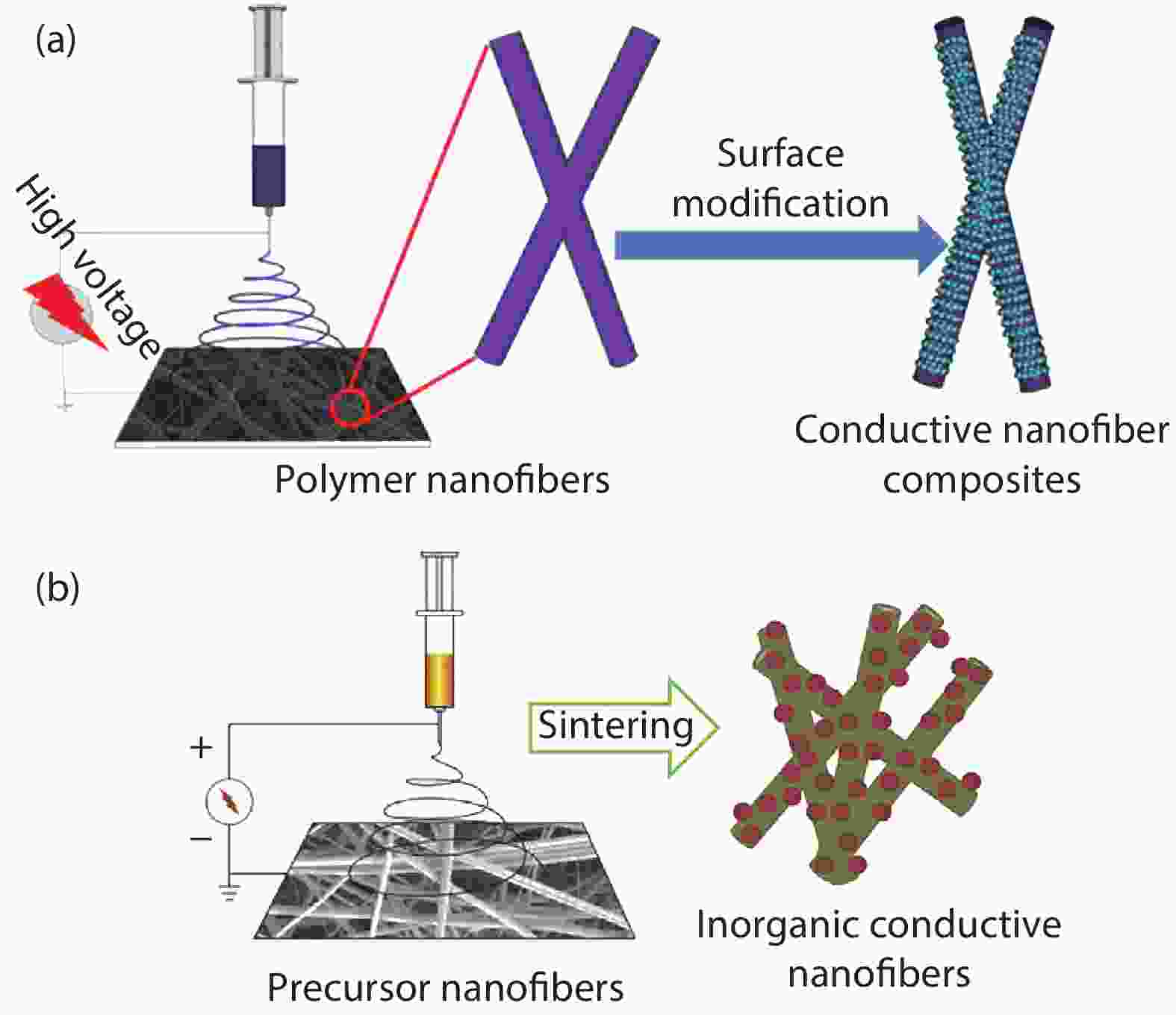

[1] Zheng J, Long Y Z, Sun B, et al. Polymer nanofibers prepared by low-voltage near-field electrospinning. Chin Phys B, 2012, 21(4), 048102 doi: 10.1088/1674-1056/21/4/048102[2] Zheng J, Sun B, Long Y Z, et al. Fabrication of nanofibers by low-voltage near-field electrospinning. Adv Mater Res, 2012, 486, 60 doi: 10.4028/www.scientific.net/AMR.486.60[3] He X X, Zheng J, Yu G F, et al. Near-field electrospinning: progress and applications. J Phys Chem C, 2017, 121(16), 8663 doi: 10.1021/acs.jpcc.6b12783[4] Si W Y, Zhang H D, Liu Y J, et al. Fabrication and pressure sensing analysis of ZnO/PVDF composite microfiber arrays by low-voltage near-field electrospinning. Chem J Chin Univ-Chin, 2017, 38(6), 997 doi: 10.7503/cjcu20160847[5] You M H, Wang X X, Yan X, et al. A self-powered flexible hybrid piezoelectric-pyroelectric nanogenerator based on non-woven nanofiber membranes. J Mater Chem A, 2018, 6(8), 3500 doi: 10.1039/C7TA10175A[6] Sui J X, Wang X X, Song C, et al. Preparation and low-temperature electrical and magnetic properties of La0.33Pr0.34Ca0.33MnO3 nanofibers via electrospinning. J Magnet Magnet Mater, 2018, 467, 74 doi: 10.1016/j.jmmm.2018.07.060[7] Shen H, Li L, Xu D. Preparation of one-dimensional SnO2–In2O3 nano-heterostructures and their gas-sensing property. RSC Adv, 2017, 7(53), 33098 doi: 10.1039/C6RA28520A[8] Chen S, Long Y Z, Zhang H D, et al. Fabrication of ultrathin In2O3 hollow fibers for UV light sensing. Phys Scrip, 2014, 89(11), 115808 doi: 10.1088/0031-8949/89/11/115808[9] Chen S, Yu M, Han W P, et al. Electrospun anatase TiO2 nanorods for flexible optoelectronic devices. Rsc Adv, 2014, 4(86), 46152 doi: 10.1039/C4RA07943D[10] You M H, Yan X, Zhang J, et al. Colorimetric humidity sensors based on electrospun polyamide/CoCl2 nanofibrous membranes. Nanoscale Res Lett, 2017, 12, 360 doi: 10.1186/s11671-017-2139-0[11] Pyo J Y, Cho W J. In-plane-gate a-IGZO thin-film transistor for high-sensitivity pH sensor applications. Sens Actuators B, 2018, 276, 101 doi: 10.1016/j.snb.2018.08.087[12] Li S, Zhang J, Ju D D, et al. Flexible inorganic composite nanofibers with carboxyl modification for controllable drug delivery and enhanced optical monitoring functionality. Chem Eng J, 2018, 350, 645 doi: 10.1016/j.cej.2018.05.166[13] Zhang J, Li S, Ju D D, et al. Flexible inorganic core-shell nanofibers endowed with tunable multicolor upconversion fluorescence for simultaneous monitoring dual drug delivery. Chem Eng J, 2018, 349, 554 doi: 10.1016/j.cej.2018.05.112[14] Chen S, Liu G S, He H W, et al. Physical structure induced hydrophobicity analyzed from electrospinning and coating polyvinyl butyral films. Adv Conden Matter Phys, 2019, 2019, 6179456 doi: https://doi.org/10.1155/2019/6179456[15] Liu G S, Yan X, Yan F F, et al. In situ electrospinning iodine-based fibrous meshes for antibacterial wound dressing. Nanoscale Res Lett, 2018, 13(1), 309 doi: 10.1186/s11671-018-2733-9[16] Yan X, Yu M, Ramakrishna S, et al. Advances in portable electrospinning devices for in situ delivery of personalized wound care. Nanoscale, 2019 doi: 10.1039/C9NR02802A[17] Liu H, Zhang Z G, Wang X X, et al. Highly flexible Fe2O3/TiO2 composite nanofibers for photocatalysis and utraviolet detection. J Phys Chem Solids, 2018, 121, 236 doi: 10.1016/j.jpcs.2018.05.019[18] Zhang J, Wang X X, B Zhang B, et al. In situ assembly of well-dispersed Ag nanoparticles throughout electrospun alginate nanofibers for monitoring human breath-smart fabrics. Acs Appl Mater Interfaces, 2018, 10(23), 19863 doi: 10.1021/acsami.8b01718[19] Zhang H D, Yu M, Zhang J C, et al. Fabrication and photoelectric properties of La-doped p-type ZnO nanofibers and crossed p–n homojunctions by electrospinning. Nanoscale, 2015, 7(23), 10513 doi: 10.1039/C5NR02191J[20] Liu S, L Liu S L, Long Y Z, et al. Fabrication of p-type ZnO nanofibers by electrospinning for field-effect and rectifying devices. Appl Phys Lett, 2014, 104(4), 042105 doi: 10.1063/1.4863409[21] Liu Y J, Zhang H D, Zhang J, et al. Effects of Ce doping and humidity on UV sensing properties of electrospun ZnO nanofibers. J Appl Phys, 2017, 122(10), 105102 doi: 10.1063/1.5000443[22] Liu X, Gu L L, Zhang Q P, et al. All-printable band-edge modulated ZnO nanowire photodetectors with ultra-high detectivity. Nat Commun, 2014, 5, 4007 doi: 10.1038/ncomms5007[23] Zhang H D, Liu Y J, Zhang J, et al. Electrospun ZnO/SiO2 hybrid nanofibers for flexible pressure sensor. J Phys D, 2018, 51(8), 085102 doi: 10.1088/1361-6463/aaa82d[24] Tong L, Wang X X, He X X, et al. Electrically conductive TPU nanofibrous composite with high stretchability for flexible strain sensor. Nanoscale Res Lett, 2018, 13, 86 doi: 10.1186/s11671-018-2499-0[25] Yu G F, Yan X, Yu M, et al. Patterned, highly stretchable and conductive nanofibrous PANI/PVDF strain sensors based on electrospinning and in situ polymerization. Nanoscale, 2016, 8(5), 2944 doi: 10.1039/C5NR08618C[26] Hu W P, Zhang B, Zhang J, et al. Ag/alginate nanofiber membrane for flexible electronic skin. Nanotechnology, 2017, 28(44), 445502 doi: 10.1088/1361-6528/aa8746[27] Zhang H D, Long Y Z, Li Z J, et al. Fabrication of comb-like ZnO nanostructures for room-temperature CO gas sensing application. Vacuum, 2014, 101, 113 doi: 10.1016/j.vacuum.2013.07.046[28] Zhang H D, Yan X, Zhang Z H, et al. Electrospun PEDOT:PSS/PVP nanofibers for CO gas sensing with quartz crystal microbalance technique. Int J Polym Sci, 2016, 2016, 3021353 doi: 10.1155/2016/3021353[29] Zhang H D, Tang C C, Long Y Z, et al. High-sensitivity gas sensors based on arranged polyaniline/PMMA composite fibers. Sens Actuators A, 2014, 219, 123 doi: 10.1016/j.sna.2014.09.005[30] Sheng C H, Zhang H D, S Chen S, et al. Fabrication, structural and humidity sensing properties of BaTiO3 nanofibers via electrospinning. Int J Modern Phys B, 2015, 29(12), 1550066 doi: 10.1142/S0217979215500666[31] Zhang Q Q, Wang X X, J Fu J, et al. Electrospinning of ultrafine conducting polymer composite nanofibers with diameter less than 70 nm as high sensitive gas sensor. Materials, 2018, 11(9), 1744 doi: 10.3390/ma11091744[32] Wang X X, Song W Z, You M H, et al. Bionic single-electrode electronic skin unit based on piezoelectric nanogenerator. Acs Nano, 2018, 12(8), 8588 doi: 10.1021/acsnano.8b04244[33] Guo W Z, Tan C X, Shi K M, et al. Wireless piezoelectric devices based on electrospun PVDF/BaTiO3 NW nanocomposite fibers for human motion monitoring. Nanoscale, 2018, 10, 17751 doi: 10.1039/C8NR05292A[34] Qiu H J, Song W Z, Wang X X, et al. A calibration-free self-powered sensor for vital sign monitoring and finger tap communication based on wearable triboelectric nanogenerator. Nano Energy, 2019, 58, 536 doi: 10.1016/j.nanoen.2019.01.069[35] Huang C, Chen S, Lai C, et al. Electrospun polymer nanofibres with small diameters. Nanotechnology, 2006, 17(6), 1558 doi: 10.1088/0957-4484/17/6/004[36] Yang R, He J, Xu L, et al. Bubble-electrospinning for fabricating nanofibers. Polymer, 2009, 50(24), 5846 doi: 10.1016/j.polymer.2009.10.021[37] Jian S, Zhu J, Jiang S, et al. Nanofibers with diameter below one nanometer from electrospinning. RSC Adv, 2018, 8(9), 4794 doi: 10.1039/C7RA13444D -

Proportional views

DownLoad:

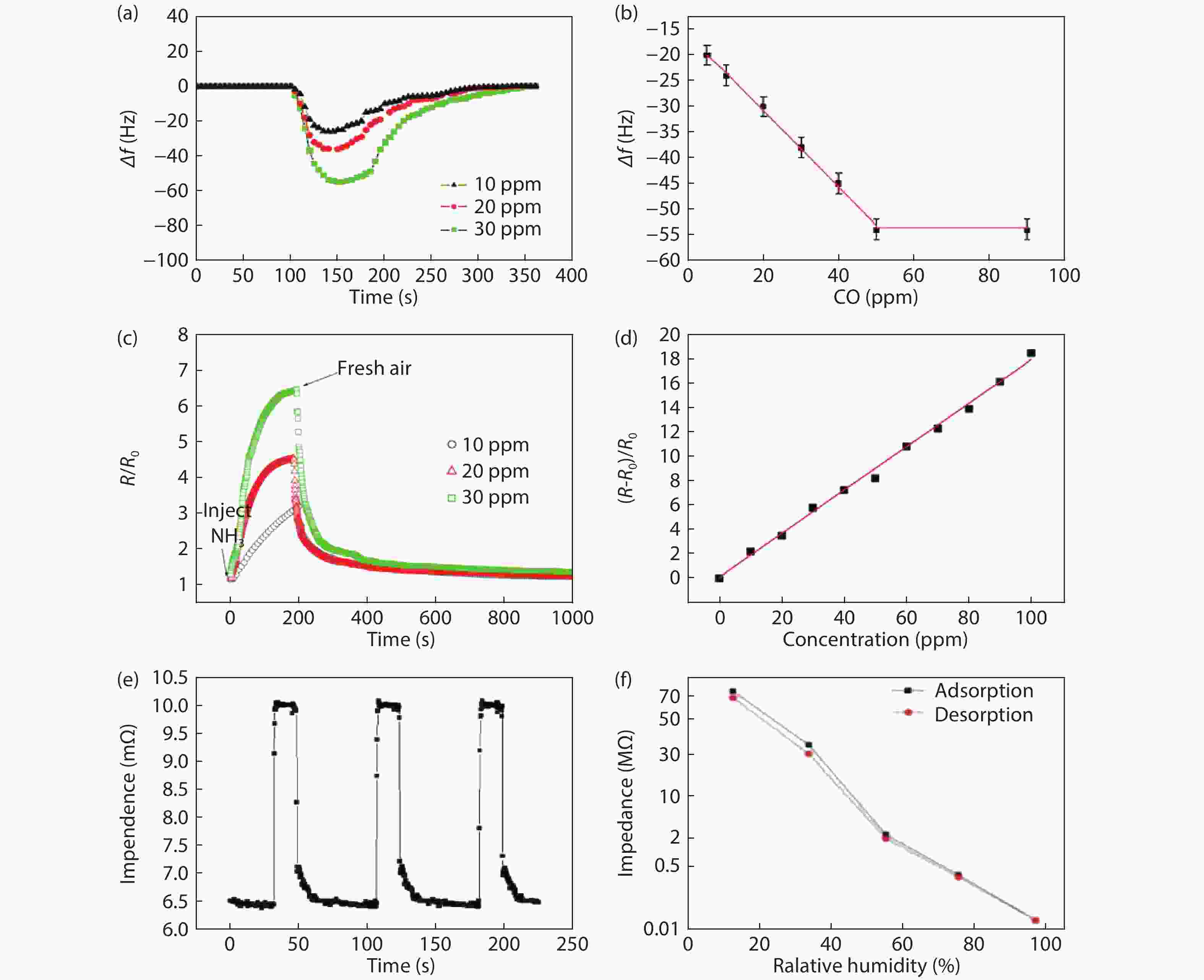

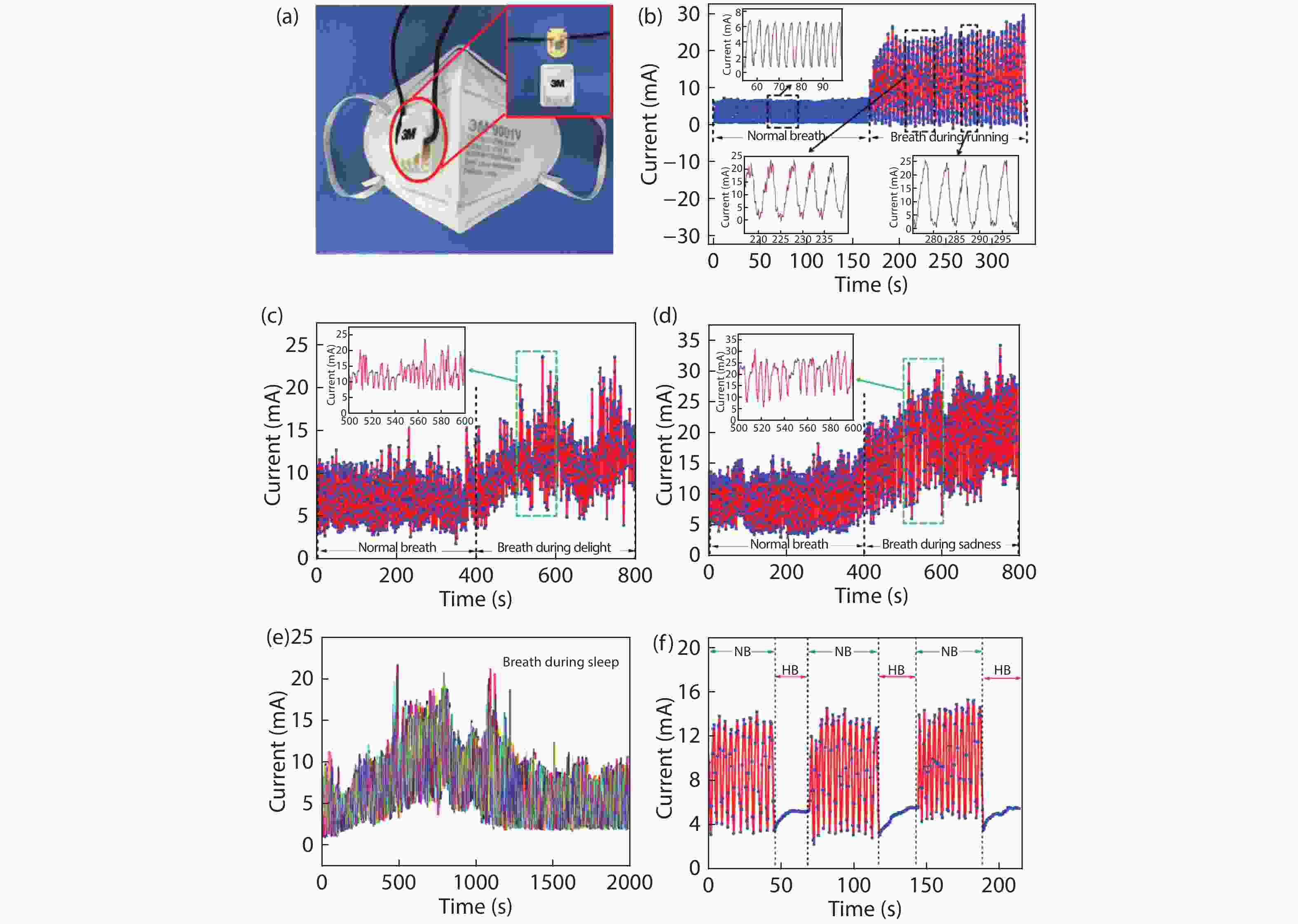

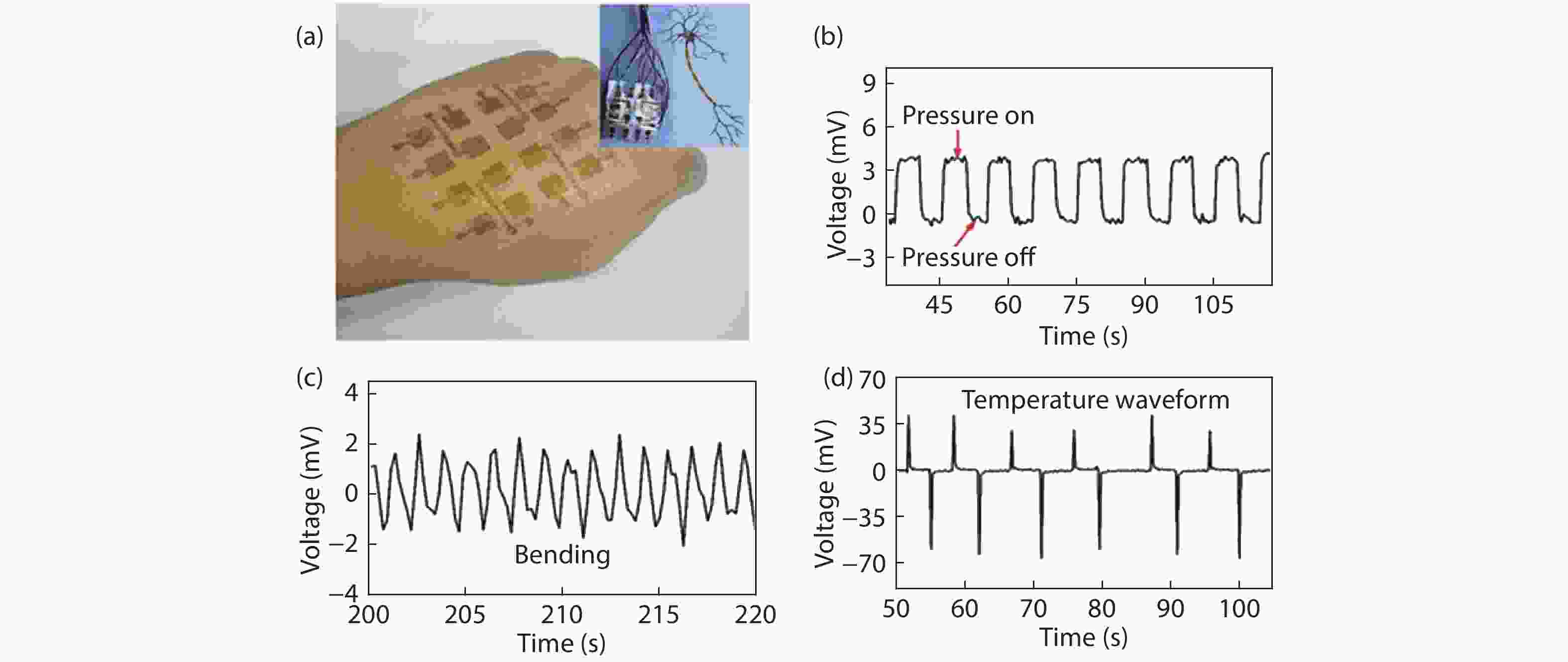

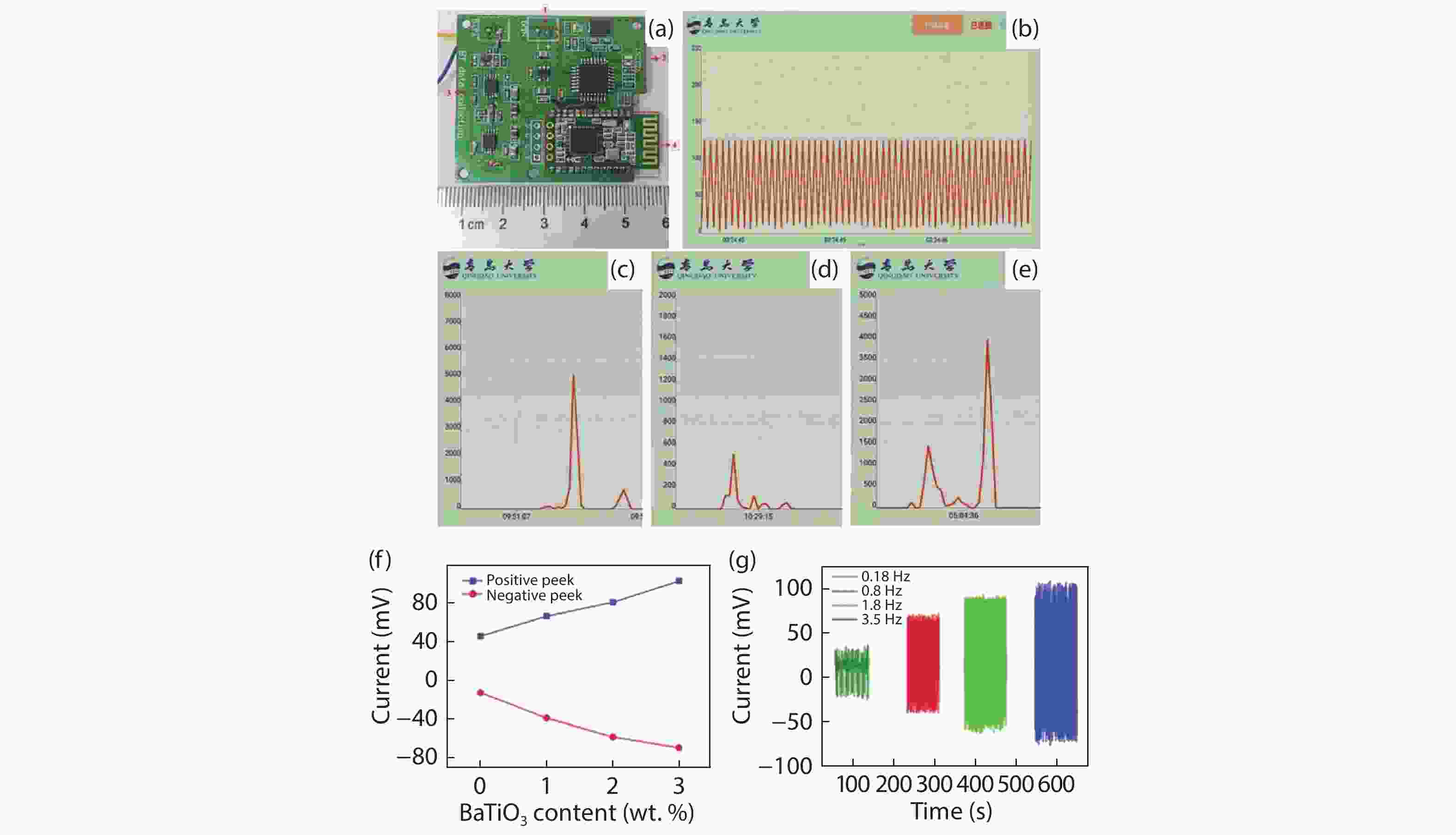

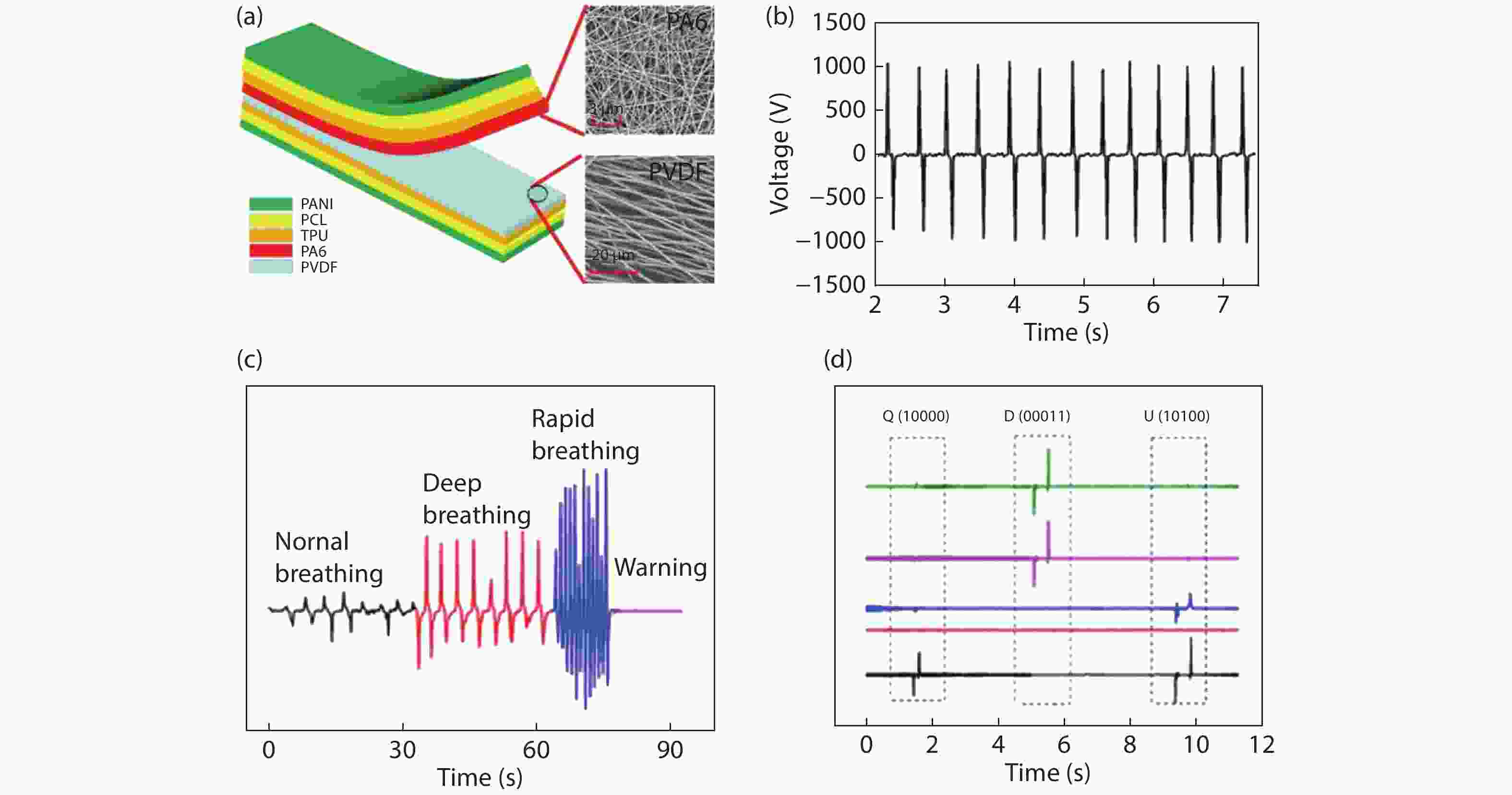

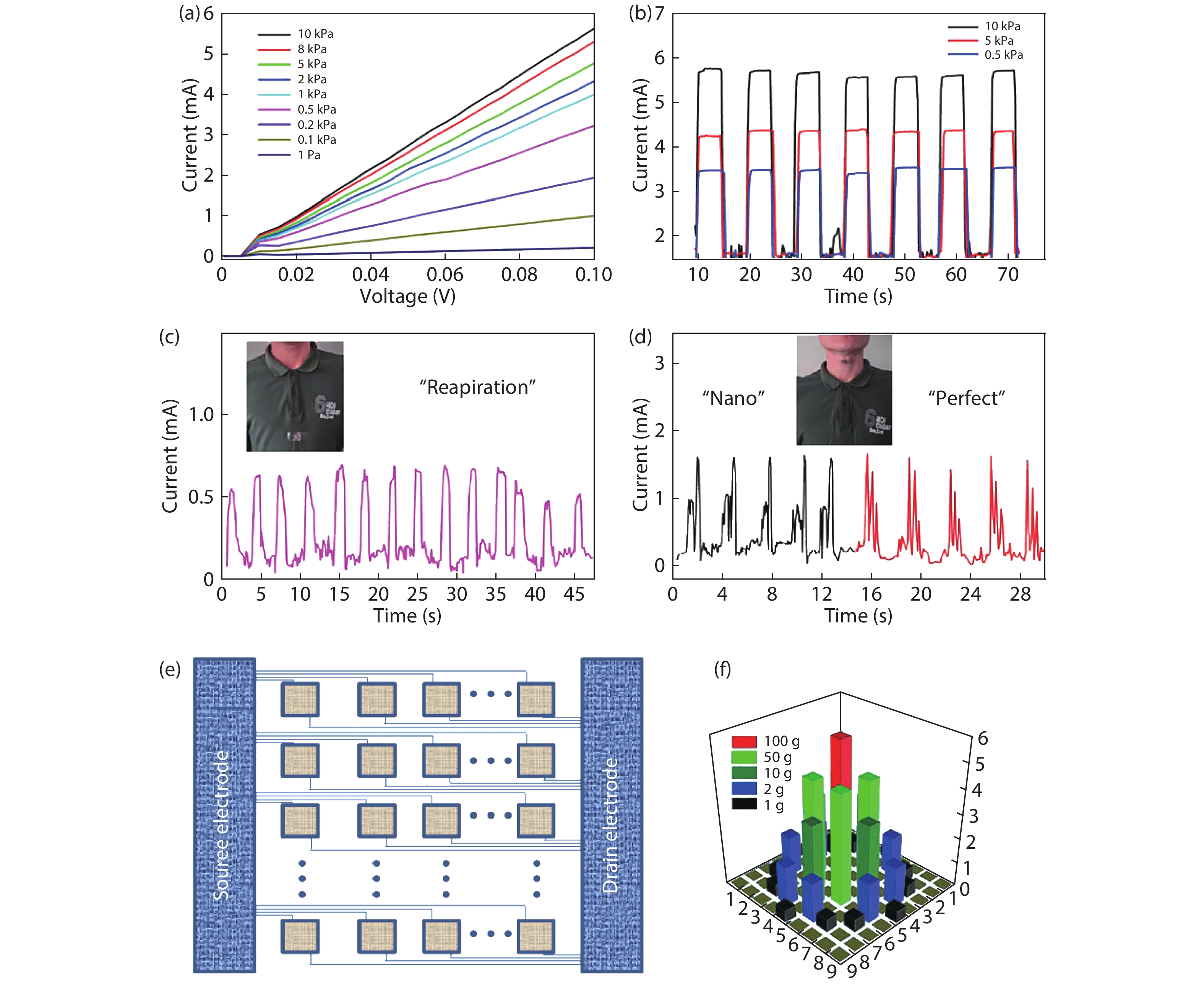

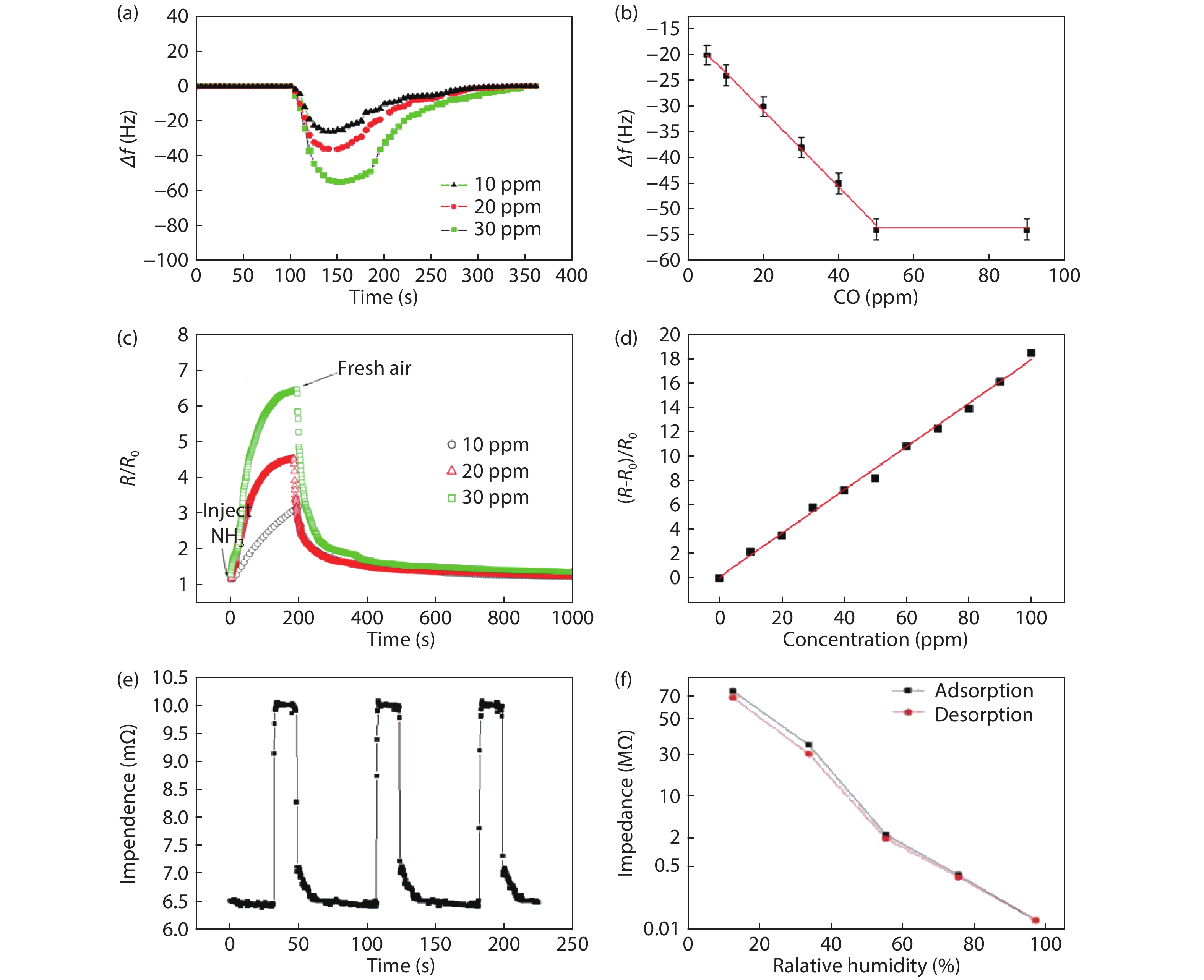

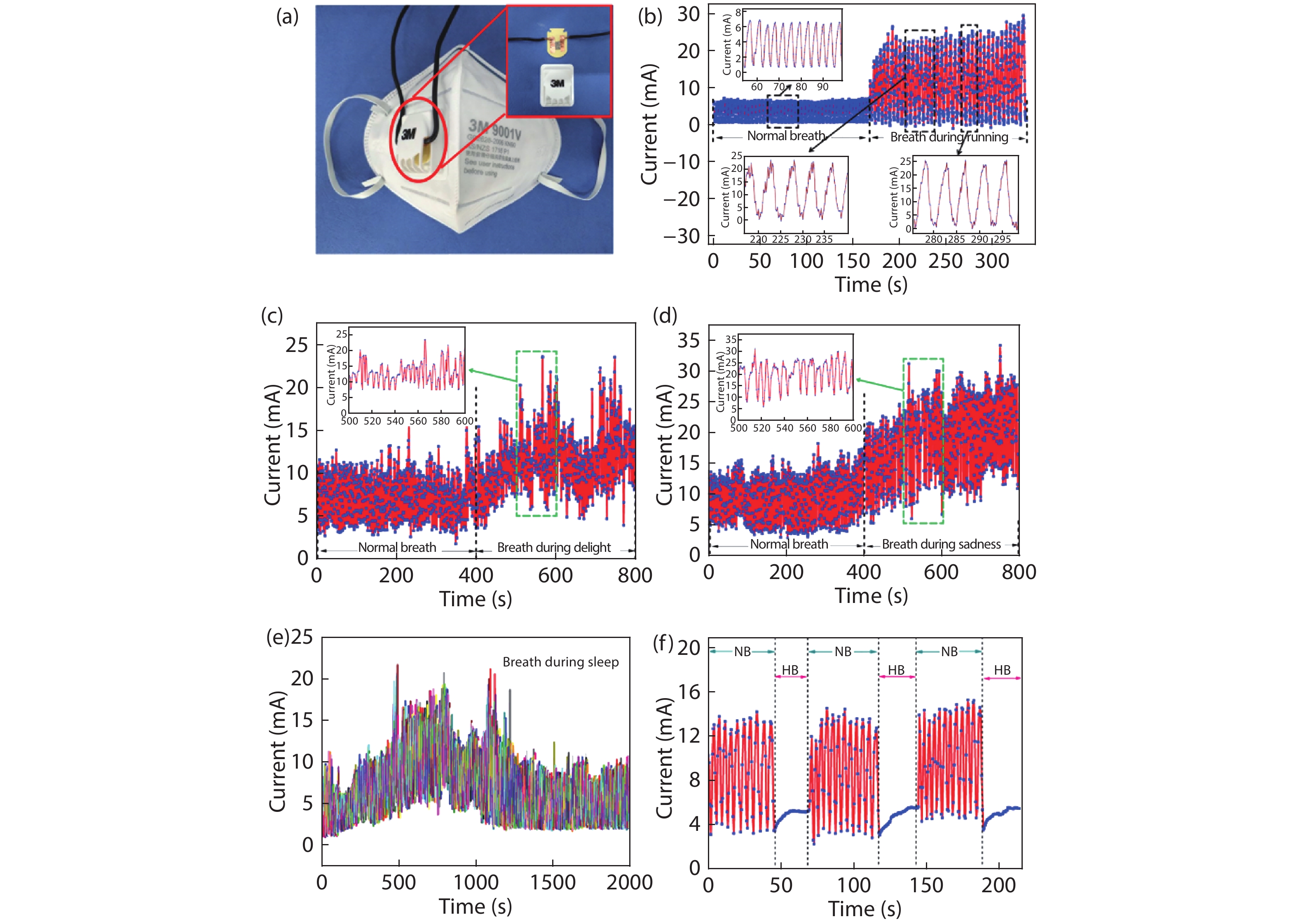

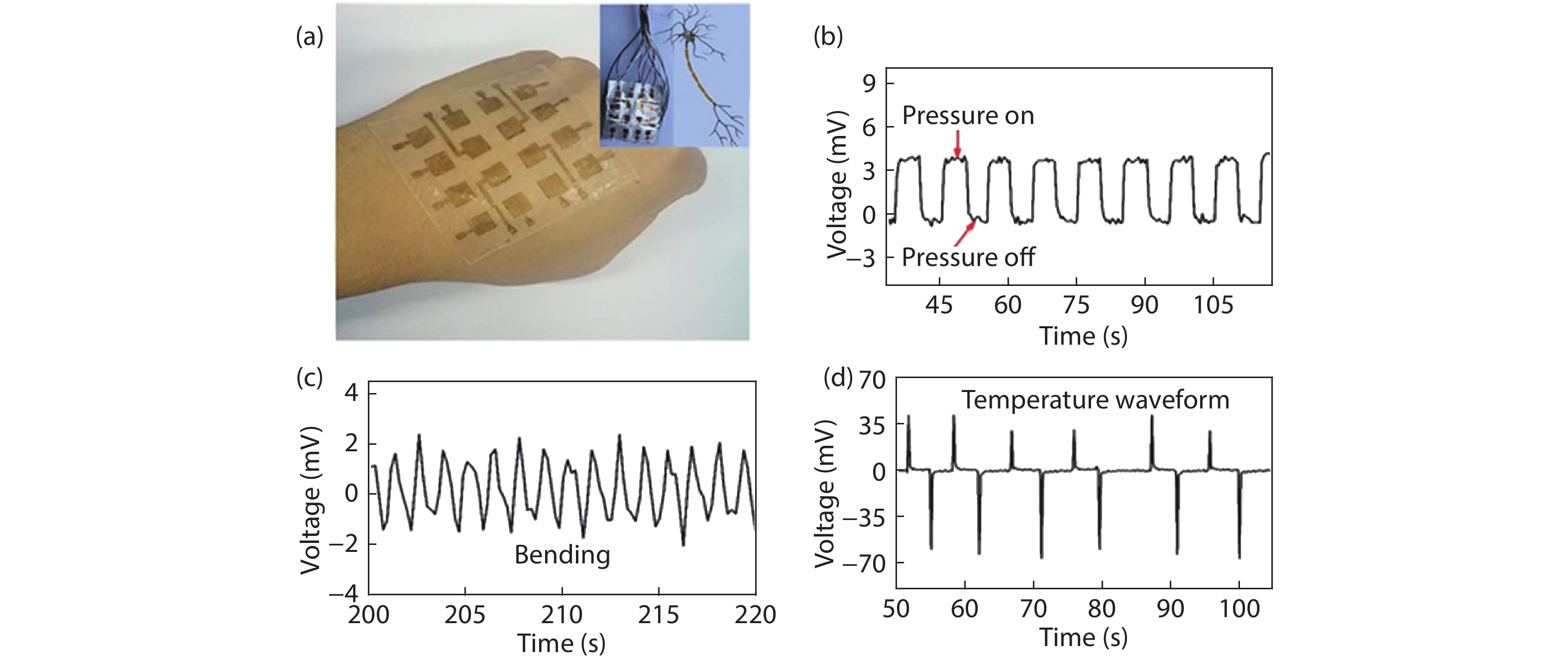

DownLoad: