| Citation: |

Haoran Fu, Ke Bai, Yonggang Huang, Yihui Zhang. Recent progress of morphable 3D mesostructures in advanced materials[J]. Journal of Semiconductors, 2020, 41(4): 041604. doi: 10.1088/1674-4926/41/4/041604

****

H R Fu, K Bai, Y G Huang, Y H Zhang, Recent progress of morphable 3D mesostructures in advanced materials[J]. J. Semicond., 2020, 41(4): 041604. doi: 10.1088/1674-4926/41/4/041604.

|

Recent progress of morphable 3D mesostructures in advanced materials

DOI: 10.1088/1674-4926/41/4/041604

More Information

-

Abstract

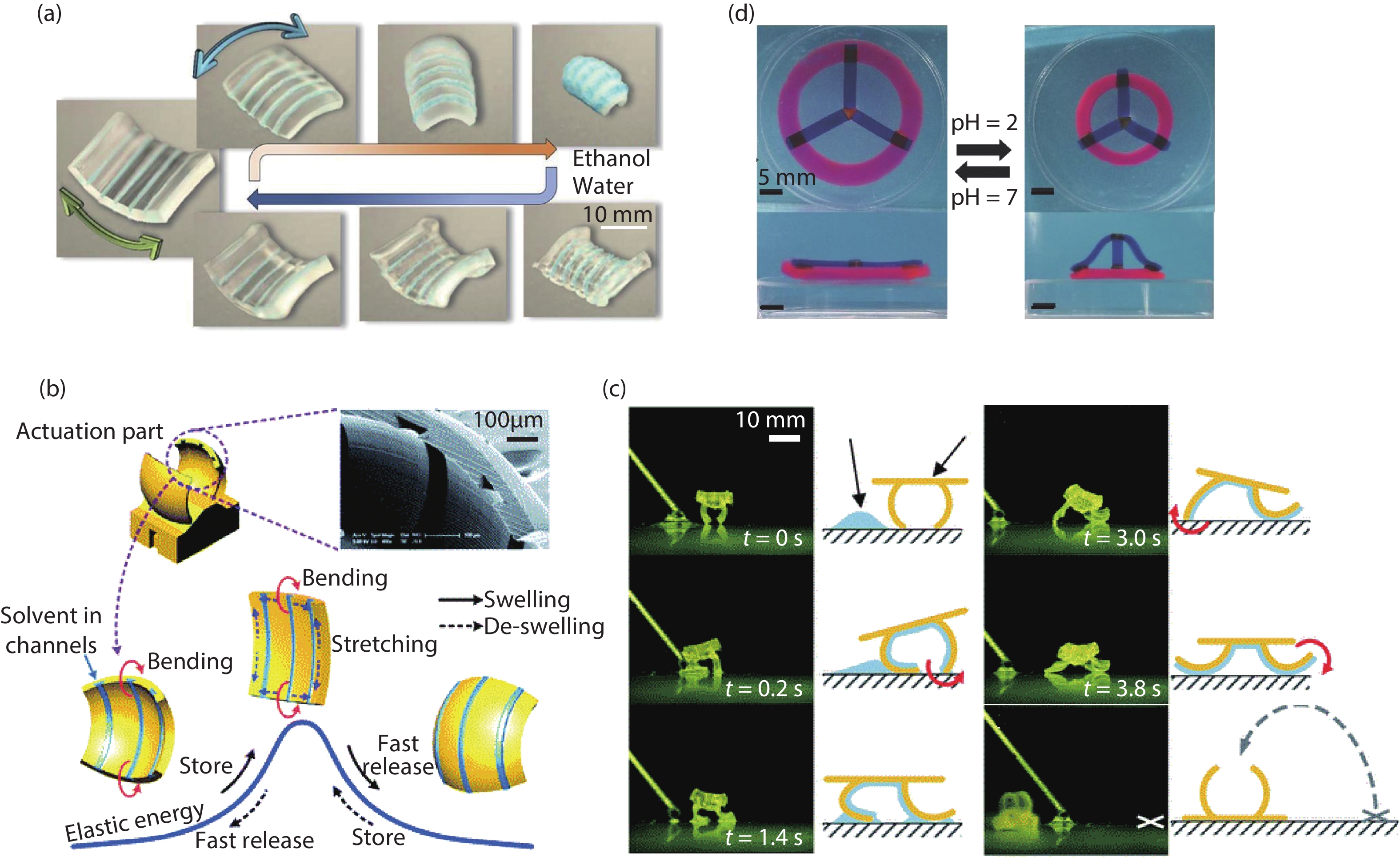

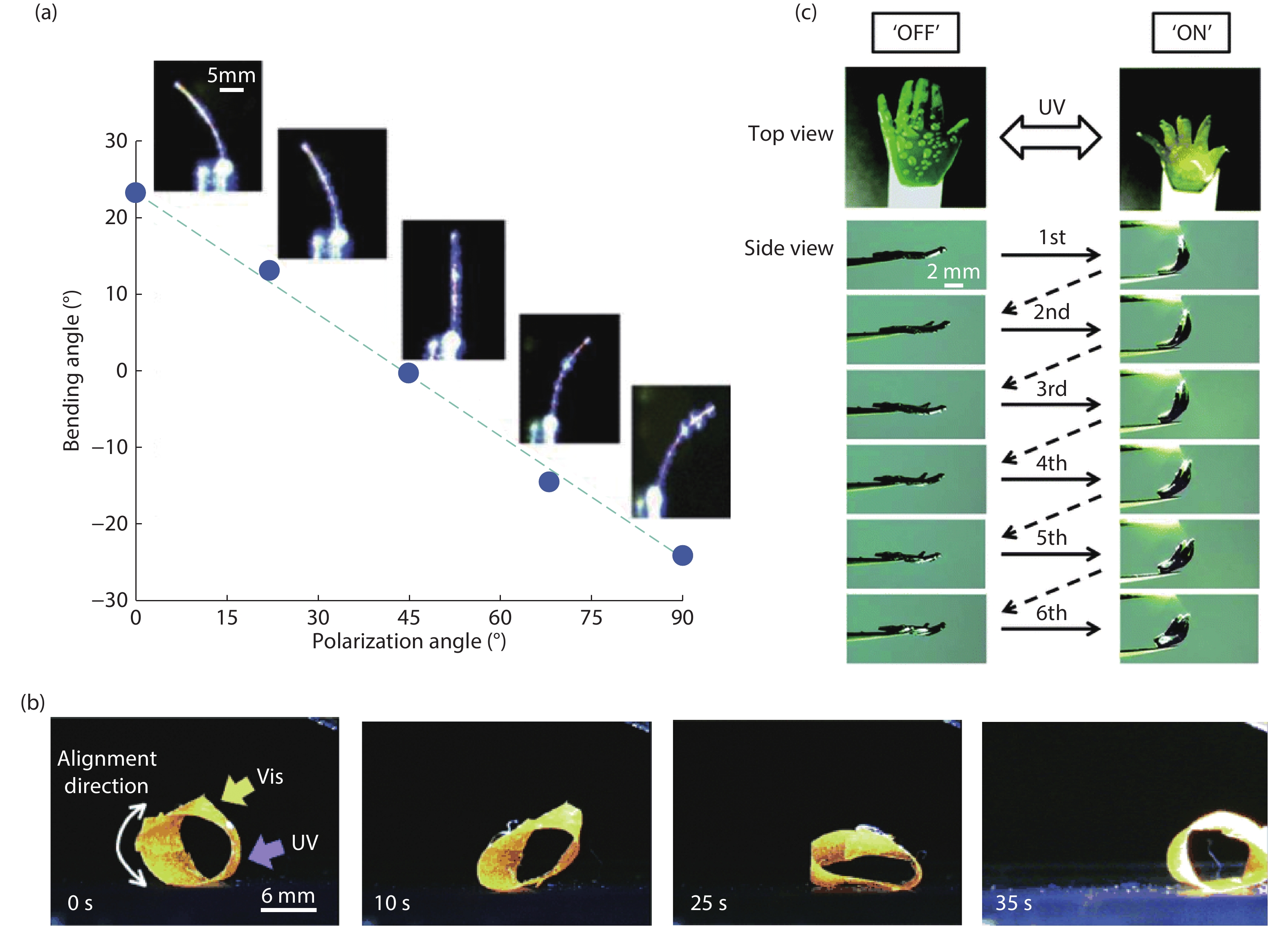

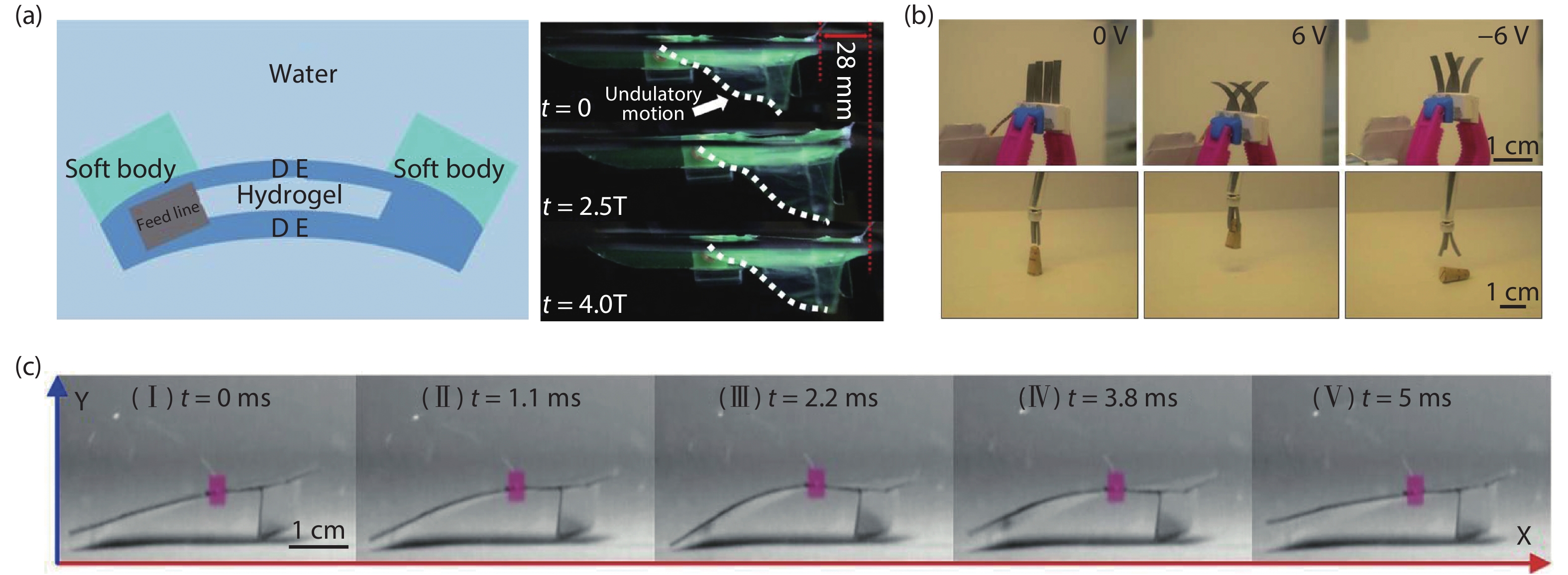

Soft robots complement the existing efforts of miniaturizing conventional, rigid robots, and have the potential to revolutionize areas such as military equipment and biomedical devices. This type of system can accomplish tasks in complex and time-varying environments through geometric reconfiguration induced by diverse external stimuli, such as heat, solvent, light, electric field, magnetic field, and mechanical field. Approaches to achieve reconfigurable mesostructures are essential to the design and fabrication of soft robots. Existing studies mainly focus on four key aspects: reconfiguration mechanisms, fabrication schemes, deformation control principles, and practical applications. This review presents a detailed survey of methodologies for morphable mesostructures triggered by a wide range of stimuli, with a number of impressive examples, demonstrating high degrees of deformation complexities and varied multi-functionalities. The latest progress based on the development of new materials and unique design concepts is highlighted. An outlook on the remaining challenges and open opportunities is provided.-

Keywords:

- morphable mesostructures,

- reconfiguration,

- stimuli

-

References

[1] Hines L, Petersen K, Lum G Z, et al. Soft actuators for small-scale robotics. Adv Mater, 2017, 29(13), 1603483 doi: 10.1002/adma.201603483[2] Kotikian A, McMahan C, Davidson E C, et al. Untethered soft robotic matter with passive control of shape morphing and propulsion. Sci Robot, 2019, 4(33), eaax7044 doi: 10.1126/scirobotics.aax7044[3] Anderson I A, Gisby T A, McKay T G, et al. Multi-functional dielectric elastomer artificial muscles for soft and smart machines. J Appl Phys, 2012, 112(4), 041101 doi: 10.1063/1.4740023[4] Cheng X, Zhang Y. Micro/nanoscale 3D assembly by rolling, folding, curving, and buckling approaches. Adv Mater, 2019, 31, 1901895 doi: 10.1002/adma.201901895[5] Zhao H, Li K, Han M, et al. Buckling and twisting of advanced materials into morphable 3D mesostructures. Proc Natl Academ Sci United States Am, 2019, 116(27), 13239 doi: 10.1073/pnas.1901193116[6] Lum G Z, Ye Z, Dong X, et al. Shape-programmable magnetic soft matter. Proceedings of the National Academy of Sciences of the United States of America, 2016, 113(41), E6007 doi: 10.1073/pnas.1608193113[7] Lendlein A, Gould O E C. Reprogrammable recovery and actuation behaviour of shape-memory polymers. Nat Rev Mater, 2019, 4(2), 116 doi: 10.1038/s41578-018-0078-8[8] Liu Y, Genzer J, Dickey M D. "2D or not 2D": Shape-programming polymer sheets. Prog Polym Sci, 2016, 52, 79 doi: 10.1016/j.progpolymsci.2015.09.001[9] Xu B, Zhang B, Wang L, et al. Tubular micro/nanomachines: from the basics to recent advances. Adv Funct Mater, 2018, 28(25), 1705872 doi: 10.1002/adfm.201705872[10] Li J, Liu T, Xia S, et al. A versatile approach to achieve quintuple-shape memory effect by semi-interpenetrating polymer networks containing broadened glass transition and crystalline segments. J Mater Chem, 2011, 21(33), 12213 doi: 10.1039/c1jm12496j[11] Hager M D, Bode S, Weber C, et al. Shape memory polymers: past, present and future developments. Prog Polym Sci, 2015, 49/50, 3 doi: 10.1016/j.progpolymsci.2015.04.002[12] Xie T. Tunable polymer multi-shape memory effect. Nature, 2010, 464(7286), 267 doi: 10.1038/nature08863[13] Behl M, Kratz K, Noechel U, et al. Temperature-memory polymer actuators. Proceedings of the National Academy of Sciences of the United States of America, 2013, 110(31), 12555 doi: 10.1073/pnas.1301895110[14] Wang Y, Villada A, Zhai Y, et al. Tunable surface wrinkling on shape memory polymers with application in smart micromirror. Appl Phys Lett, 2019, 114(19), 193701 doi: 10.1063/1.5096767[15] Wang Y, Zhai Y, Villada A, et al. Programmable localized wrinkling of thin films on shape memory polymers with application in nonuniform optical gratings. Appl Phys Lett, 2018, 112(25), 251603 doi: 10.1063/1.5037120[16] Noh M, Kim S W, An S, et al. Flea-inspired catapult mechanism for miniature jumping robots. IEEE Trans Robot, 2012, 28(5), 1007 doi: 10.1109/TRO.2012.2198510[17] Fu Y Q, Du H J, Huang W M, et al. TiNi-based thin films in MEMS applications: a review. Sens Actuators A, 2004, 112(2/3), 395 doi: 10.1016/j.sna.2004.02.019[18] Fu Y Q, Luo J K, Flewitt A J, et al. Microactuators of free-standing TiNiCu films. Smart Mater Struct, 2007, 16(6), 2651 doi: 10.1088/0964-1726/16/6/070[19] Liu K, Cheng C, Suh J, et al. Powerful, multifunctional torsional micromuscles activated by phase transition. Adv Mater, 2014, 26(11), 1746 doi: 10.1002/adma.201304064[20] Wang T, Torres D, Fernandez F E, et al. Maximizing the performance of photothermal actuators by combining smart materials with supplementary advantages. Sci Adv, 2017, 3(4), e1602697 doi: 10.1126/sciadv.1602697[21] Rúa A, Fernández F E, Sepúlveda N. Bending in VO2-coated microcantilevers suitable for thermally activated actuators. J Appl Phys, 2010, 107(7), 074506 doi: 10.1063/1.3369282[22] Ware T H, McConney M E, Wie J J, et al. Voxelated liquid crystal elastomers. Science, 2015, 347(6225), 982 doi: 10.1126/science.1261019[23] de Haan L T, Gimenez-Pinto V, Konya A, et al. Accordion-like actuators of multiple 3D patterned liquid crystal polymer films. Adv Funct Mater, 2014, 24(9), 1251 doi: 10.1002/adfm.201302568[24] Yang Y, Pei Z, Li Z, et al. Making and remaking dynamic 3D structures by shining light on flat liquid crystalline vitrimer films without a mold. J Am Chem Soc, 2016, 138(7), 2118 doi: 10.1021/jacs.5b12531[25] Ahn C, Liang X, Cai S. Inhomogeneous stretch induced patterning of molecular orientation in liquid crystal elastomers. Extrem Mechan Lett, 2015, 5, 30 doi: 10.1016/j.eml.2015.09.007[26] Pei Z, Yang Y, Chen Q, et al. Mouldable liquid-crystalline elastomer actuators with exchangeable covalent bonds. Nat Mater, 2014, 13(1), 36 doi: 10.1038/nmat3812[27] Bormashenko E, Bormashenko Y, Pogreb R, et al. Janus droplets: liquid marbles coated with dielectric/semiconductor particles. Langmuir, 2011, 27(1), 7 doi: 10.1021/la103653p[28] Lemanowicz M, Gierczycki A, Kuznik W, et al. Determination of lower critical solution temperature of thermosensitive flocculants. Miner Eng, 2014, 69, 170 doi: 10.1016/j.mineng.2014.07.022[29] Stoychev G, Turcaud S, Dunlop J W C, et al. Hierarchical multi-step folding of polymer bilayers. Adv Funct Mater, 2013, 23(18), 2295 doi: 10.1002/adfm.201203245[30] Stroganov V, Al-Hussein M, Sommer J U, et al. Reversible thermosensitive biodegradable polymeric actuators based on confined crystallization. Nano Lett, 2015, 15(3), 1786 doi: 10.1021/nl5045023[31] Wang E, Desai M S, Lee S W. Light-controlled graphene-elastin composite hydrogel actuators. Nano Lett, 2013, 13(6), 2826 doi: 10.1021/nl401088b[32] Jin B, Song H, Jiang R, et al. Programming a crystalline shape memory polymer network with thermo- and photo-reversible bonds toward a single-component soft robot. Sci Adv, 2018, 4(1), eaao3865 doi: 10.1126/sciadv.aao3865[33] Wall S, Wegkamp D, Foglia L, et al. Ultrafast changes in lattice symmetry probed by coherent phonons. Nat Commun, 2012, 3, 721 doi: 10.1038/ncomms1719[34] Cao J, Ertekin E, Srinivasan V, et al. Strain engineering and one-dimensional organization of metal-insulator domains in single-crystal vanadium dioxide beams. Nat Nanotechnol, 2009, 4(11), 732 doi: 10.1038/nnano.2009.266[35] Fusco S, Sakar M S, Kennedy S, et al. An integrated microrobotic platform for on-demand, targeted therapeutic interventions. Adv Mater, 2014, 26(6), 952 doi: 10.1002/adma.201304098[36] Miyashita S, Meeker L, Tolley M T, et al. Self-folding miniature elastic electric devices. Smart Mater Struct, 2014, 23(9), 094005 doi: 10.1088/0964-1726/23/9/094005[37] Stoychev G, Puretskiy N, Ionov L. Self-folding all-polymer thermoresponsive microcapsules. Soft Matter, 2011, 7(7), 3277 doi: 10.1039/c1sm05109a[38] Yoon C, Xiao R, Park J, et al. Functional stimuli responsive hydrogel devices by self-folding. Smart Mater Struct, 2014, 23(9), 094008 doi: 10.1088/0964-1726/23/9/094008[39] Verduzco R. Shape-shifting liquid crystals. Science, 2015, 347(6225), 949 doi: 10.1126/science.aaa6579[40] Palagi S, Mark A G, Reigh S Y, et al. Structured light enables biomimetic swimming and versatile locomotion of photoresponsive soft microrobots. Nat Mater, 2016, 15(6), 647 doi: 10.1038/nmat4569[41] Cui Y, Wang C, Sim K, et al. A simple analytical thermo-mechanical model for liquid crystal elastomer bilayer structures. AIP Adv, 2018, 8(2), 025215 doi: 10.1063/1.5013205[42] Wang C, Sim K, Chen J, et al. Soft ultrathin electronics innervated adaptive fully soft robots. Adv Mater, 2018, 30(13), 1706695 doi: 10.1002/adma.201706695[43] He Q, Wang Z, Wang Y, et al. Electrically controlled liquid crystal elastomer-based soft tubular actuator with multimodal actuation. Sci Adv, 2019, 5(10), eaax5746 doi: 10.1126/sciadv.aax5746[44] Kim S, Hawkes E, Cho K, et al. Micro artificial muscle fiber using NiTi spring for soft robotics. 2009 IEEE/RSJ International Conference on Intelligent Robots and Systems, 2009, 2228[45] Ali M S M, Takahata K. Frequency-controlled wireless shape-memory-alloy microactuators integrated using an electroplating bonding process. Sens Actuators A, 2010, 163(1), 363 doi: 10.1016/j.sna.2010.08.007[46] Colorado J, Barrientos A, Rossi C, et al. Biomechanics of smart wings in a bat robot: morphing wings using SMA actuators. Bioinspir Biomimet, 2012, 7(3), 036006 doi: 10.1088/1748-3182/7/3/036006[47] Furst S J, Bunget G, Seelecke S. Design and fabrication of a bat-inspired flapping-flight platform using shape memory alloy muscles and joints. Smart Mater Struct, 2012, 22(1), 014011 doi: 10.1088/0964-1726/22/1/014011[48] Liu K, Cheng C, Cheng Z, et al. Giant-amplitude, high-work density microactuators with phase transition activated nanolayer bimorphs. Nano Lett, 2012, 12(12), 6302 doi: 10.1021/nl303405g[49] Wang K, Cheng C, Cardona E, et al. Performance limits of microactuation with vanadium dioxide as a solid engine. ACS Nano, 2013, 7(3), 2266 doi: 10.1021/nn305419e[50] Tian Z, Huang W, Xu B, et al. Anisotropic rolling and controlled chirality of nanocrystalline diamond nanomembranes toward biomimetic helical frameworks. Nano Lett, 2018, 18(6), 3688 doi: 10.1021/acs.nanolett.8b00828[51] Zhao Q, Dunlop J W C, Qiu X, et al. An instant multi-responsive porous polymer actuator driven by solvent molecule sorption. Nat Commun, 2014, 5, 4293 doi: 10.1038/ncomms5293[52] Xiao R, Guo J, Safranski D L, et al. Solvent-driven temperature memory and multiple shape memory effects. Soft Matter, 2015, 11(20), 3977 doi: 10.1039/C5SM00543D[53] Huang W M, Yang B, An L, et al. Water-driven programmable polyurethane shape memory polymer: Demonstration and mechanism. Appl Phys Lett, 2005, 86(11), 114105 doi: 10.1063/1.1880448[54] Ma M, Guo L, Anderson D G, et al. Bio-inspired polymer composite actuator and generator driven by water gradients. Science, 2013, 339(6116), 186 doi: 10.1126/science.1230262[55] Chen X, Goodnight D, Gao Z, et al. Scaling up nanoscale water-driven energy conversion into evaporation-driven engines and generators. Nat Commun, 2015, 6, 7346 doi: 10.1038/ncomms8346[56] Lee B P, Konst S. Novel hydrogel actuator inspired by reversible mussel adhesive protein chemistry. Adv Mater, 2014, 26(21), 3415 doi: 10.1002/adma.201306137[57] Jamal M, Zarafshar A M, Gracias D H. Differentially photo-crosslinked polymers enable self-assembling microfluidics. Nat Commun, 2011, 2, 527 doi: 10.1038/ncomms1531[58] Kim J, Hanna J A, Byun M, et al. Designing responsive buckled surfaces by halftone gel lithography. Science, 2012, 335(6073), 1201 doi: 10.1126/science.1215309[59] Gladman A S, Matsumoto E A, Nuzzo R G, et al. Biomimetic 4D printing. Nat Mater, 2016, 15(4), 413 doi: 10.1038/nmat4544[60] Palleau E, Morales D, Dickey M D, et al. Reversible patterning and actuation of hydrogels by electrically assisted ionoprinting. Nat Commun, 2013, 4, 2257 doi: 10.1038/ncomms3257[61] Lee H, Xia C, Fang N X. First jump of microgel; actuation speed enhancement by elastic instability. Soft Matter, 2010, 6(18), 4342 doi: 10.1039/c0sm00092b[62] Zhang H, Guo X, Wu J, et al. Soft mechanical metamaterials with unusual swelling behavior and tunable stress-strain curves. Sci Adv, 2018, 4(6), eaar8535 doi: 10.1126/sciadv.aar8535[63] Ollagnier A, Fabre A, Thundat T, et al. Activation process of reversible Pd thin film hydrogen sensors. Sens Actuators B, 2013, 186, 258 doi: 10.1016/j.snb.2013.05.041[64] Xu B, Zhang X, Tian Z, et al. Microdroplet-guided intercalation and deterministic delamination towards intelligent rolling origami. Nat Commun, 2019, 10(1), 5019 doi: 10.1038/s41467-019-13011-w[65] Xu B, Tian Z, Wang J, et al. Stimuli-responsive and on-chip nanomembrane micro-rolls for enhanced macroscopic visual hydrogen detection. Sci Adv, 2018, 4(4), eaap8203 doi: 10.1126/sciadv.aap8203[66] Gestos A, Whitten P G, Wallace G G, et al. Actuating individual electrospun hydrogel nanofibres. Soft Matter, 2012, 8(31), 8082 doi: 10.1039/c2sm25387a[67] Techawanitchai P, Ebara M, Idota N, et al. Photo-switchable control of pH-responsive actuators via pH jump reaction. Soft Matter, 2012, 8(10), 2844 doi: 10.1039/c2sm07277g[68] Ma C, Li T, Zhao Q, et al. Supramolecular Lego assembly towards three-dimensional multi-responsive hydrogels. Adv Mater, 2014, 26(32), 5665 doi: 10.1002/adma.201402026[69] Dong L, Agarwal A K, Beebe D J, et al. Adaptive liquid microlenses activated by stimuli-responsive hydrogels. Nature, 2006, 442(7102), 551 doi: 10.1038/nature05024[70] Yu Y, Ikeda T. Soft actuators based on liquid-crystalline elastomers. Angew Chem Int Ed, 2006, 45(33), 5416 doi: 10.1002/anie.200601760[71] Yu M F, Files B S, Arepalli S, et al. Tensile loading of ropes of single wall carbon nanotubes and their mechanical properties. Phys Rev Lett, 2000, 84(24), 5552 doi: 10.1103/PhysRevLett.84.5552[72] Wei J, Yu Y. Photodeformable polymer gels and crosslinked liquid-crystalline polymers. Soft Matter, 2012, 8(31), 8050 doi: 10.1039/c2sm25474c[73] White T J, Tabiryan N V, Serak S V, et al. A high frequency photodriven polymer oscillator. Soft Matter, 2008, 4(9), 1796 doi: 10.1039/b805434g[74] Zeng H, Wasylczyk P, Parmeggiani C, et al. Light-fueled microscopic walkers. Adv Mater, 2015, 27(26), 3883 doi: 10.1002/adma.201501446[75] Tang X, Tang S Y, Sivan V, et al. Photochemically induced motion of liquid metal marbles. Appl Phys Lett, 2013, 103(17), 174104 doi: 10.1063/1.4826923[76] Lendlein A, Jiang H Y, Junger O, et al. Light-induced shape-memory polymers. Nature, 2005, 434(7035), 879 doi: 10.1038/nature03496[77] Jiang H Y, Kelch S, Lendlein A. Polymers move in response to light. Adv Mater, 2006, 18(11), 1471 doi: 10.1002/adma.200502266[78] Yu Y L, Nakano M, Ikeda T. Directed bending of a polymer film by light . Nature, 2003, 425(6954), 145 doi: 10.1038/425145a[79] Natansohn A, Rochon P. Photoinduced motions in azo-containing polymers. Chem Rev, 2002, 102(11), 4139 doi: 10.1021/cr970155y[80] Lee K M, Koerner H, Vaia R A, et al. Light-activated shape memory of glassy, azobenzene liquid crystalline polymer networks. Soft Matter, 2011, 7(9), 4318 doi: 10.1039/c1sm00004g[81] Huang C, Lv J A, Tian X, et al. Miniaturized swimming soft robot with complex movement actuated and controlled by remote light signals. Sci Rep, 2015, 5, 17414 doi: 10.1038/srep17414[82] Yamada M, Kondo M, Mamiya J, et al. Photomobile polymer materials: towards light-driven plastic motors. Angew Chem, 2008, 47(27), 4986 doi: 10.1002/anie.200800760[83] Boncheva M, Andreev S A, Mahadevan L, et al. Magnetic self-assembly of three-dimensional surfaces from planar sheets. Proc Natl Academ Sci United States of Am, 2005, 102(11), 3924 doi: 10.1073/pnas.0500807102[84] Solovev A A, Sanchez S, Pumera M, et al. Nanomotors: magnetic control of tubular catalytic microbots for the transport, assembly, and delivery of micro-objects. Adv Funct Mater, 2010, 20(15), 2430 doi: 10.1002/adfm.200902376[85] Fusco S, Huang H W, Peyer K E, et al. Shape-switching microrobots for medical applications: the influence of shape in drug delivery and locomotion. Acs Appl Mater Interfaces, 2015, 7(12), 6803 doi: 10.1021/acsami.5b00181[86] Tasoglu S, Diller E, Guven S, et al. Untethered micro-robotic coding of three-dimensional material composition. Nat Commun, 2014, 5, 3124 doi: 10.1038/ncomms4124[87] Diller E, Giltinan J, Lum G Z, et al. Six-degree-of-freedom magnetic actuation for wireless microrobotics. Int J Robot Res, 2016, 35(1–3), 114 doi: 10.1177/0278364915583539[88] Diller E, Zhuang J, Lum G Z, et al. Continuously distributed magnetization profile for millimeter-scale elastomeric undulatory swimming. Appl Phys Lett, 2014, 104(17), 174101 doi: 10.1063/1.4874306[89] Jang B, Gutman E, Stucki N, et al. Undulatory locomotion of magnetic multilink nanoswimmers. Nano Lett, 2015, 15(7), 4829 doi: 10.1021/acs.nanolett.5b01981[90] Timonen J V I, Latikka M, Leibler L, et al. Switchable static and dynamic self-assembly of magnetic droplets on superhydrophobic surfaces. Science, 2013, 341(6143), 253 doi: 10.1126/science.1233775[91] Jamin T, Py C, Falcon E. Instability of the origami of a ferrofluid drop in a magnetic field. Phys Rev Lett, 2011, 107(20), 204503 doi: 10.1103/PhysRevLett.107.204503[92] Hu W, Lum G Z, Mastrangeli M, et al. Small-scale soft-bodied robot with multimodal locomotion. Nature, 2018, 554(7690), 81 doi: 10.1038/nature25443[93] Garstecki P, Tierno P, Weibel D B, et al. Propulsion of flexible polymer structures in a rotating magnetic field. J Phys Conden Matter, 2009, 21(20), 204110 doi: 10.1088/0953-8984/21/20/204110[94] Kim J, Chung S E, Choi S E, et al. Programming magnetic anisotropy in polymeric microactuators. Nat Mater, 2011, 10(10), 747 doi: 10.1038/nmat3090[95] Kim Y, Yuk H, Zhao R, et al. Printing ferromagnetic domains for untethered fast-transforming soft materials. Nature, 2018, 558(7709), 274 doi: 10.1038/s41586-018-0185-0[96] Kim Y, Parada G A, Liu S, et al. Ferromagnetic soft continuum robots. Sci Robot, 2019, 4(33), eaax7329 doi: 10.1126/scirobotics.aax7329[97] Qiu T, Lee T C, Mark A G, et al. Swimming by reciprocal motion at low Reynolds number. Nat Commun, 2014, 5, 5119 doi: 10.1038/ncomms6119[98] Yim S, Sitti M. Design and rolling locomotion of a magnetically actuated soft capsule endoscope. IEEE Trans Robot, 2012, 28(1), 183 doi: 10.1109/TRO.2011.2163861[99] Yim S, Sitti M. Shape-programmable soft capsule robots for semi-implantable drug delivery. IEEE Trans Robot, 2012, 28(5), 1198 doi: 10.1109/TRO.2012.2197309[100] Brochu P, Pei Q. Advances in dielectric elastomers for actuators and artificial muscles. Macromolecul Rapid Commun, 2010, 31(1), 10 doi: 10.1002/marc.200900425[101] Park I S, Jung K, Kim D, et al. Physical principles of ionic polymer-metal composites as electroactive actuators and sensors. MRS Bull, 2008, 33(3), 190 doi: 10.1557/mrs2008.44[102] Miehe C, Rosato D. A rate-dependent incremental variational formulation of ferroelectricity. Int J Eng Sci, 2011, 49(6), 466 doi: 10.1016/j.ijengsci.2010.11.003[103] Mirfakhrai T, Oh J, Kozlov M, et al. Electrochemical actuation of carbon nanotube yarns. Smart Mater Struct, 2007, 16(2), S243 doi: 10.1088/0964-1726/16/2/S07[104] Foroughi J, Spinks G M, Wallace G G, et al. Torsional carbon nanotube artificial muscles. Science, 2011, 334(6055), 494 doi: 10.1126/science.1211220[105] Must I, Kaasik F, Põldsalu I, et al. Ionic and capacitive artificial muscle for biomimetic soft robotics. Adv Eng Mater, 2015, 17(1), 84 doi: 10.1002/adem.201400246[106] Palmre V, Pugal D, Kim K J, et al. Nanothorn electrodes for ionic polymer-metal composite artificial muscles. Sci Rep, 2014, 4, 6176 doi: https://doi.org/10.1038/srep06176[107] Shian S, Clarke D R. Electrically-tunable surface deformation of a soft elastomer. Soft Matter, 2016, 12(13), 3137 doi: 10.1039/C6SM00090H[108] Shintake J, Rosset S, Schubert B, et al. Versatile soft grippers with intrinsic electroadhesion based on multifunctional polymer actuators. Adv Mater, 2016, 28(2), 231 doi: 10.1002/adma.201504264[109] Kofod G, Wirges W, Paajanen M, et al. Energy minimization for self-organized structure formation and actuation. Appl Phys Lett, 2007, 90(8), 081916 doi: 10.1063/1.2695785[110] Li T, Li G, Liang Y, et al. Fast-moving soft electronic fish. Sci Adv, 2017, 3(4), e1602045 doi: 10.1126/sciadv.1602045[111] Chu W S, Lee K T, Song S H, et al. Review of biomimetic underwater robots using smart actuators. Int J Prec Eng Manufact, 2012, 13(7), 1281 doi: 10.1007/s12541-012-0171-7[112] Aureli M, Kopman V, Porfiri M. Free-locomotion of underwater vehicles actuated by ionic polymer metal composites. IEEE/ASME Trans Mechatron, 2010, 15(4), 603 doi: 10.1109/TMECH.2009.2030887[113] Barramba J, Silva J, Branco P J C. Evaluation of dielectric gel coating for encapsulation of ionic polymer-metal composite (IPMC) actuators. Sens Actuators A, 2007, 140(2), 232 doi: 10.1016/j.sna.2007.06.035[114] Must I, Kaasik T, Baranova I, et al. A power-autonomous self-rolling wheel using ionic and capacitive actuators. Proc SPIE, 2015, 9430, 94300Q doi: 10.1117/12.2084252[115] Mohammadi B, Yousefi A A, Bellah S M. Effect of tensile strain rate and elongation on crystalline structure and piezoelectric properties of PVDF thin films. Polymer Testing, 2007, 26(1), 42 doi: 10.1016/j.polymertesting.2006.08.003[116] Smith G L, Pulskamp J S, Sanchez L M, et al. PZT-based piezoelectric MEMS technology. J Am Ceram Soc, 2012, 95(6), 1777 doi: 10.1111/j.1551-2916.2012.05155.x[117] Fuller S B, Karpelson M, Censi A, et al. Controlling free flight of a robotic fly using an onboard vision sensor inspired by insect ocelli. J Royal Soc Interface, 2014, 11(97), 20140281 doi: 10.1098/rsif.2014.0281[118] Wu Y, Yim J K, Liang J, et al. Insect-scale fast moving and ultrarobust soft robot. Sci Robot, 2019, 4(32), eaax1594 doi: 10.1126/scirobotics.aax1594[119] Ma K Y, Chirarattananon P, Fuller S B, et al. Controlled flight of a biologically inspired, insect-scale robot. Science, 2013, 340(6132), 603 doi: 10.1126/science.1231806[120] Chen Y, Doshi N, Goldberg B, et al. Controllable water surface to underwater transition through electrowetting in a hybrid terrestrial-aquatic microrobot. Nat Commun, 2018, 9(1), 2495 doi: 10.1038/s41467-018-04855-9[121] Jafferis N T, Helbling E F, Karpelson M, et al. Untethered flight of an insect-sized flapping-wing microscale aerial vehicle. Nature, 2019, 570(7762), 491 doi: 10.1038/s41586-019-1322-0[122] Xu S, Yan Z, Jang K I, et al. Assembly of micro/nanomaterials into complex, three-dimensional architectures by compressive buckling. Science, 2015, 347(6218), 154 doi: 10.1126/science.1260960[123] Zhang Y, Yan Z, Nan K, et al. A mechanically driven form of Kirigami as a route to 3D mesostructures in micro/nanomembranes. Proceedings of the National Academy of Sciences of the United States of America, 2015, 112(38), 11757 doi: 10.1073/pnas.1515602112[124] Liu Y, Yan Z, Lin Q, et al. Guided formation of 3D helical mesostructures by mechanical buckling: analytical modeling and experimental validation. Adv Funct Mater, 2016, 26(17), 2909 doi: 10.1002/adfm.201505132[125] Yan Z, Zhang F, Liu F, et al. Mechanical assembly of complex, 3D mesostructures from releasable multilayers of advanced materials. Sci Adv, 2016, 2(9), e1601014 doi: 10.1126/sciadv.1601014[126] Fan Z, Hwang K C, Rogers J A, et al. A double perturbation method of postbuckling analysis in 2D curved beams for assembly of 3D ribbon-shaped structures. J Mechan Phys Solids, 2018, 111, 215 doi: 10.1016/j.jmps.2017.10.012[127] Song J. Mechanics of stretchable electronics. Curr Opin Solid State Mater Sci, 2015, 19(3), 160 doi: 10.1016/j.cossms.2015.01.004[128] Zhang Y, Zhang F, Yan Z, et al. Printing, folding and assembly methods for forming 3D mesostructures in advanced materials. Nat Rev Mater, 2017, 2(4), 17019 doi: 10.1038/natrevmats.2017.19[129] Guo X, Xu Z, Zhang F, et al. Reprogrammable 3D mesostructures through compressive buckling of thin films with prestrained shape memory polymer. Acta Mechan Solida Sinica, 2018, 31(5), 589 doi: 10.1007/s10338-018-0047-1[130] Jang K I, Li K, Chung H U, et al. Self-assembled three dimensional network designs for soft electronics. Nat Commun, 2017, 8, 15894 doi: 10.1038/ncomms15894[131] Kim B H, Liu F, Yu Y, et al. Mechanically guided post-assembly of 3D electronic systems. Adv Funct Mater, 2018, 28(48), 1803149 doi: 10.1002/adfm.201803149[132] Liu F, Chen Y, Song H, et al. High performance, tunable electrically small antennas through mechanically guided 3D assembly. Small, 2019, 15(1), 1804055 doi: 10.1002/smll.201804055[133] Yan Z, Zhang F, Wang J, et al. Controlled mechanical buckling for origami-inspired construction of 3D microstructures in advanced materials. Adv Funct Mater, 2016, 26(16), 2629 doi: 10.1002/adfm.201504901[134] Ning X, Wang H, Yu X, et al. 3D tunable, multiscale, and multistable vibrational micro-platforms assembled by compressive buckling. Adv Funct Mater, 2017, 27(14), 1605914 doi: 10.1002/adfm.201605914[135] Shi Y, Zhang F, Nan K, et al. Plasticity-induced origami for assembly of three dimensional metallic structures guided by compressive buckling. Extrem Mechan Lett, 2017, 11, 105 doi: 10.1016/j.eml.2016.11.008[136] Yan Z, Han M, Yang Y, et al. Deterministic assembly of 3D mesostructures in Adv Mater via compressive buckling: A short review of recent progress. Extrem Mechan Lett, 2017, 11, 96 doi: 10.1016/j.eml.2016.12.006[137] Fu H, Nan K, Bai W, et al. Morphable 3D mesostructures and microelectronic devices by multistable buckling mechanics. Nat Mater, 2018, 17(3), 268 doi: 10.1038/s41563-017-0011-3[138] Luo G, Fu H, Cheng X, et al. Mechanics of bistable cross-shaped structures through loading-path controlled 3D assembly. J Mechan Phys Solids, 2019, 129, 261 doi: 10.1016/j.jmps.2019.05.007[139] Liu Y, Wang X, Xu Y, et al. Harnessing the interface mechanics of hard films and soft substrates for 3D assembly by controlled buckling. Proc Natl Academ Sci, 2019, 116(31), 15368 doi: 10.1073/pnas.1907732116[140] Jani J M, Leary M, Subic A, et al. A review of shape memory alloy research, applications and opportunities. Mater Des, 2014, 56, 1078 doi: 10.1016/j.matdes.2013.11.084[141] Ma H, Hou J, Wang X, et al. Flexible, all-inorganic actuators based on vanadium dioxide and carbon nanotube bimorphs. Nano Lett, 2017, 17(1), 421 doi: 10.1021/acs.nanolett.6b04393[142] Yu H, Ikeda T. Photocontrollable liquid-crystalline actuators. Adv Mater, 2011, 23(19), 2149 doi: 10.1002/adma.201100131[143] Kwok S W, Morin S A, Mosadegh B, et al. Magnetic assembly of soft robots with hard components. Adv Funct Mater, 2014, 24(15), 2180 doi: 10.1002/adfm.201303047[144] Pelrine R, Kornbluh R, Pei Q, et al. High-speed electrically actuated elastomers with strain greater than 100%. Science, 2000, 287(5454), 836 doi: 10.1126/science.287.5454.836 -

Proportional views

DownLoad:

DownLoad: