| Citation: |

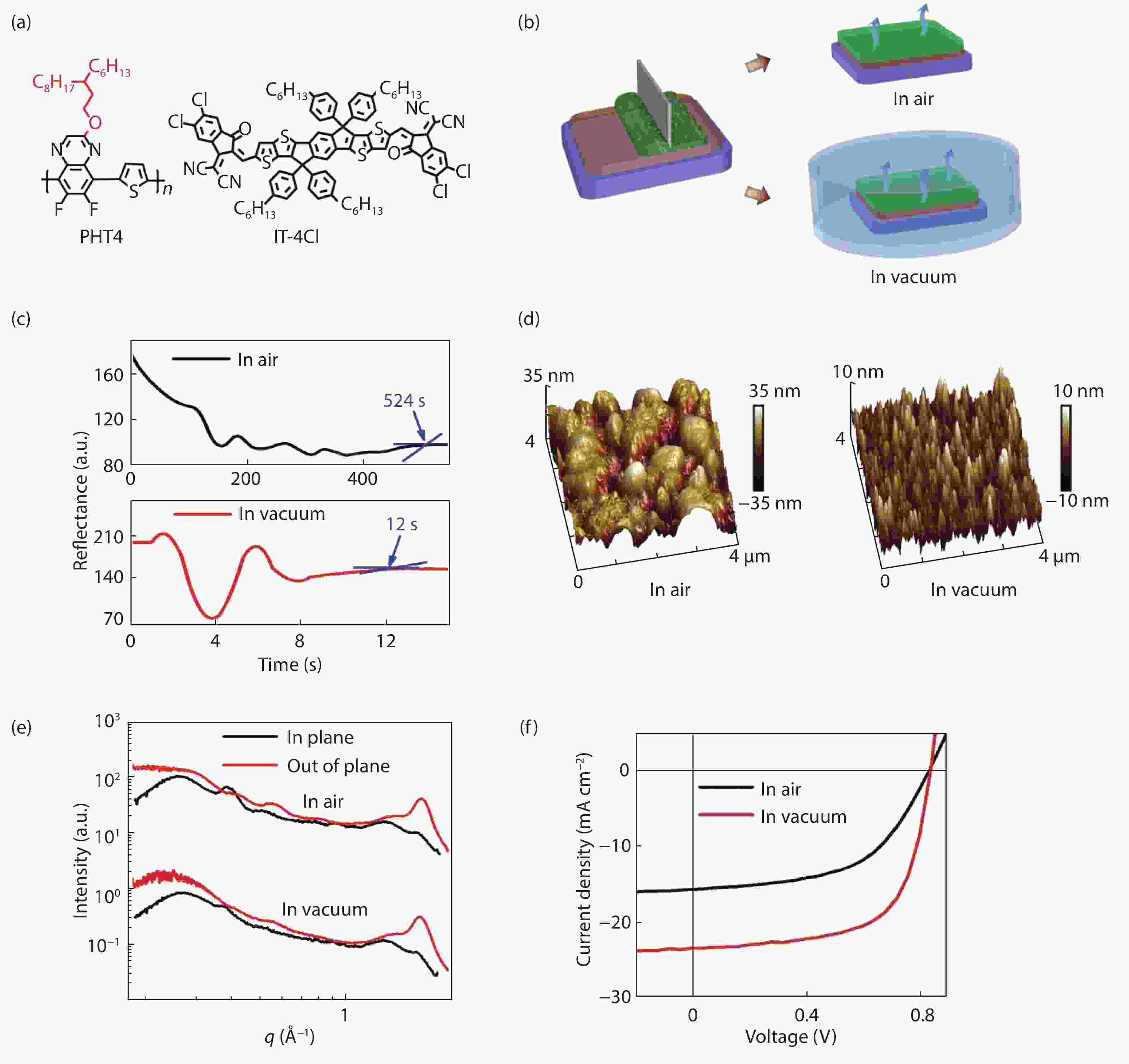

Wei Guan, Dong Yuan, Juntao Wu, Xiaobo Zhou, Hong Zhao, Fei Guo, Lianjie Zhang, Ke Zhou, Wei Ma, Wanzhu Cai, Junwu Chen, Liming Ding, Lintao Hou. Blade-coated organic solar cells from non-halogenated solvent offer 17% efficiency[J]. Journal of Semiconductors, 2021, 42(3): 030502. doi: 10.1088/1674-4926/42/3/030502

W Guan, D Yuan, J T Wu, X B Zhou, H Zhao, F Guo, L J Zhang, K Zhou, W Ma, W Z Cai, J W Chen, L M Ding, L T Hou, Blade-coated organic solar cells from non-halogenated solvent offer 17% efficiency[J]. J. Semicond., 2021, 42(3): 030502. doi: 10.1088/1674-4926/42/3/030502.

Export: BibTex EndNote

|

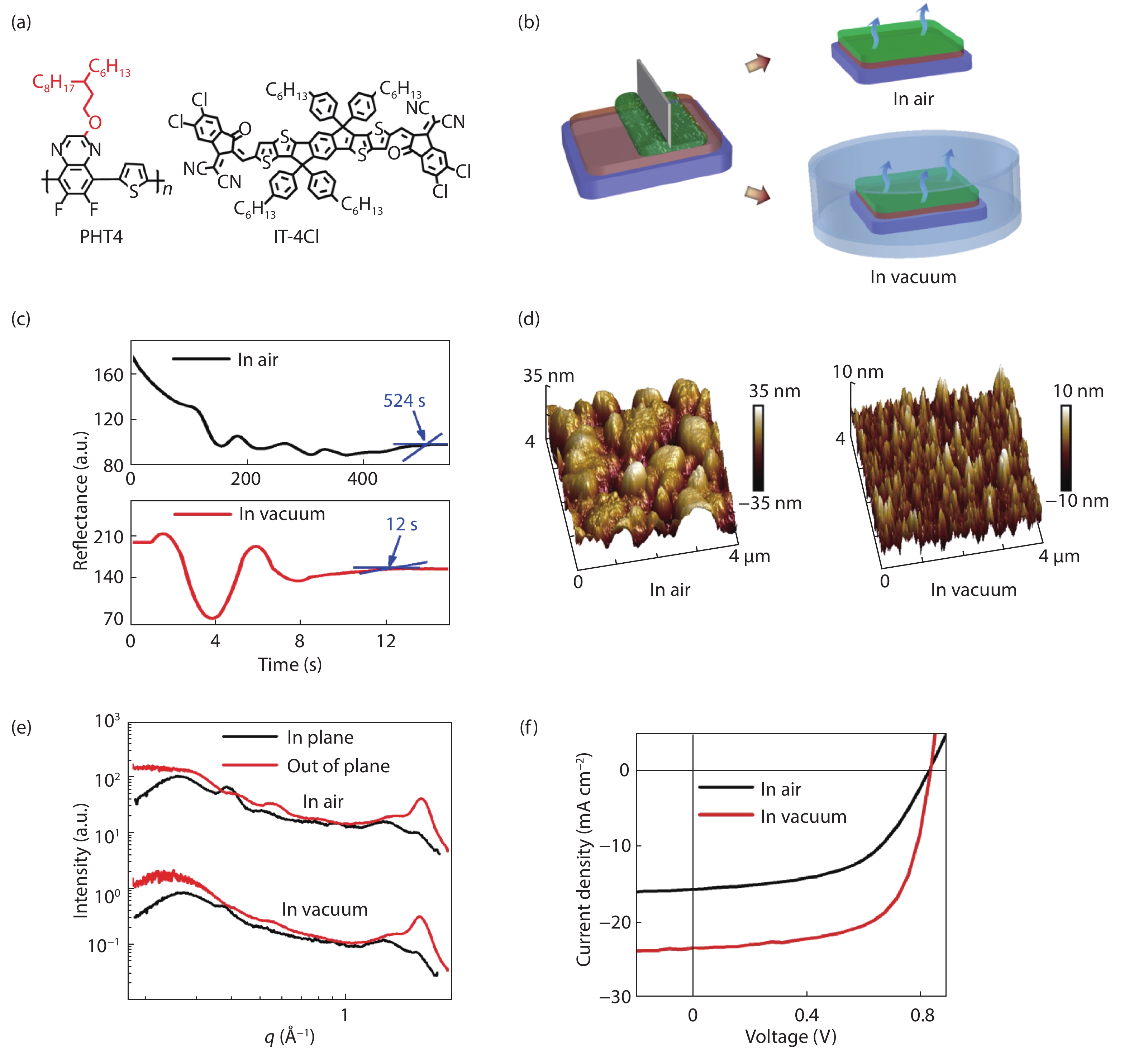

Blade-coated organic solar cells from non-halogenated solvent offer 17% efficiency

doi: 10.1088/1674-4926/42/3/030502

More Information-

References

[1] Duan C, Ding L. The new era for organic solar cells: non-fullerene small molecular acceptors. Sci Bull, 2020, 65, 1231 doi: 10.1016/j.scib.2020.04.030[2] Li W, Chen M, Cai J, et al. Molecular order control of non-fullerene acceptors for high-efficiency polymer solar cells. Joule, 2019, 3, 819 doi: 10.1016/j.joule.2018.11.023[3] Tong Y, Xiao Z, Du X, et al. Progress of the key materials for organic solar cells. Sci China Chem, 2020, 63, 758 doi: 10.1007/s11426-020-9726-0[4] Meng L, Zhang Y, Wan X, et al. Organic and solution-processed tandem solar cells with 17.3% efficiency. Science, 2018, 361, 1094 doi: 10.1126/science.aat2612[5] Li H, Xiao Z, Ding L, et al. Thermostable single-junction organic solar cells with a power conversion efficiency of 14.62%. Sci Bull, 2018, 63, 340 doi: 10.1016/j.scib.2018.02.015[6] An Q, Ma X, Gao J, et al. Solvent additive-free ternary polymer solar cells with 16.27% efficiency. Sci Bull, 2019, 64, 504 doi: 10.1016/j.scib.2019.03.024[7] Duan C, Ding L. The new era for organic solar cells: polymer acceptors. Sci Bull, 2020, 65, 1508 doi: 10.1016/j.scib.2020.05.023[8] Duan C, Ding L. The new era for organic solar cells: small molecular donors. Sci Bull, 2020, 65, 1597 doi: 10.1016/j.scib.2020.05.019[9] Zhang Y, Duan C, Ding L. Indoor organic photovoltaics. Sci Bull, 2020, 65, 2040 doi: 10.1016/j.scib.2020.08.030[10] Liu Q, Jiang Y, Jin K, et al. 18% efficiency organic solar cells. Sci Bull, 2020, 65, 272 doi: 10.1016/j.scib.2020.01.001[11] Jin K, Zuo X, Ding L. D18, an eximious solar polymer. J Semicond, 2021, 42, 010502 doi: 10.1088/1674-4926/42/1/010502[12] Qin J, Zhang L, Zuo C, et al. A chlorinated copolymer donor demonstrates a 18.13% power conversion efficiency. J Semicond, 2021, 42, 010501 doi: 10.1088/1674-4926/42/1/010501[13] Qin J, Zhang L, Xiao Z, et al. Over 16% efficiency from thick-film organic solar cells. Sci Bull, 2020, 65, 1979 doi: 10.1016/j.scib.2020.08.027[14] Lin Y, Cai C, Zhang Y, et al. Study of ITO-free roll-to-roll compatible polymer solar cells using the one-step doctor blading technique. J Mater Chem A, 2017, 5, 4093 doi: 10.1039/C6TA10018J[15] Lin Y, Jin Y, Dong S, et al. Printed nonfullerene organic solar cells with the highest efficiency of 9.5%. Adv Energy Mater, 2018, 8, 1701942 doi: 10.1002/aenm.201701942[16] Liu A, Zheng W, Yin X, et al. Manipulate micrometer surface and nanometer bulk phase separation structures in the active layer of organic solar cells via synergy of ultrasonic and high-pressure gas spraying. ACS Appl Mater Interfaces, 2019, 11, 10777 doi: 10.1021/acsami.8b22215[17] Zhao J, Li Y, Yang G, et al. Efficient organic solar cells processed from hydrocarbon solvents. Nat Energy, 2016, 1, 15027 doi: 10.1038/nenergy.2015.27[18] Liu F, Ferdous S, Schaible E, et al. Fast printing and in situ morphology observation of organic photovoltaics using slot-die coating. Adv Mater, 2015, 27, 886 doi: 10.1002/adma.201404040[19] Zhao W, Zhang Y, Zhang S, et al. Vacuum-assisted annealing method for high efficiency printable large-area polymer solar cell modules. J Mater Chem C, 2019, 7, 3206 doi: 10.1039/C8TC06513F[20] Zhao W, Zhang S, Zhang Y, et al. Environmentally friendly solvent-processed organic solar cells that are highly efficient and adaptable for the blade-coating method. Adv Mater, 2018, 30, 1704837 doi: 10.1002/adma.201704837[21] Ma Z, Zhao B, Gong Y, et al. Green-solvent-processable strategies for achieving large-scale manufacture of organic photovoltaics. J Mater Chem A, 2019, 7, 22826 doi: 10.1039/C9TA09277C[22] Bouzid H, Prosa M, Bolognesi M, et al. Impact of environmentally friendly processing solvents on the properties of blade-coated polymer solar cells. J Polym Sci Part A Polym Chem, 2019, 57, 487 doi: 10.1002/pola.29286[23] Zhang K, Chen Z, Armin A, et al. Efficient large area organic solar cells processed by blade-coating with single-component green solvent. Sol RRL, 2018, 2, 1700169 doi: 10.1002/solr.201700169[24] Pérez-Gutiérrez E, Lozano J, Gaspar-Tánori J, et al. Organic solar cells all made by blade and slot–die coating techniques. Sol Energy, 2017, 146, 79 doi: 10.1016/j.solener.2017.02.004[25] Ye L, Xiong Y, Yao H, et al. High performance organic solar cells processed by blade coating in air from a benign food additive solution. Chem Mater, 2016, 28, 7451 doi: 10.1021/acs.chemmater.6b03083[26] Sun C, Pan F, Bin H, et al. A low cost and high performance polymer donor material for polymer solar cells. Nat Commun, 2018, 9, 743 doi: 10.1038/s41467-018-03207-x[27] Duan C, Ding L. The new era for organic solar cells: polymer donors. Sci Bull, 2020, 65, 1422 doi: 10.1016/j.scib.2020.04.044[28] Yuan J, Zhang Y, Zhou L, et al. Single-junction organic solar cell with over 15% efficiency using fused-ring acceptor with electron-deficient core. Joule, 2019, 3, 1140 doi: 10.1016/j.joule.2019.01.004[29] Bergqvist J, Mauger S, Tvingstedt K, et al. In situ reflectance imaging of organic thin film formation from solution deposition. Sol Energy Mater Sol Cells, 2013, 114, 89 doi: 10.1016/j.solmat.2013.02.030[30] Xiong K, Hou L, Wu M, et al. From spin coating to doctor blading: a systematic study on the photovoltaic performance of an isoindigo-based polymer. Sol Energy Mater Sol Cells, 2015, 132, 252 doi: 10.1016/j.solmat.2014.08.039 -

Supplements

21020001suppl.pdf

21020001suppl.pdf

-

Proportional views

DownLoad:

DownLoad: