| Citation: |

Yongqiang Sun, Guangzhou Cui, Kai Guo, Jinchuan Zhang, Ning Zhuo, Lijun Wang, Shuman Liu, Zhiwei Jia, Teng Fei, Kun Li, Junqi Liu, Fengqi Liu, Shenqiang Zhai. Quantum cascade lasers grown by MOCVD[J]. Journal of Semiconductors, 2023, 44(12): 121901. doi: 10.1088/1674-4926/44/12/121901

Y Q Sun, G Z Cui, K Guo, J C Zhang, N Zhuo, L J Wang, S M Liu, Z W Jia, T Fei, K Li, J Q Liu, F Q Liu, S Q Zhai. Quantum cascade lasers grown by MOCVD[J]. J. Semicond, 2023, 44(12): 121901. doi: 10.1088/1674-4926/44/12/121901

Export: BibTex EndNote

|

-

Abstract

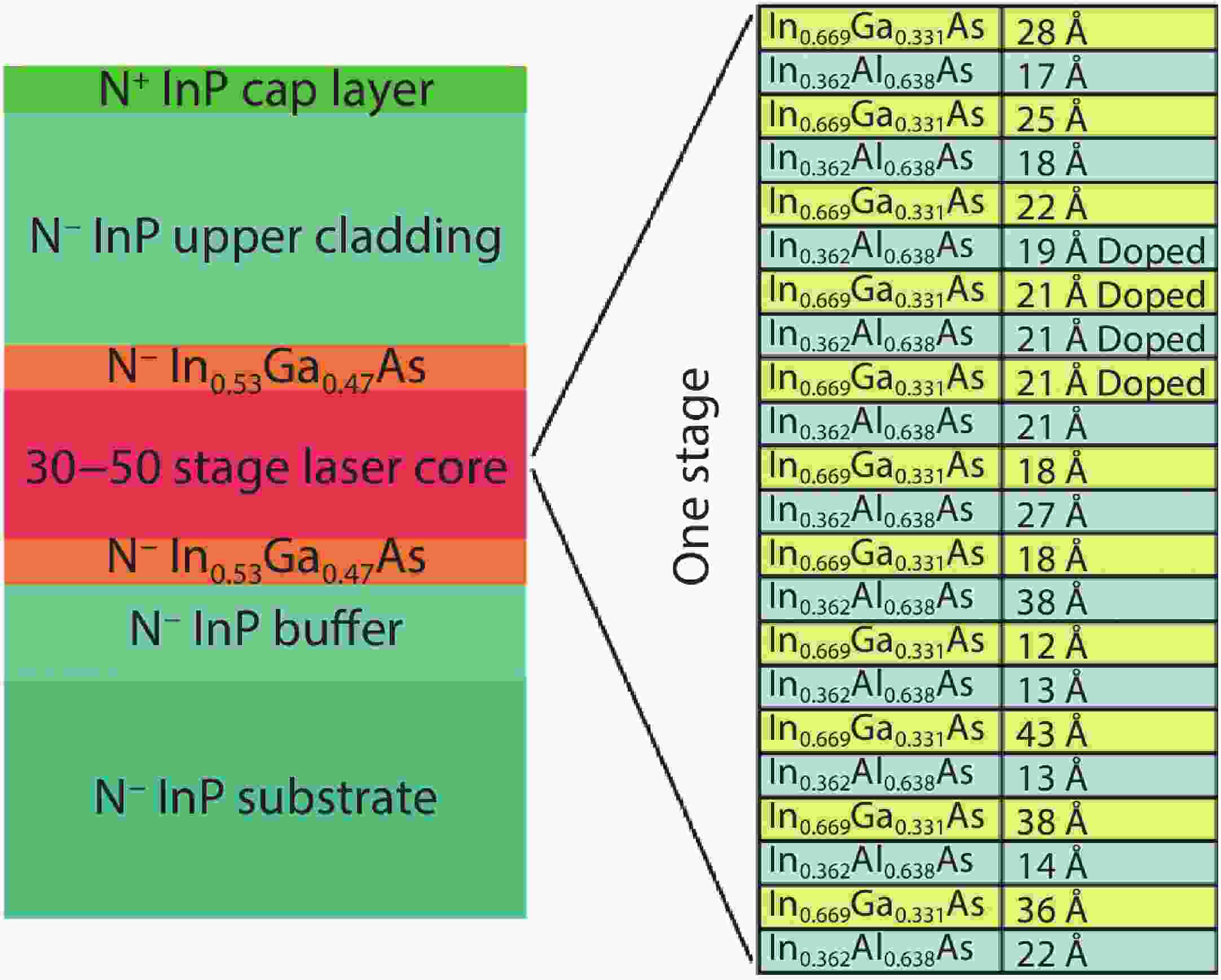

Sharing the advantages of high optical power, high efficiency and design flexibility in a compact size, quantum cascade lasers (QCLs) are excellent mid-to-far infrared laser sources for gas sensing, infrared spectroscopic, medical diagnosis, and defense applications. Metalorganic chemical vapor deposition (MOCVD) is an important technology for growing high quality semiconductor materials, and has achieved great success in the semiconductor industry due to its advantages of high efficiency, short maintenance cycles, and high stability and repeatability. The utilization of MOCVD for the growth of QCL materials holds a significant meaning for promoting the large batch production and industrial application of QCL devices. This review summarizes the recent progress of QCLs grown by MOCVD. Material quality and the structure design together determine the device performance. Research progress on the performance improvement of MOCVD-grown QCLs based on the optimization of material quality and active region structure are mainly reviewed. -

References

[1] Faist J, Capasso F, Sivco D L, et al. Quantum cascade laser. Science, 1994, 264, 553 doi: 10.1126/science.264.5158.553[2] Curl R F, Capasso F, Gmachl C, et al. Quantum cascade lasers in chemical physics. Chem Phys Lett, 2010, 487, 1 doi: 10.1016/j.cplett.2009.12.073[3] Liu X, Van Neste C W, Gupta M, et al. Standoff reflection–absorption spectra of surface adsorbed explosives measured with pulsed quantum cascade lasers. Sens Actuator B-Chem, 2014, 191, 450 doi: 10.1016/j.snb.2013.10.026[4] Wysocki G, Kosterev A A, Tittel F K. Spectroscopic trace-gas sensor with rapidly scanned wavelengths of a pulsed quantum cascade laser for in situ NO monitoring of industrial exhaust systems. Appl Phys B, 2005, 80, 617 doi: 10.1007/s00340-005-1764-y[5] Zhang L Z, Tian G A, Li J S, et al. Applications of absorption spectroscopy using quantum cascade lasers. Appl Spectrosc, 2014, 68, 1095 [ doi: 10.1366/14-00001[6] Liu J H, Wang H A, et al. Broad tuning range, high power quantum cascade laser at λ ~ 7.4 µm. Opt Express, 2022, 30, 40704 doi: 10.1364/OE.472942[7] Sun Y, Yang K, Liu J, et al. , High sensitivity and fast detection system for sensing of explosives and hazardous materials. Sens Actuator B-Chem, 2022, 360, 131640 doi: 10.1016/j.snb.2022.131640[8] Schwaighofer A, Brandstetter M, Lendl B. Quantum cascade lasers (QCLs) in biomedical spectroscopy. Chem Soc Rev, 2017, 46, 5903 doi: 10.1039/C7CS00403F[9] Yao Y, Hoffman A J, Gmachl C F. Mid-infrared quantum cascade lasers. Nature Photon, 2012, 6, 432 doi: 10.1038/nphoton.2012.143[10] Corrigan P, Martini R, Whittaker E A, et al. Quantum cascade lasers and the Kruse model in free space optical communication. Opt Express, 2009, 17, 4355 doi: 10.1364/OE.17.004355[11] Zhuo N, Liu F Q, Wang Z G. Quantum cascade lasers: From sketch to mainstream in the mid and far infrared. J Semicond, 2020, 41, 010301 doi: 10.1088/1674-4926/41/1/010301[12] Bai Y, Bandyopadhyay N, Tsao S, et al. Room temperature quantum cascade lasers with 27% wall plug efficiency. Appl Phys Lett, 2011, 98, 181102 doi: 10.1063/1.3586773[13] Roberts J S, Green R P, Wilson L R, et al. Quantum cascade lasers grown by metalorganic vapor phase epitaxy. Appl Phys Lett, 2003, 82, 4221 doi: 10.1063/1.1583858[14] Green R P, Krysa A, Roberts J S, et al. Room-temperature operation of InGaAs/AlInAs quantum cascade lasers grown by metalorganic vapor phase epitaxy. Appl Phys Lett, 2003, 83, 1921 doi: 10.1063/1.1609055[15] Diehl L, Bour D, Corzine S, et al. Pulsed- and continuous-mode operation at high temperature of strained quantum-cascade lasers grown by metalorganic vapor phase epitaxy. Appl Phys Lett, 2006, 88, 041102 doi: 10.1063/1.2166206[16] Wang X J, Fan J Y, Tanbun-Ek T, et al. Low threshold quantum-cascade lasers of room temperature continuous-wave operation grown by metal-organic chemical-vapor deposition. Appl Phys Lett, 2007, 90, 211103 doi: 10.1063/1.2741409[17] Evans A, Yu J S, David J, et al. High-temperature, high-power, continuous-wave operation of buried heterostructure quantum-cascade lasers. Appl Phys Lett, 2004, 84, 314 doi: 10.1063/1.1641174[18] Lyakh A, Pflügl C, Diehl L, et al. 1.6W high wall plug efficiency, continuous-wave room temperature quantum cascade laser emitting at 4.6μm. Appl Phys Lett, 2008, 92, 201103 doi: 10.1063/1.2931057[19] Sun Y Q, Yin R, Zhang J C, et al. High-performance quantum cascade lasers at λ ~ 9 µm grown by MOCVD. Opt Express, 2022, 30, 37272 doi: 10.1364/OE.469573[20] Xie F, Caneau C, Leblanc H P, et al. Watt-level room temperature continuous-wave operation of quantum cascade lasers with λ >10 μm. IEEE J Sel Top Quantum Electron, 2013, 19, 1200407 doi: 10.1109/JSTQE.2013.2240658[21] Xie F, Caneau C, LeBlanc H P, et al. Room temperature CW operation of short wavelength quantum cascade lasers made of strain balanced GaxIn1-xAs/AlyIn1-yAs material on InP substrates. IEEE J Sel Top Quantum Electron, 2011, 17, 1445 doi: 10.1109/JSTQE.2011.2136325[22] Xie F, Caneau C G, LeBlanc H P, et al. High power and high temperature continuous-wave operation of distributed Bragg reflector quantum cascade lasers. Appl Phys Lett, 2014, 104, 071109 doi: 10.1063/1.4863233[23] Wang C A, Schwarz B, Siriani D F, et al. MOVPE growth of LWIR AlInAs/GaInAs/InP quantum cascade lasers: Impact of growth and material quality on laser performance. IEEE J Sel Top Quantum Electron, 2017, 23, 1 doi: 10.1109/JSTQE.2017.2677899[24] Botez D, Kirch J D, Boyle C, et al. High-efficiency, high-power mid-infrared quantum cascade lasers [Invited]. Opt Mater Express, 2018, 8, 1378 doi: 10.1364/OME.8.001378[25] Botez D, Chang C C, Mawst L J. Temperature sensitivity of the electro-optical characteristics for mid-infrared ( λ = 3–16 μm)-emitting quantum cascade lasers. J Phys D: Appl Phys, 2016, 49, 043001 doi: 10.1088/0022-3727/49/4/043001[26] Troccoli M, Bour D, Corzine S, et al. Low-threshold continuous-wave operation of quantum-cascade lasers grown by metalorganic vapor phase epitaxy. Appl Phys Lett, 2004, 85, 5842 doi: 10.1063/1.1834715[27] Krysa A B, Roberts J S, Green R P, et al. MOVPE-grown quantum cascade lasers operating at ~9μm wavelength. J Cryst Growth, 2004, 272, 682 doi: 10.1016/j.jcrysgro.2004.08.066[28] Troccoli M, Corzine S, Bour D, et al. Room temperature continuous-wave operation of quantum-cascade lasers grown by metal organic vapour phase epitaxy. Electron Lett, 2005, 41, 1059 doi: 10.1049/el:20052626[29] Diehl L, Bour D, Corzine S, et al. High-temperature continuous wave operation of strain-balanced quantum cascade lasers grown by metal organic vapor-phase epitaxy. Appl Phys Lett, 2006, 89, 081101 doi: 10.1063/1.2337284[30] Fujita K, Furuta S, Sugiyama A, et al. Room temperature, continuous-wave operation of quantum cascade lasers with single phonon resonance-continuum depopulation structures grown by metal organic vapor-phase epitaxy. Appl Phys Lett, 2007, 91, 141121 doi: 10.1063/1.2795793[31] Fujita K, Furuta S, Sugiyama A, et al. High-performance λ~8.6 μm quantum cascade lasers with single phonon-continuum depopulation structures. IEEE J Quantum Electron, 2010, 46, 683 doi: 10.1109/JQE.2010.2048015[32] Pflügl C, Diehl L, Tsekoun A, et al. Room-temperature continuous-wave operation of long wavelength (λ=9.5 μm) MOVPE-grown quantum cascade lasers. Electron Lett, 2007, 43, 1026 doi: 10.1049/el:20072162[33] Huang Y, Ryou J H, Dupuis R D, et al. Optimization of growth conditions for InGaAs/InAlAs/InP quantum cascade lasers by metalorganic chemical vapor deposition. J Cryst Growth, 2011, 316, 75 doi: 10.1016/j.jcrysgro.2010.12.028[34] Demir I, Elagoz S. Interruption time effects on InGaAs/InAlAs superlattices of quantum cascade laser structures grown by MOCVD. Superlattices Microstruct, 2016, 100, 723 doi: 10.1016/j.spmi.2016.10.027[35] Demir I, Elagoz S. V/III ratio effects on high quality InAlAs for quantum cascade laser structures. Superlattices Microstruct, 2017, 104, 140 doi: 10.1016/j.spmi.2017.02.022[36] Wang C A, Goyal A K, Menzel S, et al. High power (>5 W) λ~9.6 μm tapered quantum cascade lasers grown by OMVPE. J Cryst Growth, 2013, 370, 212 doi: 10.1016/j.jcrysgro.2012.11.045[37] Wang C A, Schwarz B, Siriani D F, et al. Sensitivity of heterointerfaces on emission wavelength of quantum cascade lasers. J Cryst Growth, 2017, 464, 215 doi: 10.1016/j.jcrysgro.2016.11.029[38] Kelly T F, Miller M K. Invited review article: Atom probe tomography. Rev Sci Instrum, 2007, 78, 031101 doi: 10.1063/1.2709758[39] Schwarz B, Wang C A, Missaggia L, et al. Watt-level continuous-wave emission from a bifunctional quantum cascade laser/detector. ACS Photonics, 2017, 4, 1225 doi: 10.1021/acsphotonics.7b00133[40] Molodtsov I S, Raspopov N A, Lobintsov A V, et al. Quantum cascade laser with bound-to-quasi-continuum optical transitions at a temperature of up to 371 K. Quantum Electron, 2020, 50, 710 doi: 10.1070/QEL17317[41] Fan J A, Belkin M A, Troccoli M, et al. Double-metal waveguide $\backsimeq $19 μm quantum cascade lasers grown by metal organic vapour phase epitaxy. Electron Lett, 2007, 43, 1284 doi: 10.1049/el:20079450[42] Fei T, Zhai S Q, Zhang J C, et al. High power λ ~ 8.5 μm quantum cascade laser grown by MOCVD operating continuous-wave up to 408 K. J Semicond, 2021, 42, 112301 doi: 10.1088/1674-4926/42/11/112301[43] Fujita K, Yamanishi M, Furuta S, et al. Extremely temperature-insensitive continuous-wave quantum cascade lasers. Appl Phys Lett, 2012, 101, 181111 doi: 10.1063/1.4765073[44] Kirch J D, Shin J C, Chang C C, et al. Tapered active-region quantum cascade lasers (λ=4.8 µm) for virtual suppression of carrier-leakage currents. Electron Lett, 2012, 48, 234 doi: 10.1049/el.2012.0017[45] Liu Z J, Wasserman D, Howard S S, et al. Room-temperature continuous-wave quantum cascade lasers grown by MOCVD without lateral regrowth. IEEE Photonics Technol Lett, 2006, 18, 1347 doi: 10.1109/LPT.2006.877006[46] Kirch J D, Chang C C, Boyle C, et al. 86% internal differential efficiency from 8 to 9 µm-emitting, step-taper active-region quantum cascade lasers. Opt Express, 2016, 24, 24483 doi: 10.1364/OE.24.024483[47] Lyakh A, Zory P, Wasserman D, et al. Narrow stripe-width, low-ridge high power quantum cascade lasers. Appl Phys Lett, 2007, 90, 141107 doi: 10.1063/1.2720260[48] Blaser S, Bächle A, Jochum S, et al. Low-consumption (below 2 W) continuous-wave singlemode quantum-cascade lasers grown by metal-organic vapour-phase epitaxy. Electron Lett, 2007, 43, 1201 doi: 10.1049/el:20072576[49] Wang C A, Huang R K, Goyal A, et al. OMVPE growth of highly strain-balanced GaInAs/AlInAs/InP for quantum cascade lasers. J Cryst Growth, 2008, 310, 5191 doi: 10.1016/j.jcrysgro.2008.07.100[50] Wang C A, Goyal A, Huang R, et al. Strain-compensated GaInAs/AlInAs/InP quantum cascade laser materials. J Cryst Growth, 2010, 312, 1157 doi: 10.1016/j.jcrysgro.2009.11.005[51] Evans A, Yu J S, Slivken S, et al. Continuous-wave operation of λ~4.8μm quantum-cascade lasersat room temperature. Appl Phys Lett, 2004, 85, 2166 doi: 10.1063/1.1793340[52] Shin J C, D’Souza M, Liu Z, et al. Highly temperature insensitive, deep-well 4.8 μm emitting quantum cascade semiconductor lasers. Appl Phys Lett, 2009, 94, 201103 doi: 10.1063/1.3139069[53] Xu D P, D’Souza M, Shin J C, et al. InGaAs/GaAsP/AlGaAs, deep-well, quantum-cascade light-emitting structures grown by metalorganic chemical vapor deposition. J Cryst Growth, 2008, 310, 2370 doi: 10.1016/j.jcrysgro.2007.11.218[54] Shin J C, Mawst L J, Botez D. Crystal growth via metal-organic vapor phase epitaxy of quantum-cascade-laser structures composed of multiple alloy compositions. J Cryst Growth, 2012, 357, 15 doi: 10.1016/j.jcrysgro.2012.07.013[55] Fei T, Zhai S Q, Zhang J C, et al. 3 W continuous-wave room temperature quantum cascade laser grown by metal-organic chemical vapor deposition. Photonics, 2023, 10, 47 doi: 10.3390/photonics10010047[56] Bandyopadhyay N, Slivken S, Bai Y, et al. High power, continuous wave, room temperature operation of λ ~ 3.4 μm and λ ~ 3.55 μm InP-based quantum cascade lasers. Appl Phys Lett, 2012, 100, 212104 doi: 10.1063/1.4719110[57] Lyakh A, Maulini R, Tsekoun A, et al. High-performance continuous-wave room temperature 4.0-μm quantum cascade lasers with single-facet optical emission exceeding 2 W. Proc Natl Acad Sci USA, 2010, 107, 18799 doi: 10.1073/pnas.1013250107[58] Mawst L J, Kirch J D, Chang C C, et al. InGaAs/AlInAs strain-compensated Superlattices grown on metamorphic buffer layers for low-strain, 3.6 μm-emitting quantum-cascade-laser active regions. J Cryst Growth, 2013, 370, 230 doi: 10.1016/j.jcrysgro.2012.06.053[59] Troccoli M, Lyakh A, Fan J, et al. Long-wave IR quantum cascade lasers for emission in the λ = 8-12μm spectral region. Opt Mater Express, 2013, 3, 1546 doi: 10.1364/OME.3.001546[60] Faist J, Beck M, Aellen T, et al. Quantum-cascade lasers based on a bound-to-continuum transition. Appl Phys Lett, 2001, 78, 147 doi: 10.1063/1.1339843[61] Fujita K, Edamura T, Furuta S, et al. High-performance, homogeneous broad-gain quantum cascade lasers based on dual-upper-state design. Appl Phys Lett, 2010, 96, 241107 doi: 10.1063/1.3455102[62] Fujita K, Furuta S, Sugiyama A, et al. High-performance quantum cascade lasers with wide electroluminescence (~600 cm–1), operating in continuous-wave above 100 °C. Appl Phys Lett, 2011, 98, 231102 doi: 10.1063/1.3596706[63] Fujita K, Furuta S, Dougakiuchi T, et al. Broad-gain (Δλ/λ0~04), temperature-insensitive (T0~510K) quantum cascade lasers. Opt Express, 2011, 19, 2694 doi: 10.1364/OE.19.002694[64] Wittmann A, Bonetti Y, Faist J, et al. Intersubband linewidths in quantum cascade laser designs. Appl Phys Lett, 2008, 93, 141103 doi: 10.1063/1.2993212[65] Yao Y, Wang X J, Fan J Y, et al. High performance “continuum-to-continuum” quantum cascade lasers with a broad gain bandwidth of over 400 cm–1. Appl Phys Lett, 2010, 97, 081115 doi: 10.1063/1.3484279[66] Dougakiuchi T, Fujita K, Sugiyama A, et al. Broadband tuning of continuous wave quantum cascade lasers in long wavelength (> 10μm) range. Opt Express, 2014, 22, 19930 doi: 10.1364/OE.22.019930[67] Hugi A, Terazzi R, Bonetti Y, et al. External cavity quantum cascade laser tunable from 7.6 to 11.4 μm. Appl Phys Lett, 2009, 95, 061103 doi: 10.1063/1.3193539[68] Maulini R, Mohan A R, Giovannini M, et al. External cavity quantum-cascade laser tunable from 8.2 to10.4μm using a gain element with a heterogeneous cascade. Appl Phys Lett, 2006, 88, 201113 doi: 10.1063/1.2205183[69] Bandyopadhyay N, Bai Y, Slivken S, et al. High power operation of λ ~ 5.2–11 μm strain balanced quantum cascade lasers based on the same material composition. Appl Phys Lett, 2014, 105, 201113 doi: 10.1063/1.4893746[70] Bandyopadhyay N, Chen M, Sengupta S, et al. Ultra-broadband quantum cascade laser, tunable over 760 cm–1, with balanced gain. Opt Express, 2015, 23, 21159 doi: 10.1364/OE.23.021159[71] Xie F, Caneau C, Leblanc H, et al. Ultra-broad gain quantum cascade lasers tunable from 65 to 104 μm. Opt Lett, 2015, 40, 4158 doi: 10.1364/OL.40.004158 -

Proportional views

DownLoad:

DownLoad: