| Citation: |

Guowei Han, Chaowei Si, Jin Ning, Weiwei Zhong, Guosheng Sun, Yongmei Zhao, Fuhua Yang. Feed-through cancellation of a MEMS filter using the difference method and analysis of the induced notch[J]. Journal of Semiconductors, 2013, 34(4): 045006. doi: 10.1088/1674-4926/34/4/045006

G W Han, C W Si, J Ning, W W Zhong, G S Sun, Y M Zhao, F H Yang. Feed-through cancellation of a MEMS filter using the difference method and analysis of the induced notch[J]. J. Semicond., 2013, 34(4): 045006. doi: 10.1088/1674-4926/34/4/045006.

Export: BibTex EndNote

|

Feed-through cancellation of a MEMS filter using the difference method and analysis of the induced notch

doi: 10.1088/1674-4926/34/4/045006

More Information-

Abstract

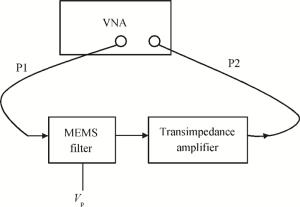

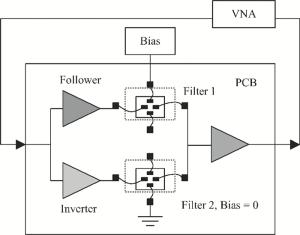

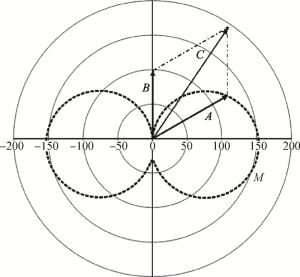

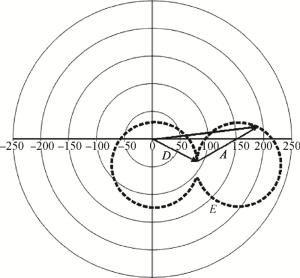

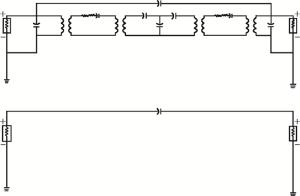

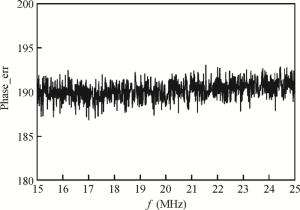

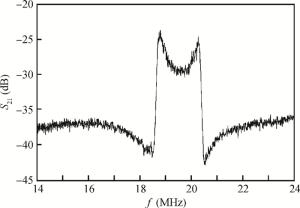

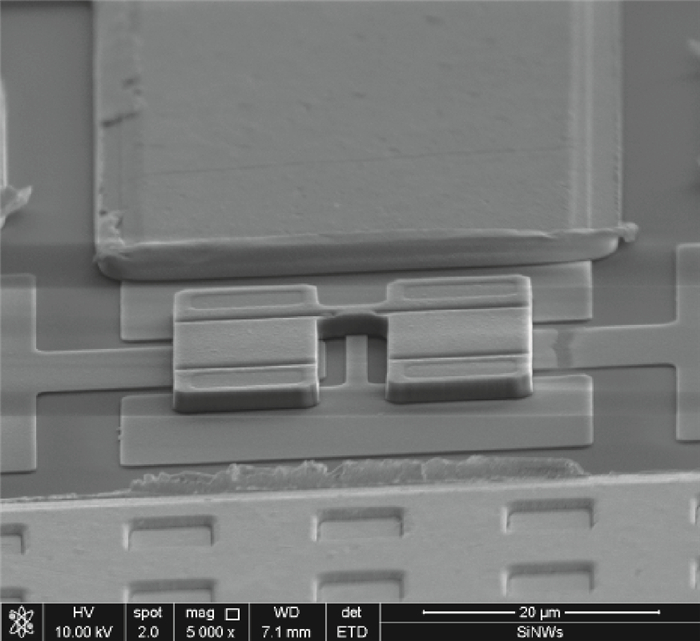

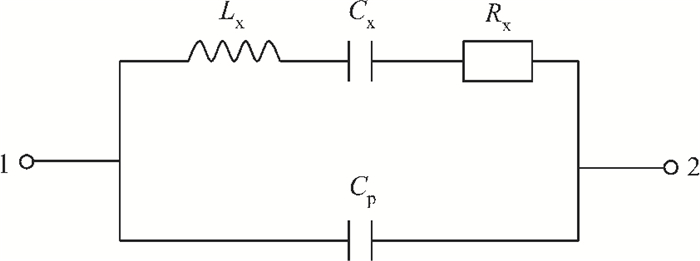

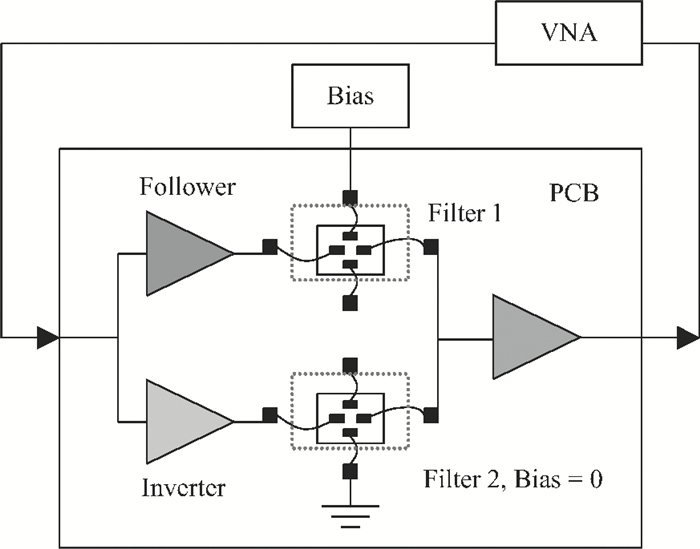

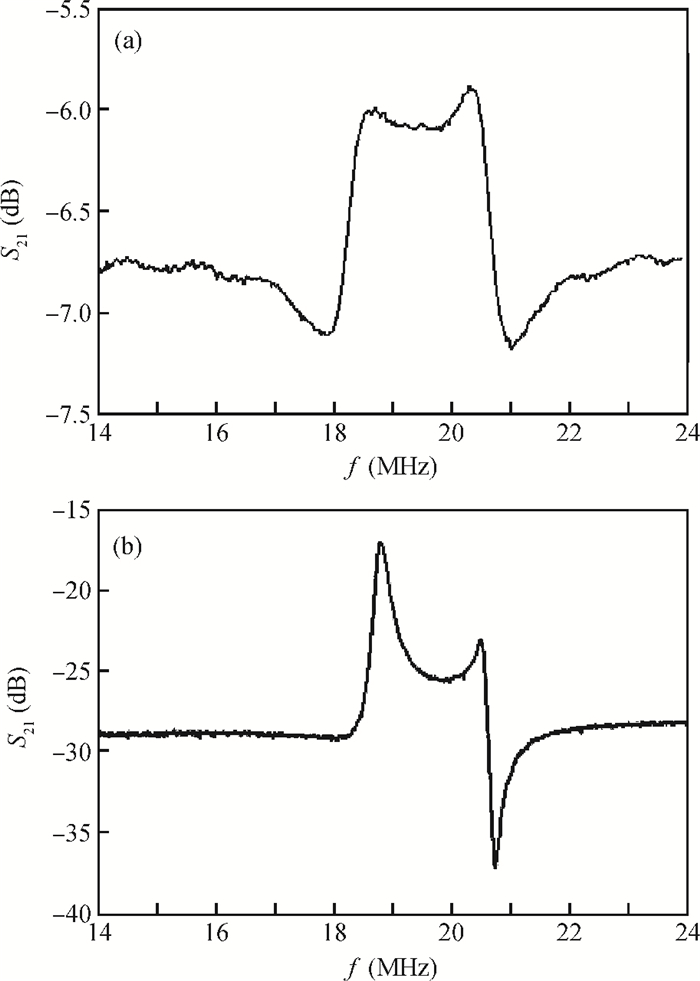

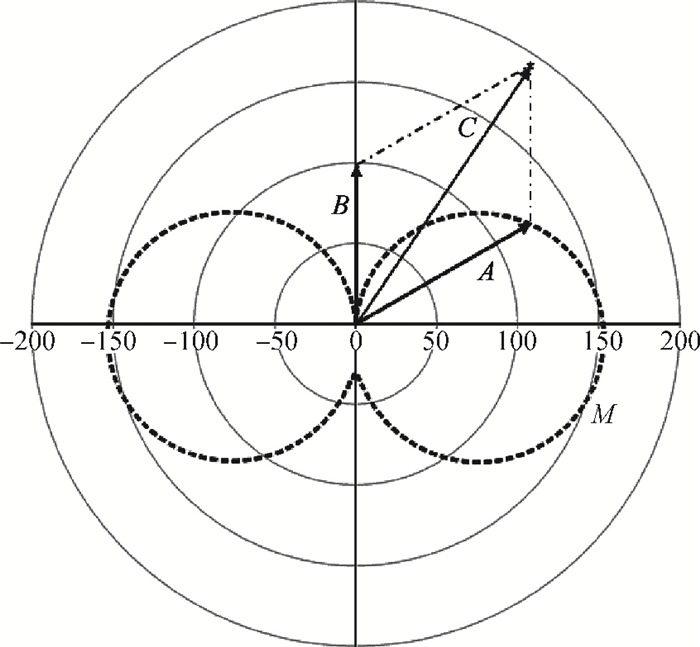

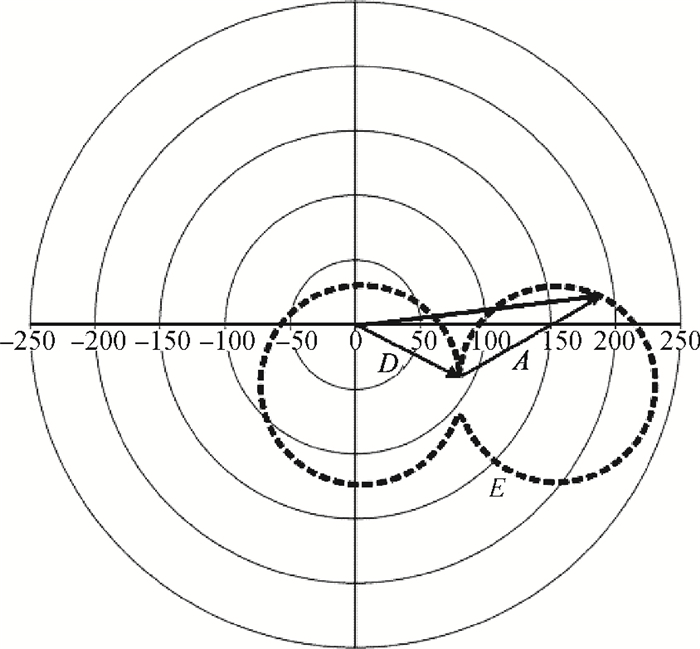

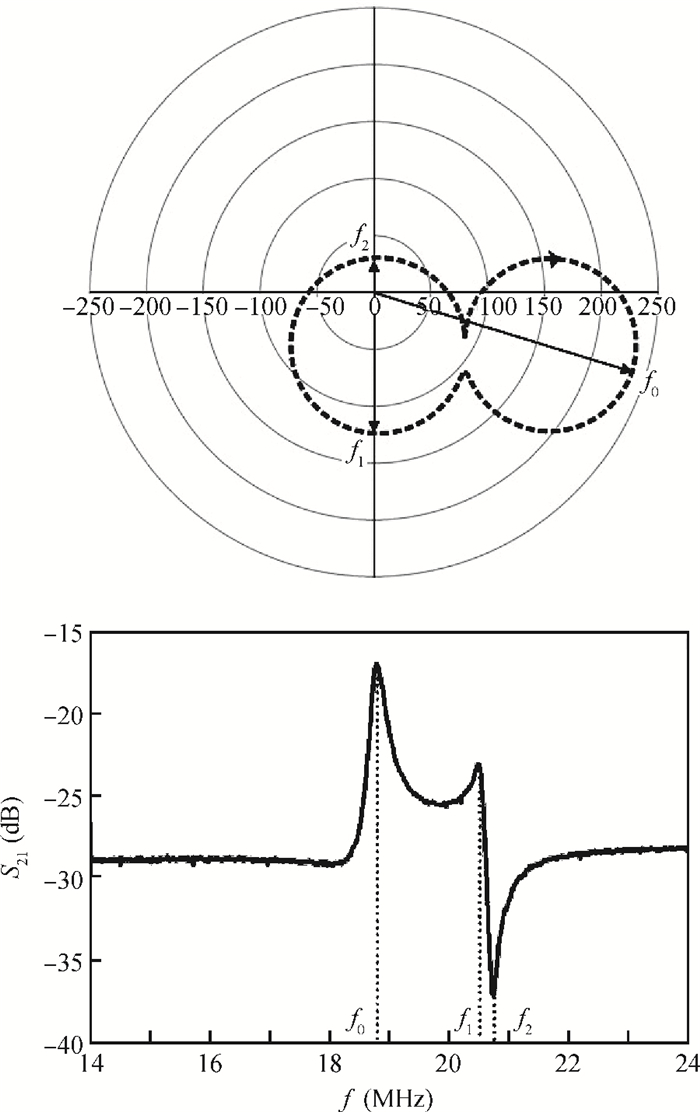

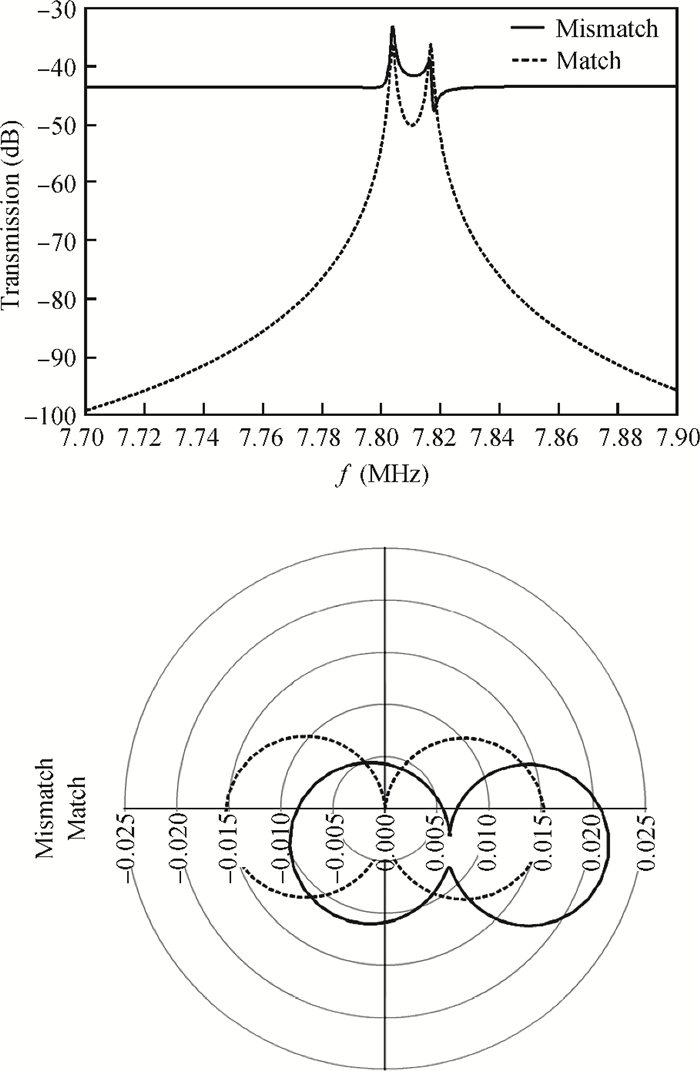

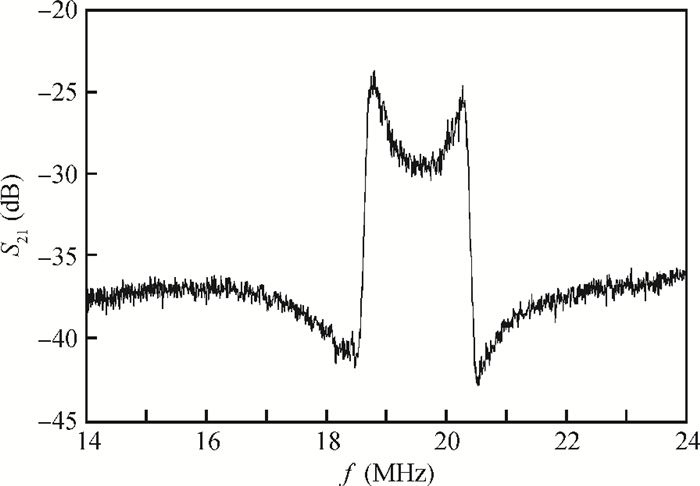

This paper presents and analyzes a notch observed in MEMS (micro electric mechanical system) filter characterization using the difference method. The difference method takes advantage of the cancellation of parasitic feed-through, which could potentially obscure the relatively small motional signal and lead to failure in characterization of the MEMS components. In this paper, typical clamped-clamped beam MEMS filters are fabricated and characterized with the difference method. Using the difference method a better performance is obtained but a notch is induced as a potential problem. Analysis is performed and reveals the mismatch of the two differential excitation signals in measurement circuit contributes to the notch. The relevant circuit design rule is also proposed to avoid the notch in the difference method.-

Keywords:

- MEMS filter,

- feed-through cancellation,

- difference method,

- notch

-

References

[1] Bannon F D Ⅲ, Nguyen C T C. High frequency microelectromechanical IF filters. Tech Dig IEEE Electron Devices Meeting, 1996:773 https://people.eecs.berkeley.edu/~ctnguyen/Research/ConferencePubs/1996/iedm96.2resCCbeamFilter.corr.ctnguyen.pdf[2] Wang S, Chandorkar S A, Graham A B, et al. Encapsulated mechanically coupled fully-differential breathe-mode ring filters with ultra-narrow bandwidth. 16th Int Conf on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS), 2011:942 http://ieeexplore.ieee.org/document/5969668/authors[3] Lee J E Y, Zhu Y, Seshia A A. A bulk acoustic mode single-crystal silicon microresonatorwith a high quality factor. J Micromech Microeng, 2008, 18(6):064001 doi: 10.1088/0960-1317/18/6/064001[4] Li S S, Lin Y W, Ren Z, et al. Disk-array design for suppression of unwanted modes in micromechanical composite-array filters. 19th IEEE Int Conf on Micro Electro Mechanical Systems, 2006:22 http://ieeexplore.ieee.org/document/1627937/[5] Lo C C, Chen F, Fedder G K. Integrated HF CMOS-MEMS square-frame resonators with on-chip electronics and electrothermal narrow gap mechanism. 13th IEEE Int Conf on Solid-State Sensors, Actuators and Microsystems, 2005:2074 http://ieeexplore.ieee.org/document/1497511/[6] Cheng T J, Bhave S A. High-Q, low impedance polysilicon resonators with 10 nm air gaps. 23rd IEEE Int Conf on Micro Electro Mechanical Systems (MSMS), 2010:695 https://engineering.purdue.edu/oxidemems/papers/MEMS2010_VerySmallGap.pdf[7] Lin Y W, Li S S, Ren Z. Low phase noise array-composite micromechanical wine-glass disk oscillator. IEEE Int Electron Devices Mtg, 2005:287 http://www-personal.umich.edu/~ssli/Publication/ArrayOsc.iedm05.pdf[8] Lee J E Y, Seshia A A. Parasitic feedthrough cancellation techniques for enhanced electrical characterization of electrostatic microresonators. Sensors and Actuators, 2009, A156:36 http://www.sciencedirect.com/science/article/pii/S0924424709000405[9] Nguyen C T C. High-Q HF microelectromechanical filters. IEEE J Solid-State Circuits, 2000, 35(4):512 doi: 10.1109/4.839911 -

Proportional views

DownLoad:

DownLoad: