| Citation: |

Wenqi Wei, Qi Feng, Zihao Wang, Ting Wang, Jianjun Zhang. Perspective: optically-pumped III–V quantum dot microcavity lasers via CMOS compatible patterned Si (001) substrates[J]. Journal of Semiconductors, 2019, 40(10): 101303. doi: 10.1088/1674-4926/40/10/101303

****

W Q Wei, Q Feng, Z H Wang, T Wang, J J Zhang, Perspective: optically-pumped III–V quantum dot microcavity lasers via CMOS compatible patterned Si (001) substrates[J]. J. Semicond., 2019, 40(10): 101303. doi: 10.1088/1674-4926/40/10/101303.

|

Perspective: optically-pumped III–V quantum dot microcavity lasers via CMOS compatible patterned Si (001) substrates

DOI: 10.1088/1674-4926/40/10/101303

More Information

-

Abstract

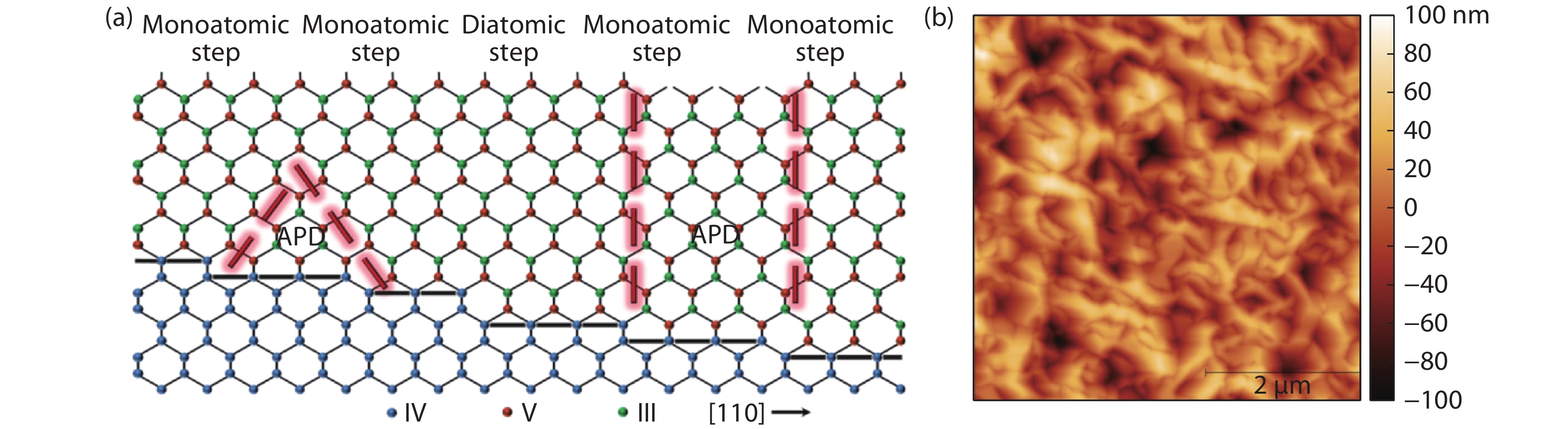

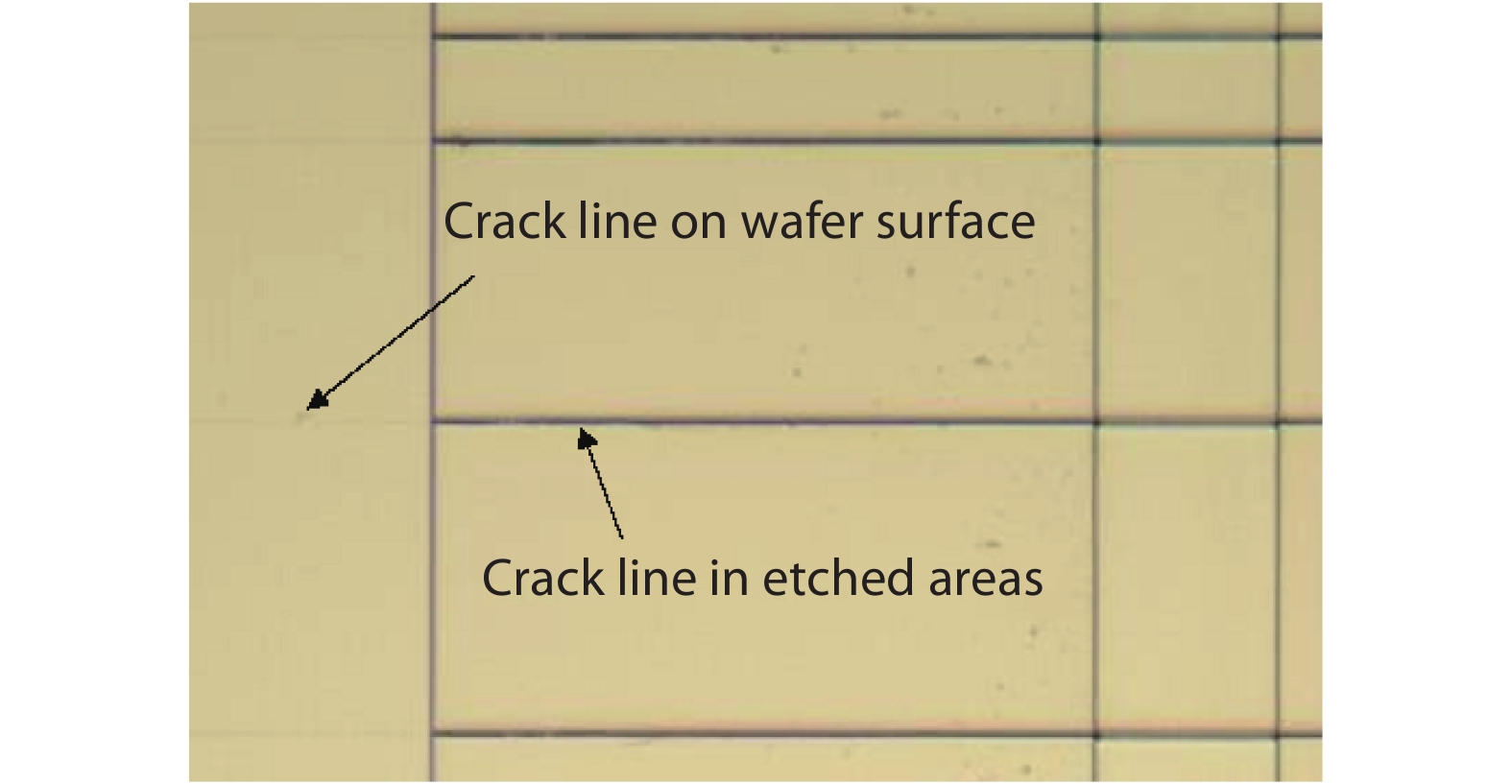

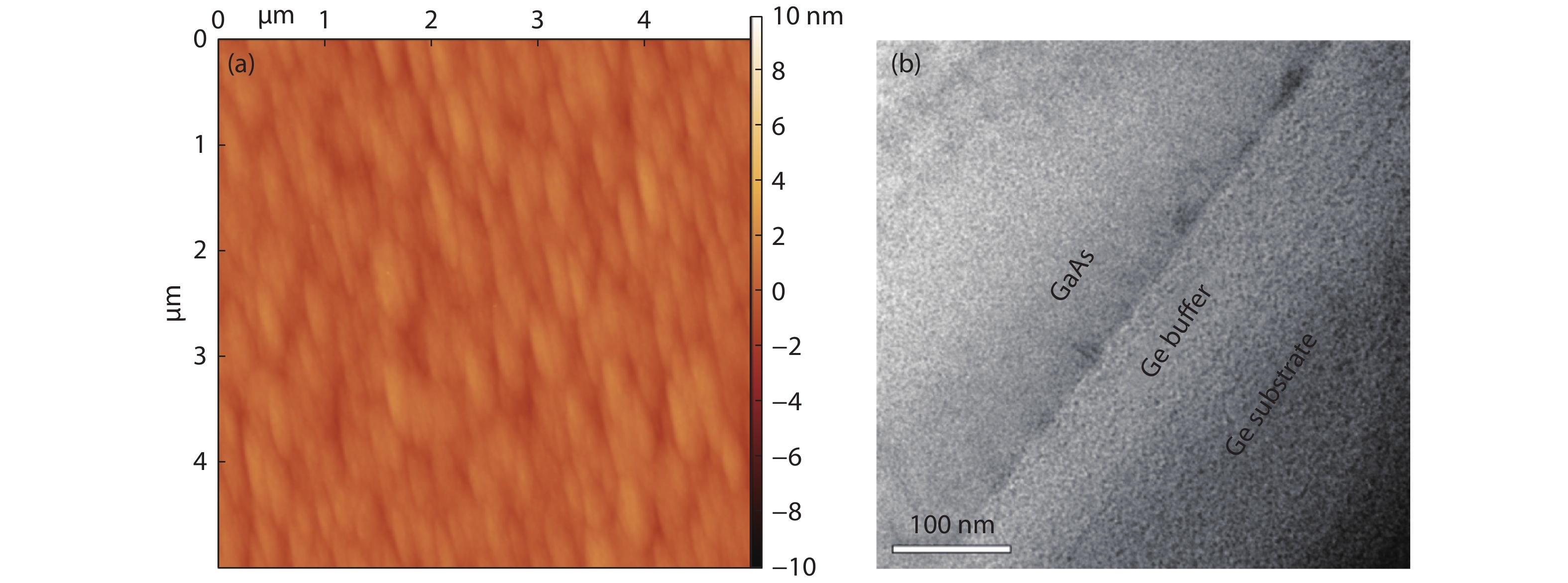

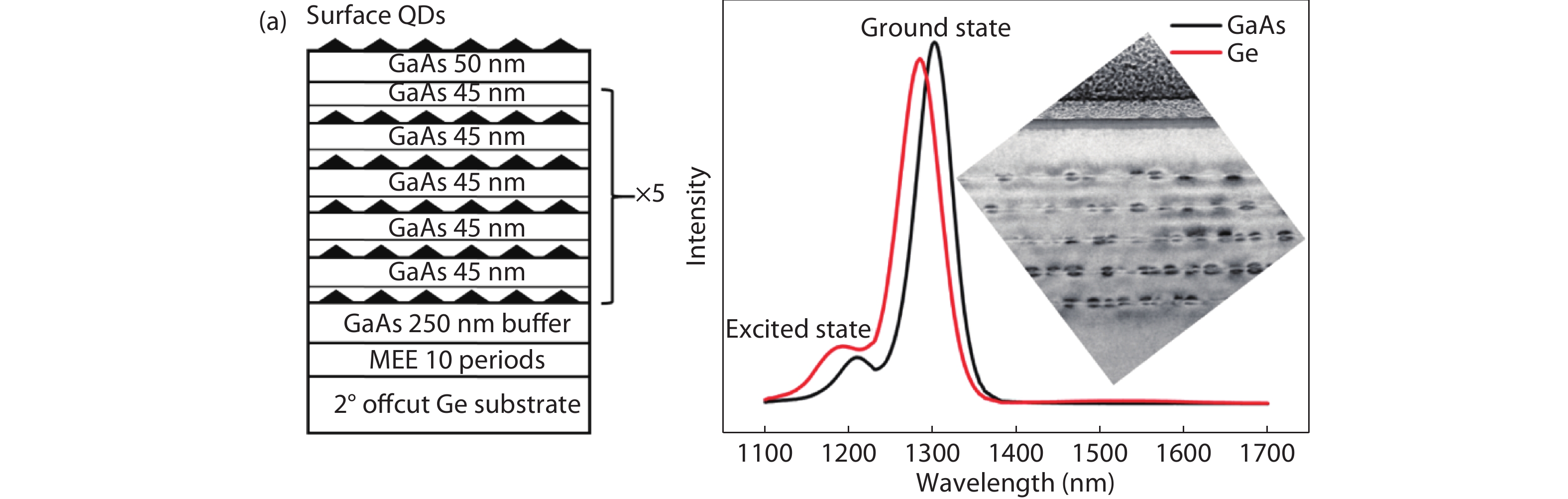

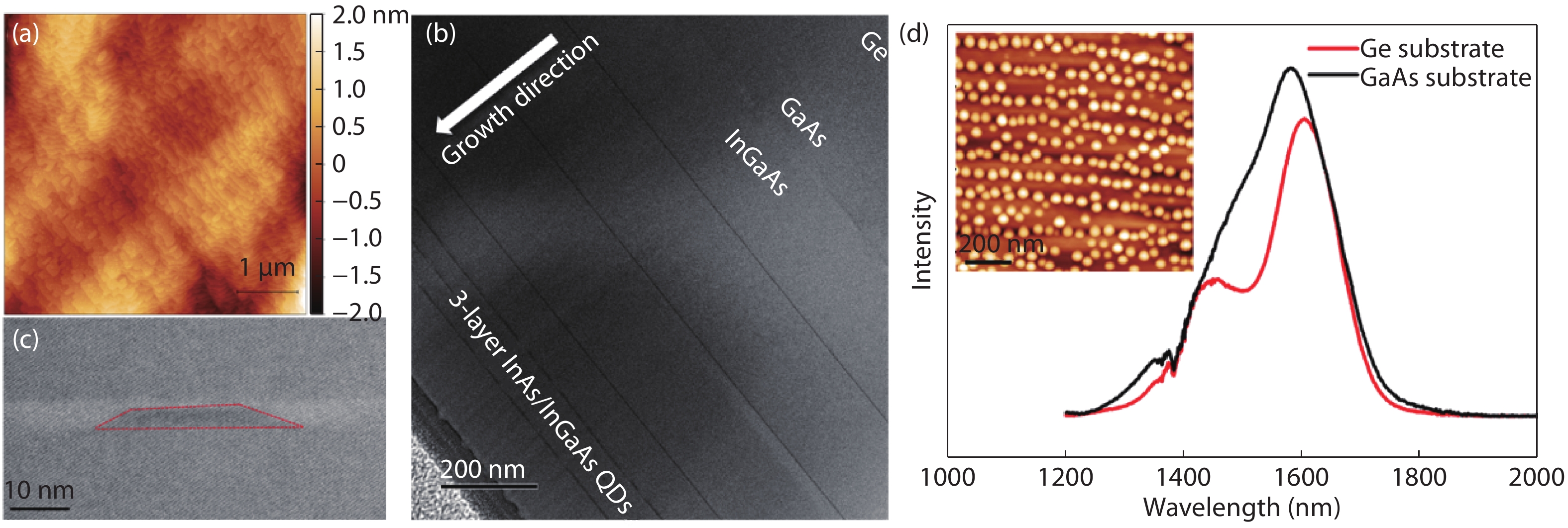

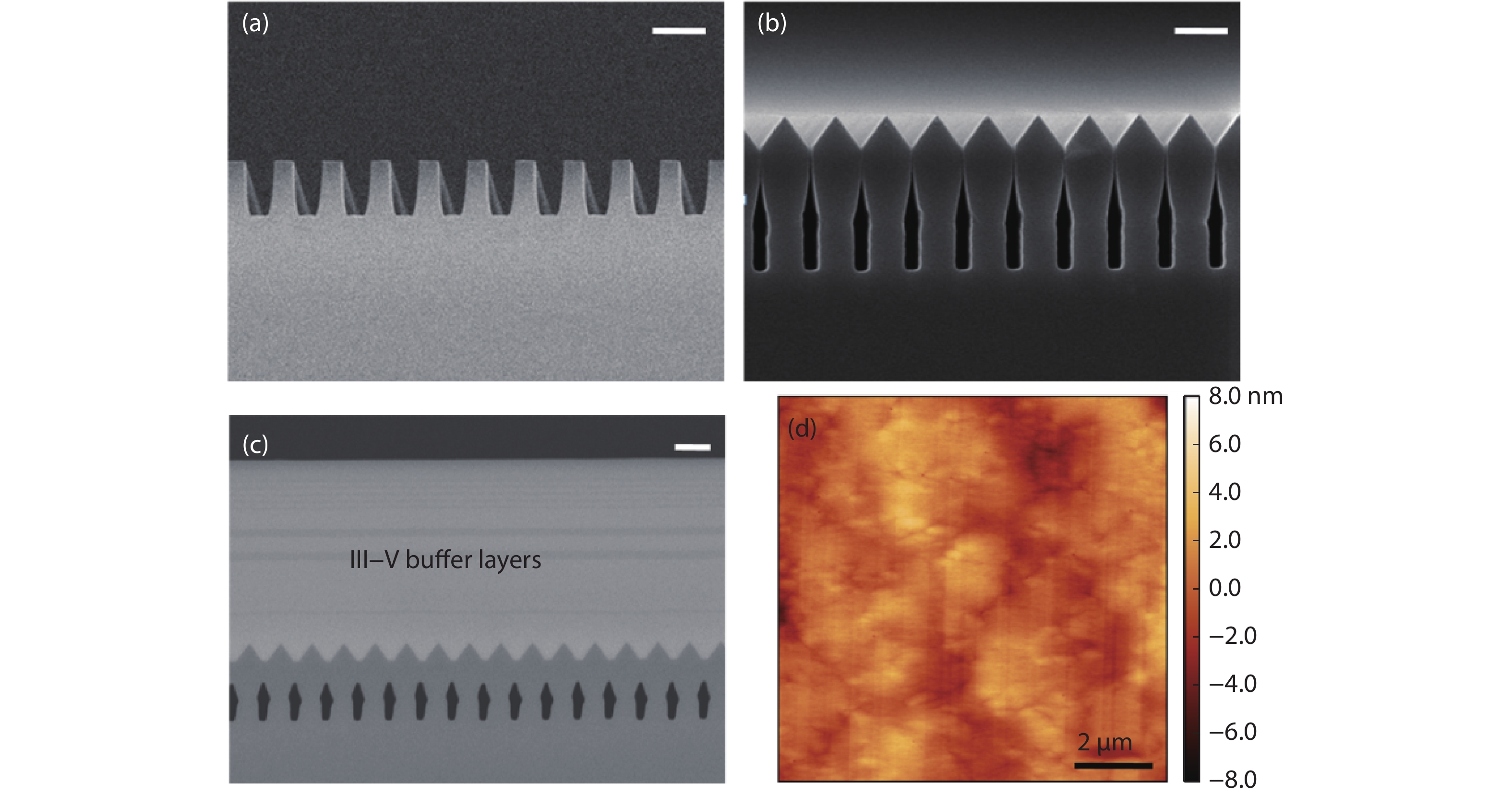

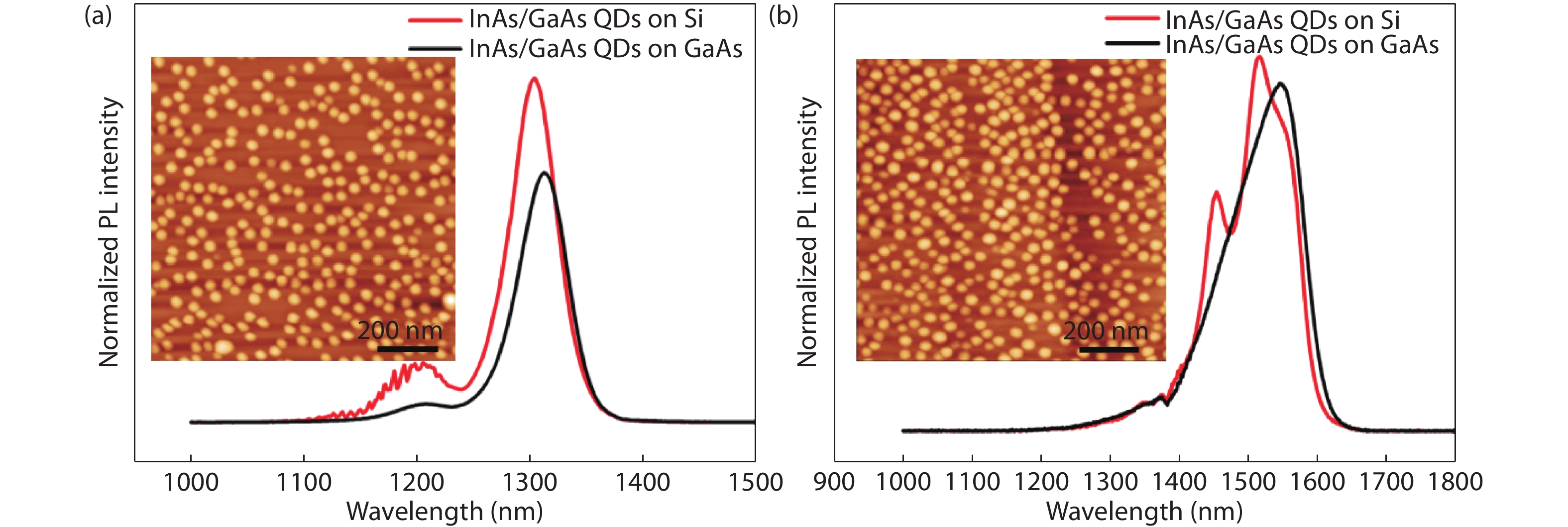

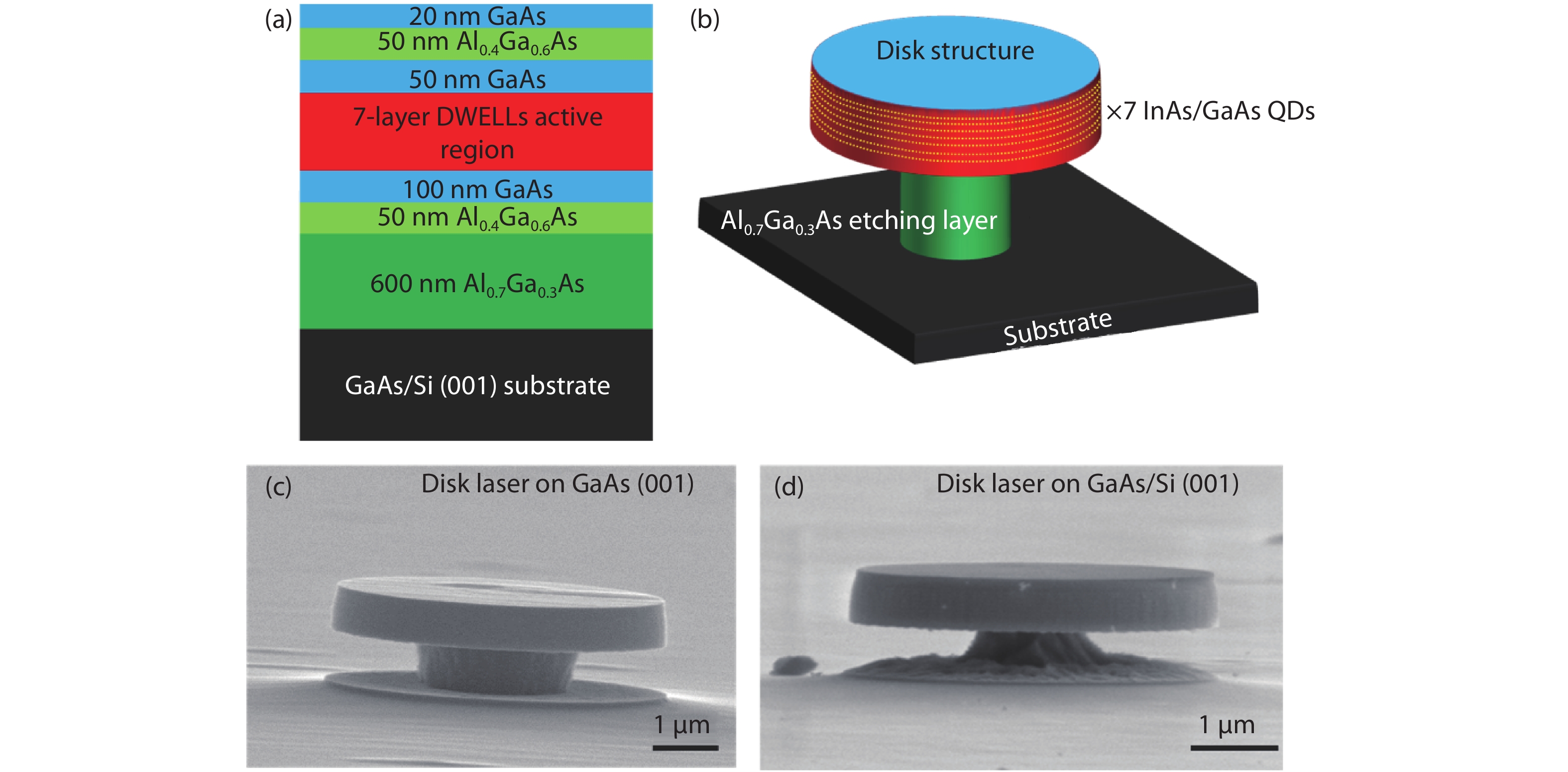

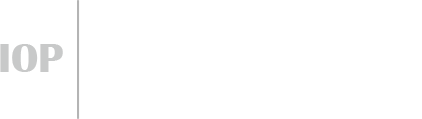

Direct epitaxial growth III–V quantum dot (QD) structures on CMOS-compatible silicon substrates is considered as one of the most promising approaches to achieve low-cost and high-yield Si-based lasers for silicon photonic integration. However, epitaxial growth of III–V materials on Si encounters the following three major challenges: high density of threading dislocations, antiphase boundaries and thermal cracks, which significantly degrade the crystal quality and potential device performance. In this review, we will focus on some recent results related to InAs/GaAs quantum dot lasers on Si (001) substrates by III–V/IV hybrid epitaxial growth via (111)-faceted Si hollow structures. Moreover, by using the step-graded epitaxial growth process the emission wavelength of InAs QDs can be extended from O-band to C/L-band. High-performance InAs/GaAs QD micro-disk lasers with sub-milliwatts threshold on Si (001) substrates are fabricated and characterized. The above results pave a promising path towards the on-chip lasers for optical interconnect applications. -

References

[1] Asghari M, Krishnamoorthy A V. Silicon photonics: Energy-efficient communication. Nat Photonics, 2011, 5(5), 268 doi: 10.1038/nphoton.2011.68[2] Rickman A. The commercialization of silicon photonics. Nat Photonics, 2014, 8(8), 579 doi: 10.1038/nphoton.2014.175[3] Vahdat A, Liu H, Zhao X, et al. The emerging optical data center. Optical Fiber Communication Conference, 2011, OTuH2[4] Bauters J F, Davenport M L, Heck M J R, et al. Silicon on ultra-low-loss waveguide photonic integration platform. Opt Express, 2013, 21(1), 544 doi: 10.1364/OE.21.000544[5] Heck M J R, Bauters J F, Davenport M L, et al. Ultra-low loss waveguide platform and its integration with silicon photonics. Laser Photonics Rev, 2014, 8(5), 667 doi: 10.1002/lpor.201300183[6] Yin T, Cohen R, Morse M M, et al. 31 GHz Ge n–i–p waveguide photodetectors on silicon-on-insulator substrate. Opt Express, 2007, 15(21), 13965 doi: 10.1364/OE.15.013965[7] Vivien L, Polzer A, Marris-Morini D, et al. Zero-bias 40 Gbit/s germanium waveguide photodetector on silicon. Opt Express, 2012, 20(2), 1096 doi: 10.1364/OE.20.001096[8] Reed G T, Mashanovich G, Gardes F Y, et al. Silicon optical modulators. Nat Photonics, 2010, 4(8), 518 doi: 10.1038/nphoton.2010.179[9] Xiao X, Xu H, Li X, et al. High-speed, low-loss silicon Mach-Zehnder modulators with doping optimization. Opt Express, 2013, 21(4), 4116 doi: 10.1364/OE.21.004116[10] Zheng X, Shubin I, Li G, et al. A tunable 1 × 4 silicon CMOS photonic wavelength multiplexer/demultiplexer for dense optical interconnects. Opt Express, 2010, 18(5), 5151 doi: 10.1364/OE.18.005151[11] Liang D, Bowers J E. Recent progress in lasers on silicon. Nat Photonics, 2010, 4(8), 511 doi: 10.1038/nphoton.2010.167[12] Rong H, Liu A, Jones R, et al. An all-silicon Raman laser. Nature, 2005, 433(7023), 292 doi: 10.1038/nature03273[13] Camacho-Aguilera R E, Cai Y, Patel N, et al. An electrically pumped germanium laser. Opt Express, 2012, 20(10), 11316 doi: 10.1364/OE.20.011316[14] Liu J, Sun X, Pan D, et al. Tensile-strained, n-type Ge as a gain medium for monolithic laser integration on Si. Opt Express, 2007, 15(18), 11272 doi: 10.1364/OE.15.011272[15] Liu A Y, Bowers J. Photonic integration with epitaxial III–V on silicon. IEEE J Sel Top in Quantum Electron, 2018, 24(6), 1 doi: 10.1109/JSTQE.2018.2854542[16] Tanabe K, Watanabe K, Arakawa Y. III–V/Si hybrid photonic devices by direct fusion bonding. Sci Rep, 2012, 2, 349 doi: 10.1038/srep00349[17] Wang Z, Van Gasse K, Moskalenko V, et al. A III–V-on-Si ultra-dense comb laser. Light: Sci Appl, 2017, 6(5), e16260 doi: 10.1038/lsa.2016.260[18] Zhou Z, Yin B, Michel J. On-chip light sources for silicon photonics. Light: Sci Appl, 2015, 4(11), e358 doi: 10.1038/lsa.2015.131[19] Wang Z, Abbasi A, Dave U, et al. Novel light source integration approaches for silicon photonics. Laser Photonics Rev, 2017, 11(4), 1700063 doi: 10.1002/lpor.201700063[20] Liu C W, Östling M, Hannon J B. New materials for post-Si computing. MRS Bulletin, 2014, 39(8), 658 doi: 10.1557/mrs.2014.162[21] Wu J, Chen S, Seeds A, et al. Quantum dot optoelectronic devices: lasers, photodetectors and solar cells. J Phys D, 2015, 48(36), 363001 doi: 10.1088/0022-3727/48/36/363001[22] Tang M, Chen S, Wu J, et al. 1.3-μm InAs/GaAs quantum-dot lasers monolithically grown on Si substrates using InAlAs/GaAs dislocation filter layers. Opt Express, 2014, 22(10), 11528 doi: 10.1364/OE.22.011528[23] Wang J, Hu H Y, Deng C, et al. Defect reduction in GaAs/Si film with InAs quantum-dot dislocation filter grown by metalorganic chemical vapor deposition. Chin Phys B, 2015, 24(2), 028101 doi: 10.1088/1674-1056/24/2/028101[24] Li Q, Lau K M. Epitaxial growth of highly mismatched III–V materials on (001) silicon for electronics and optoelectronics. Prog Cryst Growth Charact Mater, 2017, 63(4), 105 doi: 10.1016/j.pcrysgrow.2017.10.001[25] Faucher J, Masuda T, Lee M L. Initiation strategies for simultaneous control of antiphase domains and stacking faults in GaAs solar cells on Ge. J Vac Sci Technol B, 2016, 34(4), 041203 doi: 10.1116/1.4945659[26] Liao M, Chen S, Park J S, et al. III–V quantum-dot lasers monolithically grown on silicon. Semicond Sci Technol, 2018, 33(12), 123002 doi: 10.1088/1361-6641/aae6a5[27] Brammertz G, Mols Y, Degroote S, et al. Low-temperature photoluminescence study of thin epitaxial GaAs films on Ge substrates. J Appl Phys, 2006, 99(9), 093514 doi: 10.1063/1.2194111[28] Alcotte R, Martin M, Moeyaert J, et al. Epitaxial growth of antiphase boundary free GaAs layer on 300 mm Si (001) substrate by metalorganic chemical vapour deposition with high mobility. Appl Mater, 2016, 4(4), 046101 doi: 10.1063/1.4945586[29] Akiyama M, Kawarada Y, Kaminishi K. Growth of single domain GaAs layer on (100)-oriented Si substrate by MOCVD. Jpn J Appl Phys, 1984, 23(11A), L843 doi: DOI:10.7567/SSDM.1983.B-6-3[30] Chadi D J. Stabilities of single-layer and bilayer steps on Si (001) surfaces. Phys Rev Lett, 1987, 59(15), 1691 doi: 10.1103/PhysRevLett.59.1691[31] Wang T, Liu H, Lee A, et al. 1.3-μm InAs/GaAs quantum-dot lasers monolithically grown on Si substrates. Opt Express, 2011, 19(12), 11381 doi: 10.1364/OE.19.011381[32] Lee A, Jiang Q, Tang M, et al. Continuous-wave InAs/GaAs quantum-dot laser diodes monolithically grown on Si substrate with low threshold current densities. Opt Express, 2012, 20(20), 22181 doi: 10.1364/OE.20.022181[33] Liao M, Chen S, Huo S, et al. Monolithically integrated electrically pumped continuous-wave III–V quantum dot light sources on silicon. IEEE J Sel Top Quantum Electron, 2017, 23(6), 1 doi: 10.1109/JSTQE.2017.2693025[34] Chen S, Liao M, Tang M, et al. Electrically pumped continuous-wave 1.3 μm InAs/GaAs quantum dot lasers monolithically grown on on-axis Si (001) substrates. Opt Express, 2017, 25(5), 4632 doi: 10.1364/OE.25.004632[35] Norman J, Kennedy M J, Selvidge J, et al. Electrically pumped continuous wave quantum dot lasers epitaxially grown on patterned, on-axis (001) Si. Opt Express, 2017, 25(4), 3927 doi: 10.1364/OE.25.003927[36] Volz K, Beyer A, Witte W, et al. GaP-nucleation on exact Si (001) substrates for III/V device integration. J Cryst Growth, 2011, 315(1), 37 doi: 10.1016/j.jcrysgro.2010.10.036[37] Liu A Y, Peters J, Huang X, et al. Electrically pumped continuous-wave 1.3 μm quantum-dot lasers epitaxially grown on on-axis (001) GaP/Si. Opt Lett, 2017, 42(2), 338 doi: 10.1364/OL.42.000338[38] Jung D, Zhang Z, Norman J, et al. Highly reliable low-threshold InAs quantum dot lasers on on-axis (001) Si with 87% injection efficiency. ACS Photonics, 2017, 5(3), 1094 doi: 10.1021/acsphotonics.7b01387[39] Kwoen J, Jang B, Lee J, et al. All MBE grown InAs/GaAs quantum dot lasers on on-axis Si (001). Opt Express, 2018, 26(9), 11568 doi: 10.1364/OE.26.011568[40] Yang V K, Groenert M, Leitz C W, et al. Crack formation in GaAs heteroepitaxial films on Si and SiGe virtual substrates. J Appl Phys, 2003, 93(7), 3859 doi: 10.1063/1.1558963[41] Wei W Q, Wang J H, Gong Y, et al. C/L-band emission of InAs QDs monolithically grown on Ge substrate. Opt Mater Express, 2017, 7(8), 2955 doi: 10.1364/OME.7.002955[42] Wei W Q, Wang J H, Zhang B, et al. InAs QDs on (111)-faceted Si (001) hollow substrates with strong emission at 1300 nm and 1550 nm. Appl Phys Lett, 2018, 113(5), 053107 doi: 10.1063/1.5043169[43] Feng Q, Wei W, Zhang B, et al. O-band and C/L-band III–V quantum dot lasers monolithically grown on Ge and Si substrate. Appl Sci, 2019, 9(3), 385 doi: 10.3390/app9030385[44] Liu H, Wang T, Jiang Q, et al. Long-wavelength InAs/GaAs quantum-dot laser diode monolithically grown on Ge substrate. Nat Photonics, 2011, 5(7), 416 doi: 10.1038/nphoton.2011.120[45] Kaspar P, Brenot R, Le Liepvre A, et al. Packaged hybrid III–V/silicon SOA. The European Conference on Optical Communication (ECOC), 2014, 1[46] Ledentsov N N, Kovsh A R, Zhukov A E, et al. High performance quantum dot lasers on GaAs substrates operating in 1.5 μm range. Electron Lett, 2003, 39(15), 1126 doi: 10.1049/el:20030753[47] Wang T, Lee A, Tutu F, et al. The effect of growth temperature of GaAs nucleation layer on InAs/GaAs quantum dots monolithically grown on Ge substrates. Appl Phys Lett, 2012, 100(5), 052113 doi: 10.1063/1.3682314[48] Lee A, Liu H, Seeds A. Semiconductor III–V lasers monolithically grown on Si substrates. Semicond Sci Technol, 2012, 28(1), 015027 doi: 10.1088/0268-1242/28/1/015027[49] Lee A D, Jiang Q, Tang M, et al. InAs/GaAs quantum-dot lasers monolithically grown on Si, Ge, and Ge-on-Si substrates. IEEE J Sel Top Quantum Electron, 2013, 19(4), 1901107 doi: 10.1109/JSTQE.2013.2247979[50] Liu A Y, Zhang C, Norman J, et al. High performance continuous wave 1.3 μm quantum dot lasers on silicon. Appl Phys Lett, 2014, 104(4), 041104 doi: 10.1063/1.4863223[51] Chen S, Li W, Wu J, et al. Electrically pumped continuous-wave III–V quantum dot lasers on silicon. Nat Photonics, 2016, 10(5), 307 doi: 10.1038/nphoton.2016.21[52] Wan Y, Li Q, Geng Y, et al. InAs/GaAs quantum dots on GaAs-on-V-grooved-Si substrate with high optical quality in the 1.3 μm band. Appl Phys Lett, 2015, 107(8), 081106 doi: 10.1063/1.4929441[53] Wan Y, Li Q, Liu A Y, et al. Temperature characteristics of epitaxially grown InAs quantum dot micro-disk lasers on silicon for on-chip light sources. Appl Phys Lett, 2016, 109(1), 011104 doi: 10.1063/1.4955456[54] Li Q, Ng K W, Lau K M. Growing antiphase-domain-free GaAs thin films out of highly ordered planar nanowire arrays on exact (001) silicon. Appl Phys Lett, 2015, 106(7), 072105 doi: 10.1063/1.4913432[55] Shi B, Zhu S, Li Q, et al. Continuous-wave optically pumped 1.55 μm InAs/InAlGaAs quantum dot microdisk lasers epitaxially grown on silicon. ACS Photonics, 2017, 4(2), 204 doi: 10.1021/acsphotonics.6b00731[56] Shi B, Zhu S, Li Q, et al. 1.55 μm room-temperature lasing from subwavelength quantum-dot microdisks directly grown on (001) Si. Appl Phys Lett, 2017, 110(12), 121109 doi: 10.1063/1.4979120[57] Zhu S, Shi B, Wan Y, et al. 1.55 μm band low-threshold, continuous-wave lasing from InAs/InAlGaAs quantum dot microdisks. Opt Lett, 2017, 42(4), 679 doi: 10.1364/OL.42.000679[58] Wan Y, Jung D, Shang C, et al. Low-threshold continuous-wave operation of electrically pumped 1.55 μm InAs quantum dash microring lasers. ACS Photonics, 2018, 6(2), 279 doi: 10.1021/acsphotonics.8b01341[59] Zhang B, Wei W Q, Wang J H, et al. 1310 nm InAs quantum-dot microdisk lasers on SOI by hybrid epitaxy. Opt Express, 2019, 27(14), 19348 doi: 10.1364/OE.27.019348[60] McCall S L, Levi A F J, Slusher R E, et al. Whispering-gallery mode microdisk lasers. Appl Phys Lett, 1992, 60(3), 289 doi: 10.1063/1.106688[61] Wan Y, Li Q, Liu A Y, et al. Optically pumped 1.3 μm room-temperature InAs quantum-dot micro-disk lasers directly grown on (001) silicon. Opt Lett, 2016, 41(7), 1664 doi: 10.1364/OL.41.001664[62] Li Q, Wan Y, Liu A Y, et al. 1.3-μm InAs quantum-dot micro-disk lasers on V-groove patterned and unpatterned (001) silicon. Opt Express, 2016, 24(18), 21038 doi: 10.1364/OE.24.021038[63] Wan Y, Norman J, Li Q, et al. 1.3 μm submilliamp threshold quantum dot micro-lasers on Si. Optia, 2017, 4(8), 940 doi: 10.1364/OPTICA.4.000940[64] Siegman A E. Lasers. University Science Books, Mill Valley, CA, 1986 -

Proportional views

DownLoad:

DownLoad: