| Citation: |

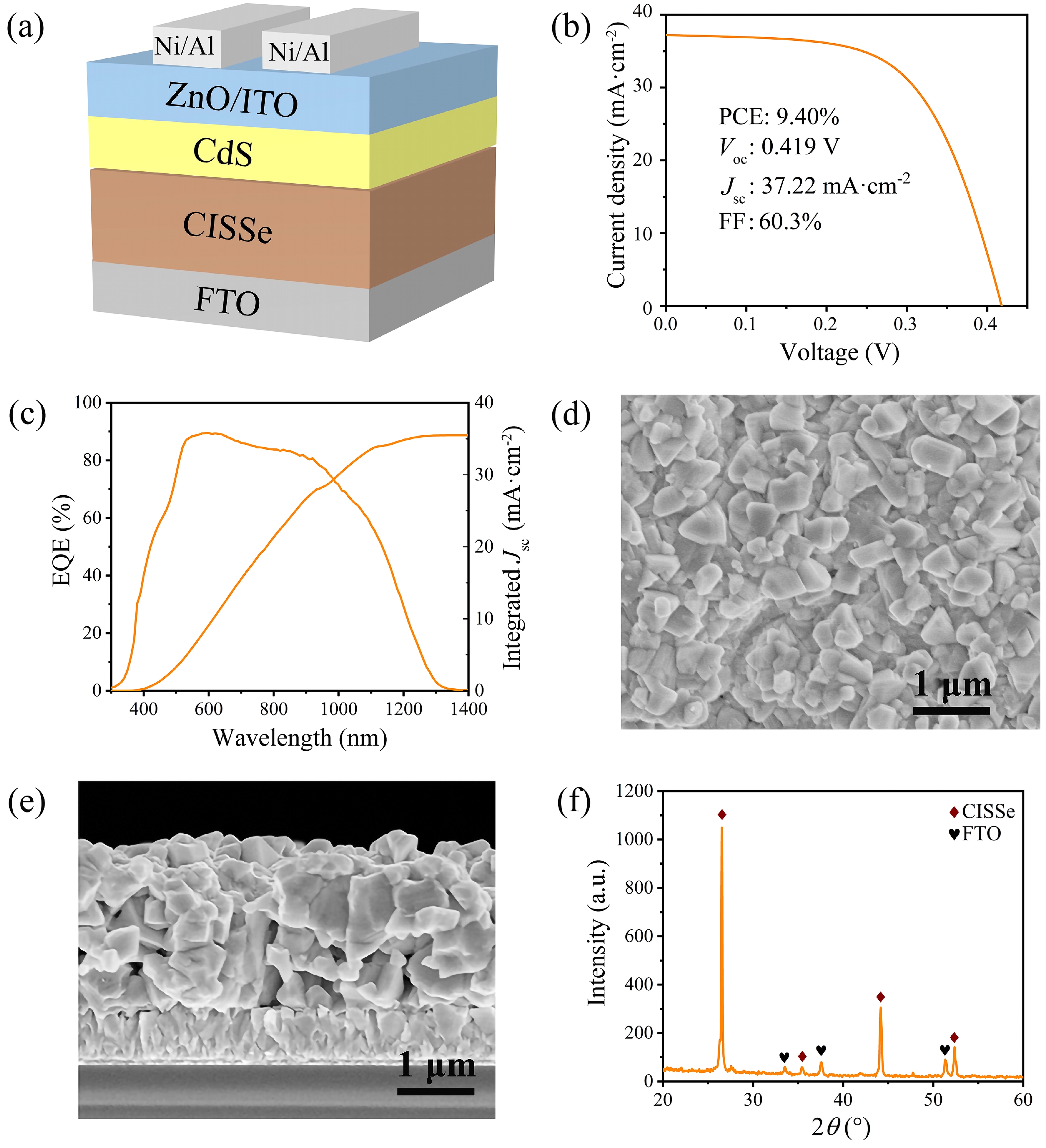

Xinge Liu, Chengfeng Ma, Hao Xin, Liming Ding. Solution-processed CuIn(S,Se)2 solar cells on transparent electrode offering 9.4% efficiency[J]. Journal of Semiconductors, 2023, 44(8): 080501. doi: 10.1088/1674-4926/44/8/080501

****

X G Liu, C F Ma, H Xin, L M Ding. Solution-processed CuIn(S,Se)2 solar cells on transparent electrode offering 9.4% efficiency[J]. J. Semicond, 2023, 44(8): 080501. doi: 10.1088/1674-4926/44/8/080501

|

Solution-processed CuIn(S,Se)2 solar cells on transparent electrode offering 9.4% efficiency

DOI: 10.1088/1674-4926/44/8/080501

More Information

-

References

[1] Suresh S, Uhl A R. Present status of solution-processing routes for Cu(In,Ga)(S,Se)2 solar cell absorbers. Adv Energy Mater, 2021, 11(14), 2003743 doi: 10.1002/aenm.202003743[2] Nakamura M, Yamaguchi K, Kimoto Y, et al. Cd-free Cu(In,Ga)(Se,S)2 thin-film solar cell with record efficiency of 23.35%. IEEE J Photovolt, 2019, 9(6), 1863 doi: 10.1109/JPHOTOV.2019.2937218[3] Ramanujam J, Singh U P. Copper indium gallium selenide based solar cells–a review. Energy Environ Sci, 2017, 10, 1306 doi: 10.1039/C7EE00826K[4] Repins I, Contreras M A, Egaas B, et al. 19.9%-efficient ZnO/CdS/CuInGaSe2 solar cell with 81.2% fill factor. Prog Photovolt Res Appl, 2008, 16, 235 doi: 10.1002/pip.822[5] Chirilă A, Reinhard P, Pianezzi F, et al. Potassium-induced surface modification of Cu(In,Ga)Se2 thin films for high-efficiency solar cells. Nat Mater, 2013, 12, 1107 doi: 10.1038/nmat3789[6] Jiang J J, Giridharagopal R, Jedlicka E, et al. Highly efficient copper-rich chalcopyrite solar cells from DMF molecular solution. Nano Energy, 2020, 69, 104438 doi: 10.1016/j.nanoen.2019.104438[7] Ma C F, Xiang C X, Liu X G, et al. Over 12% efficient CuIn(S,Se)2 solar cell with the absorber fabricated from dimethylformamide solution by doctor-blading in ambient air. Sol RRL, 2022, 6(6), 2200150 doi: 10.1002/solr.202200150[8] Arnou P, van Hest M F A M, Cooper C S, et al. Hydrazine-free solution-deposited CuIn(S,Se)2 solar cells by spray deposition of metal chalcogenides. ACS Appl Mater Interfaces, 2016, 8(19), 11893 doi: 10.1021/acsami.6b01541[9] Lin X Z, Klenk R, Wang L, et al. 11.3% efficiency Cu(In,Ga)(S,Se)2 thin film solar cells via drop-on-demand inkjet printing. Energy Environ Sci, 2016, 9, 2037 doi: 10.1039/C6EE00587J[10] Moon S H, Park S J, Hwang Y J, et al. Printable, wide band-gap chalcopyrite thin films for power generating window applications. Sci Rep, 2014, 4, 4408 doi: 10.1038/srep04408[11] Ben Chu V, Park S J, Park G S, et al. Semi-transparent thin film solar cells by a solution process. Korean J Chem Eng, 2016, 33(3), 880 doi: 10.1007/s11814-015-0200-1[12] Gao Y, Yin G C, Li Y, et al. 8.0% efficient submicron CuIn(S,Se)2 solar cells on Sn: In2O3 back contact via a facile solution process. ACS Appl Energy Mater, 2022, 5(10), 12252 doi: 10.1021/acsaem.2c01764[13] Jiang J J, Yu S T, Gong Y C, et al. 10.3% efficient CuIn(S,Se)2 solar cells from DMF molecular solution with the absorber selenized under high argon pressure. Sol RRL, 2018, 2, 1800044 doi: 10.1002/solr.201800044[14] Zhou Y G, Xiang C X, Dai Q, et al. 11.4% efficiency kesterite solar cells on transparent electrode. Adv Energy Mater, 2023, 13, 2370079 doi: 10.1002/aenm.202370079[15] Yu S T, Li B Y, Jiang J J, et al. Solution-processed chalcopyrite solar cells: The grain growth mechanism and the effects of Cu/In mole ratio. Adv Energy Mater, 2022, 12, 2103644 doi: 10.1002/aenm.202103644[16] Wang Y Z, Lv S S, Li Z C. Review on incorporation of alkali elements and their effects in Cu(In,Ga)Se2 solar cells. J Mater Sci Technol, 2022, 96(10), 179 doi: 10.1016/j.jmst.2020.07.050[17] Witte W, Abou-Ras D, Albe K, et al. Gallium gradients in Cu(In,Ga)Se2 thin-film solar cells. Prog Photovolt Res Appl, 2015, 23(6), 717 doi: 10.1002/pip.2485 -

Supplements

23050025SI.pdf

23050025SI.pdf

-

Proportional views

Supplementary materials to this article can be found on-line at https://doi.org/1674-4926/44/8/080501.

§Xinge Liu and Chengfeng Ma contributed equally to this work and should be considered as co-first authors.

§Xinge Liu and Chengfeng Ma contributed equally to this work and should be considered as co-first authors.

DownLoad:

DownLoad: