| Citation: |

Guang Yang, Lingbo Xu, Can Cui, Xiaodong Pi, Deren Yang, Rong Wang. Anisotropic etching mechanisms of 4H-SiC: Experimental and first-principles insights[J]. Journal of Semiconductors, 2024, 45(1): 012502. doi: 10.1088/1674-4926/45/1/012502

G Yang, L B Xu, C Cui, X D Pi, D R Yang, R Wang. Anisotropic etching mechanisms of 4H-SiC: Experimental and first-principles insights[J]. J. Semicond, 2024, 45(1): 012502. doi: 10.1088/1674-4926/45/1/012502

Export: BibTex EndNote

|

Anisotropic etching mechanisms of 4H-SiC: Experimental and first-principles insights

doi: 10.1088/1674-4926/45/1/012502

More Information-

Abstract

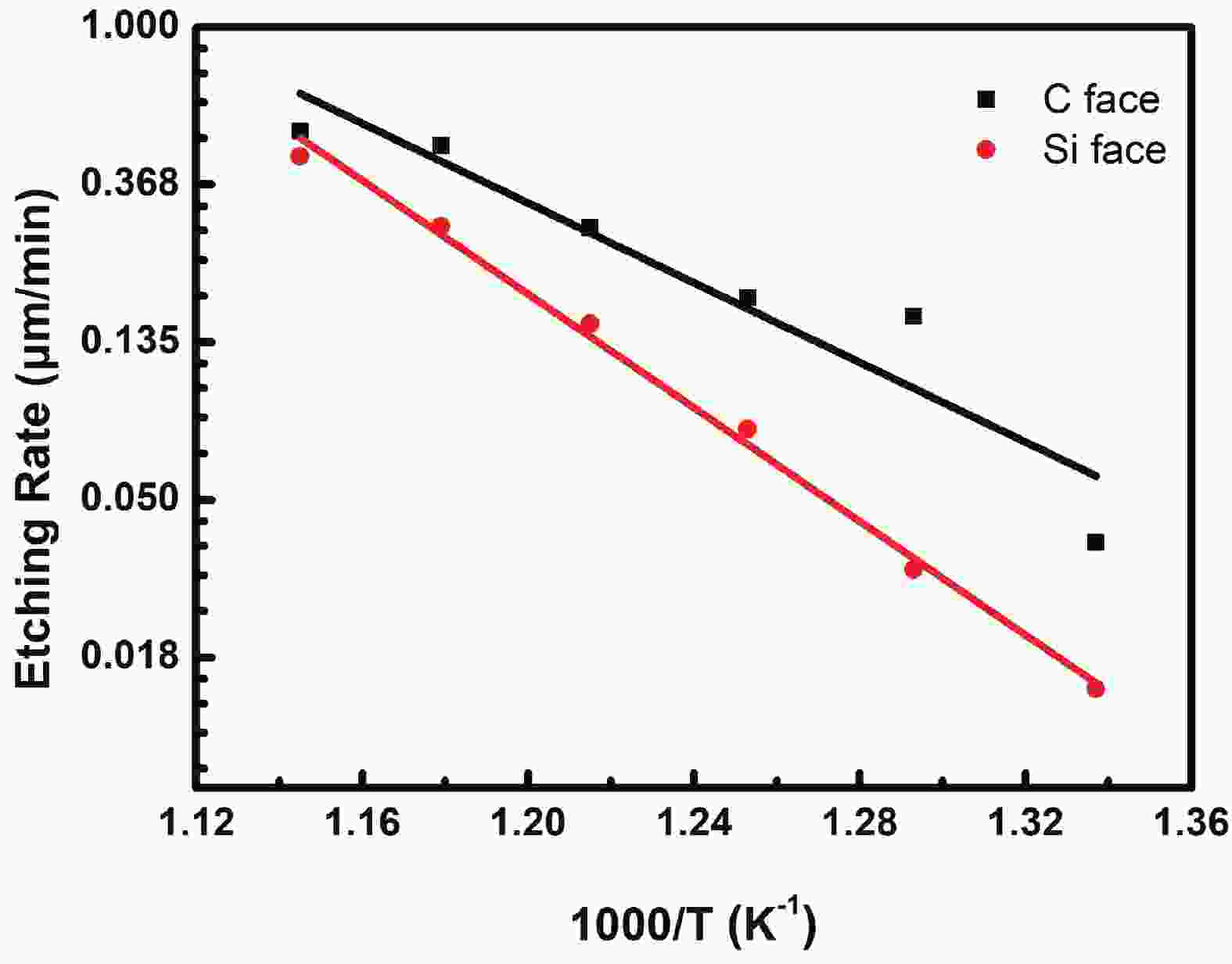

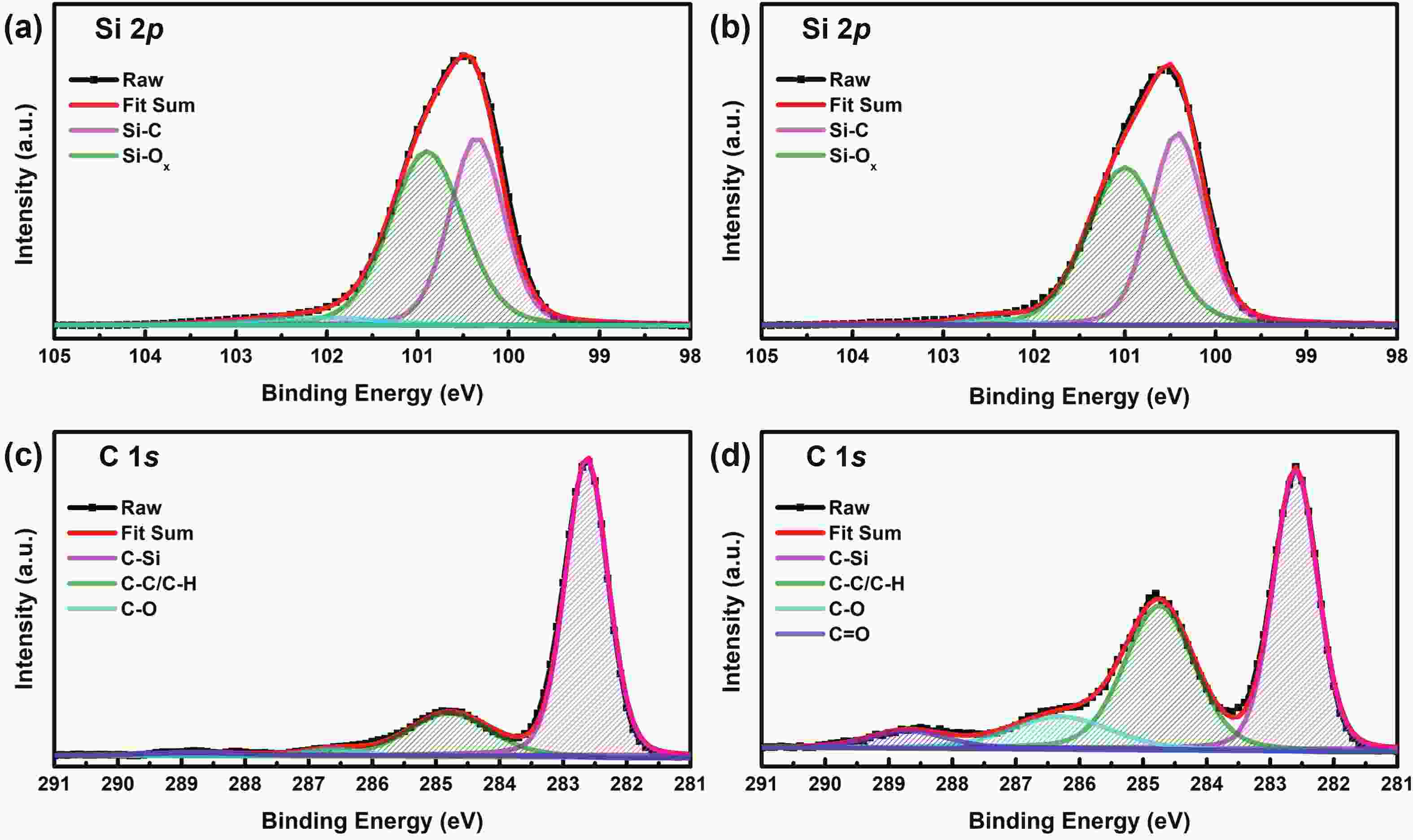

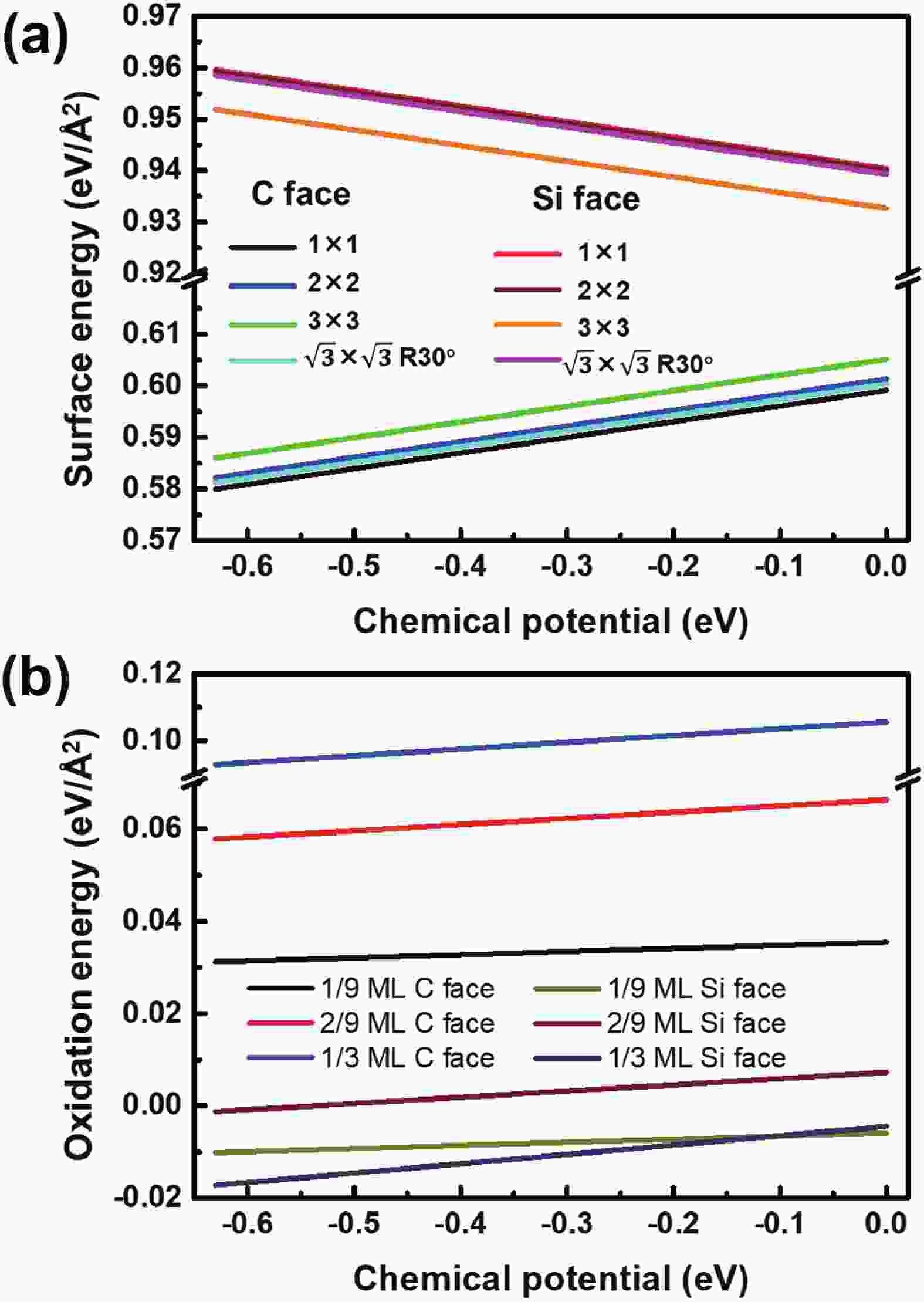

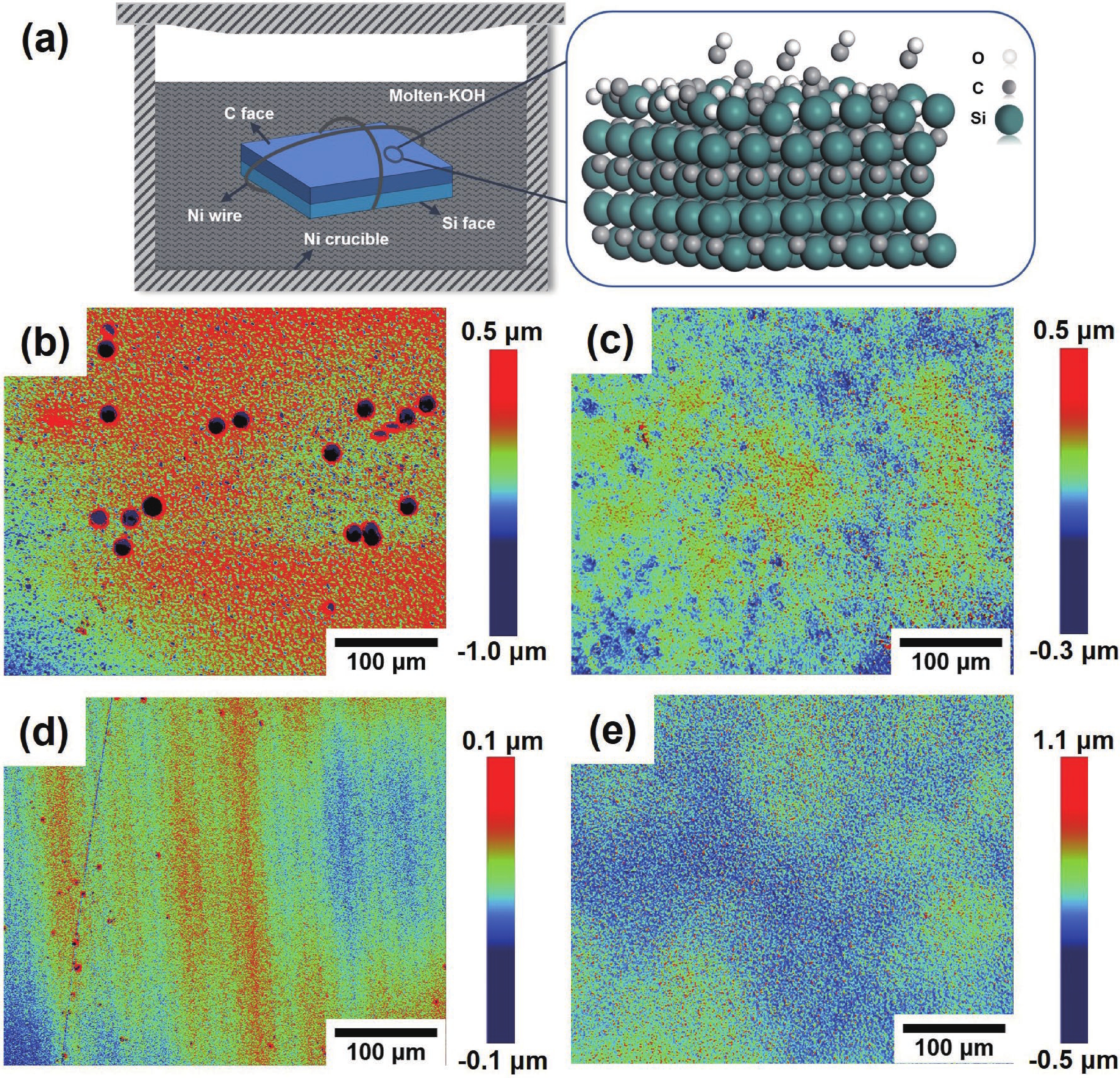

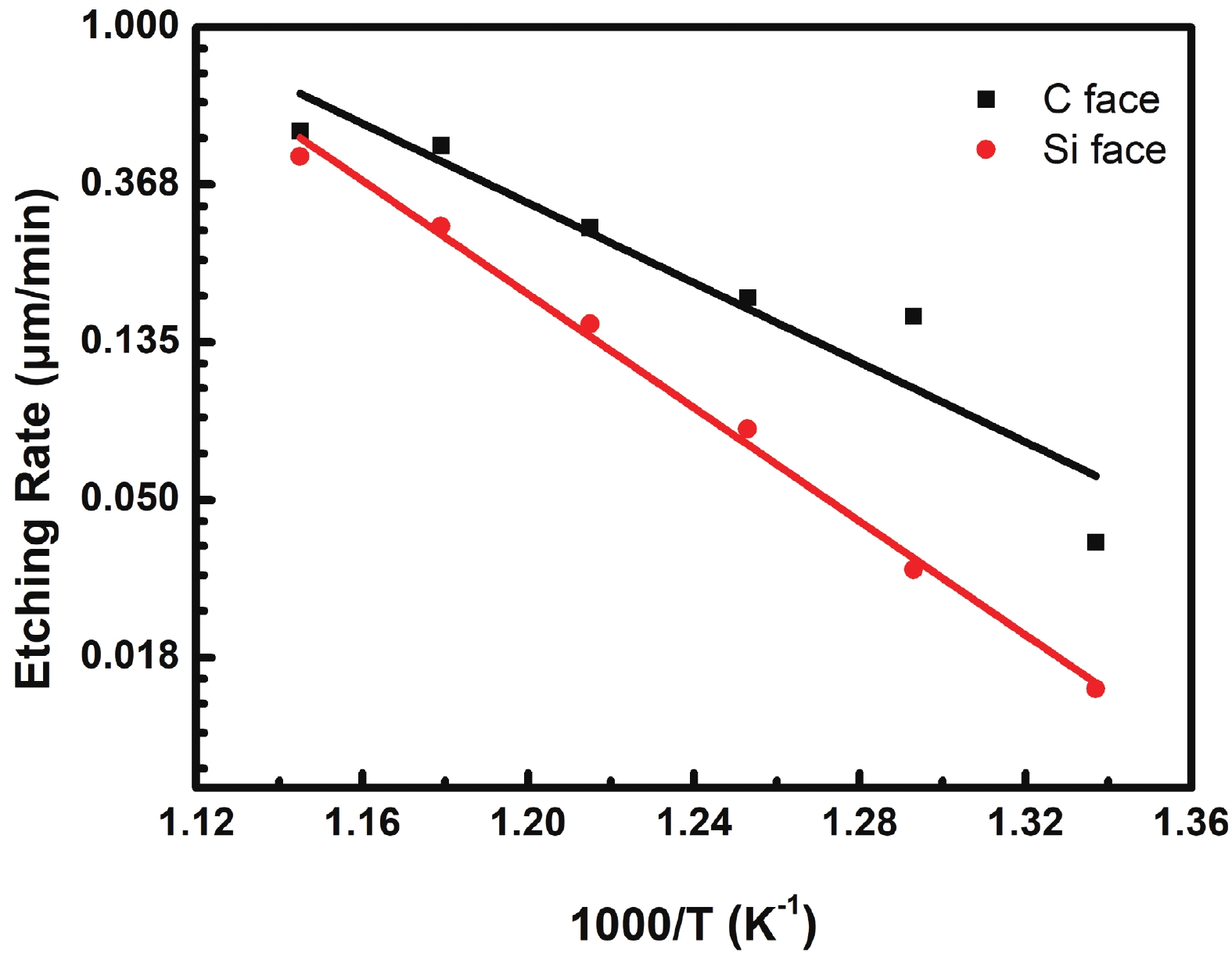

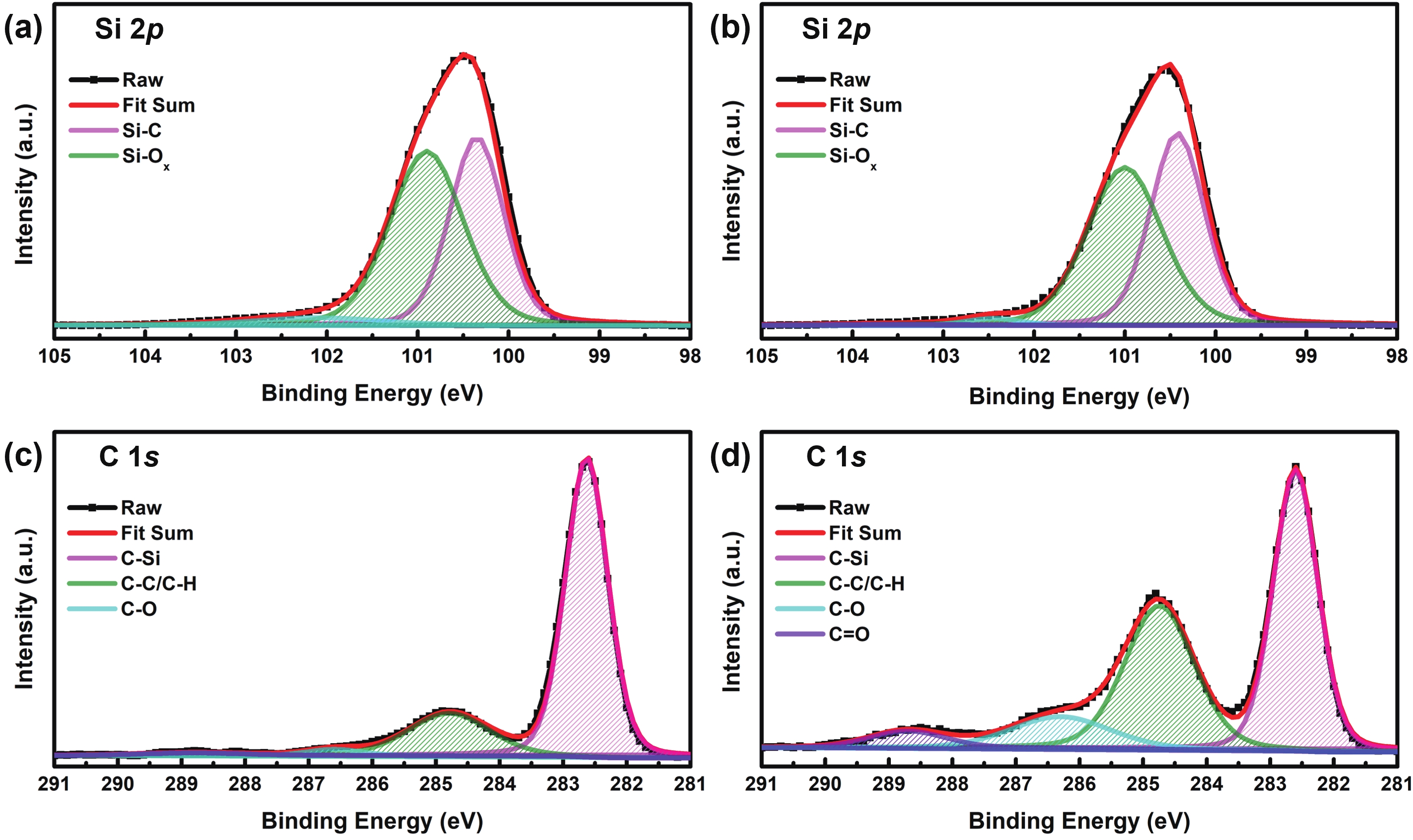

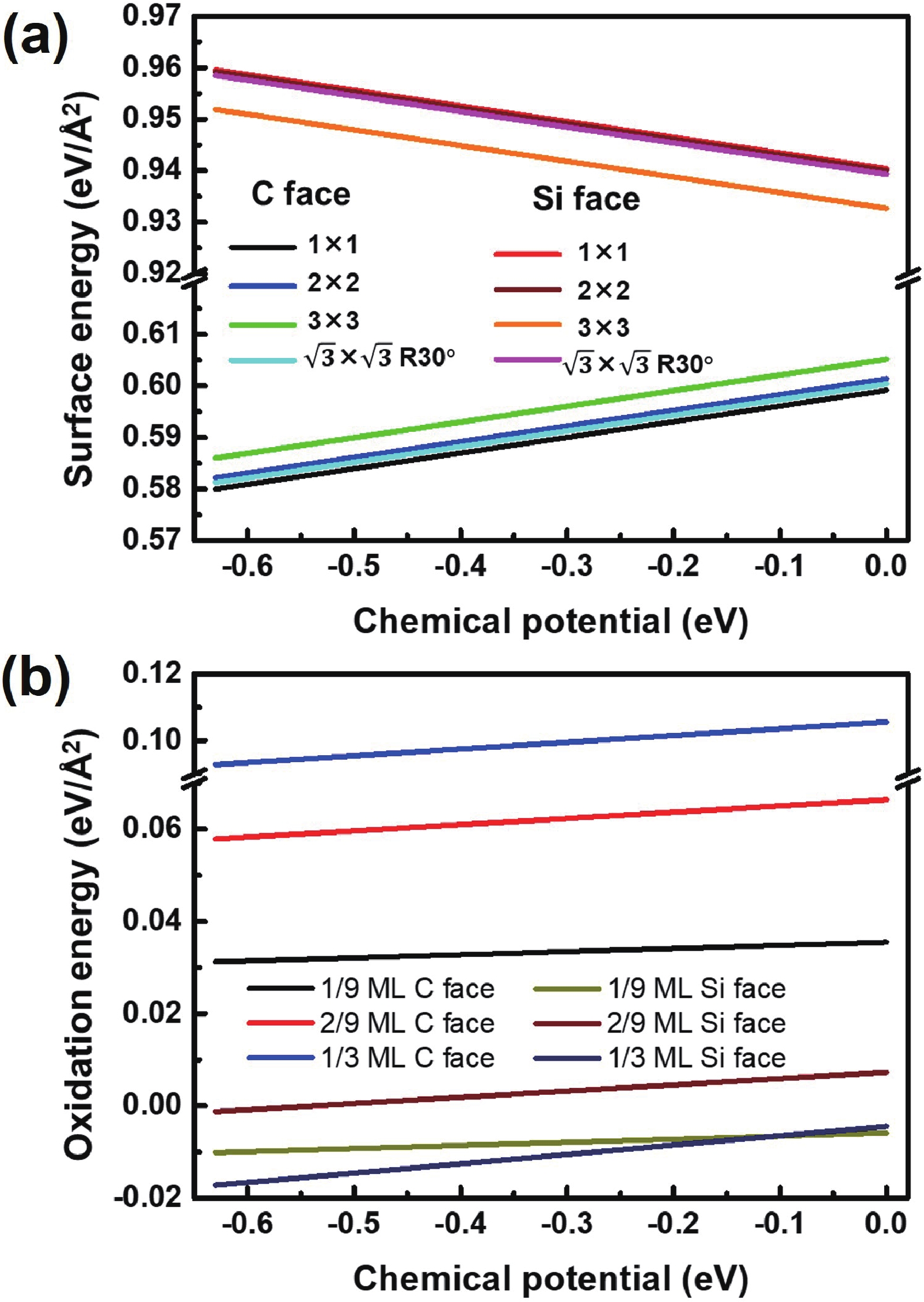

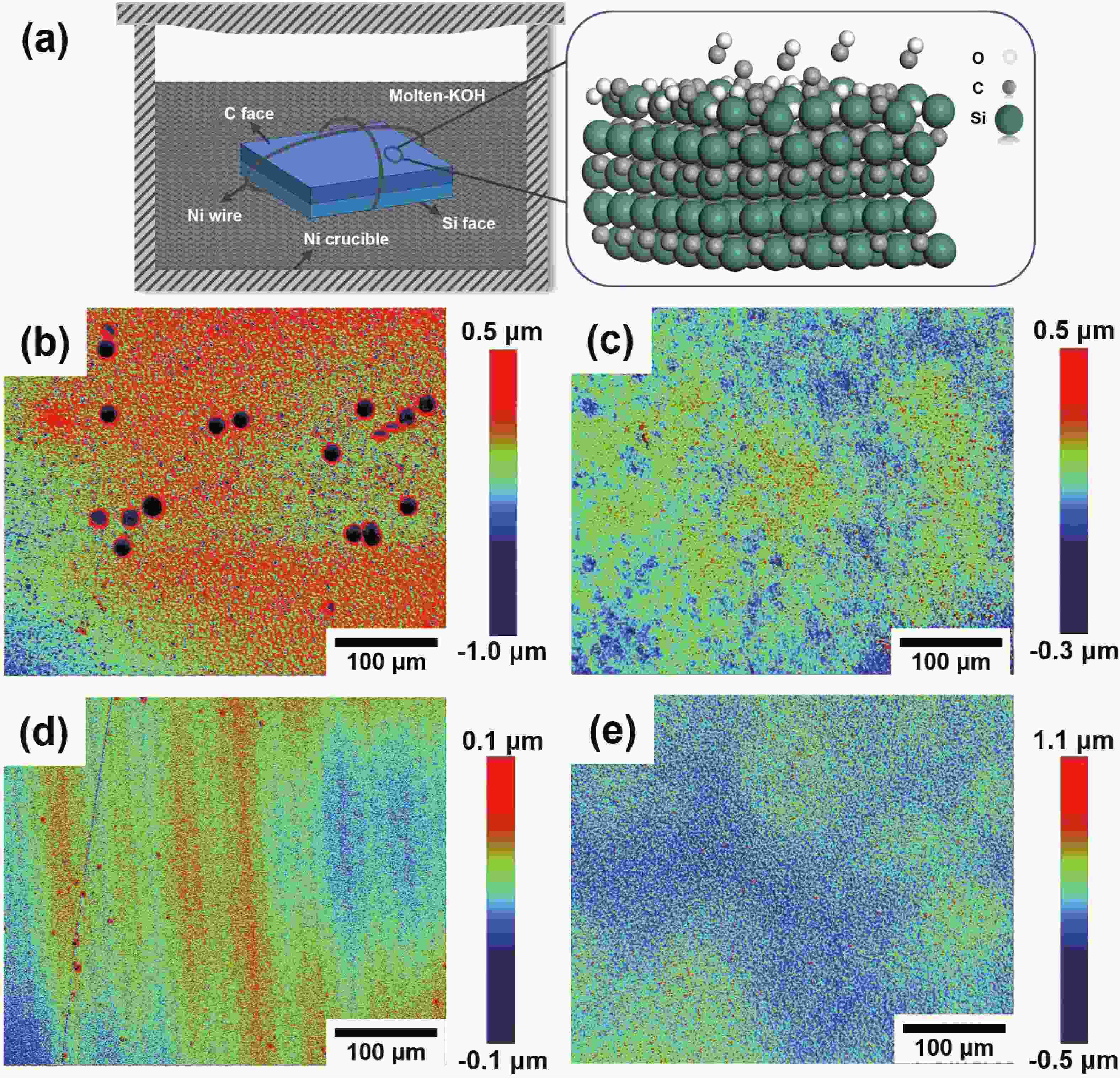

Molten-alkali etching has been widely used to reveal dislocations in 4H silicon carbide (4H-SiC), which has promoted the identification and statistics of dislocation density in 4H-SiC single crystals. However, the etching mechanism of 4H-SiC is limited misunderstood. In this letter, we reveal the anisotropic etching mechanism of the Si face and C face of 4H-SiC by combining molten-KOH etching, X-ray photoelectron spectroscopy (XPS) and first-principles investigations. The activation energies for the molten-KOH etching of the C face and Si face of 4H-SiC are calculated to be 25.09 and 35.75 kcal/mol, respectively. The molten-KOH etching rate of the C face is higher than the Si face. Combining XPS analysis and first-principles calculations, we find that the molten-KOH etching of 4H-SiC is proceeded by the cycling of the oxidation of 4H-SiC by the dissolved oxygen and the removal of oxides by molten KOH. The faster etching rate of the C face is caused by the fact that the oxides on the C face are unstable, and easier to be removed with molten alkali, rather than the C face being easier to be oxidized. -

References

[1] Itoh A, Matsunami H. Single crystal growth of SiC and electronic devices. Crit Rev Solid State Mater Sci, 1997, 22, 111 doi: 10.1080/10408439708241260[2] Li J J, Yang G, Liu X S, et al. Dislocations in 4H silicon carbide. J Phys D:Appl Phys, 2022, 55, 463001 doi: 10.1088/1361-6463/ac8a58[3] Yang S, Liang X W, Cui J W, et al. Impact of switching frequencies on the TID response of SiC power MOSFETs. J Semicond, 2021, 42, 082802 doi: 10.1088/1674-4926/42/8/082802[4] Lebedev A A, Oganesyan G A, Kozlovski V V, et al. Radiation defects in heterostructures 3C-SiC/4H-SiC. Crystals, 2019, 9, 115 doi: 10.3390/cryst9020115[5] Casady J B, Johnson R W. Status of silicon carbide (SiC) as a wide-bandgap semiconductor for high-temperature applications: A review. Solid State Electron, 1996, 39, 1409 doi: 10.1016/0038-1101(96)00045-7[6] Kimoto T, Watanabe H. Defect engineering in SiC technology for high-voltage power devices. Appl Phys Express, 2020, 13, 120101 doi: 10.35848/1882-0786/abc787[7] Grekov A, Zhang Q C, Fatima H, et al. Effect of crystallographic defects on the reverse performance of 4H–SiC JBS diodes. Microelectron Reliab, 2008, 48, 1664 doi: 10.1016/j.microrel.2008.05.001[8] Gao W D, Yang G, Qian Y X, et al. Dislocation-related leakage-current paths of 4H silicon carbide. Front Mater, 2023, 10, 1022878 doi: 10.3389/fmats.2023.1022878[9] Skowronski M. Degradation of hexagonal silicon carbide-based bipolar devices. 2005 International Semiconductor Device Research Symposium, 2006, 138 doi: 10.1063/1.2159578[10] Song H Z, Sudarshan T S. Basal plane dislocation conversion near the epilayer/substrate interface in epitaxial growth of 4° off-axis 4H–SiC. J Cryst Growth, 2013, 371, 94 doi: 10.1016/j.jcrysgro.2013.02.011[11] Yang G, Luo H, Li J J, et al. Discrimination of dislocations in 4H-SiC by inclination angles of molten-alkali etched pits. J Semicond, 2022, 43, 122801 doi: 10.1088/1674-4926/43/12/122801[12] Luo H, Li J J, Yang G, et al. Electronic and optical properties of threading dislocations in n-type 4H-SiC. ACS Appl Electron Mater, 2022, 4, 1678 doi: 10.1021/acsaelm.1c01330[13] Yu J Y, Yang X L, Peng Y, et al. Revelation of the dislocations in the C-face of 4H-SiC substrates using a microwave plasma etching treatment. CrystEngComm, 2021, 23, 353 doi: 10.1039/D0CE01489C[14] Yao Y Z, Ishikawa Y, Sato K, et al. Dislocation revelation from (0001) carbon-face of 4H-SiC by using vaporized KOH at high temperature. Appl Phys Express, 2012, 5, 075601 doi: 10.1143/APEX.5.075601[15] Syväjärvi M, Yakimova R, Janzén E. Anisotropic etching of SiC. J Electrochem Soc, 2000, 147, 3519 doi: 10.1149/1.1393930[16] Katsuno M, Ohtani N, Takahashi J, et al. Mechanism of molten KOH etching of SiC single crystals: Comparative study with thermal oxidation. Jpn J Appl Phys, 1999, 38, 4661 doi: 10.1143/JJAP.38.4661[17] Hatayama T, Shimizu T, Yano H, et al. Anisotropic etching of SiC in the mixed gas of chlorine and oxygen. Mater Sci Forum, 2008, 600/601/602/603, 659 doi: 10.4028/www.scientific.net/MSF.600-603.659[18] Segovia J J, Lozano-Martín D, Martín M C, et al. Updated determination of the molar gas constant Rby acoustic measurements in argon at UVa-CEM. Metrologia, 2017, 54, 663 doi: 10.1088/1681-7575/aa7c47[19] Fukunaga K, Jun S D, Kimoto T. Anisotropic etching of single crystalline SiC using molten KOH for SiC bulk micromachining. Proceedings of SPIE - The International Society for Optical Engineering, San Jose, CA, US, 2006, 6109, 6109 doi: 10.1117/12.647116[20] Tengeler S, Kaiser B, Chaussende D, et al. (001) 3C SiC/Ni contact interface: in situ XPS observation of annealing induced Ni2Si formation and the resulting barrier height changes. Appl Surf Sci, 2017, 400, 6 doi: 10.1016/j.apsusc.2016.12.136[21] Wang B J, Yin J H, Chen D H, et al. Optical and surface properties of 3C–SiC thin epitaxial films grown at different temperatures on 4H–SiC substrates. Superlattices Microstruct, 2021, 156, 106960 doi: 10.1016/j.spmi.2021.106960[22] Wee A T S, Feng Z C, Hng H H, et al. Surface chemical states on 3C-SiC/Si epilayers. Appl Surf Sci, 1994, 81, 377 doi: 10.1016/0169-4332(94)90041-8[23] Cui Y X, Hu X B, Xie X J, et al. Threading dislocation classification for 4H-SiC substrates using the KOH etching method. CrystEngComm, 2018, 20, 978 doi: 10.1039/C7CE01855J[24] Kresse G, Furthmüller J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys Rev B Condens Matter, 1996, 54, 11169 doi: 10.1103/PhysRevB.54.11169[25] Kresse G, Furthmüller J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comput Mater Sci, 1996, 6, 15 doi: 10.1016/0927-0256(96)00008-0[26] Blöchl P E. Projector augmented-wave method. Phys Rev B Condens Matter, 1994, 50, 17953 doi: 10.1103/PhysRevB.50.17953[27] Perdew J P, Burke K, Ernzerhof M. Generalized gradient approximation made simple. Phys Rev Lett, 1996, 77, 3865 doi: 10.1103/PhysRevLett.77.3865[28] Heyd J, Scuseria G E, Ernzerhof M. Hybrid functionals based on a screened Coulomb potential. J Chem Phys, 2003, 118, 8207 doi: 10.1063/1.1564060[29] Zhang J Z, Zhang Y O, Tse K, et al. New approaches for calculating absolute surface energies of wurtzite (0001)/ $ (000\bar{1}) $: A study of ZnO and GaN. J Appl Phys, 2016, 119, 205302 doi: 10.1063/1.4952395[30] Zhang Y O, Zhang J Z, Tse K, et al. Pseudo-hydrogen passivation: A novel way to calculate absolute surface energy of zinc blende (111)/ $ (\bar{1}\bar{1}\bar{1}) $ surface. Sci Rep, 2016, 6, 20055 doi: 10.1038/srep20055[31] Li W B, Zhao J J, Zhu Q Z, et al. Insight into the initial oxidation of 4H-SiC from first-principles thermodynamics. Phys Rev B, 2013, 87, 085320 doi: 10.1103/PhysRevB.87.085320 -

Proportional views

DownLoad:

DownLoad: