| Citation: |

Li Liu, Lei Tang, Huaping Jiang, Fanyi Wei, Zonghua Li, Changhong Du, Qianlei Peng, Guocheng Lu. Reliability evaluation of IGBT power module on electric vehicle using big data[J]. Journal of Semiconductors, 2024, 45(5): 052301. doi: 10.1088/1674-4926/45/5/052301

L Liu, L Tang, H P Jiang, F Y Wei, Z H Li, C H Du, Q L Peng, and G C Lu, Reliability evaluation of IGBT power module on electric vehicle using big data[J]. J. Semicond., 2024, 45(5), 052301 doi: 10.1088/1674-4926/45/5/052301

Export: BibTex EndNote

|

Reliability evaluation of IGBT power module on electric vehicle using big data

doi: 10.1088/1674-4926/45/5/052301

More Information-

Abstract

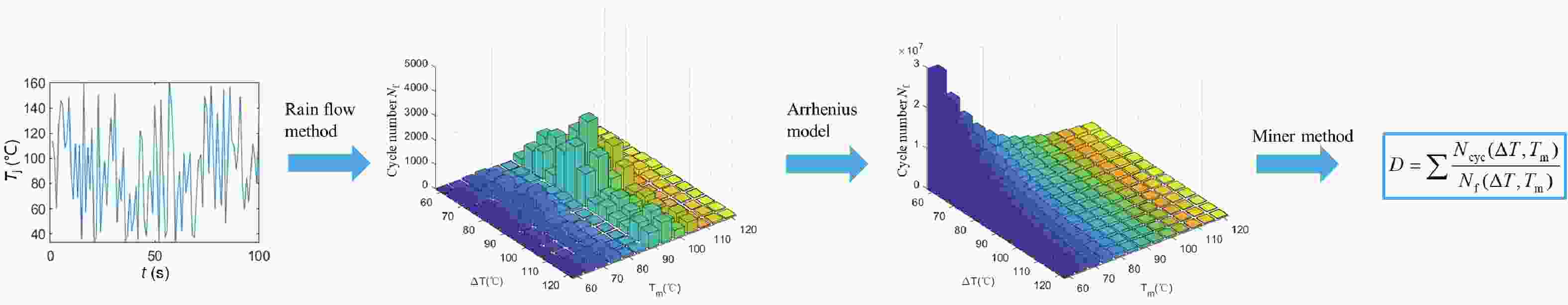

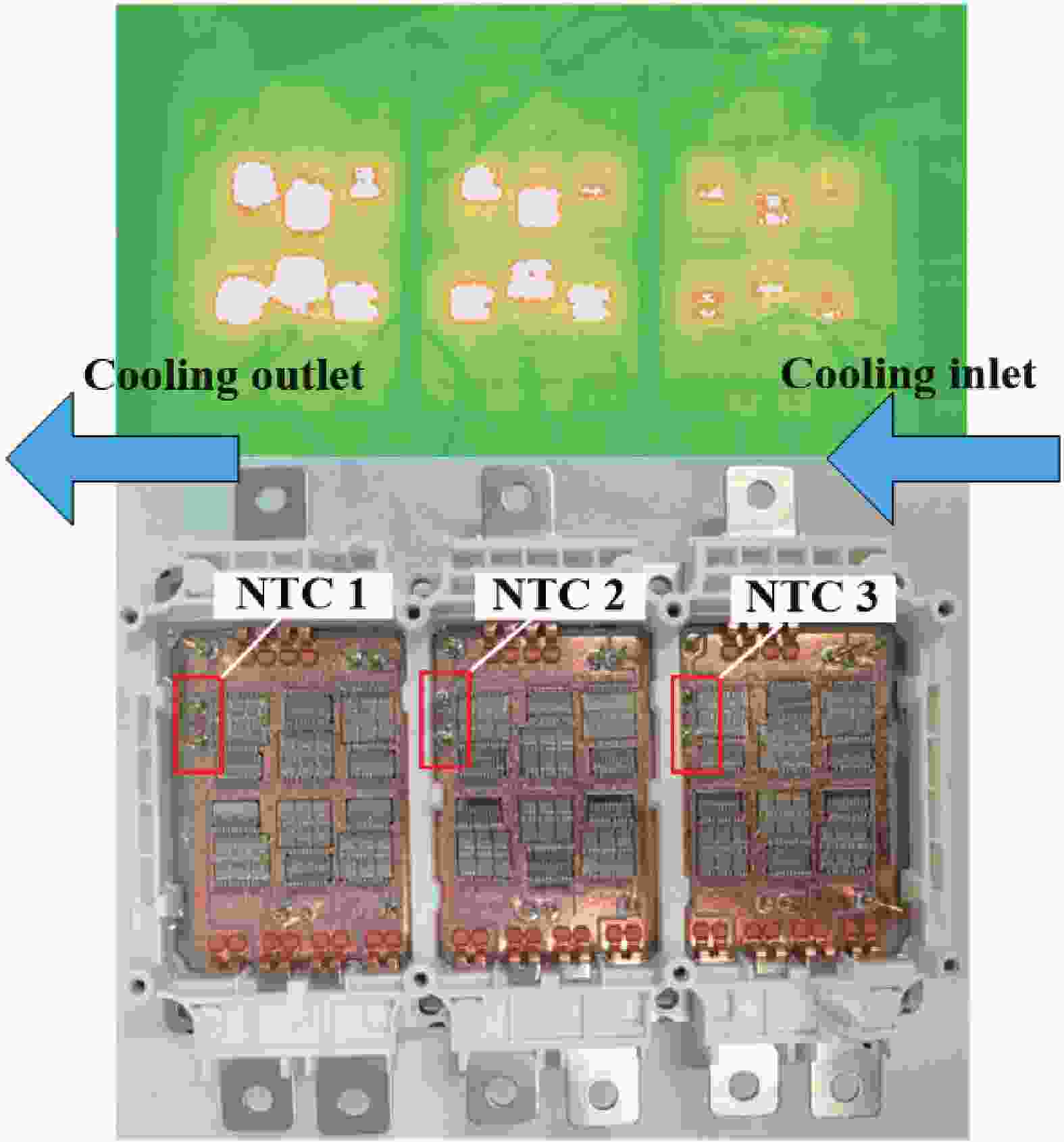

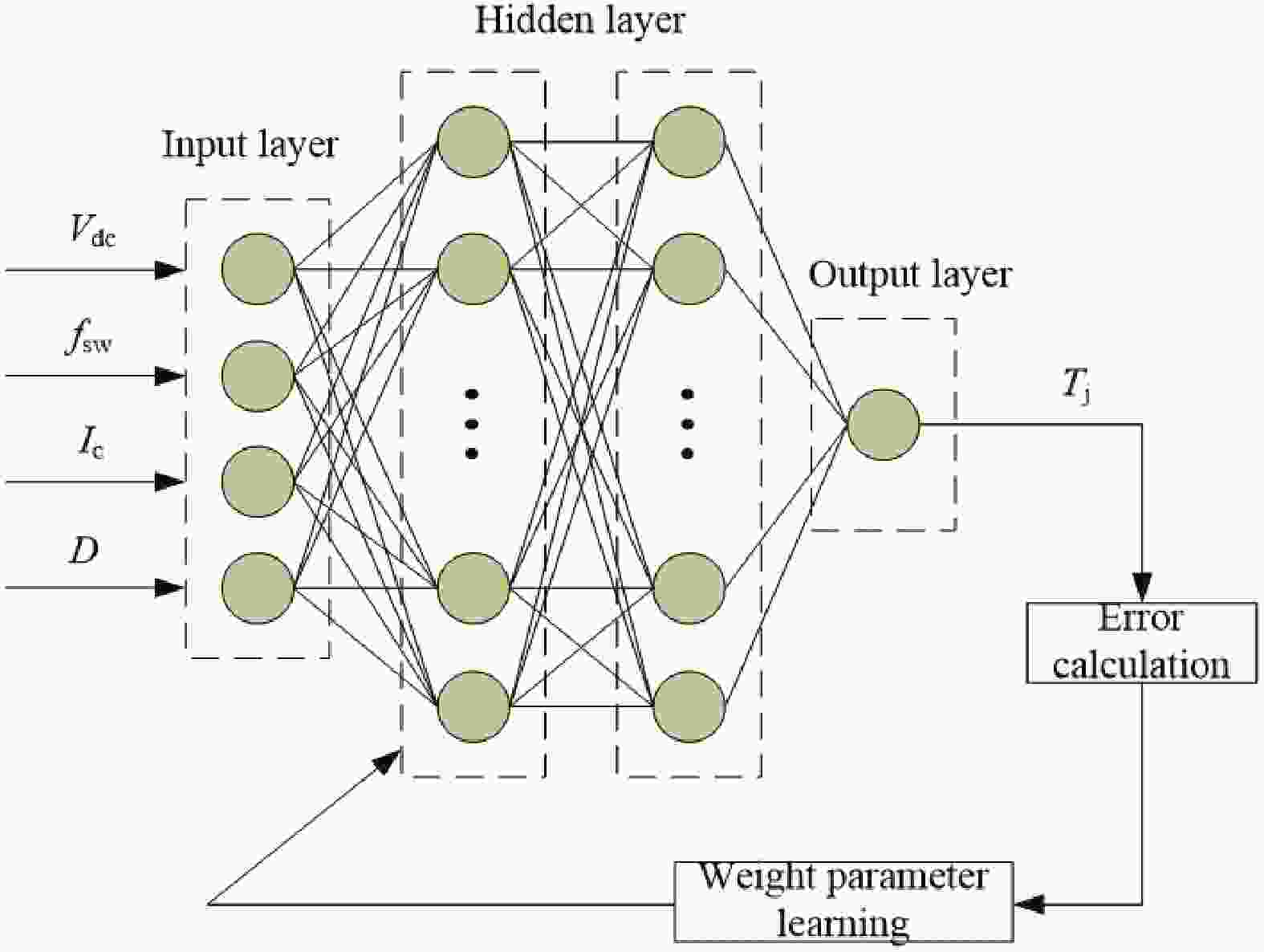

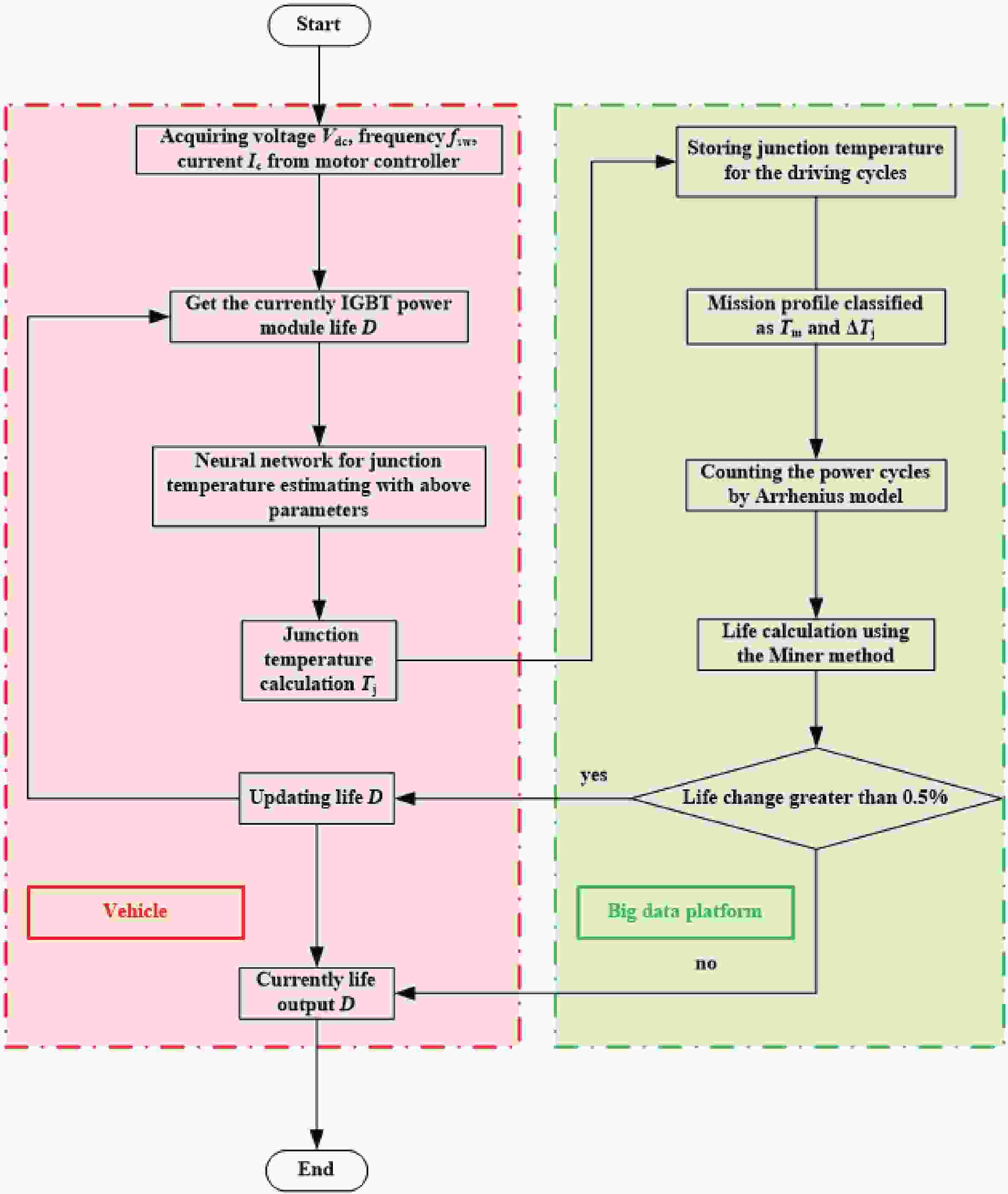

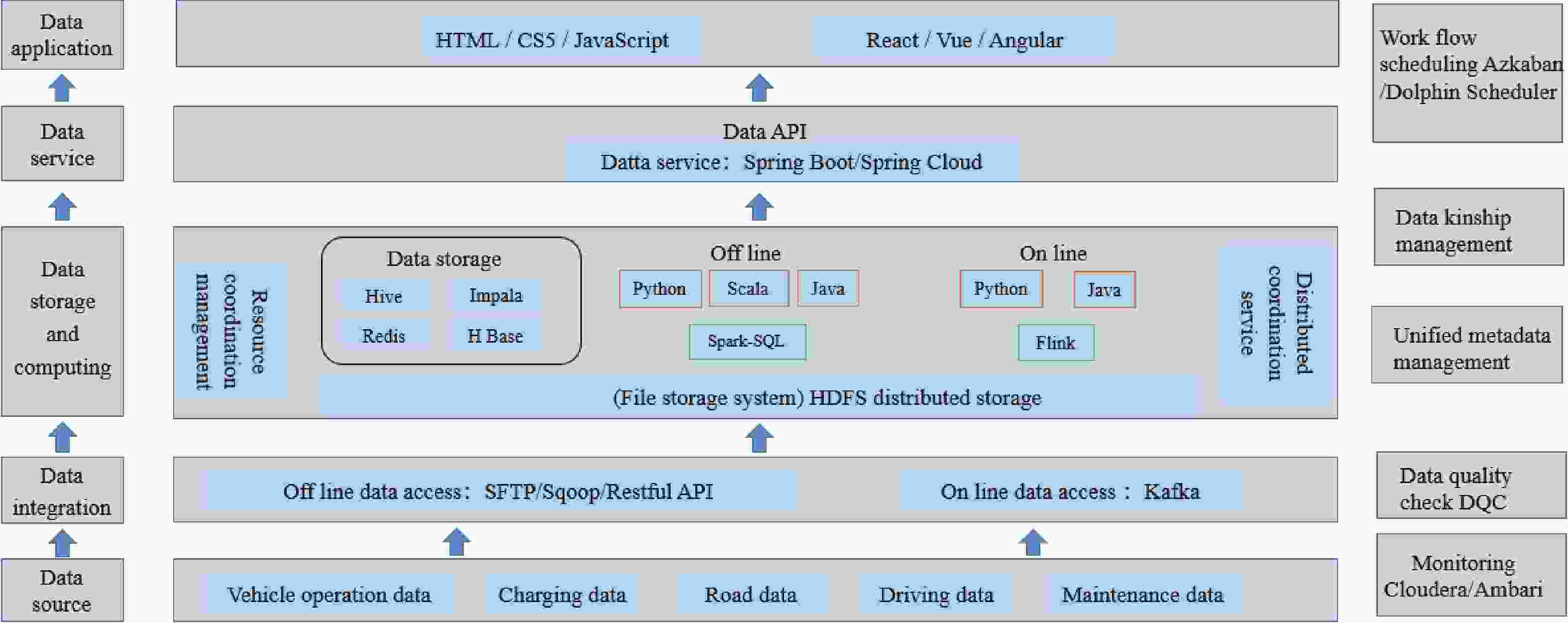

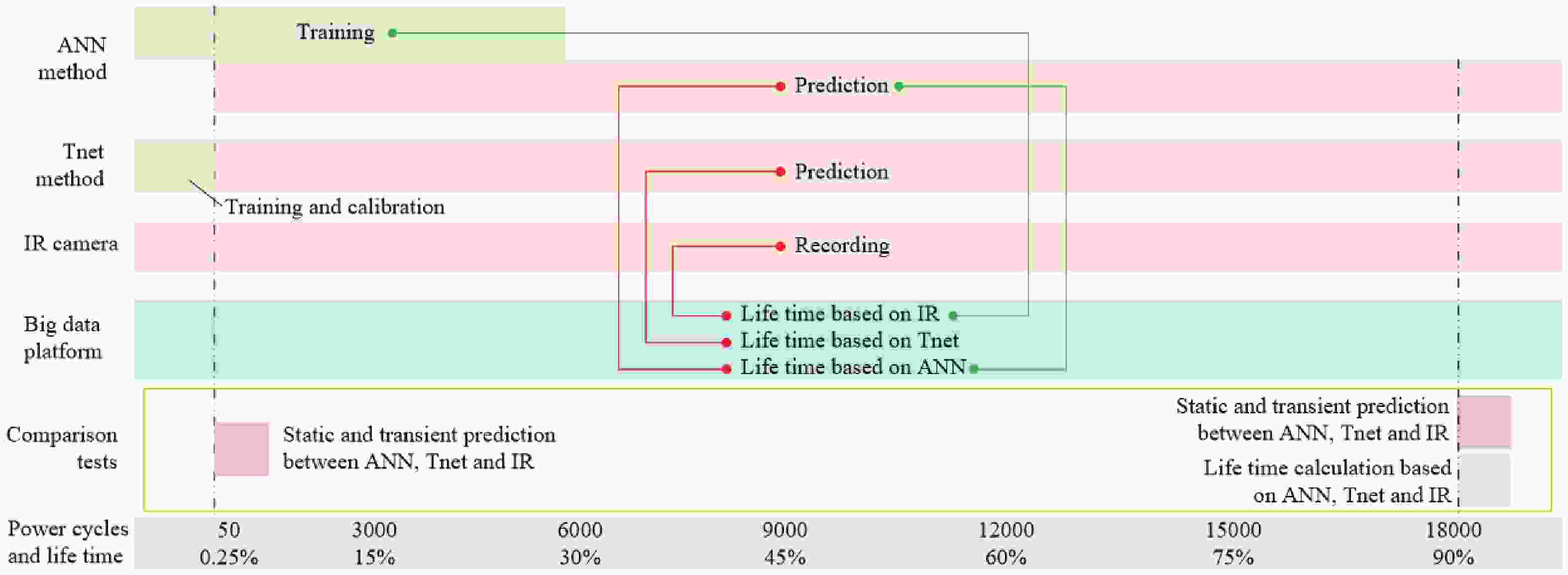

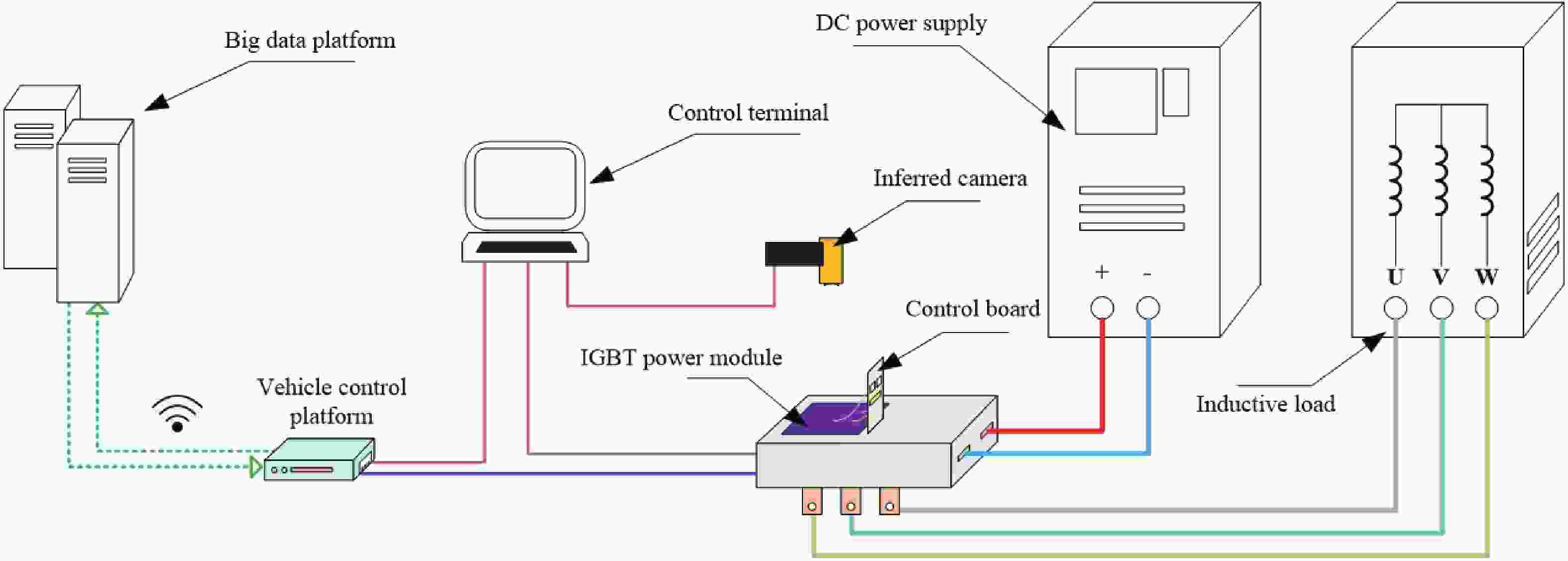

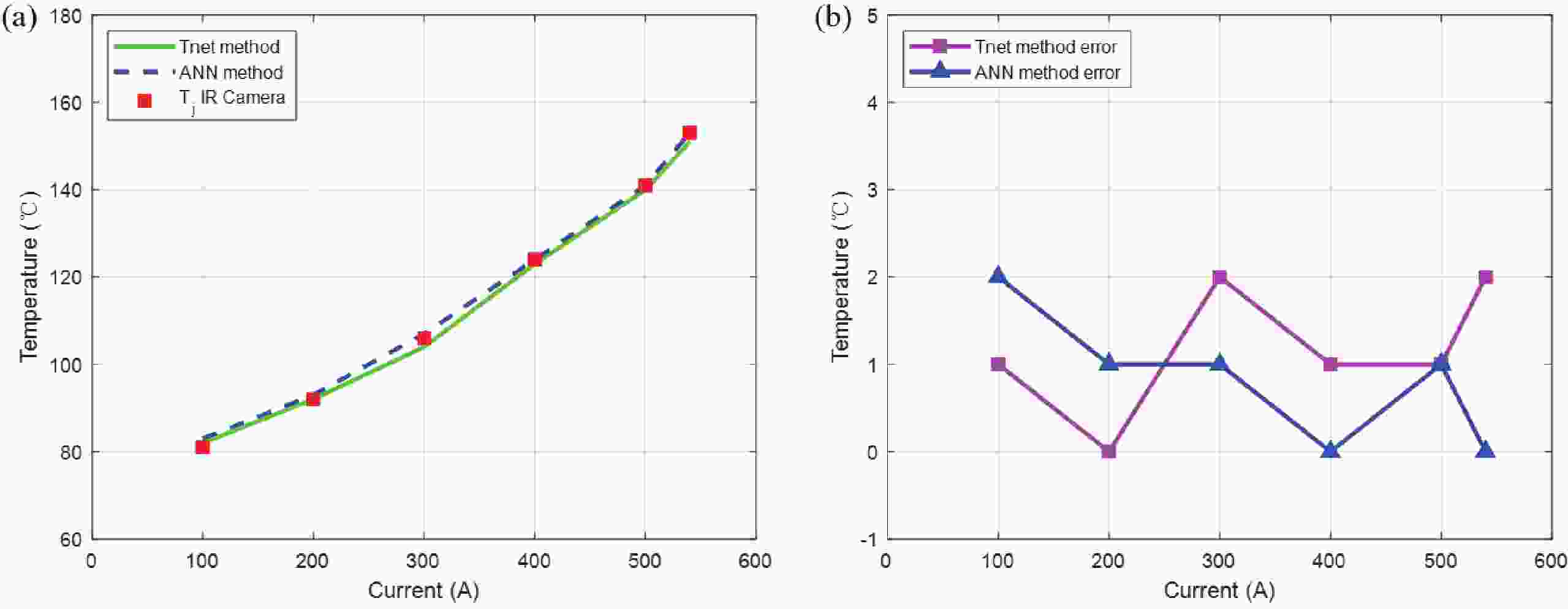

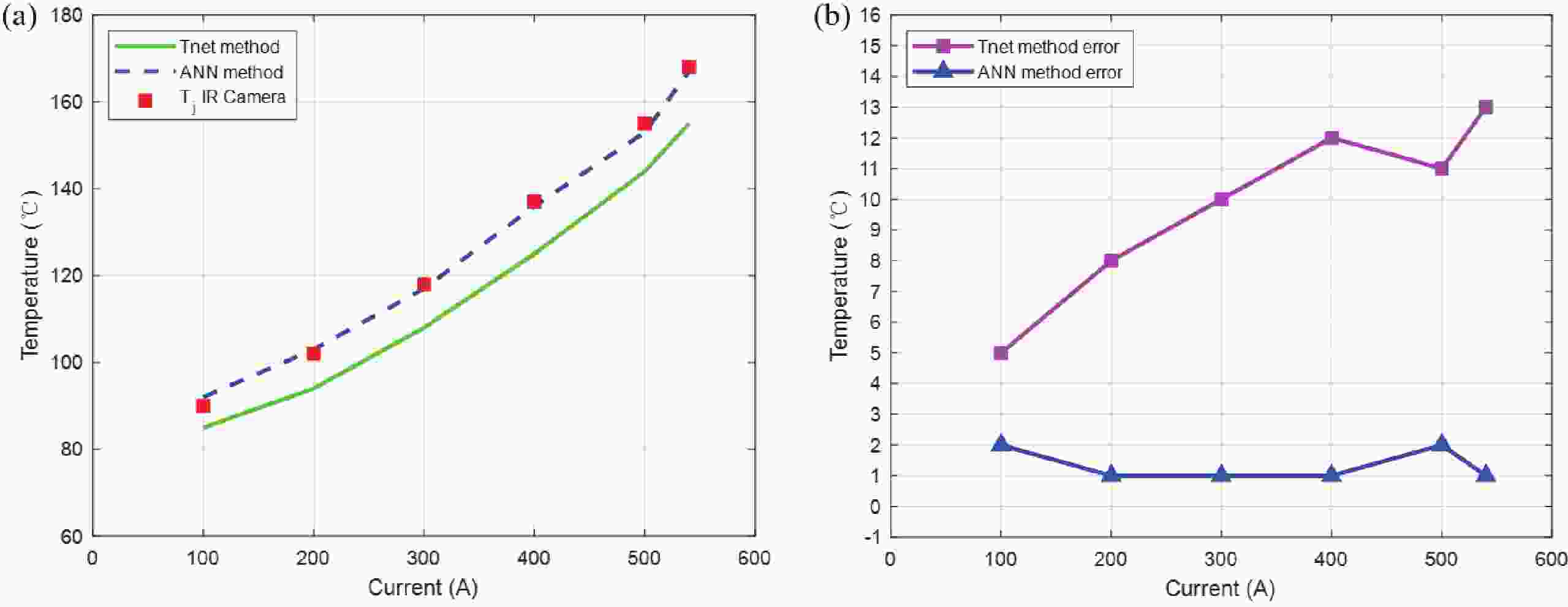

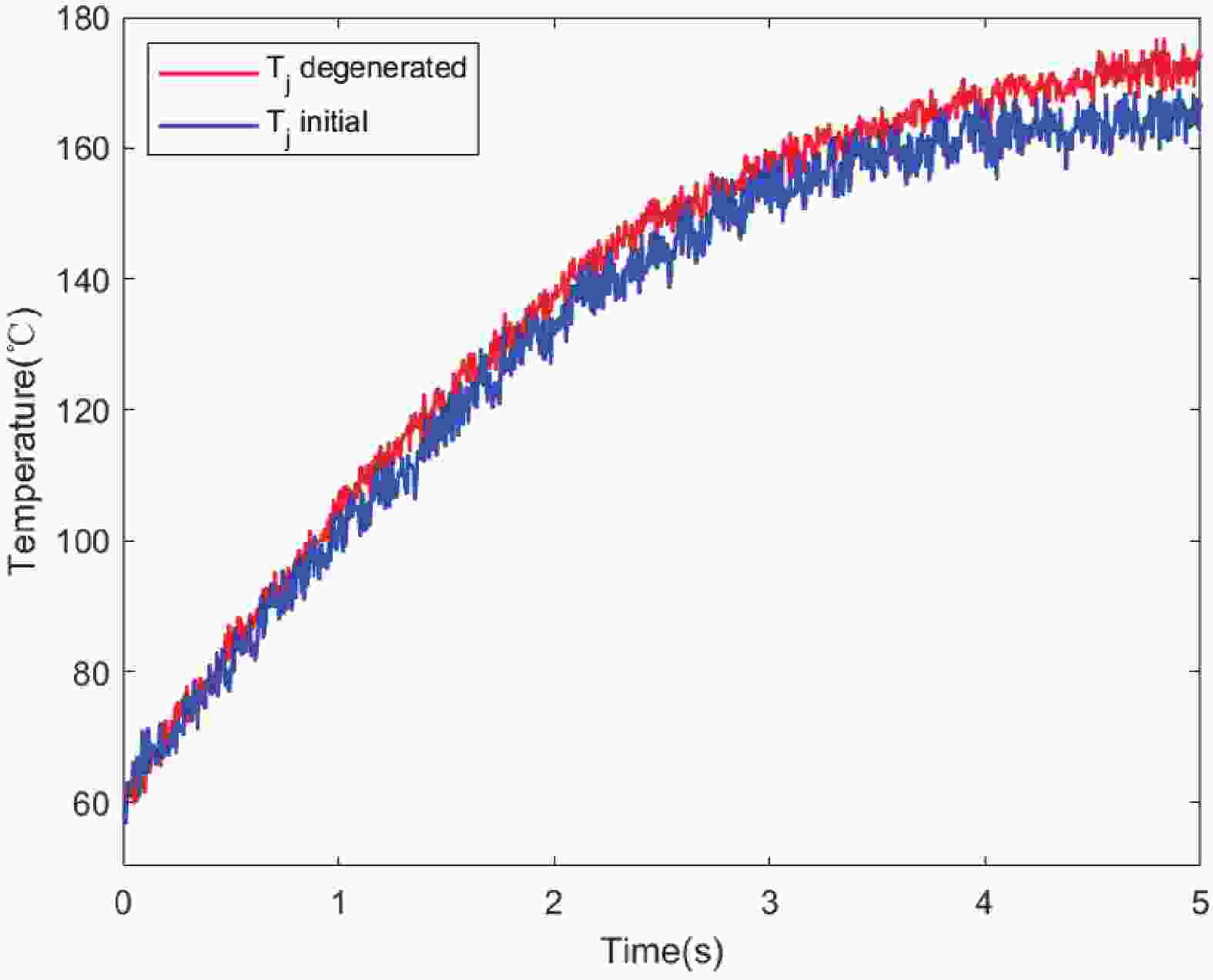

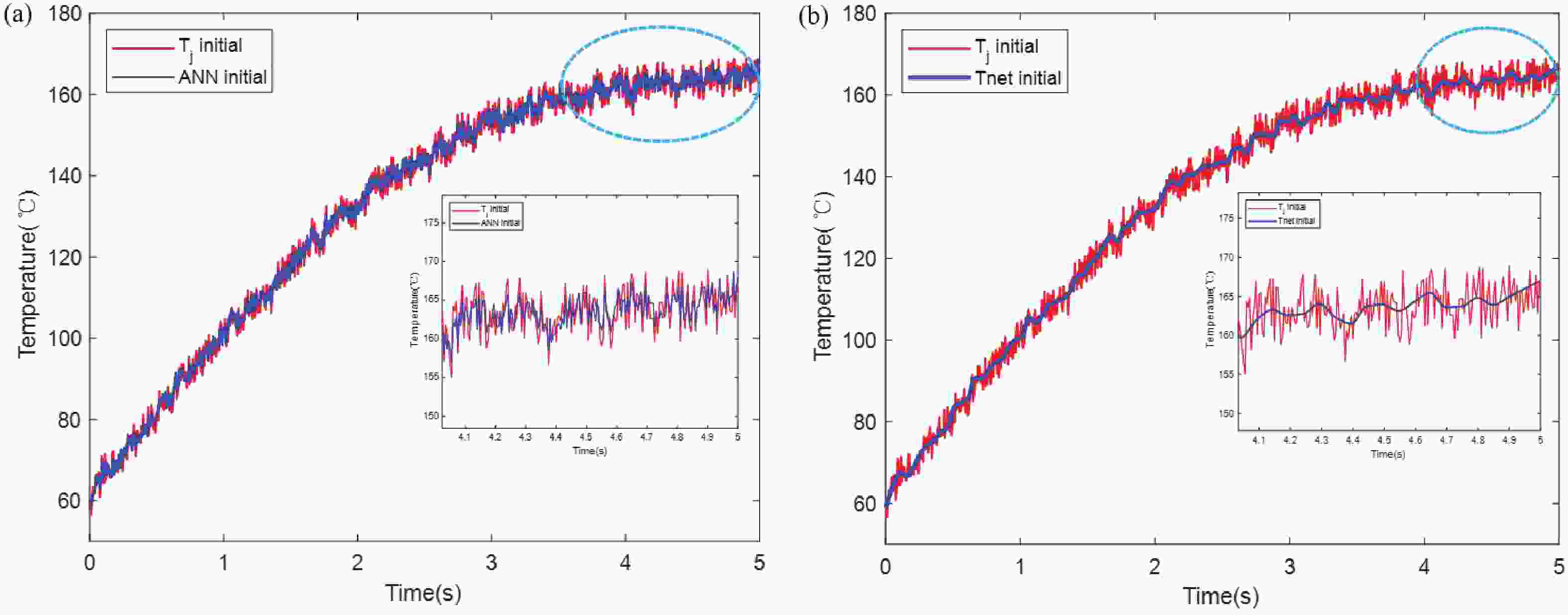

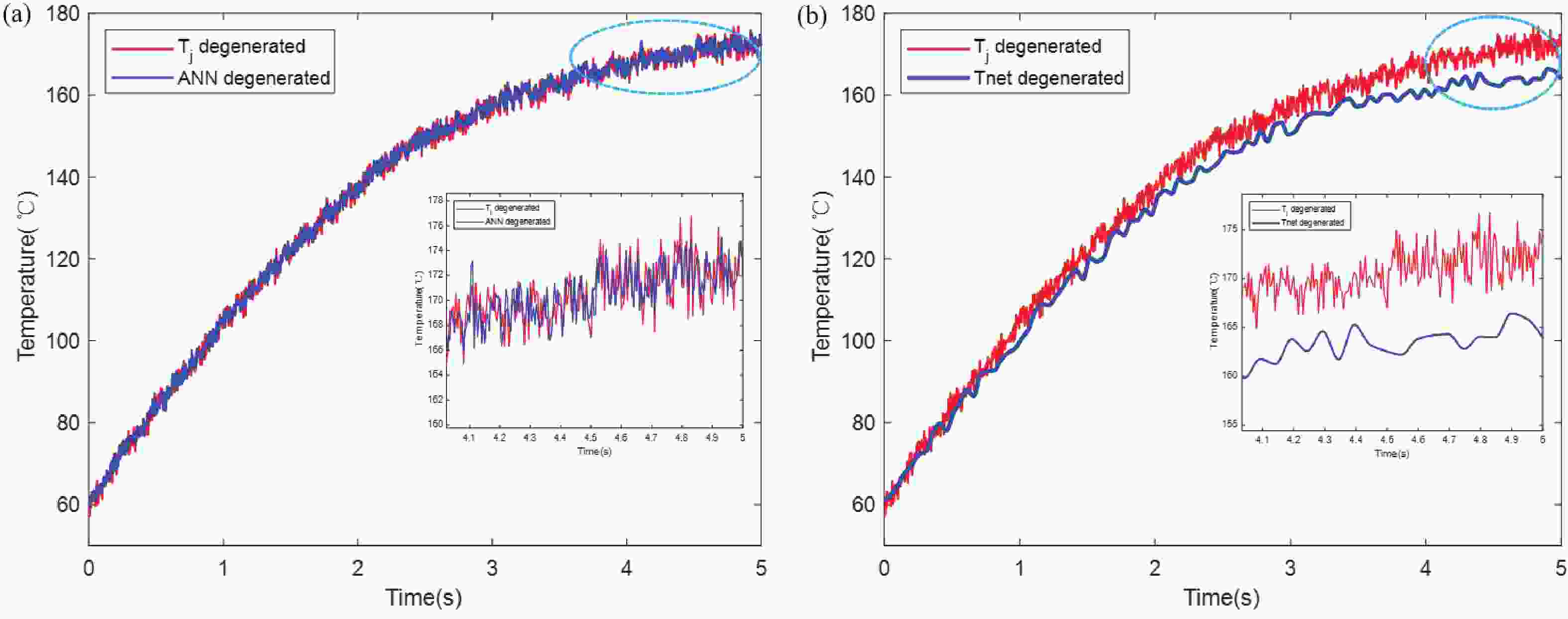

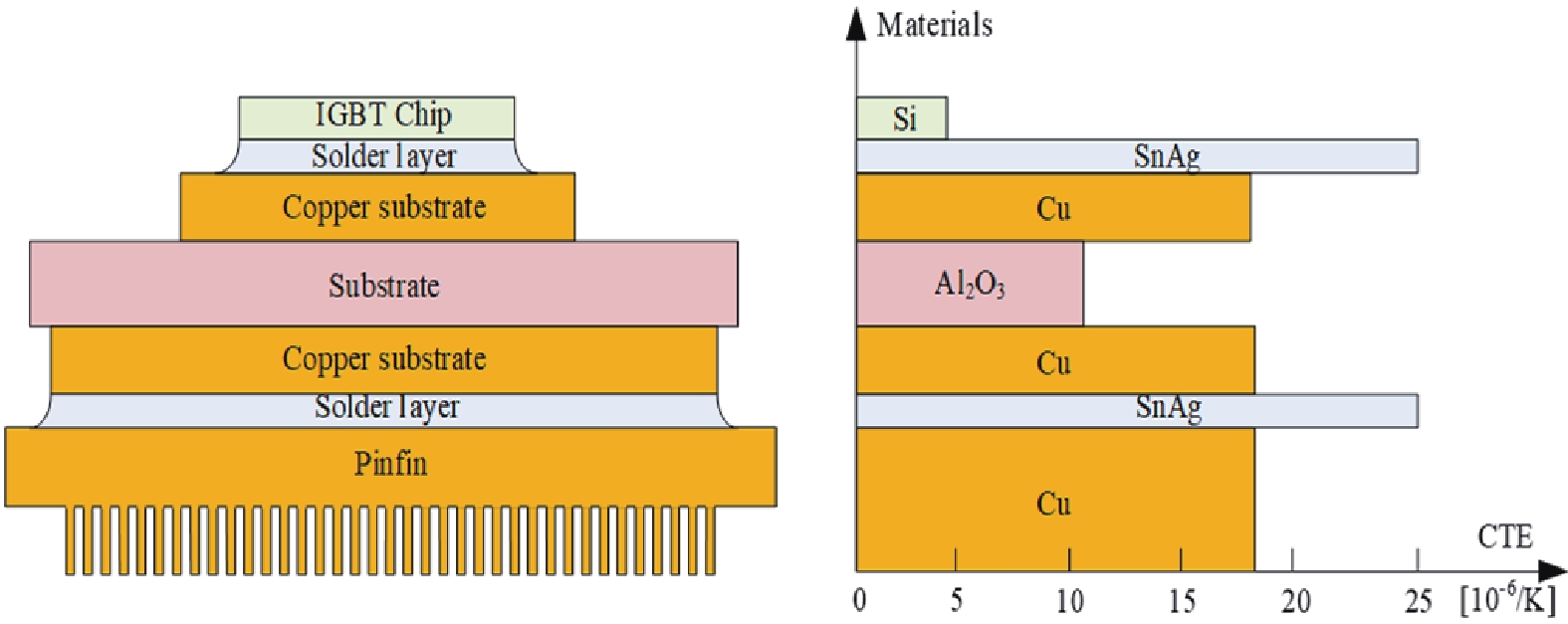

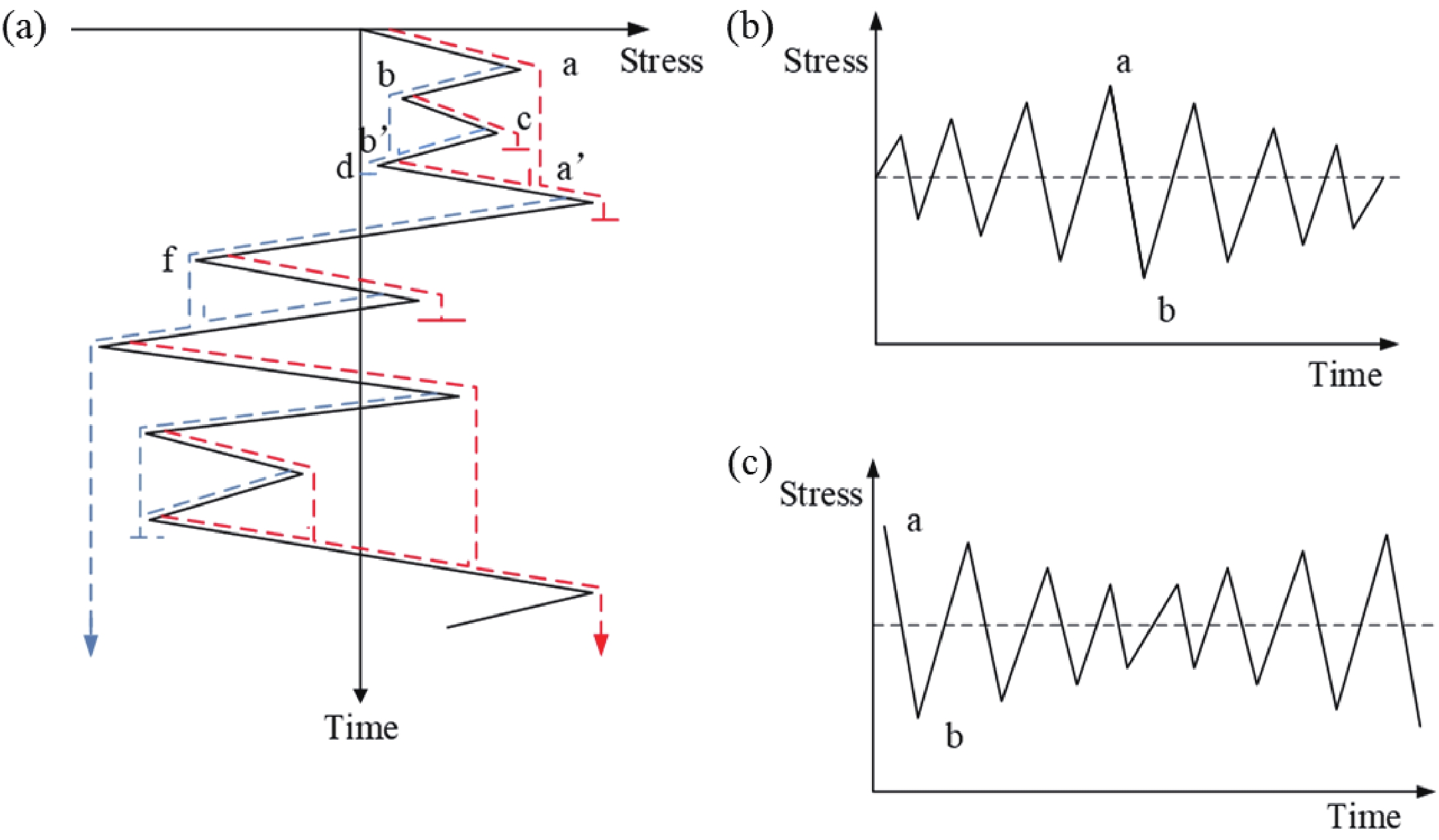

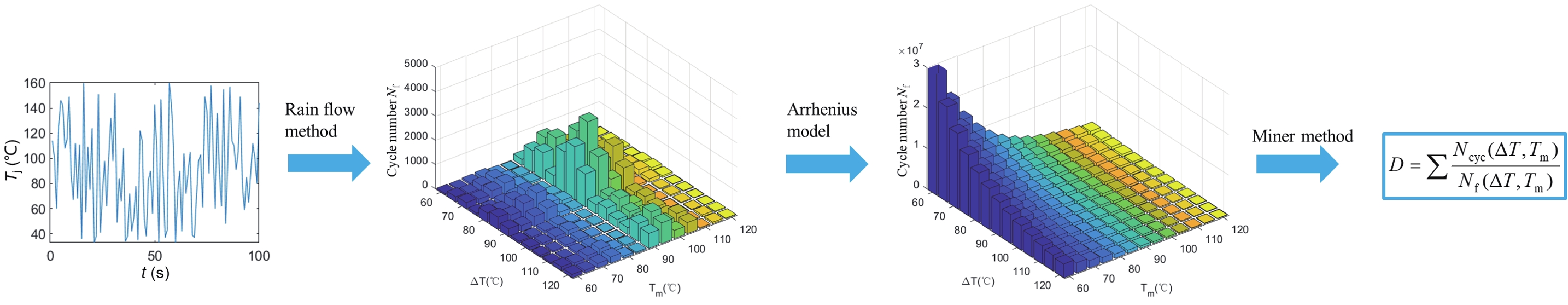

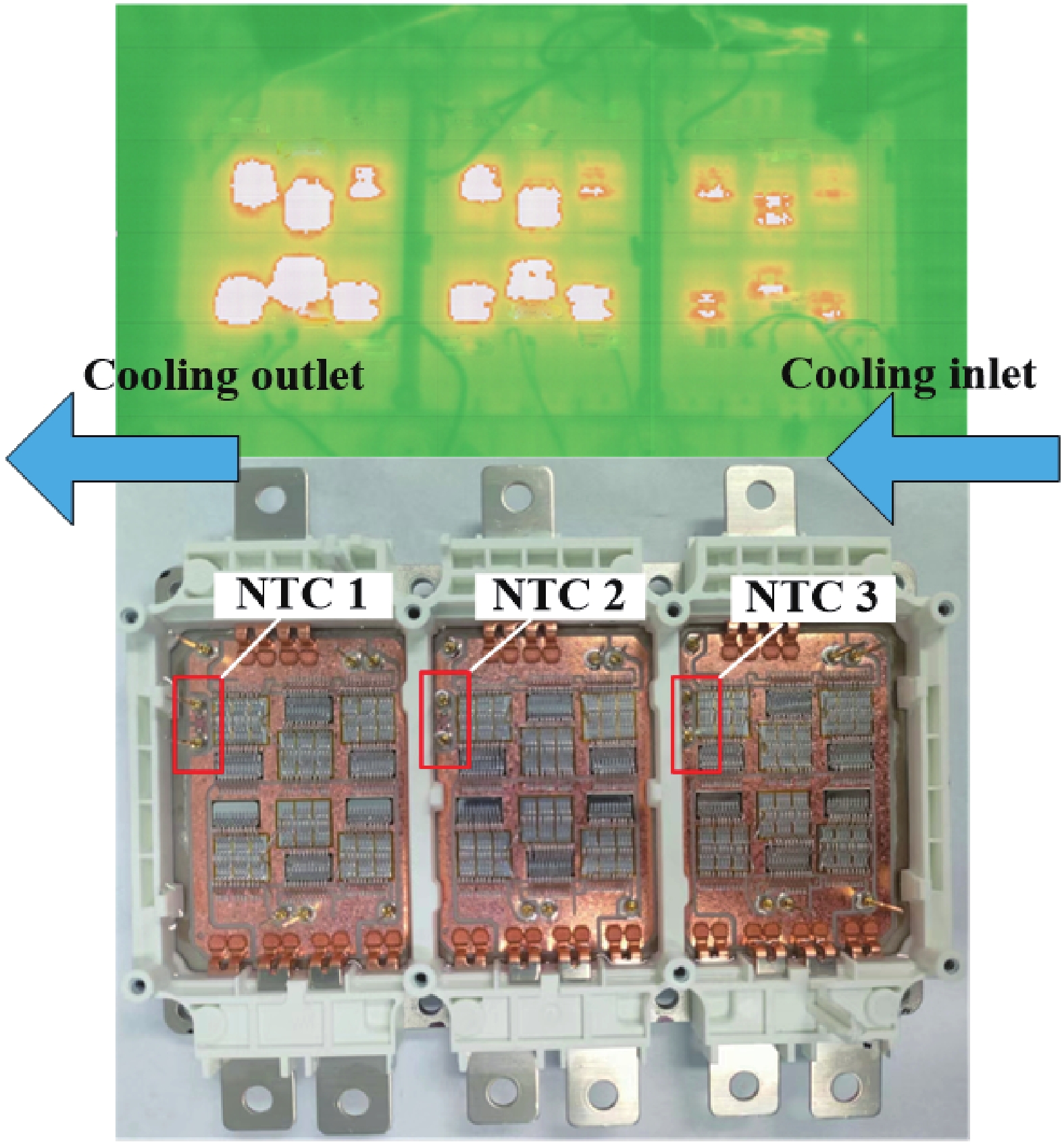

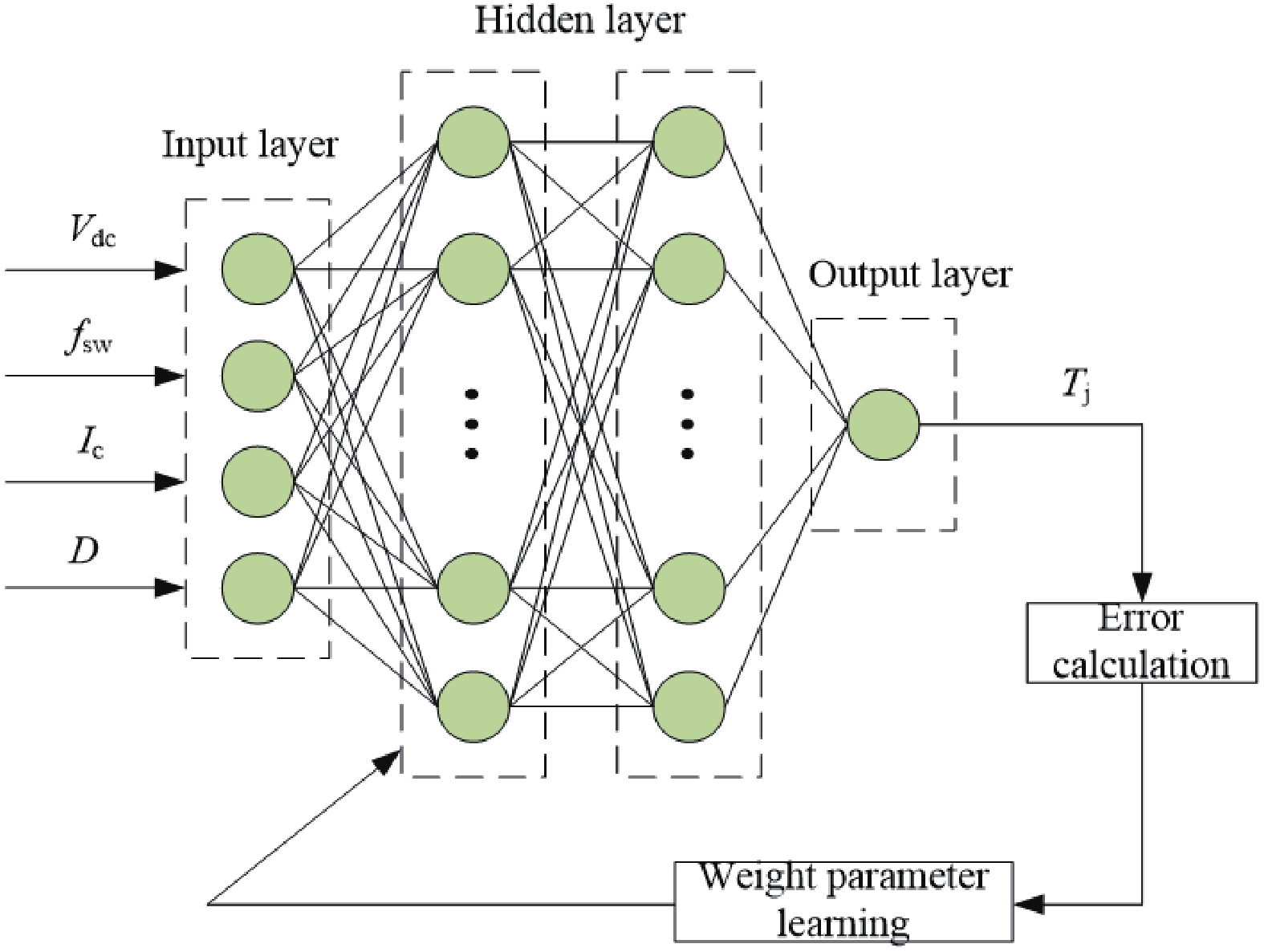

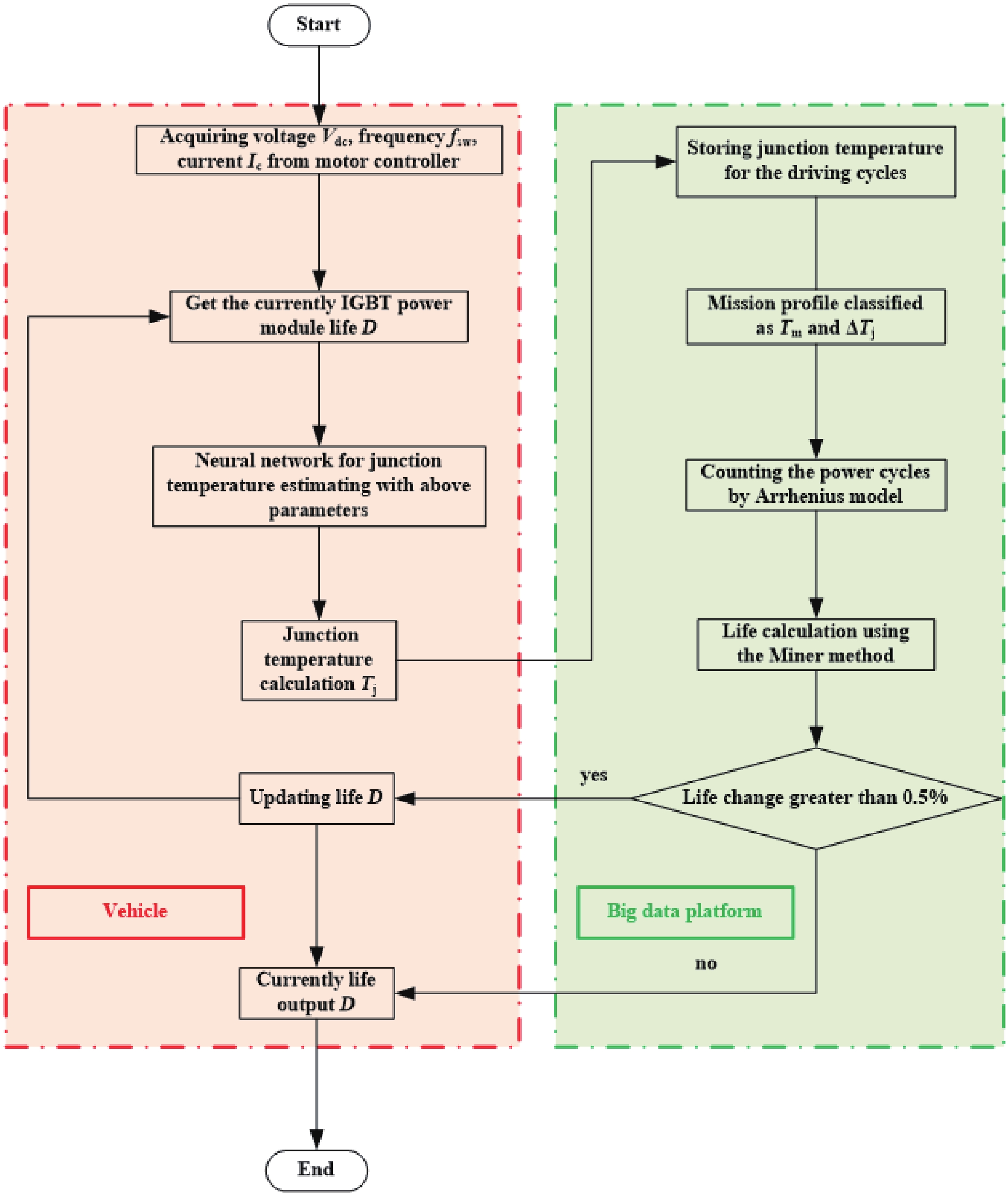

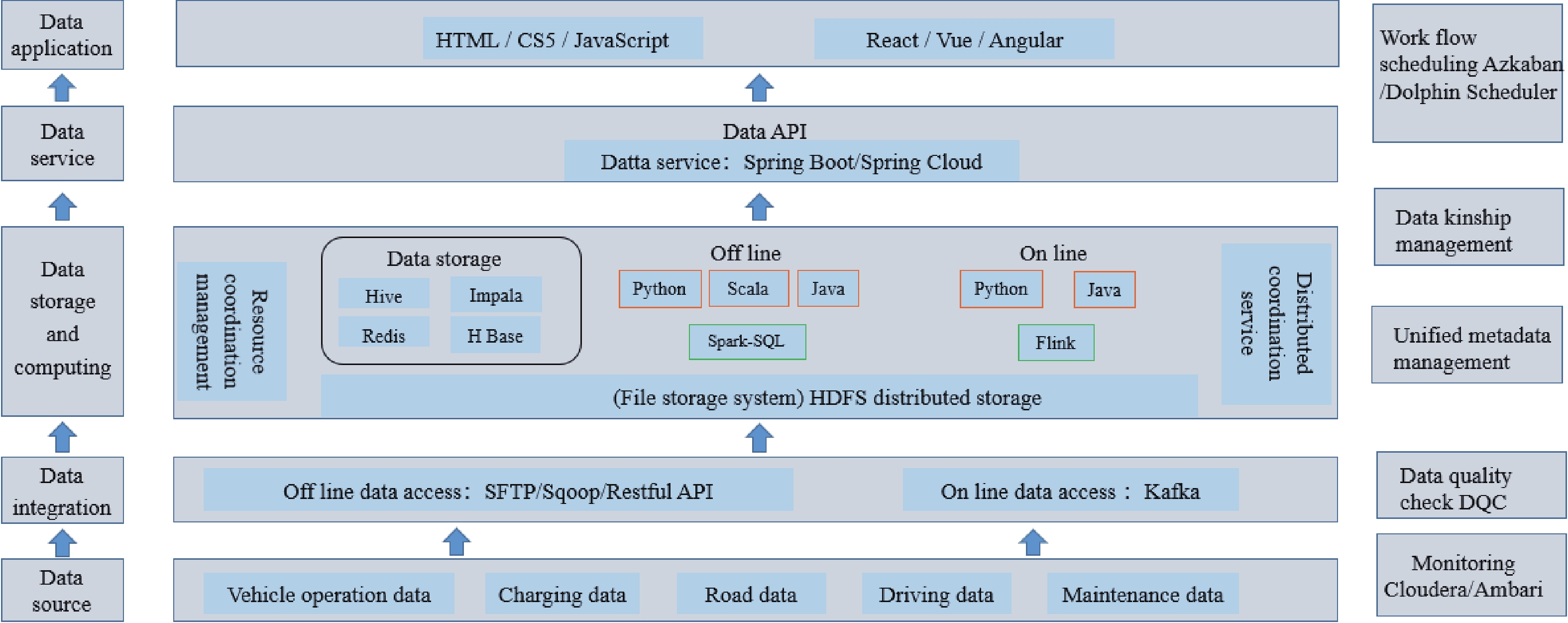

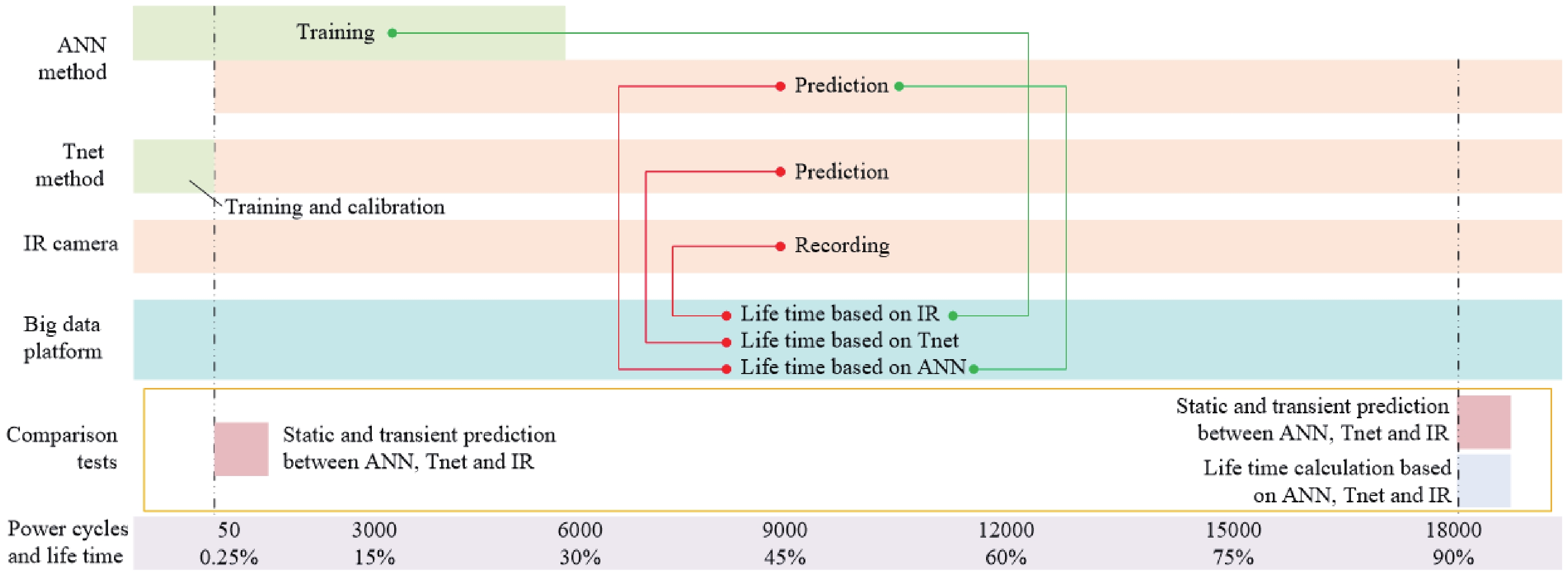

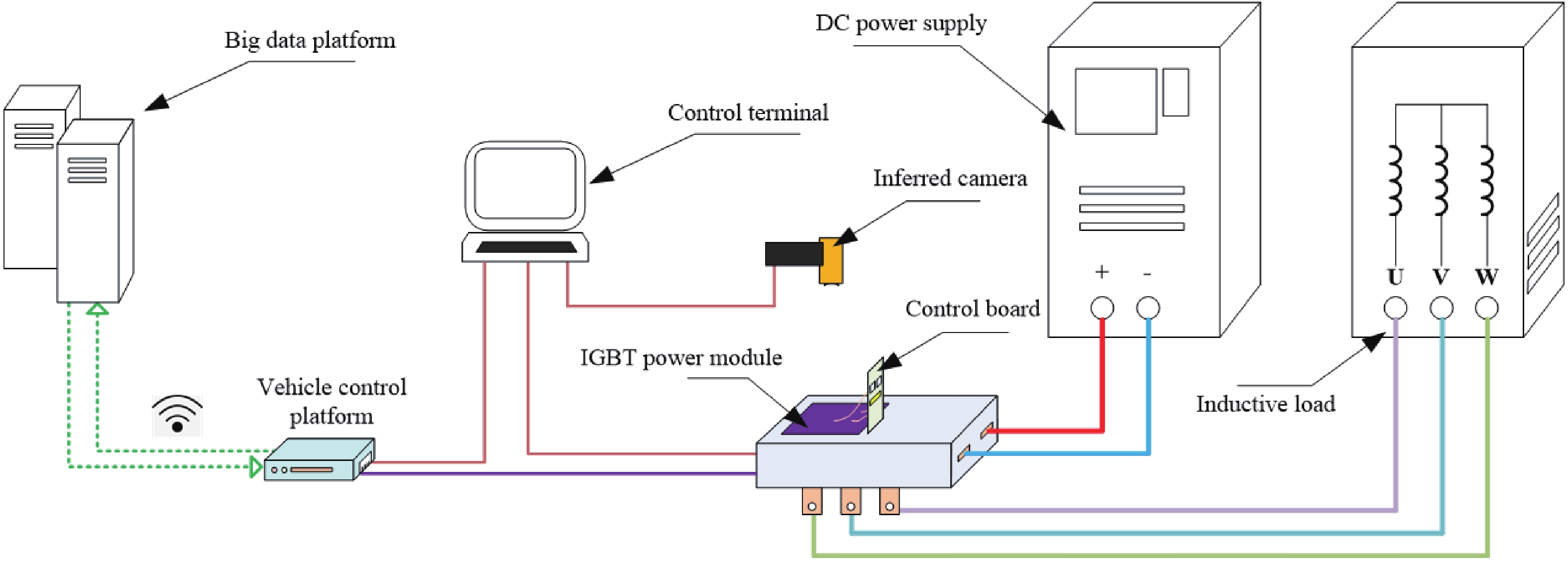

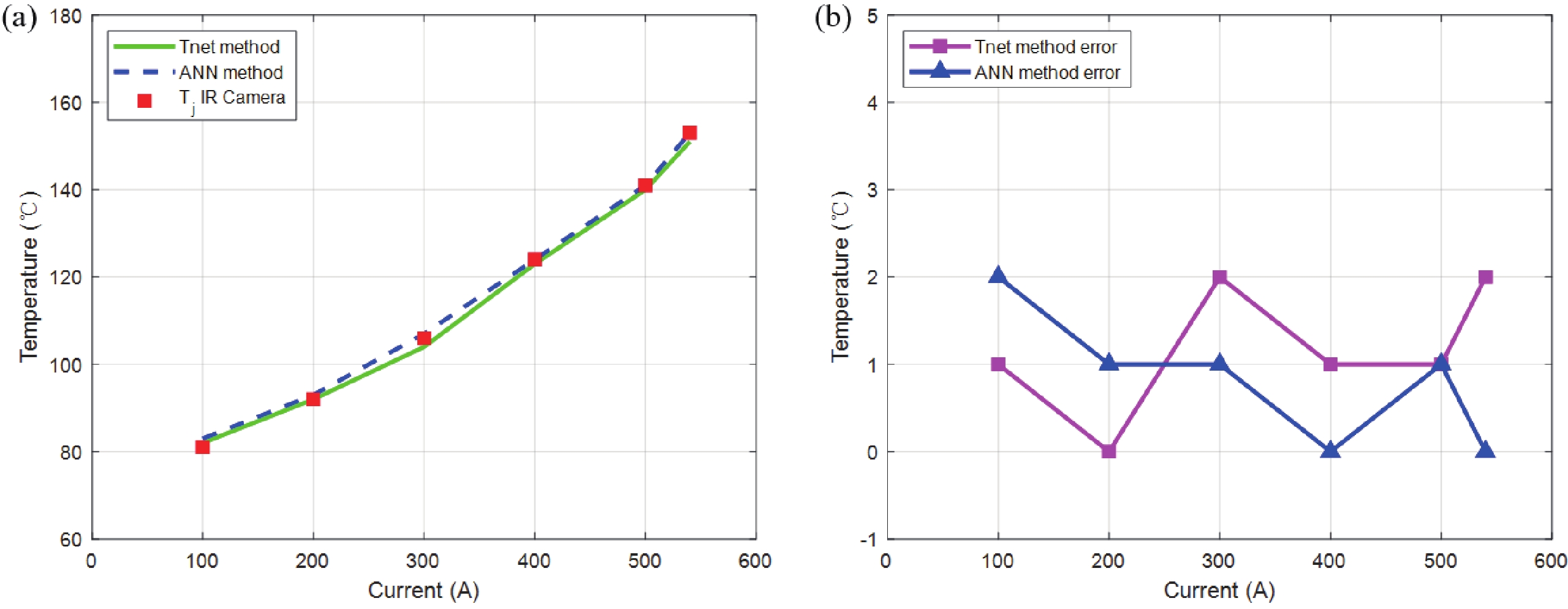

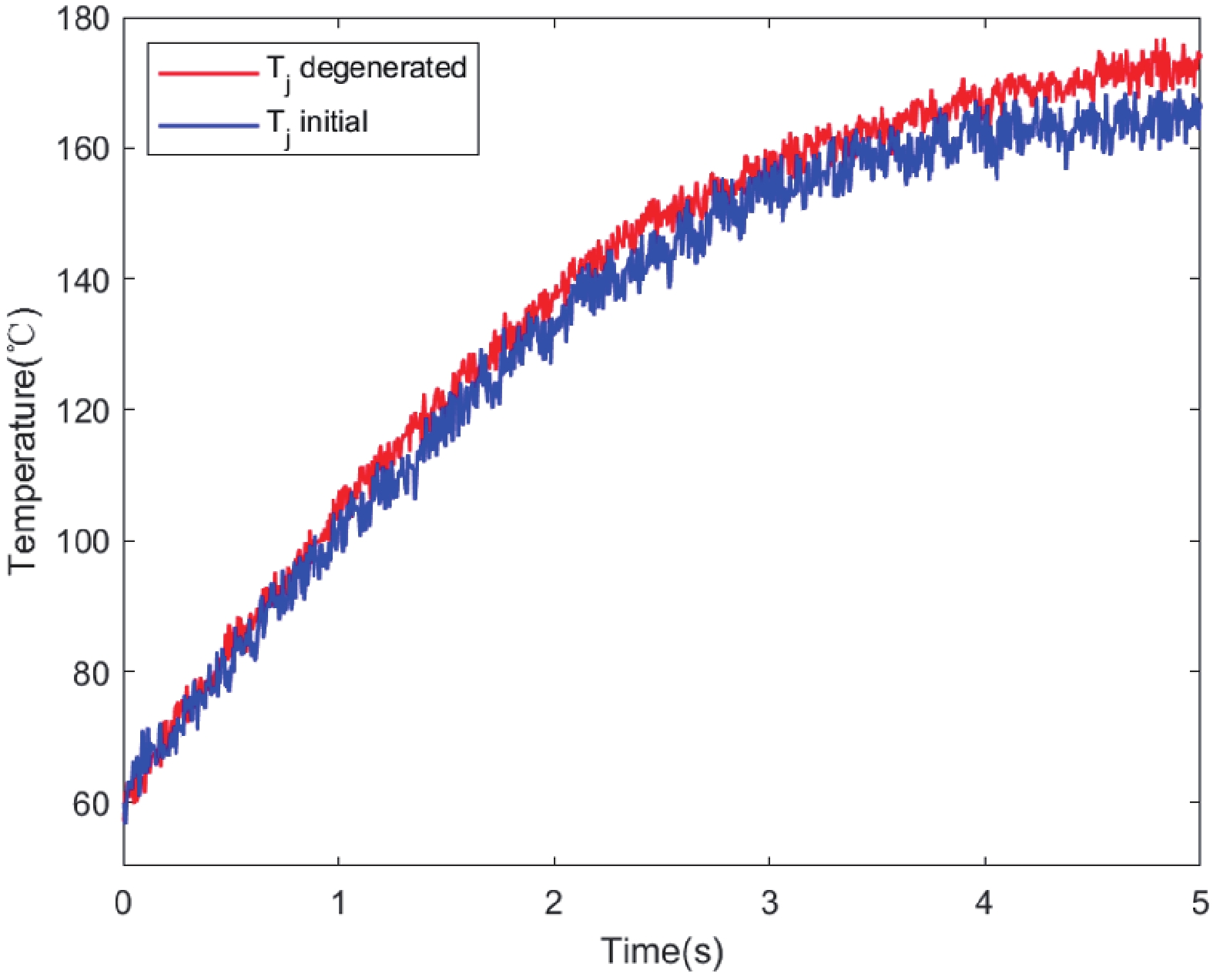

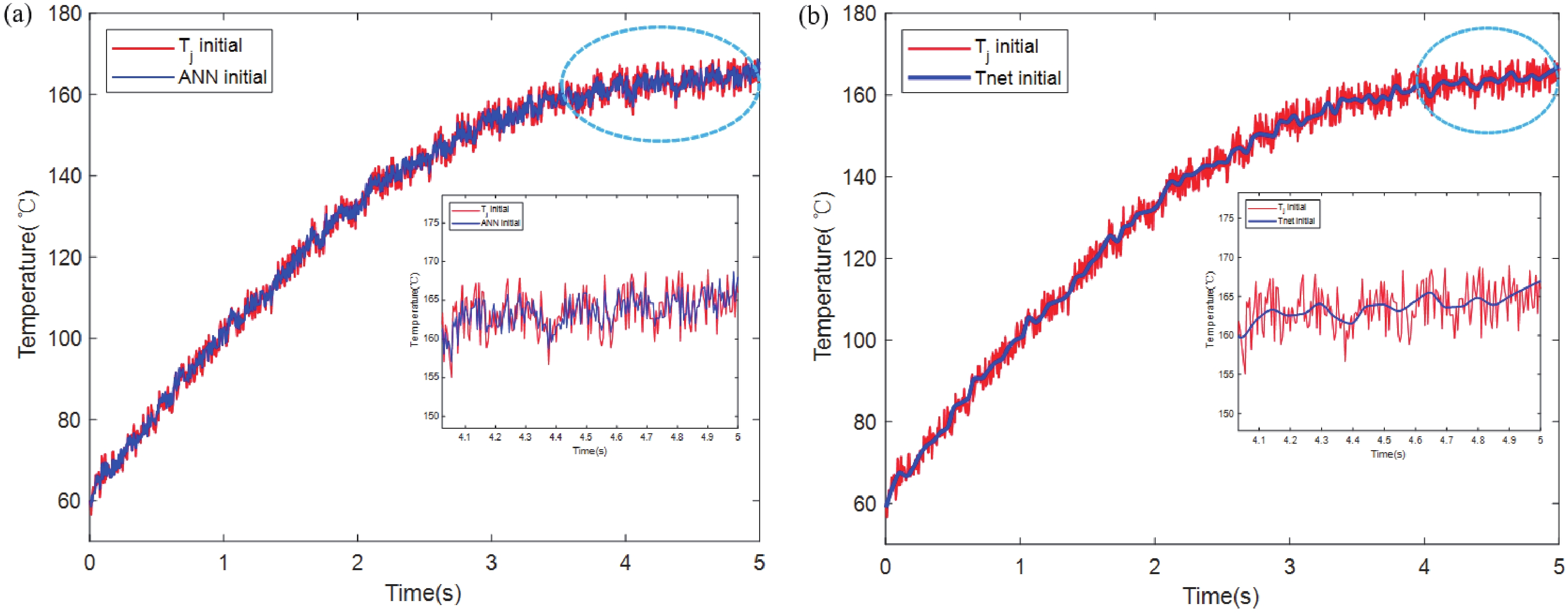

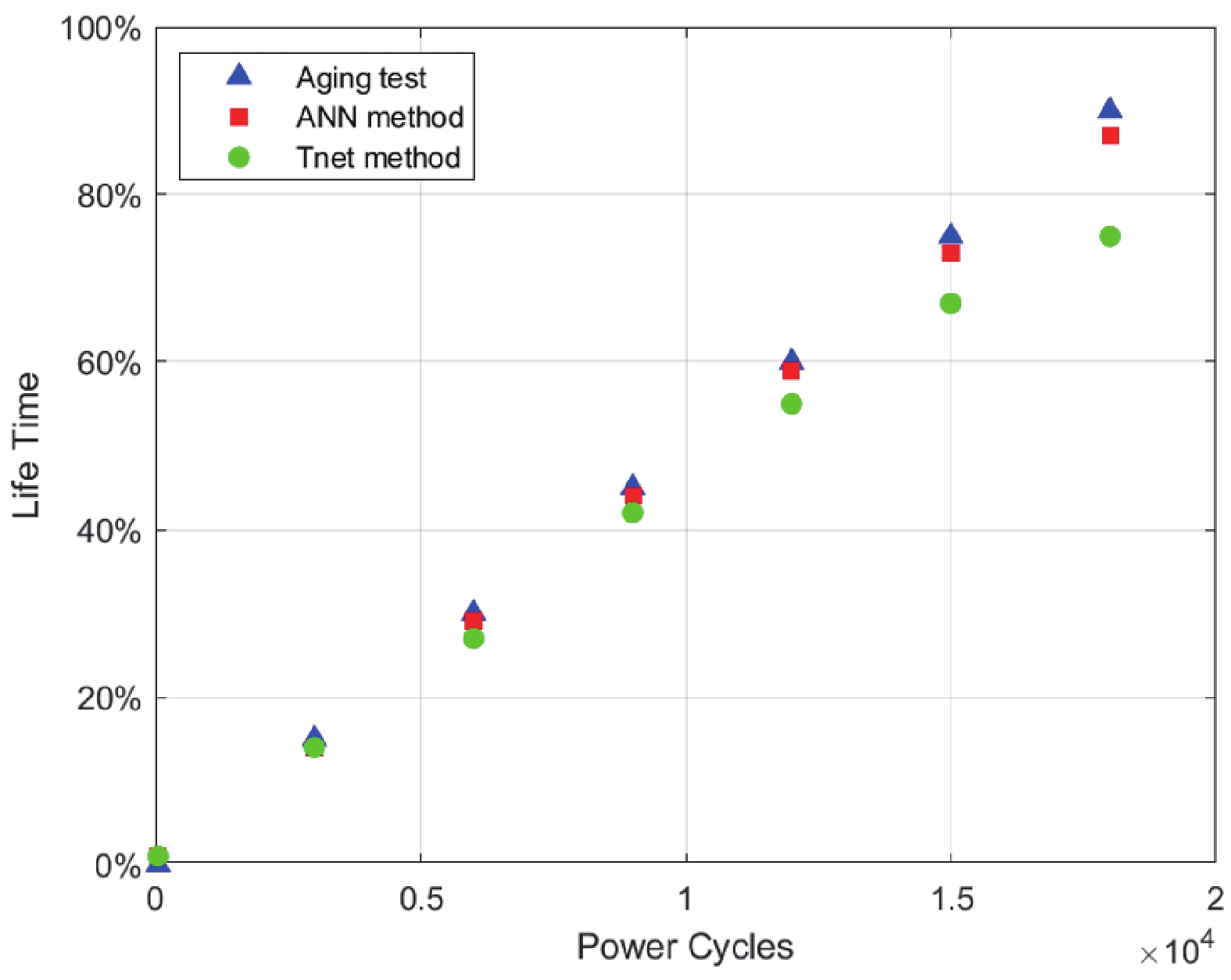

There are challenges to the reliability evaluation for insulated gate bipolar transistors (IGBT) on electric vehicles, such as junction temperature measurement, computational and storage resources. In this paper, a junction temperature estimation approach based on neural network without additional cost is proposed and the lifetime calculation for IGBT using electric vehicle big data is performed. The direct current (DC) voltage, operation current, switching frequency, negative thermal coefficient thermistor (NTC) temperature and IGBT lifetime are inputs. And the junction temperature (Tj) is output. With the rain flow counting method, the classified irregular temperatures are brought into the life model for the failure cycles. The fatigue accumulation method is then used to calculate the IGBT lifetime. To solve the limited computational and storage resources of electric vehicle controllers, the operation of IGBT lifetime calculation is running on a big data platform. The lifetime is then transmitted wirelessly to electric vehicles as input for neural network. Thus the junction temperature of IGBT under long-term operating conditions can be accurately estimated. A test platform of the motor controller combined with the vehicle big data server is built for the IGBT accelerated aging test. Subsequently, the IGBT lifetime predictions are derived from the junction temperature estimation by the neural network method and the thermal network method. The experiment shows that the lifetime prediction based on a neural network with big data demonstrates a higher accuracy than that of the thermal network, which improves the reliability evaluation of system.-

Keywords:

- IGBT,

- junction temperature,

- neural network,

- electric vehicles,

- big data

-

References

[1] Kimura K, Rahman T, Misumi T, et al. Development of new IGBT to reduce electrical power losses and size of power control unit for hybrid vehicles. SAE International Journal of Alternative Powertrains, 2017, 6, 303 doi: 10.4271/2017-01-1244[2] Moosavi S S, Kazemi A, Akbari H. A comparison of various open-circuit fault detection methods in the IGBT-based DC/AC inverter used in electric vehicle. Eng Fail Anal, 2019, 96, 223 doi: 10.1016/j.engfailanal.2018.09.020[3] Dimitrov B, Hayatleh K, et al. A buck-boost transformerless DC–DC converter based on IGBT modules for fast charge of electric vehicles. Electronics, 2020, 9, 397 doi: 10.3390/electronics9030397[4] Ma M Y, Yan X S, Guo W S, et al. Online junction temperature estimation using integrated NTC thermistor in IGBT modules for PMSM drives. Microelectron Reliab, 2020, 114, 113836 doi: 10.1016/j.microrel.2020.113836[5] Aranzabal I, de Alegría I M, Delmonte N, et al. Comparison of the heat transfer capabilities of conventional single- and two-phase cooling systems for an electric vehicle IGBT power module. IEEE Trans Power Electron, 2019, 34, 4185 doi: 10.1109/TPEL.2018.2862943[6] Ma M Y, Guo W S, Yan X S, et al. A three-dimensional boundary-dependent compact thermal network model for IGBT modules in new energy vehicles. IEEE Trans Ind Electron, 2021, 68, 5248 doi: 10.1109/TIE.2020.2991926[7] Zhu Y, Xiao M K, Su X Z, et al. IGBT junction temperature measurement under active-short-circuit and locked-rotor modes in new energy vehicles. IEEE Access, 2020, 8, 114401 doi: 10.1109/ACCESS.2020.3003654[8] Lai W, Wei Y H, Chen M Y, et al. In-situ calibration method of online junction temperature estimation in IGBTs for electric vehicle drives. IEEE Trans Power Electron, 2023, 38, 1178 doi: 10.1109/TPEL.2022.3204547[9] Li C M, Sun X X, Zha M J, et al. IGBT thermal model-based predictive energy management strategy for plug-In hybrid electric vehicles using game theory. IEEE Trans Transp Electrif, 2023, 9, 3268 doi: 10.1109/TTE.2022.3227334[10] Lu Y P, Xiang E Y, Zhu A K, et al. Mission-profile-based reliability evaluation of IGBT modules for wide-speed range electric vehicle drive using fast multistep mapping simulation strategy. IEEE J Emerg Sel Top Power Electron, 2023, 11, 5376 doi: 10.1109/JESTPE.2023.3299464[11] Górecki K, Górecki P, Zarębski J. Measurements of parameters of the thermal model of the IGBT module. IEEE Trans Instrum Meas, 2019, 68, 4864 doi: 10.1109/TIM.2019.2900144[12] Huang H, Mawby P A. A lifetime estimation technique for voltage source inverters. IEEE Trans Power Electron, 2013, 28, 4113 doi: 10.1109/TPEL.2012.2229472[13] Fuchs F, Mertens A. Steady state lifetime estimation of the power semiconductors in the rotor side converter of a 2 MW DFIG wind turbine via power cycling capability analysis. Proceedings of the 2011 14th European Conference on Power Electronics and Applications. Birmingham, UK. IEEE, 2011, 1[14] Lai W, Wang Z, Chen M Y, et al. Reliability evaluation of IGBT modules in wind power converter considering the effects of different failure sites. 2020 IEEE MTT-S International Conference on Numerical Electromagnetic and Multiphysics Modeling and Optimization (NEMO). Hangzhou, China. IEEE, 2020, 1 doi: 10.1109/NEMO49486.2020.9343566[15] Ji B, Song X G, Cao W P, et al. In situ diagnostics and prognostics of solder fatigue in IGBT modules for electric vehicle drives. IEEE Trans Power Electron, 2015, 30, 1535 doi: 10.1109/TPEL.2014.2318991[16] Meng H L, Wang Y H, Zheng X H, et al. Study of IGBTs reliability under coupled electrical–thermal environment. IEEE J Emerg Sel Top Power Electron, 2021, 9, 4260 doi: 10.1109/JESTPE.2020.2988847[17] Ahsan M, Hon S T, Batunlu C, et al. Reliability assessment of IGBT through modelling and experimental testing. IEEE Access, 2020, 8, 39561 doi: 10.1109/ACCESS.2020.2973578[18] Gonzalez J O, Wu R Z, Jahdi S, et al. Performance and reliability review of 650 V and 900 V silicon and SiC devices: MOSFETs, cascode JFETs and IGBTs. IEEE Trans Ind Electron, 2020, 67, 7375 doi: 10.1109/TIE.2019.2945299[19] Held M, Jacob P, Nicoletti G, et al. Fast power cycling test of IGBT modules in traction application. Proceedings of Second International Conference on Power Electronics and Drive Systems. Singapore. IEEE, 2002, 425 doi: 10.1109/PEDS.1997.618742[20] Schlegel R, Herr E, Richter F. Reliability of non-hermetic pressure contact IGBT modules. Microelectron Reliab, 2001, 41, 1689 doi: 10.1016/S0026-2714(01)00193-7[21] Lefranc G, Licht T, Schultz H J, et al. Reliability testing of high-power multi-chip IGBT modules. Microelectron Reliab, 2000, 40, 1659 doi: 10.1016/S0026-2714(00)00185-2[22] Wang H, Liserre M, Blaabjerg F, et al. Transitioning to physics-of-failure as a reliability driver in power electronics. IEEE J Emerg Sel Top Power Electron, 2014, 2, 97 doi: 10.1109/JESTPE.2013.2290282[23] Samavatian V, Iman-Eini H, Avenas Y. An efficient online time-temperature-dependent creep-fatigue rainflow counting algorithm. Int J Fatigue, 2018, 116, 284 doi: 10.1016/j.ijfatigue.2018.06.037[24] Chen D J, Liu Y T, Zhang W, et al. Detection of IGBT degradation in NPC inverter based on infrared thermography. J Comput Meth Sci Eng, 2018, 18, 459 doi: 10.3233/JCM-180801[25] Luo H Z, Li W H, Iannuzzo F, et al. Enabling junction temperature estimation via collector-side thermo-sensitive electrical parameters through emitter stray inductance in high-power IGBT modules. IEEE Trans Ind Electron, 2018, 65, 4724 doi: 10.1109/TIE.2017.2745442[26] Li H, Liu S, Li Y, et al. Thermal evaluation model for IGBT module in wind power converter considering multi-heat sources coupling. IEEE Trans Ind Appl, 2013, 49, 1599 doi: 10.1109/TIA.2013.2255852[27] Wang Z, Qiao W. A physics-based improved cauer-type thermal equivalent circuit for IGBT modules. IEEE Trans Power Electron, 2016, 31, 6781 doi: 10.1109/TPEL.2016.2539208[28] Volke A. IGBT modules technologies, driver, and application. Munich: Infineon, 2010 doi: US20050194660A1[29] Das S C, Narayanan G, Tiwari A. Experimental study on the dependence of IGBT switching energy loss on DC link voltage. 2014 IEEE International Conference on Power Electronics, Drives and Energy Systems (PEDES). Mumbai, India. IEEE, 2014, 1 doi: 10.1109/PEDES.2014.7042140[30] Das S C, Narayanan G, Tiwari A. Experimental study on the influence of junction temperature on the relationship between IGBT switching energy loss and device current. Microelectron Reliab, 2018, 80, 134 doi: 10.1016/j.microrel.2017.11.023[31] Yang H C, Simanjorang R, See K Y. A method of junction temperature estimation for SiC power MOSFETs via turn-on saturation current measurement. IEEJ Journal IA, 2019, 8, 306 doi: 10.1541/ieejjia.8.306[32] Wang W, Song Q, Zhang S, et al. The loss analysis and efficiency optimization of power inverter based on SiC mosfets under the high-switching frequency. IEEE Trans Ind Appl, 2021, 57, 1521 doi: 10.1109/TIA.2020.3045116[33] Liu L, Peng Q L, Jiang H P, et al. BP neural network for non-invasive IGBT junction temperature online detection. Microelectron Reliab, 2023, 141, 114882 doi: 10.1016/j.microrel.2022.114882[34] Lai W, Wang Z, Hu Y L, et al. Evaluation of IGBT module remaining lifetime in wind power converters considering impacts of failure location. IEEE Trans Electron Devices, 2021, 68, 1810 doi: 10.1109/TED.2021.3061517[35] Lai W, Li H R, Li H, et al. Analytical remaining lifetime modeling for electric locomotive IGBT Modules based on failure evolution simulation. Proceedings of the CSEE, 2023 doi: 10.13334/j.0258-8013.pcsee.230855[36] Ma L Y, Huang J J, Chai X L, et al. Life prediction for IGBT based on improved long short-term memory network. 2023 IEEE 18th Conference on Industrial Electronics and Applications (ICIEA). Ningbo, China. IEEE, 2023, 868 doi: 10.1109/ICIEA58696.2023.10241612 -

Proportional views

DownLoad:

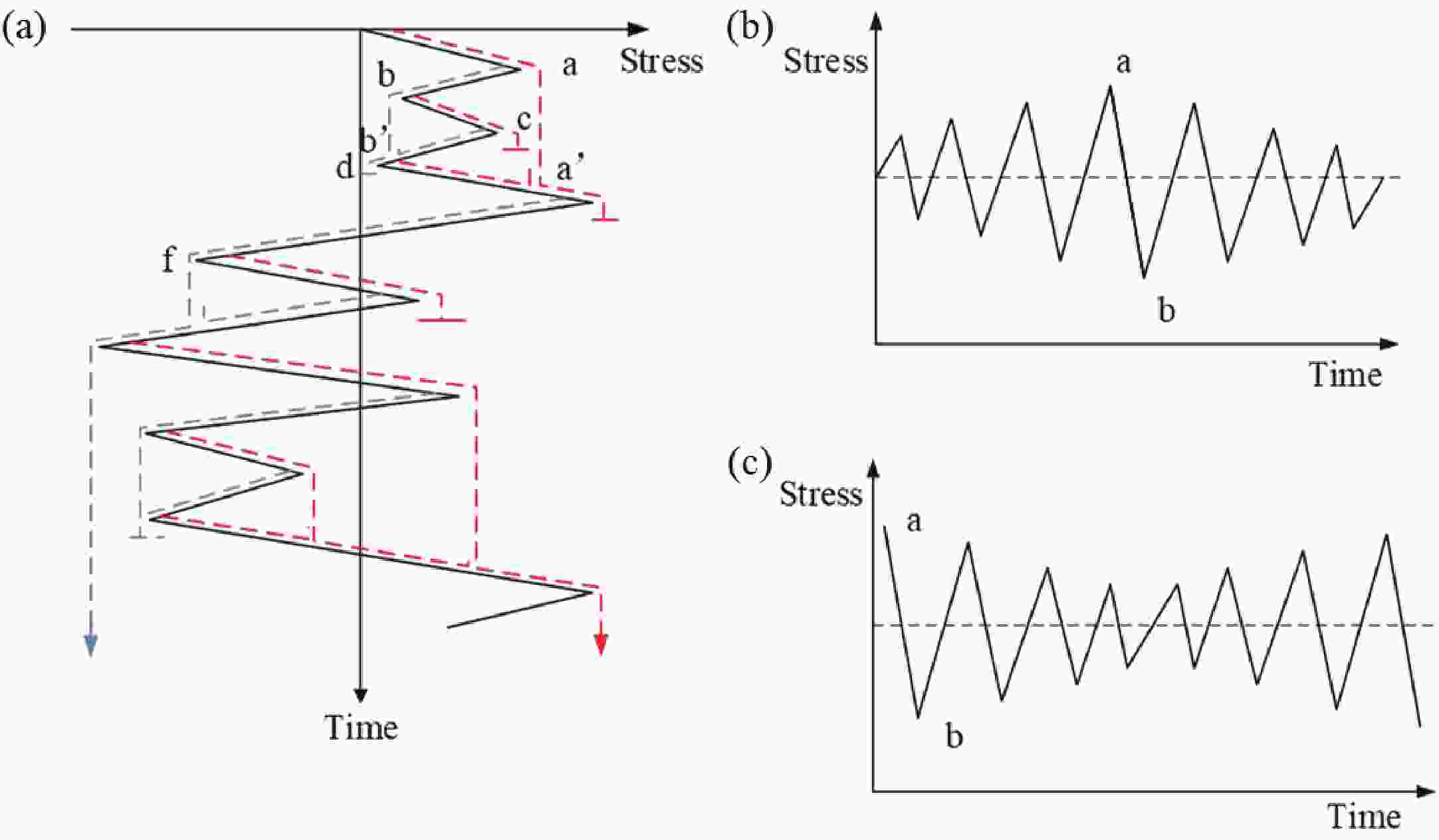

DownLoad: