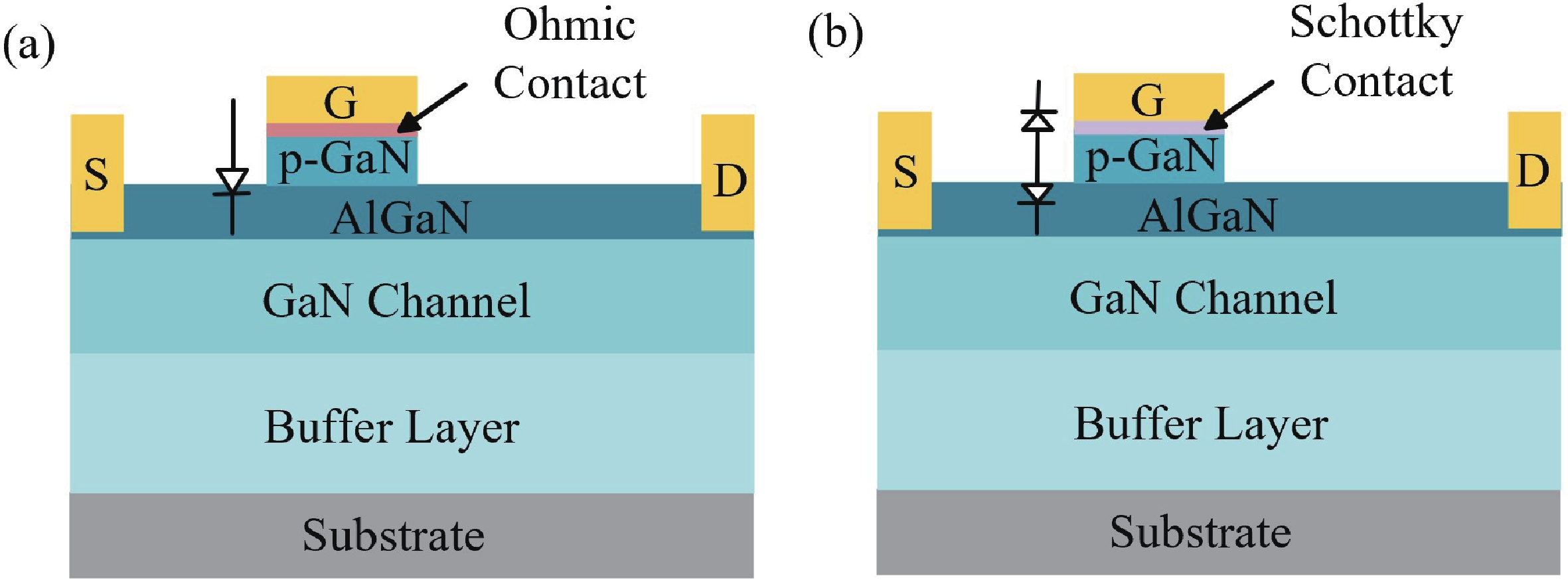

In this paper, a novel gate-series-diode structure for the Schottky-type p-GaN HEMTs is proposed, and the impact of the proposed structure on gate-source voltage oscillation is investigated when the device is turned on. The proposed structure is capable of effectively mitigating the gate-source voltage overshoot problem of GaN device, and has little effect on the switching characteristics. The gate voltage oscillations can be greatly stabilized at the steady-state turn-on voltage level when the turn-on voltage is 5 V. Compared with the conventional structure, the overshoots of the proposed structure reduce by 31.4%−71.4% and 40.6%−80.4% respectively under the two pulses, as drain-source voltage rises. The proposed structure is proved to be a potential method on improving gate reliability of the most GaN power devices.

Just Accepted manuscripts are peer-reviewed and accepted for publication. They are posted online prior to technical editing formatting for publication and author proofing.

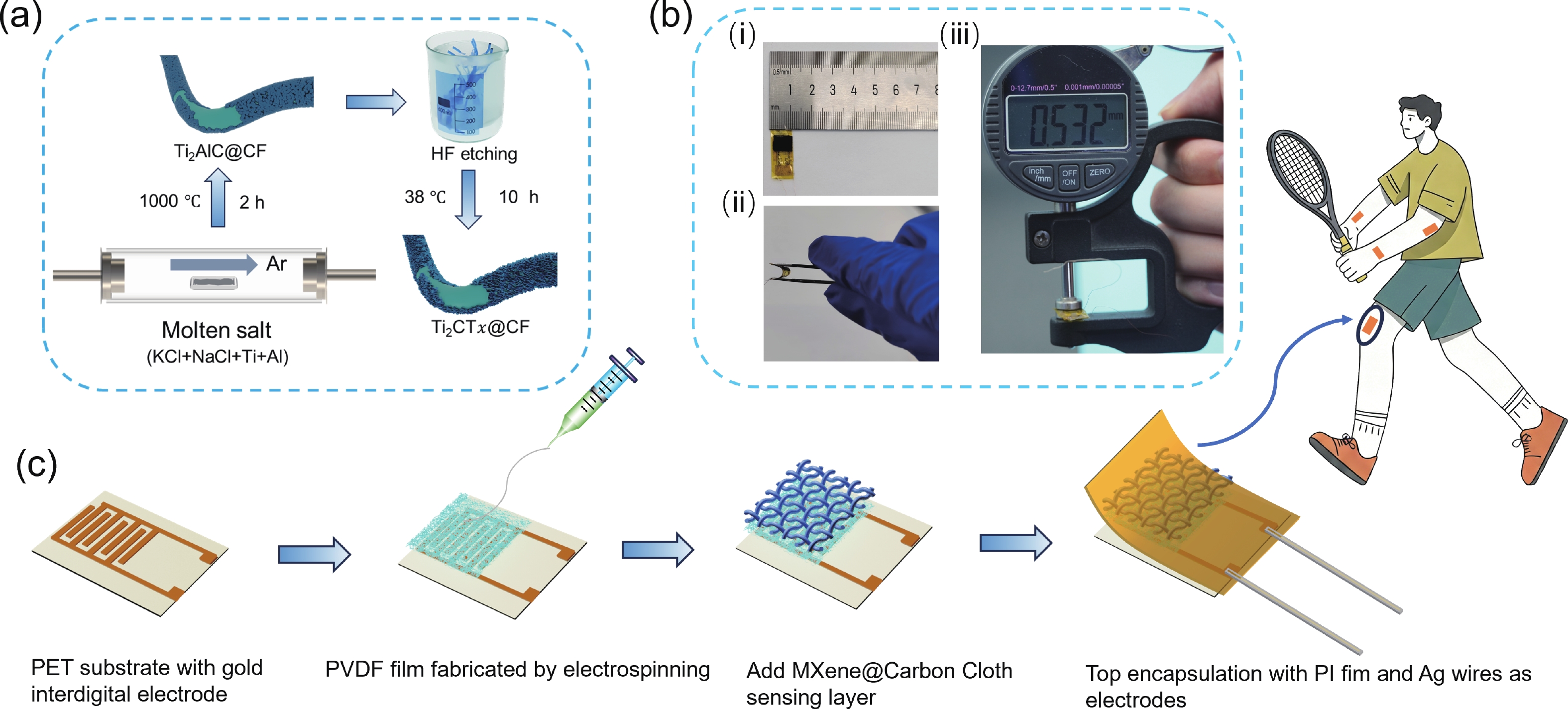

High performance flexible pressure sensors, as a very important group of electronic component for information transmission and collection, have gained widespread attention. Herein, Ti2CTx MXene nanosheets were vertically grown on carbon cloth substrate (Ti2CTx@CC) via the simple sintering and subsequent etching process. Flexible pressure sensors featuring the Ti2CTx MXene nanosheets as the sensitive material were then fabricated using polyvinylidene fluoride (PVDF) film weaved by the electrospinning route between the sensitive material and the interdigital electrodes to improve the sensitivity. As-fabricated flexible sensor exhibited superior performances including high sensitivity up to 3109.2 kPa−1, good response and recovery time of 80/80 ms, and favorable stability over 8000 loading/unloading cycles. Boasting the high sensitivity across a broad range, the sensor can in real-time capture a spectrum of human activities—from the faint pulse signal to the large pressure of joint activities and shows promising capability for mapping spatial pressure distribution.

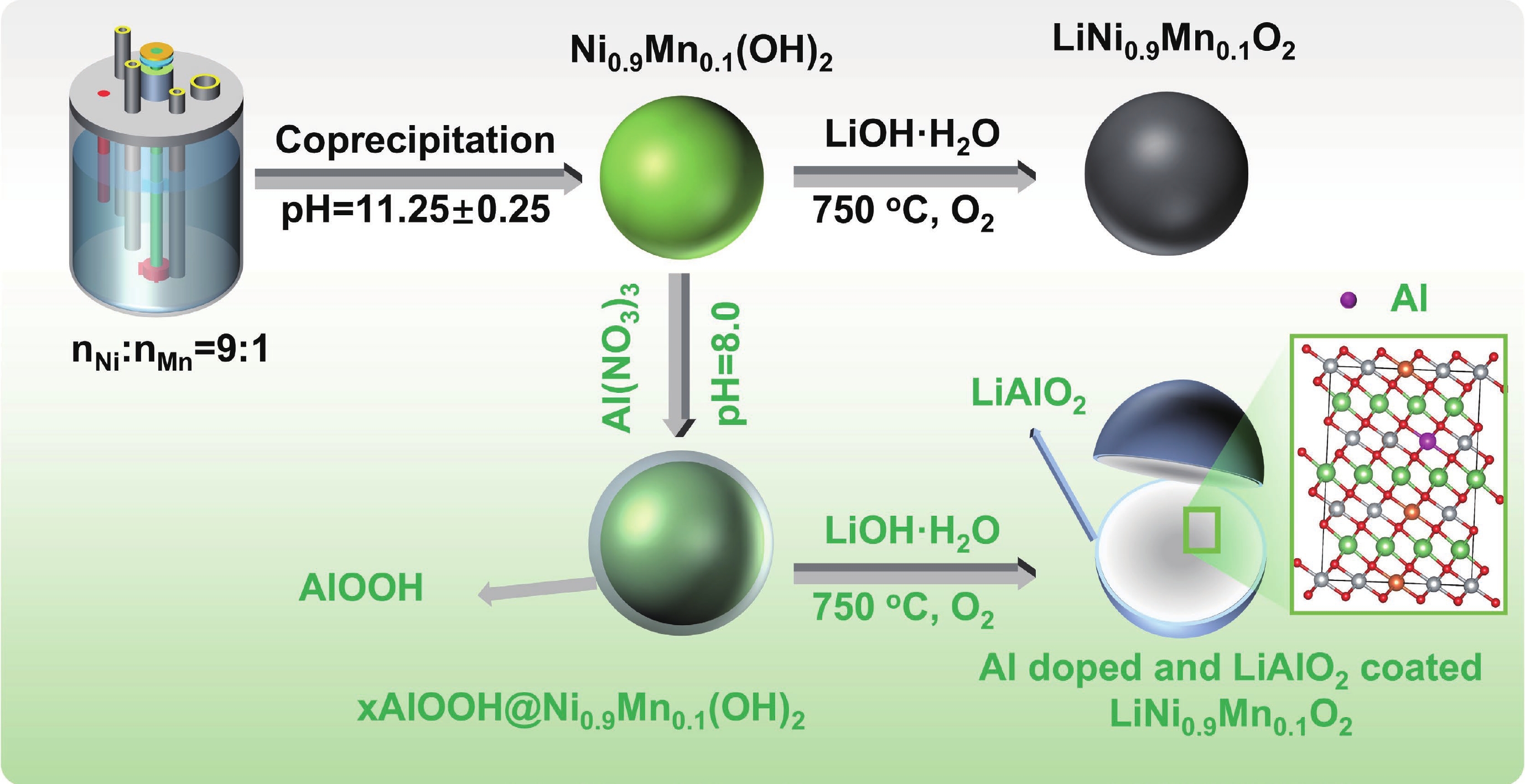

LiNi0.9Mn0.1O2 (LNM91) is a promising cobalt-free, high-energy cathode material for next-generation lithium-ion batteries, but its commercialization is challenged by rapid capacity fading resulting from bulk and interfacial structural degradation. Herein, an in-situ surface-to-bulk dual-modification strategy is developed to synthesize 6Al-LNM91 (6 mol% Al modified LNM91) via a one-step calcination process based on Al diffusion chemistry. This method concurrently constructs a protective LiAlO2 coating and incorporates Al3+ into the bulk lattice, effectively enhancing the structural integrity of the cathode during cycling. The optimized 6Al-LNM91 cathode delivers a remarkable rate capability of 165 mA∙h∙g−1 at 10 C and maintains 94.03% capacity retention after 120 cycles at 0.5 C (2.8 − 4.4 V), substantially outperforming the pristine material (76.82% of LNM91). This organic solvent-free, single-step modification approach offers a scalable and efficient route for improving high-nickel layered oxide cathodes.