| Citation: |

Yuchun Sun, Jia Cheng, Yijia Lu, Yuemin Hou, Linhong Ji. Design space of electrostatic chuck in etching chamber[J]. Journal of Semiconductors, 2015, 36(8): 084004. doi: 10.1088/1674-4926/36/8/084004

****

Y C Sun, J Cheng, Y J Lu, Y M Hou, L H Ji. Design space of electrostatic chuck in etching chamber[J]. J. Semicond., 2015, 36(8): 084004. doi: 10.1088/1674-4926/36/8/084004.

|

Design space of electrostatic chuck in etching chamber

DOI: 10.1088/1674-4926/36/8/084004

More Information

-

Abstract

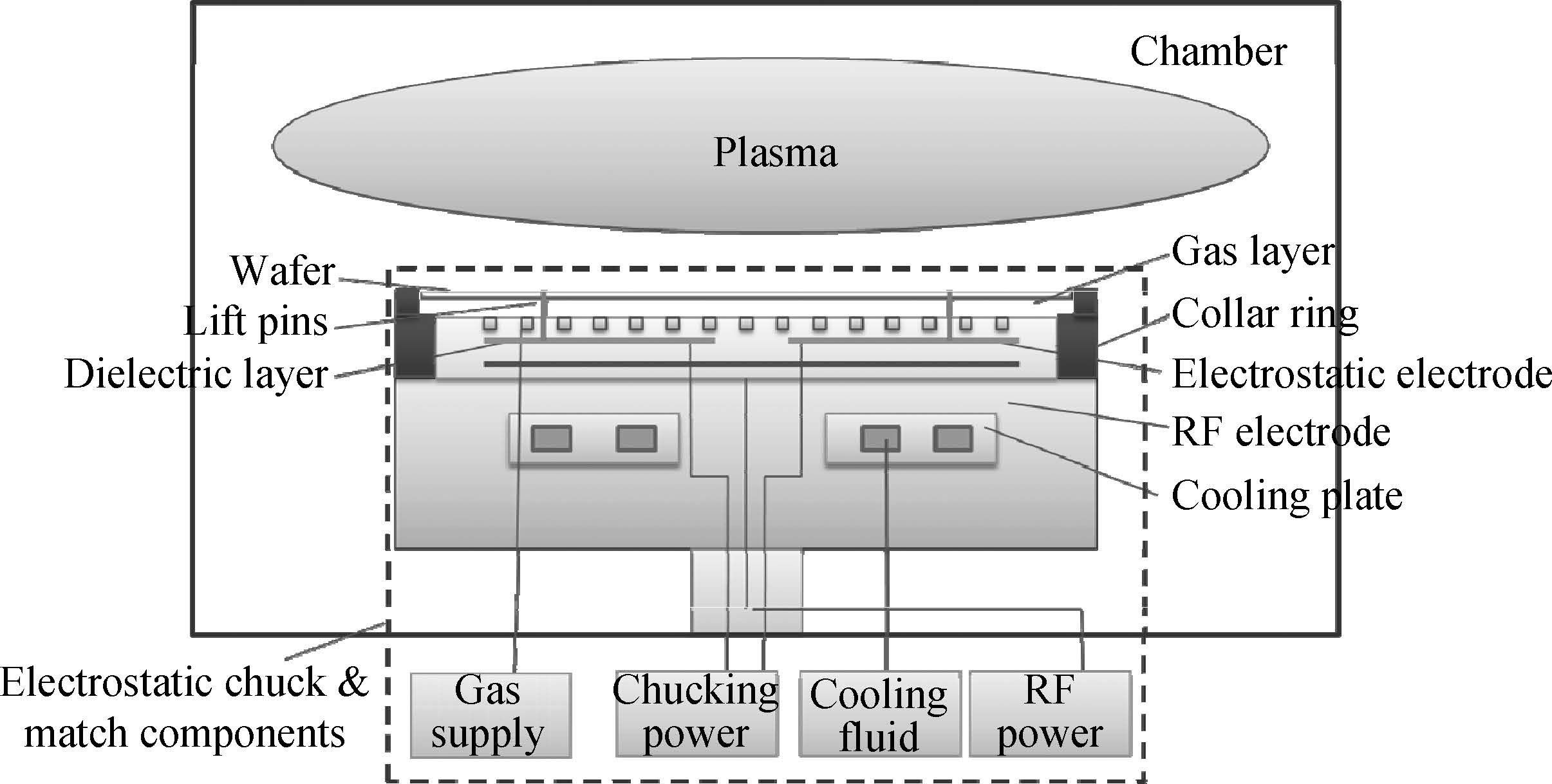

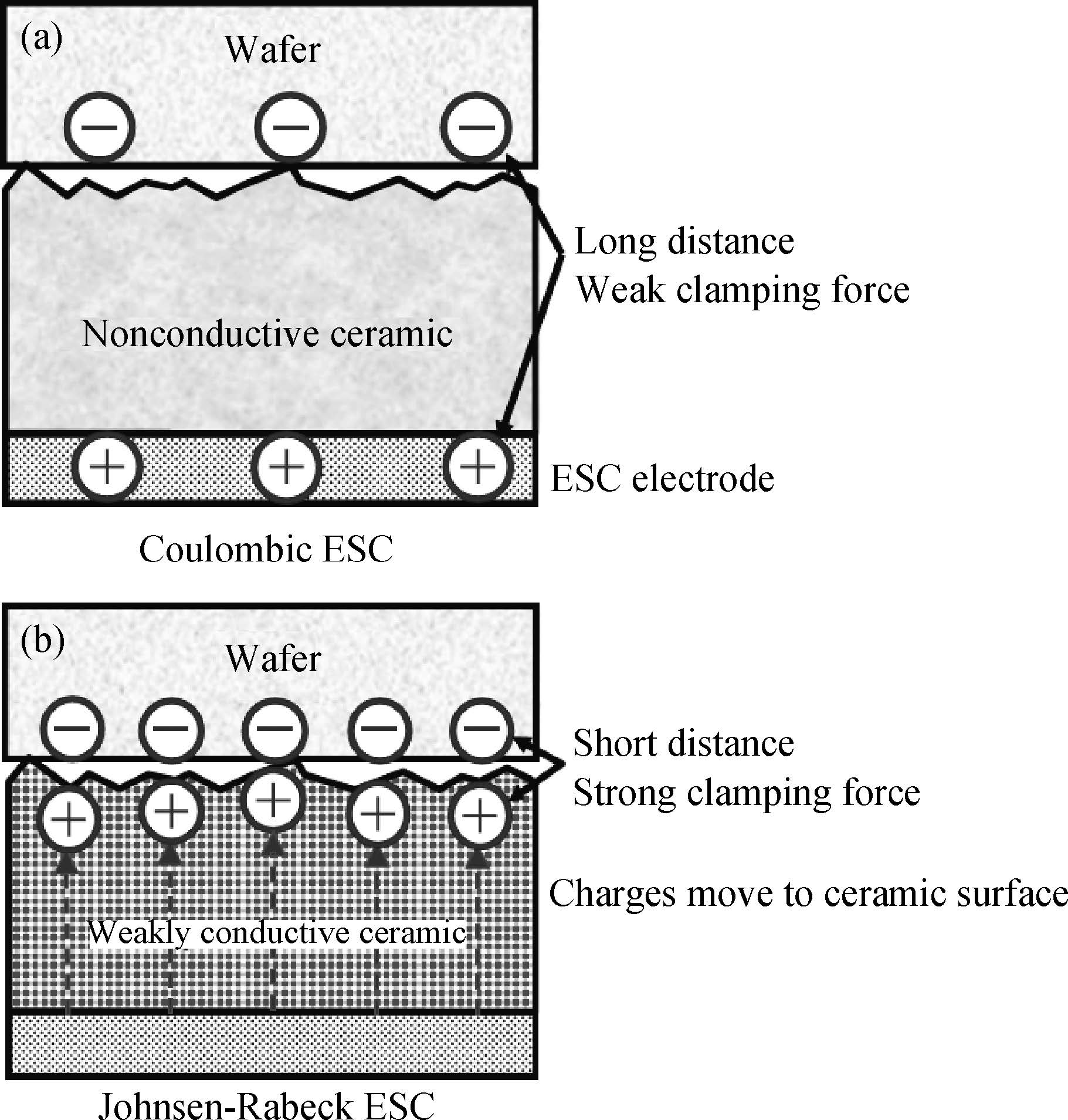

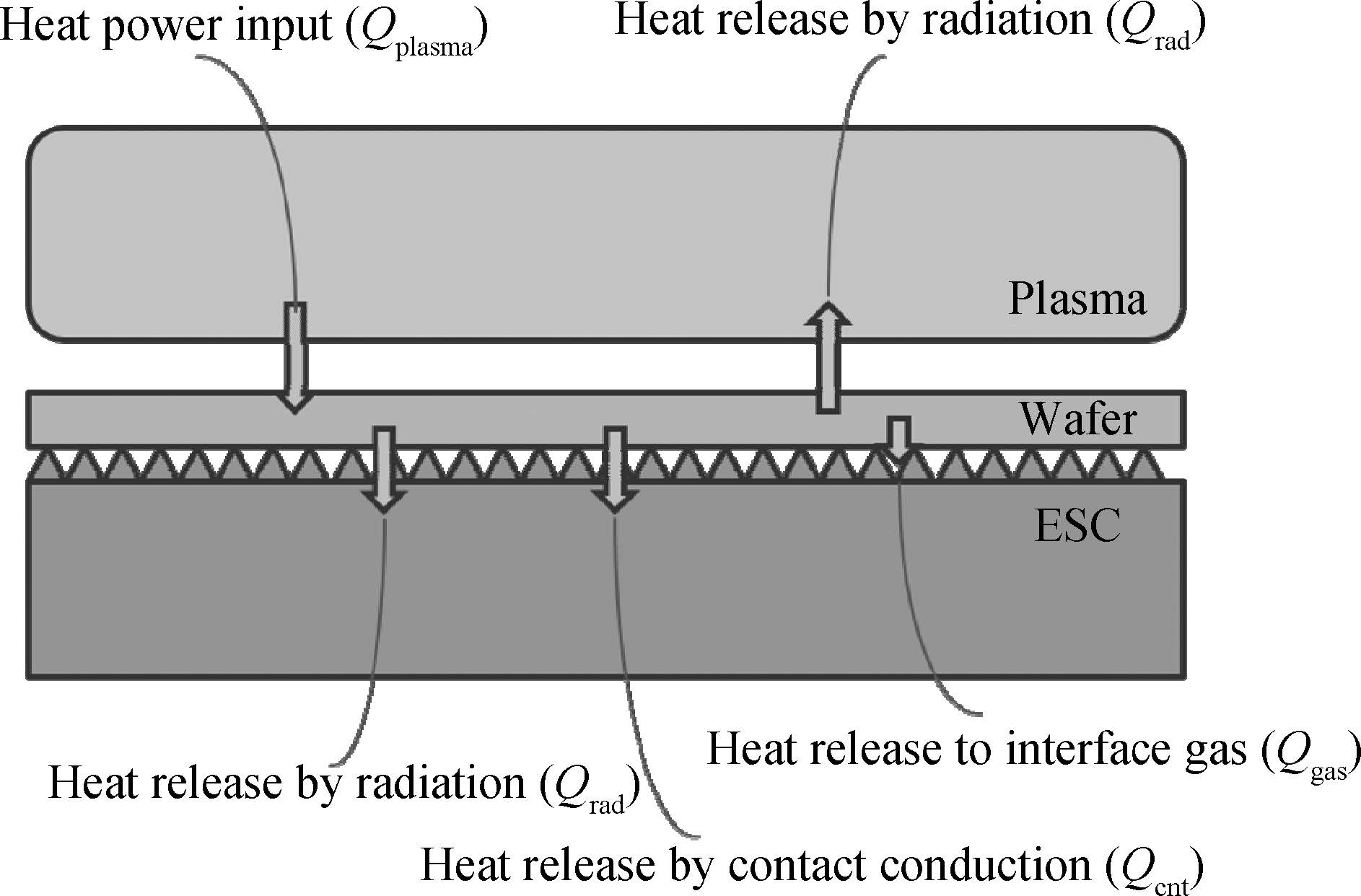

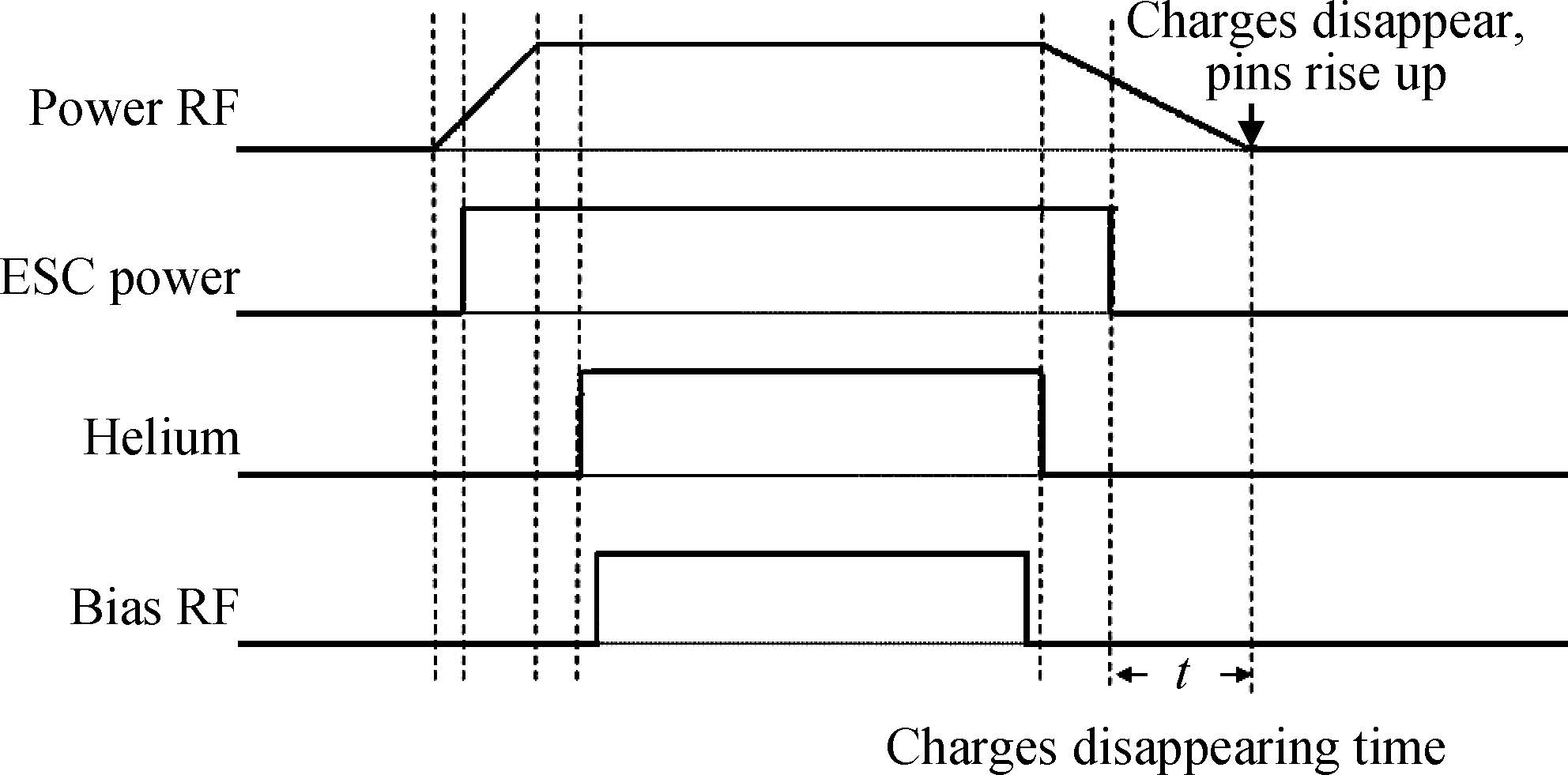

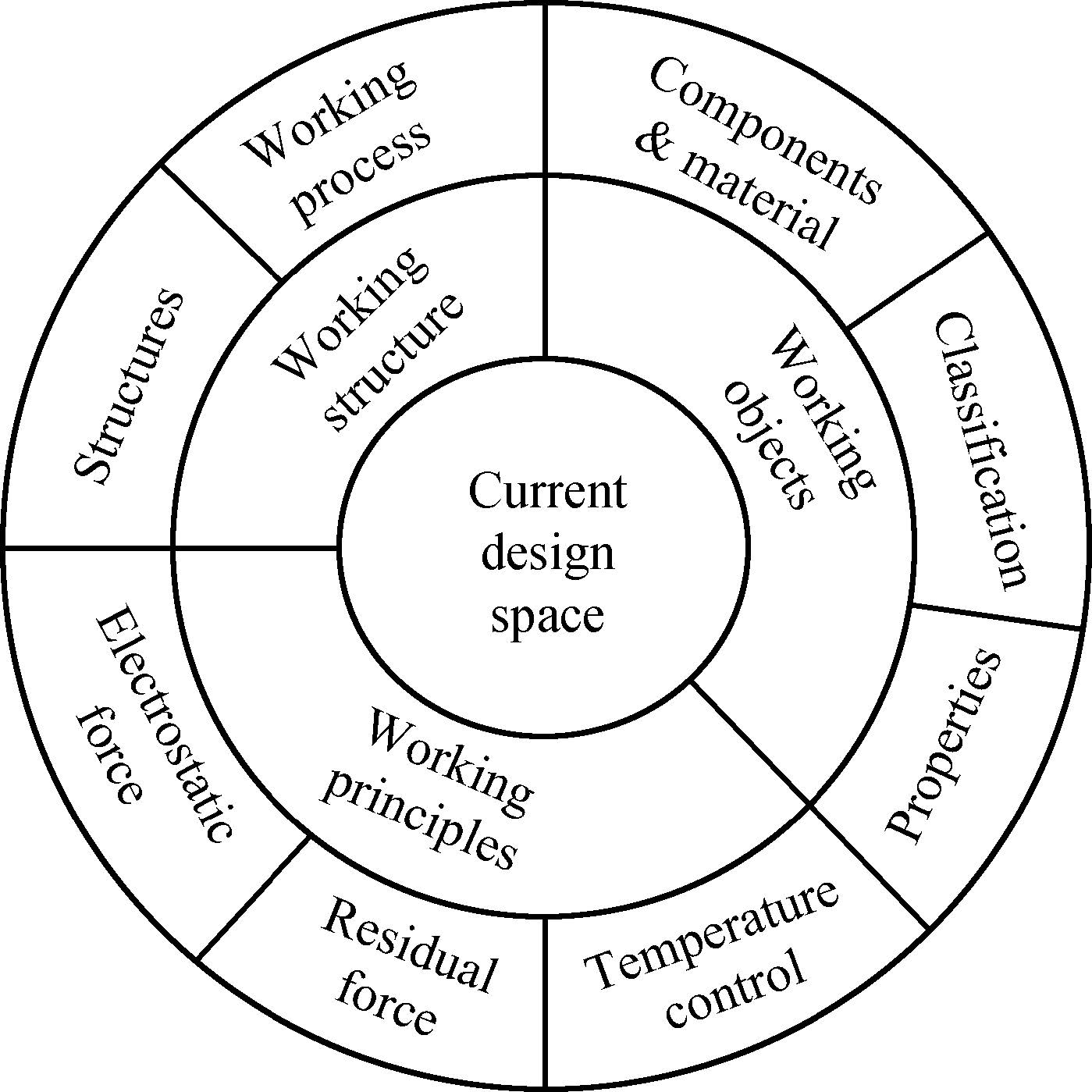

One of the core semiconductor devices is the electrostatic chuck. It has been widely used in plasma-based and vacuum-based semiconductor processing. The electrostatic chuck plays an important role in adsorbing and cooling/heating wafers, and has technical advantages on non-edge exclusion, high reliability, wafer planarity, particles reduction and so on. This article extracts key design elements from the existing knowledge and techniques of electrostatic chuck by the method proposed by Paul and Beitz, and establishes a design space systematically. The design space is composed of working objects, working principles and working structures. The working objects involve electrostatic chuck components and materials, classifications, and relevant properties; the working principles involve clamping force, residual force, and temperature control; the working structures describe how to compose an electrostatic chuck and to fulfill the overall functions. The systematic design space exhibits the main issues during electrostatic chuck design. The design space will facilitate and inspire designers to improve the design quality and shorten the design time in the conceptual design.-

Keywords:

- design space,

- electrostatic chuck,

- clamping force,

- temperature control

-

References

[1] [2] [3] [4] [5] [6] [7] [8] [9] [10] [11] [12] [13] [14] [15] [16] [17] [18] [19] [20] [21] [22] [23] [24] [25] [26] [27] [28] [29] [30] [31] [32] [33] [34] [35] [36] [37] [38] -

Proportional views

DownLoad:

DownLoad: