| Citation: |

Zongcun Liang, Dianlei Wang, Yanbin Zhu. Effects of substrate characteristics on the passivation performance of ALD-Al2O3 thin film for high-efficiency solar cells[J]. Journal of Semiconductors, 2014, 35(5): 054002. doi: 10.1088/1674-4926/35/5/054002

****

Z C Liang, D L Wang, Y B Zhu. Effects of substrate characteristics on the passivation performance of ALD-Al2O3 thin film for high-efficiency solar cells[J]. J. Semicond., 2014, 35(5): 054002. doi: 10.1088/1674-4926/35/5/054002.

|

Effects of substrate characteristics on the passivation performance of ALD-Al2O3 thin film for high-efficiency solar cells

DOI: 10.1088/1674-4926/35/5/054002

More Information

-

Abstract

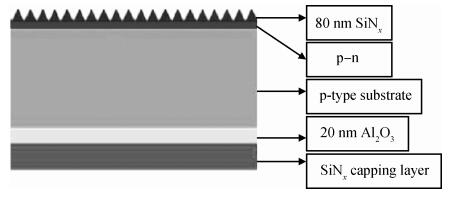

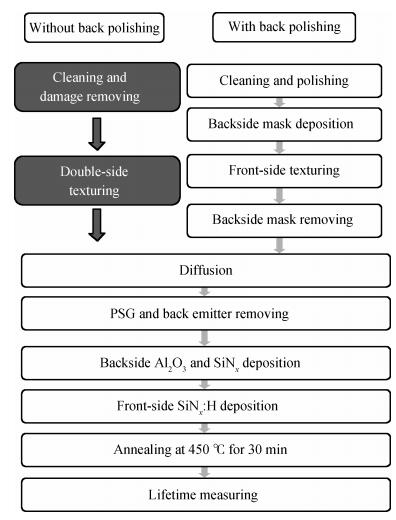

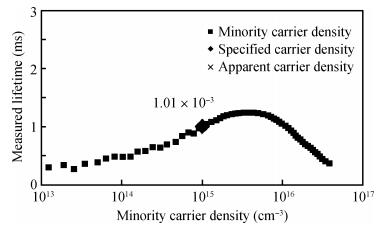

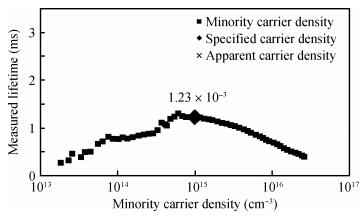

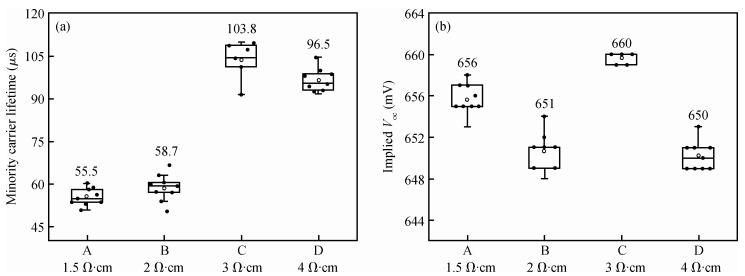

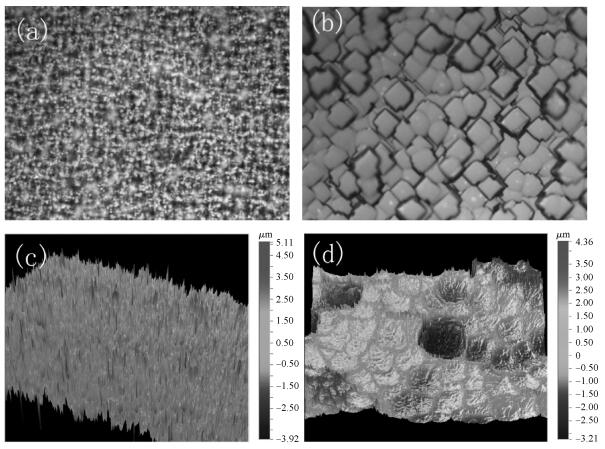

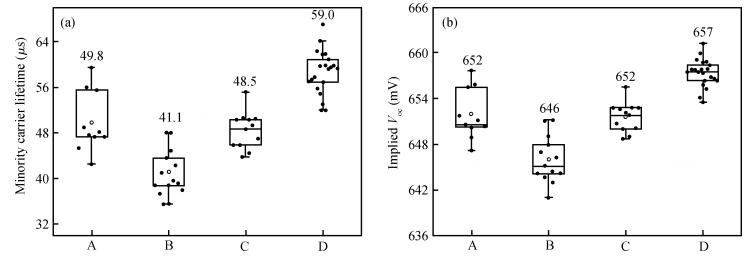

Atom layer deposition (ALD)-Al2O3 thin films are considered effective passivation layers for p-type silicon surfaces. A lower surface recombination rate was obtained through optimizing the deposition parameters. The effects of some of the basic substrate characteristics including material type, bulk resistivity and surface morphology on the passivation performance of ALD-Al2O3 are evaluated in this paper. Surface recombination velocities of 7.8 cm/s and 6.5 cm/s were obtained for p-type and n-type wafers without emitters, respectively. Substrates with bulk resistivity ranging from 1.5 to 4 Ω · cm were all great for such passivation films, and a higher implied Voc of 660 mV on the 3 Ω · cm substrate was achieved. A minority carrier lifetime (MCL) of nearly 10 μs higher was obtained for cells with a polished back surface compared to those with a textured surface, which indicates the necessity of the polishing process for high-efficiency solar cells. For n-type semi-finished solar cells, a lower effective front surface recombination velocity of 31.8 cm/s was acquired, implying the great potential of (ALD)-Al2O3 thin films for high-efficiency n-type solar cells. -

References

[1] Hezel R, Jaeger K. Low-temperature surface passivation of silicon for solar cells. J Electrochem Soc, 1989, 136: 518[2] Wu Dawei, Jia Rui, Wu Deqi, et al. Al2O3 passivation for crystalline silicon solar cells. Micronanoelectron Technol, 2011, 48(8):1671[3] Liu J, Dieter T, Englert M, et al. Al2O3 as surface passivation coating for c-Si solar cells by large-scale in-line sputtering. 25th European Photovoltaic Solar Energy Conference and Exhibition, Valencia, Spain, 2010:1686[4] Bähr M, Sperlich H P, Laades A, et al. Influence of a thermally grown SiO2 interface on the passivation quality of PECVD AlOx-SiNx passivation layers for PERC solar cells. 26th European Photovoltaic Solar Energy Conference and Exhibition, Hamburg, Germany, 2011:2284[5] Black L E, Provancha K M, McIntosh K R. Surface passivation of crystalline silicon by APCVD aluminium oxide. 26th European Photovoltaic Solar Energy Conference and Exhibition, Hamburg, Germany, 2011:1120[6] Agostinelli G, Vitanov P, Alexieva Z, et al. Surface passivation of silicon by means of negative charge dielectrics. Proceedings of the 19th European PVSEC, WIP, Paris, 2004:132[7] Werner F, Veith B, Zielke D, et al. Improved understanding of recombination at the Si/Al2O3 interface. 25th European Photovoltaic Solar Energy Conference and Exhibition, Valencia, Spain, 2010:1121[8] Hoex B, Heil S B S, Langereis E, et al. Ultralow surface recombination of substrates passivated by plasma-assisted atomic layer deposited. Appl Phys Lett, 2006, 89:042112 doi: 10.1063/1.2240736[9] Terlinden N M, Dingemans G, van de Sanden M C M, et al. Role of field-effect on c-Si surface passivation by ultrathin (2-20 nm) atomic layer deposited Al2O3. Appl Phys Lett, 2010, 96:112101 doi: 10.1063/1.3334729[10] Hoex B, Gielis J J H, van de Sanden M C M, et al. On the c-Si surface passivation mechanism by the negative-charge-dielectric Al2O3. J Appl Phys, 2008, 104:113703 doi: 10.1063/1.3021091[11] Agostinelli G, Delabie A, Vitanov P, et al. Very low surface recombination velocities on p-type silicon wafers passivated with a dielectric with fixed negative charge. Sol Energ Mat Sol C, 2006, 90:3438 doi: 10.1016/j.solmat.2006.04.014[12] Van Hemmen J L, Heil S B, Klootwijk J, et al. Plasma and thermal ALD of Al2O3 in a commercial 200 mm ALD reactor. J Electrochem Soc, 2007, 154: G165[13] Kessels W M, Hoex B, van de Sanden M C. Atomic layer deposition:prospects for solar cell manufacturing. 33rd IEEE Photovoltaic Specialists Conference, San Diego, 2008[14] Saint-Cast P, Kania D, Hofmann M, et al. Very low surface recombination velocity on p-type c-Si by high-rate plasma-deposited aluminum oxide. Appl Phys Lett, 2009, 95:151502 doi: 10.1063/1.3250157[15] Hoex B, Schmidt J, Pohl P, et al. Silicon surface passivation by atomic layer deposited Al2O3. J Appl Phys, 2008, 104:044903 doi: 10.1063/1.2963707[16] Benick J, Hoex B, van de Sanden M C M, et al. High efficiency n-type Si solar cells on Al2O3-passivated boron emitters. Appl Phys Lett, 2008, 92:253504 doi: 10.1063/1.2945287[17] Schmidt J, Merkle A, Brendel R, et al. Surface passivation of high-efficiency silicon solar cells by atomic-layer-deposited Al2O3. Prog Photovoltaics, 2008, 16:461 doi: 10.1002/pip.v16:6[18] Riikka L P. Surface chemistry of atomic layer deposition:a case study for the trimethylaluminum/water process. J Appl Phys, 2005, 97:121301 doi: 10.1063/1.1940727[19] Arafune K, Miki S, Matsutani R, et al. Surface recombination of crystalline silicon substrates passivated by atomic-layer-deposited AlOx. Jpn J Appl Phys, 2012, 51:04DP06[20] Cacciato A, Duerinckx F, Baert K, et al. Industrial PERL-type Si solar cells with efficiencies exceeding 19.5%. IEEE J Photovoltaics, 2013, 3(2):628 doi: 10.1109/JPHOTOV.2012.2231725[21] Kranz C, Wyczanowski S, Dorn S, et al. Impact of the rear surface roughness on industrial-type perc solar cells. 27th European Photovoltaic Solar Energy Conference, Frankfurt, Germany, 2012[22] Dingemans G, Kessels W M M. Status and prospects of Al2O3-based surface passivation schemes for silicon solar cells. J Vac Sci Technol A, 2012, 30(4):040802 doi: 10.1116/1.4728205[23] Green M A. Solar cells operating principles, technology and system applications. Translated by Di Dawei, Cao Shaoyang, Li Xiuwen, et al. Shanghai Jiaotong University Press, 2010: 48 -

Proportional views

DownLoad:

DownLoad: