| Citation: |

Guodong Chen, Yuling Liu, Chenwei Wang, Weijuan Liu, Mengting Jiang, Haobo Yuan. Stability for a novel low-pH alkaline slurry during the copper chemical mechanical planarization[J]. Journal of Semiconductors, 2014, 35(8): 086001. doi: 10.1088/1674-4926/35/8/086001

****

G D Chen, Y L Liu, C W Wang, W J Liu, M T Jiang, H B Yuan. Stability for a novel low-pH alkaline slurry during the copper chemical mechanical planarization[J]. J. Semicond., 2014, 35(8): 086001. doi: 10.1088/1674-4926/35/8/086001.

|

Stability for a novel low-pH alkaline slurry during the copper chemical mechanical planarization

DOI: 10.1088/1674-4926/35/8/086001

More Information

-

Abstract

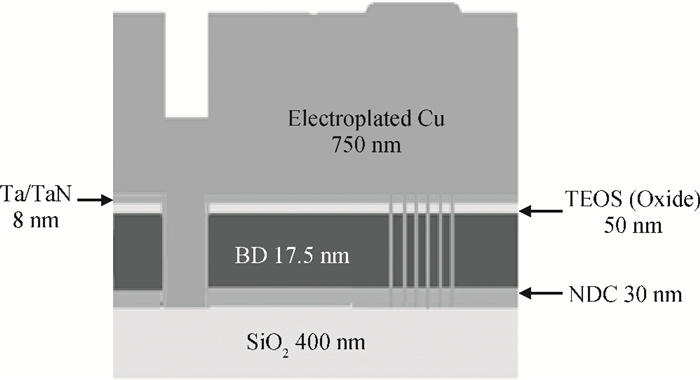

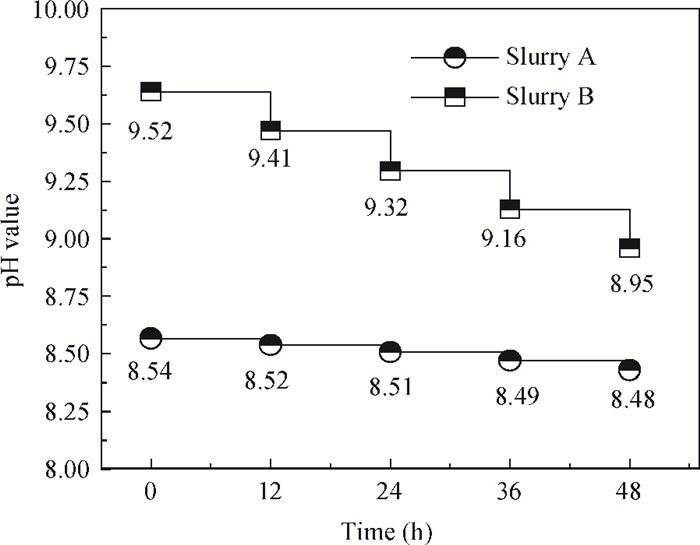

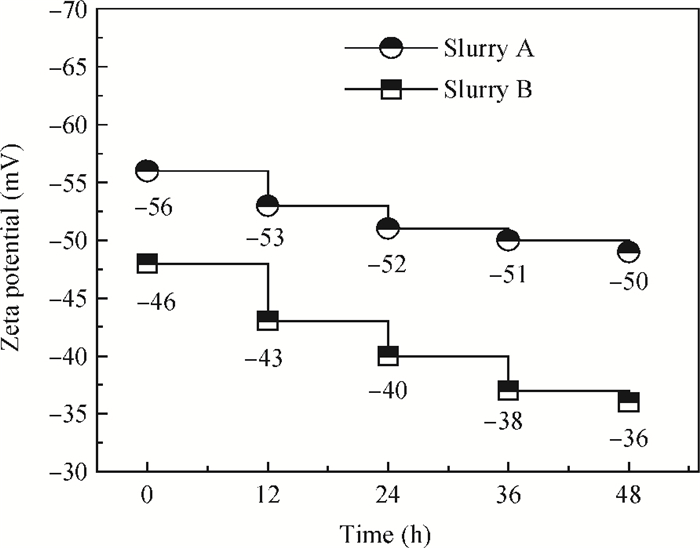

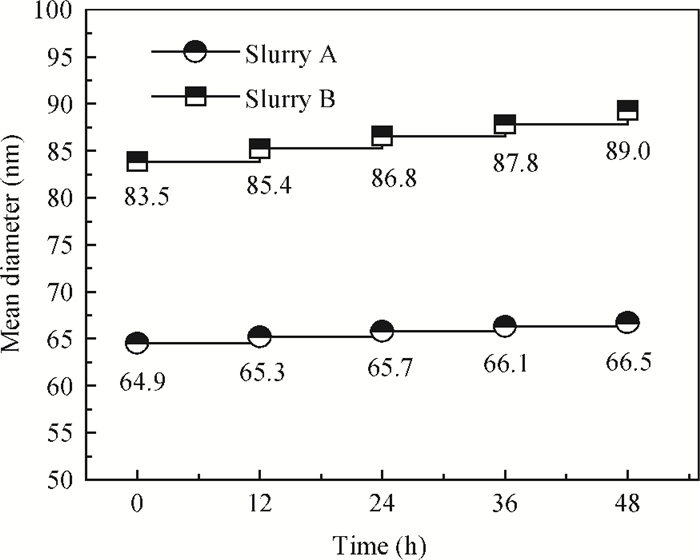

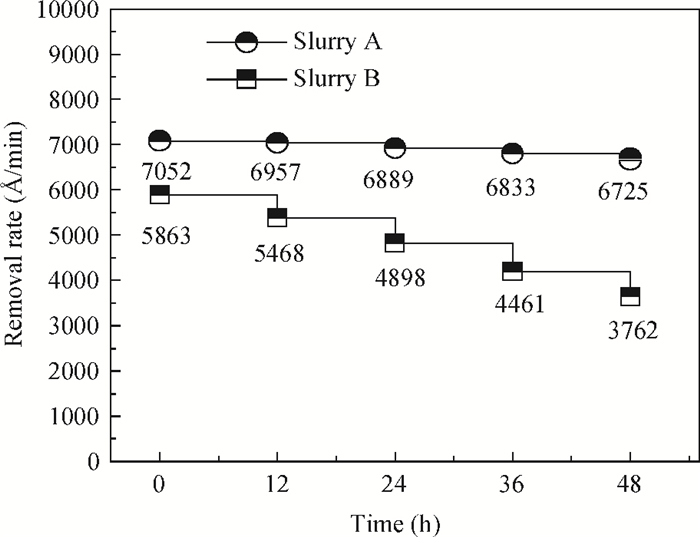

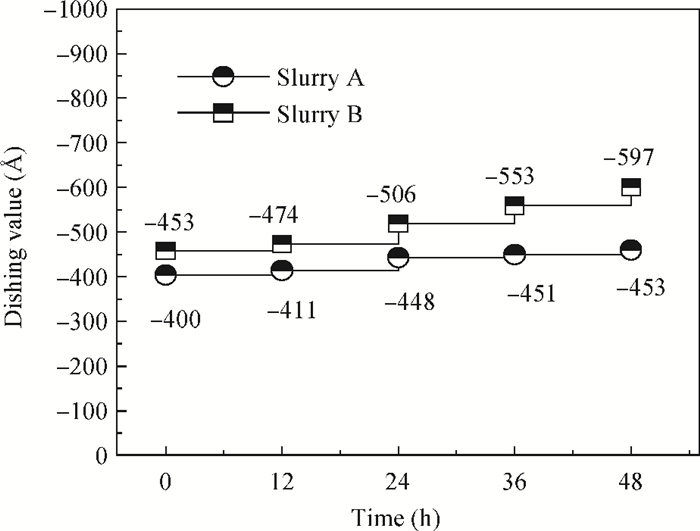

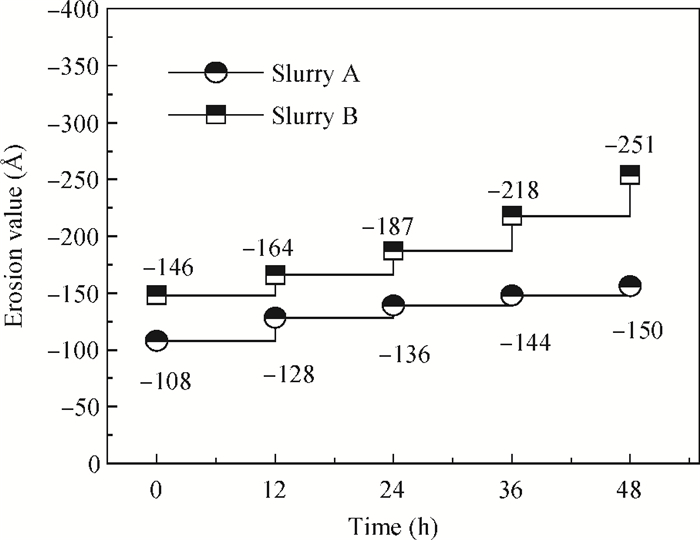

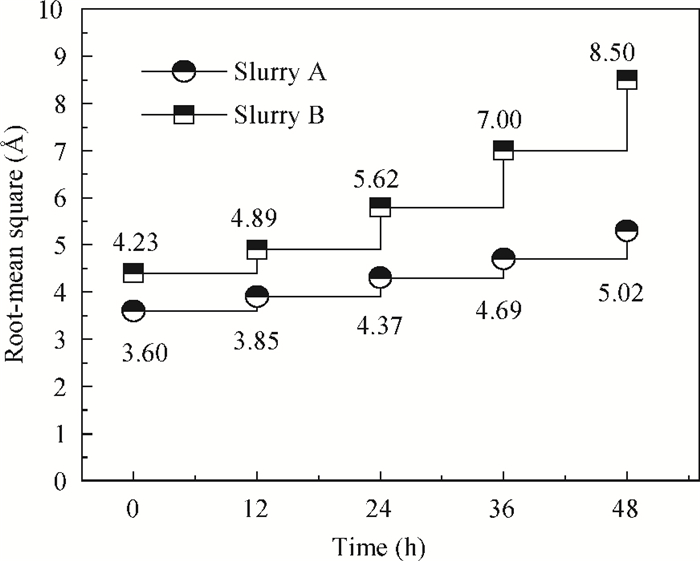

The stability of a novel low-pH alkaline slurry (marked as slurry A, pH=8.5) for copper chemical mechanical planarization was investigated in this paper. First of all, the stability mechanism of the alkaline slurry was studied. Then many parameters have been tested for researching the stability of the slurry through comparing with a traditional alkaline slurry (marked as slurry B, pH=9.5), such as the pH value, particle size and zeta potential. Apart from this, the stability of the copper removal rate, dishing, erosion and surface roughness were also studied. All the results show that the stability of the novel low-pH alkaline slurry is better than the traditional alkaline slurry. The working-life of the novel low-pH alkaline slurry reaches 48 h.-

Keywords:

- stability,

- low-pH,

- alkaline slurry,

- copper multilevel,

- CMP

-

References

[1] Zantye P B, Kumar A, Sikder A K. Chemical mechanical planarization for microelectronics applications. Mater Sci Eng R, 2004, 45:89 doi: 10.1016/j.mser.2004.06.002[2] DeNardis D, Rosales-Yeomans D, Borucki L. A three-step copper chemical mechanical planarization model including the dissolution effects of a commercial slurry. Thin Solid Films, 2010, 518:3910 doi: 10.1016/j.tsf.2009.12.088[3] Wang Chenwei. Planarization properties of an alkaline slurry without an inhibitor on copper patterned wafer CMP. Journal of Semiconductors, 2012, 33(11):116001 doi: 10.1088/1674-4926/33/11/116001[4] Liang Jiang. Functions of Trilon®Pas a polyamine in copper chemical mechanical polishing. Appl Surf Sci, 2014, 288:265 doi: 10.1016/j.apsusc.2013.10.020[5] Chen Rui, Kang Jin, Liu Yuling. Study of a new weakly alkaline slurry for copper planarization at a reduced down pressure. Journal of Semiconductors, 2014, 35(2):026005 doi: 10.1088/1674-4926/35/2/026005[6] Bahar Basim G. Effect of slurry aging on stability and performance of chemical mechanical planarization process. Adv Powder Technol, 2011, 22:257 doi: 10.1016/j.apt.2011.02.002[7] Tsai T H, Wu Y F, Yen S C. Glycolic acid in hydrogen peroxide-based slurry for enhancing copper chemical mechanical polishing. Microelectron Eng, 2005, 77:193 doi: 10.1016/j.mee.2004.10.008[8] Song M G, Lee J H, Lee Y G. Stabilization of gamma alumina slurry for chemical mechanical polishing of copper. Journal of Colloid and Interface Science, 2006, 300:603 doi: 10.1016/j.jcis.2006.04.046[9] Kanki T. Chemical and mechanical properties of Cu surface reaction layers in Cu-CMP to improve planarization. ECS Journal of Solid State Science and Technology, 2013, 2(9):375 doi: 10.1149/2.023309jss[10] Kim N H. Effects of phosphoric acid stabilizer on copper and tantalum nitride CMP. Mater Lett, 2003, 57:4601 doi: 10.1016/S0167-577X(03)00368-9 -

Proportional views

DownLoad:

DownLoad: