| Citation: |

Weijuan Liu, Yuling Liu, Chenwei Wang, Guodong Chen, Mengting Jiang, Haobo Yuan, Pengfei Cheng. Effect of novel alkaline copper slurry on 300 mm copper global planarization[J]. Journal of Semiconductors, 2014, 35(9): 096003. doi: 10.1088/1674-4926/35/9/096003

****

W J Liu, Y L Liu, C W Wang, G D Chen, M T Jiang, H B Yuan, P F Cheng. Effect of novel alkaline copper slurry on 300 mm copper global planarization[J]. J. Semicond., 2014, 35(9): 096003. doi: 10.1088/1674-4926/35/9/096003.

|

Effect of novel alkaline copper slurry on 300 mm copper global planarization

DOI: 10.1088/1674-4926/35/9/096003

More Information

-

Abstract

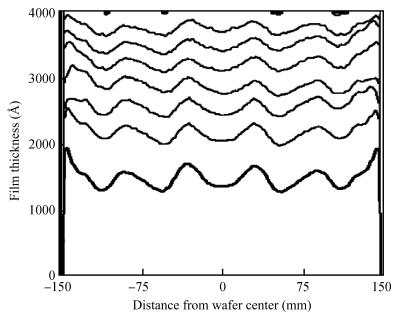

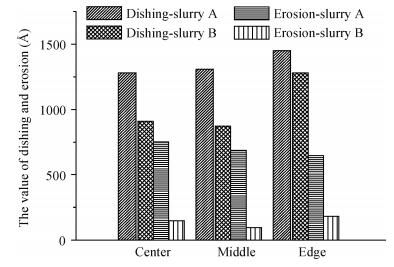

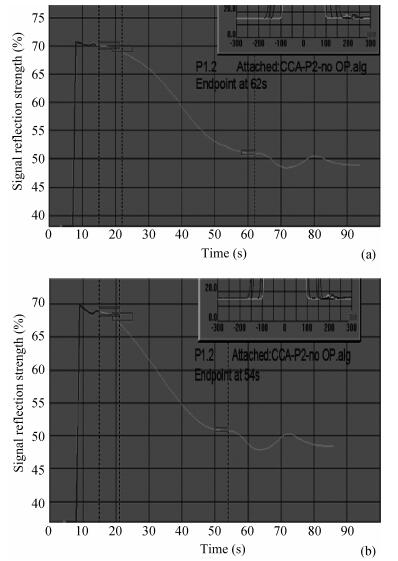

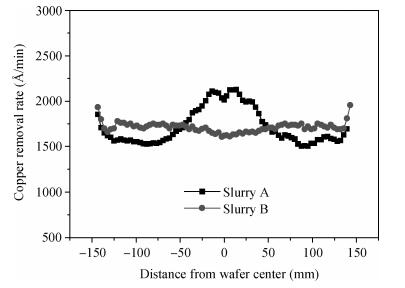

The copper removal rate and uniformity of two types copper slurries were investigated, which was performed on the 300 mm chemical mechanical planarization (CMP) platform. The experiment results illustrate that the removal rate of the two slurries is nearly the same. Slurry A is mainly composed of a FA/OⅡ type chelating agent and the uniformity reaches to 88.32%. While the uniformity of slurry B is 96.68%, which is mainly composed of a FA/OV type chelating agent. This phenomenon demonstrates that under the same process conditions, the uniformity of different slurries is vastly different. The CMP performance was evaluated in terms of the dishing and erosion values. In this paper, the relationship between the uniformity and the planarization was deeply analyzed, which is mainly based on the endpoint detection mechanism. The experiment results reveal that the slurry with good uniformity has low dishing and erosion. The slurry with bad uniformity, by contract, increases Cu dishing significantly and causes copper loss in the recessed region. Therefore, the following conclusions are drawn:slurry B can improve the wafer leveling efficiently and minimize the resistance and current density along the line, which is helpful to improve the device yield and product reliability. This investigation provides a guide to improve the uniformity and achieve the global and local planarization. It is very significant to meet the requirements for 22 nm technology nodes and control the dishing and erosion efficiently.-

Keywords:

- CMP,

- removal rate,

- uniformity,

- dishing,

- erosion,

- endpoint detection

-

References

[1] Wang Chenwei, Liu Yuling, Tian Jianying, et al. Planarization properties of an alkaline slurry without an inhibitor on copper patterned wafer CMP. Journal of Semiconductors, 2012, 33(11):116001 doi: 10.1088/1674-4926/33/11/116001[2] Wang Chenwei, Liu Yuling, Niu Xinhuan, et al. An advanced alkaline slurry for barrier chemical mechanical planarization on patterned wafers. Journal of Semiconductors, 2012, 33(4):046001 doi: 10.1088/1674-4926/33/4/046001[3] Wang C W, Liu Y L, Tian J Y, et al. A study on the comparison of CMP performance between a novel alkaline slurry and a commercial slurry for barrier removal. Microelectron Eng, 2012, 98:29 doi: 10.1016/j.mee.2012.05.028[4] Wang C W, Gao J J, Tian J Y, et al. Chemical mechanical planarization of barrier layers by using a weakly alkaline slurry. Microelectron Eng, 2013, 108:71 doi: 10.1016/j.mee.2013.04.001[5] Cao Y, Liu Y L, Wang C W. Study on dishing control properties of an high dilution ration alkaline copper clearing slurry. International Conference on Planarization/CMP Technology, 2013:203[6] Nagar M, Vaes J, Ein-Eli Y. Potassium sorbate as an inhibitor in copper chemical mechanical planarization slurries. Part Ⅱ:Effects of sorbate on chemical mechanical planarization performance. Electrochimica Acta, 2010, 55:2810 doi: 10.1016/j.electacta.2009.10.086[7] Noh K, Saka N, Chun J H. Effect of slurry selectivity on dielectric erosion and copper dishing in copper chemical-mechanical polishing. CIRP Annals Manufacturing Technology, 2004, 53(1):463 doi: 10.1016/S0007-8506(07)60740-9[8] Liu X Y, Liu Y L, Liang Y, et al. Optimization of slurry components for a copper chemical mechanical polishing at low down pressure using response surface methodology. Microelectron Eng, 2011, 88:99 doi: 10.1016/j.mee.2010.09.007[9] Chuan L W, Liu Y L, Wang C W. Effect of back pressure on the uniformity of wafer thickness in the Cu CMP process. Micronanoelectron Technol, 2012, 49(5):340 http://en.cnki.com.cn/Article_en/CJFDTotal-BDTQ201205011.htm[10] Zeidler D, Plotoner M, Drescher K. Endpoint detection method for CMP of copper. Microelectron Eng, 2000, 50:411 doi: 10.1016/S0167-9317(99)00309-3[11] Lee H, Park B, Jeong H. Influence of slurry components on uniformity in copper chemical mechanical planarization. Microelectron Eng, 2008, 85:689 doi: 10.1016/j.mee.2007.12.044[12] Wang T Q, Lu X C. Numerical and experimental investigation on multi-zone chemical mechanical planarization. Microelectron Eng, 2011, 88:3327 doi: 10.1016/j.mee.2011.08.011[13] Nguyen V H. Daamen R, Hoofman R. Impact of different slurry and polishing pad choices on the planarization efficiency of a copper CMP process. Microelectron Eng, 2004, 76:95 doi: 10.1016/j.mee.2004.07.019[14] Lee H, Park B, Jeong H. Influence of slurry components on uniformity in copper chemical mechanical planarization. Microelectron Eng, 2008, 85:689 doi: 10.1016/j.mee.2007.12.044 -

Proportional views

DownLoad:

DownLoad: