| Citation: |

Yang Liu, Fenglian Sun, Ping Liu, Xiaolong Gu, Guoqi Zhang. Shear strength of LED solder joints using SAC-nano Cu solder pastes[J]. Journal of Semiconductors, 2017, 38(9): 096003. doi: 10.1088/1674-4926/38/9/096003

****

Y Liu, F L Sun, P Liu, X L Gu, G Q Zhang. Shear strength of LED solder joints using SAC-nano Cu solder pastes[J]. J. Semicond., 2017, 38(9): 096003. doi: 10.1088/1674-4926/38/9/096003.

|

Shear strength of LED solder joints using SAC-nano Cu solder pastes

DOI: 10.1088/1674-4926/38/9/096003

More Information

-

Abstract

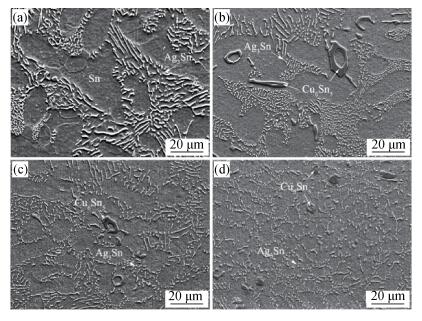

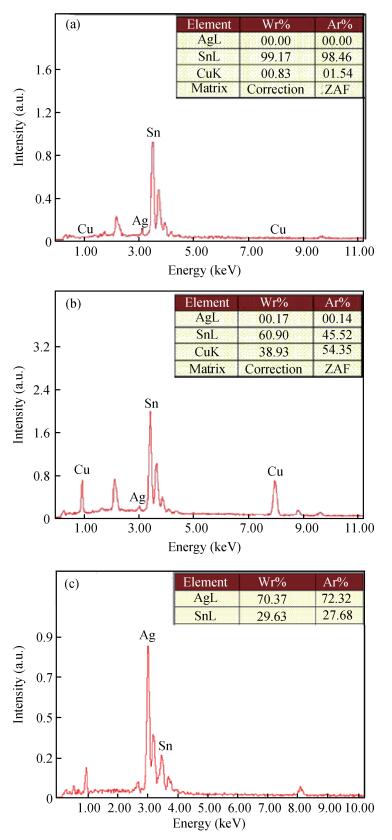

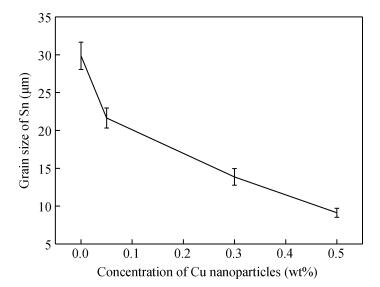

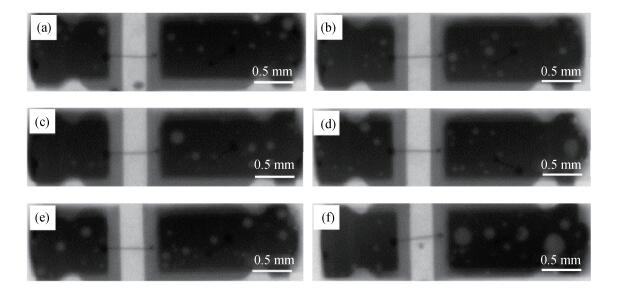

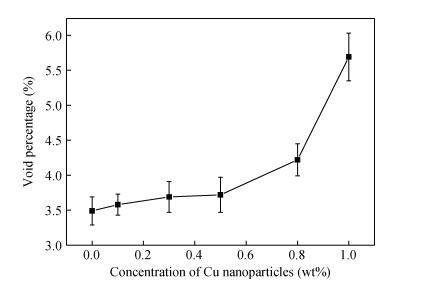

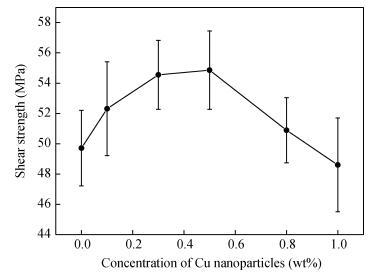

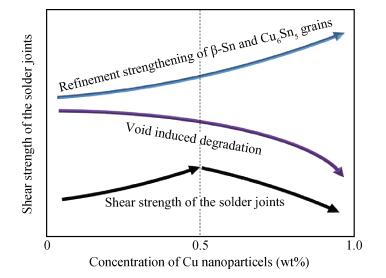

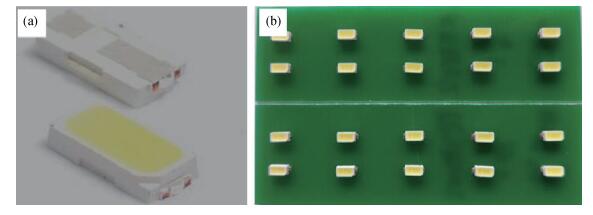

The addition of Cu nanoparticles into the solder pastes by mechanical mixing method creates a positive effect on the microstructure refinement of the LED solder joints. The grain size of β-Sn and Cu6Sn5 decrease obviously due to the increasing concentration of the nanoparticles in the solder pastes. However, the addition of nanoparticles facilitates the formation of voids in the solder joints, especially when the concentration of nanoparticles is higher than 0.5 wt% in the solder pastes. Both the microstructure refinement and void percentage affect the shear strength of the solder joints. Since the increase of the void percentage is limited when the concentration of nanoparticles increases from 0 to 0.5 wt%, the microstructure refinement shows a dominant effect on the shear performance and thus improves the shear strength of the solder joints from 49.8 to 55 MPa. Further addition of nanoparticles in the solder pastes leads to a sharp increase of the void percentage. Consequently, the shear strength of the solder joints decreases from 55 to 48.8 MPa when the concentration of doped particles increases from 0.5 to 1 wt% in the solder pastes.-

Keywords:

- shear strength,

- LED,

- solder,

- nano Cu,

- microstructure

-

References

[1] Pimputkar S, Speck J S, DenBaars S P, et al. Prospects for LED lighting. Nat Photonics, 2009, 3(4):180 doi: 10.1038/nphoton.2009.32[2] Lozano G, Louwers D J, Rodríguez S R K, et al. Plasmonics for solid-state lighting:enhanced excitation and directional emission of highly efficient light sources. Light Sci Appl, 2013, 2(5):e66 doi: 10.1038/lsa.2013.22[3] Luo X, Hu R, Liu S, et al. Heat and fluid flow in high-power LED packaging and applications. Prog Energ Combust, 2016, 56:1 doi: 10.1016/j.pecs.2016.05.003[4] George E, Das D, Osterman M, et al. Thermal cycling reliability of lead-free solders (SAC305 and Sn3.5Ag) for high-temperature applications. IEEE Trans Device Mater Res, 2011, 11(2):328 doi: 10.1109/TDMR.2011.2134100[5] Zhou Q, Zhou B, Lee T K, et al. Microstructural evolution of SAC305 solder joints in wafer level chip-scale packaging (WLCSP) with continuous and interrupted accelerated thermal cycling. J Electron Mater, 2016, 45(6):3013 doi: 10.1007/s11664-016-4343-6[6] Mäusezahl M, Hornaff M, Burkhardt T, et al. Mechanical properties of laser-jetted SAC305 solder on coated optical surfaces. Phys Proc, 2016, 83:532 doi: 10.1016/j.phpro.2016.08.055[7] Liu Y, Sun F, Zhang H, et al. Interfacial reaction and failure mode analysis of the solder joints for flip-chip LED on ENIG and Cu-OSP surface finishes. Microelectron Reliab, 2015, 55(8):1234 doi: 10.1016/j.microrel.2015.05.005[8] Elger G, Kandaswamy S V, Liu E, et al. Analysis of solder joint reliability of high power LEDs by transient thermal testing and transient finite element simulations. Microelectron J, 2015, 46(12):1230 doi: 10.1016/j.mejo.2015.08.007[9] El-Daly A A, Elmosalami T A, Desoky W M, et al. Tensile deformation behavior and melting property of nano-sized ZnO particles reinforced Sn-3.0Ag-0.5Cu lead-free solder. Mater Sci Eng A, 2014, 618:389 doi: 10.1016/j.msea.2014.09.028[10] Chen G, Liu L, Du J, et al. Thermo-migration behavior of SAC305 lead-free solder reinforced with fullerene nanoparticles. J Mater Sci, 2016, 51(22):10077 doi: 10.1007/s10853-016-0234-8[11] Zhao Z, Liu L, Choi H S, et al. Effect of nano-Al2O3 reinforcement on the microstructure and reliability of Sn-3.0Ag-0.5Cu solder joints. Microelectron Reliab, 2016, 60:126 doi: 10.1016/j.microrel.2016.03.005[12] Meng H, Luo J, Wang W, et al. Top-emission organic light-emitting diode with a novel copper/graphene composite anode. Adv Funct Mater, 2013, 23(26):3324 doi: 10.1002/adfm.v23.26[13] Yang L, Leung S Y Y, Wong C K Y, et al. Thermal simulation of flexible LED package enhanced with copper pillars. J Semicond, 2015, 36(6):064011 doi: 10.1088/1674-4926/36/6/064011[14] Horng R H, Lin R C, Chiang Y C, et al. Failure modes and effects analysis for high-power GaN-based light-emitting diodes package technology. Microelectron Reliab, 2012, 52(5):818 doi: 10.1016/j.microrel.2011.02.021[15] Liu Y, Zhang H, Sun F. Solder ability of SnBi-nano Cu solder pastes and microstructure of the solder joints. J Mater Sci:Mater Electron, 2016, 27(3):2235 doi: 10.1007/s10854-015-4016-x[16] Chen X, Zhou J, Xue F, et al. Microstructures and mechanical properties of Sn-0.1Ag-0.7Cu-(Co, Ni, and Nd) lead-free solders. J Electron Mater, 2015, 44(2):725 doi: 10.1007/s11664-014-3537-z[17] Abdul A S D, Faizul B M S M, Anjum B I, et al. A review on effect of minor alloying elements on thermal cycling and drop impact reliability of low-Ag Sn-Ag-Cu solder joints. Microelectron Int, 2012, 29(1):47 doi: 10.1108/13565361211219202[18] Shen J, Pu Y, Wu D, et al. Effects of minor Bi, Ni on the wetting properties, microstructures, and shear properties of Sn-0.7Cu lead-free solder joints. J Mater Sci:Mater Electron, 2015, 26(3):1572 doi: 10.1007/s10854-014-2577-8[19] Shnawah D A, Sabri M F M, Badruddin I A. A review on thermal cycling and drop impact reliability of SAC solder joint in portable electronic products. Microelectron Reliab, 2012, 52(1):90 doi: 10.1016/j.microrel.2011.07.093[20] Ochoa F, Williams J J, Chawla N. The effects of cooling rate on microstructure and mechanical behavior of Sn-3.5Ag solder. JOM, 2003, 55(6):56 doi: 10.1007/s11837-003-0142-7[21] Liu Y, Leung S Y Y, Zhao J, et al. Thermal and mechanical effects of voids within flip chip soldering in LED packages. Microelectron Reliab, 2014, 54(9):2028 https://www.deepdyve.com/lp/elsevier/thermal-and-mechanical-effects-of-voids-within-flip-chip-soldering-in-R0A76ITrj0 -

Proportional views

DownLoad:

DownLoad: