| Citation: |

Jie Zhang, Jianqiang Han, Yijun Yin, Lizhen Dong, Wenju Niu. Study on the failure temperature of Ti/Pt/Au and Pt5Si2-Ti/Pt/Au metallization systems[J]. Journal of Semiconductors, 2017, 38(9): 096005. doi: 10.1088/1674-4926/38/9/096005

****

J Zhang, J Q Han, Y J Yin, L Z Dong, W J Niu. Study on the failure temperature of Ti/Pt/Au and Pt5Si2-Ti/Pt/Au metallization systems[J]. J. Semicond., 2017, 38(9): 096005. doi: 10.1088/1674-4926/38/9/096005.

|

Study on the failure temperature of Ti/Pt/Au and Pt5Si2-Ti/Pt/Au metallization systems

DOI: 10.1088/1674-4926/38/9/096005

More Information

-

Abstract

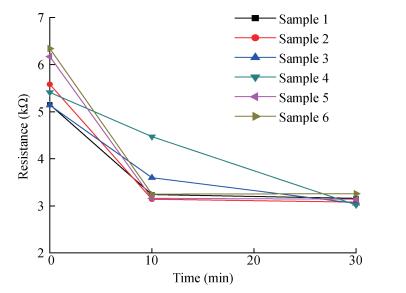

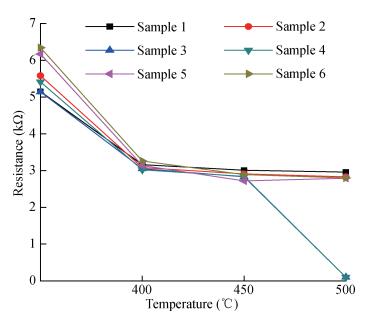

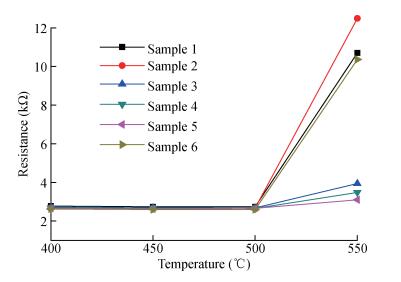

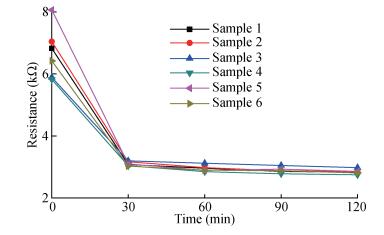

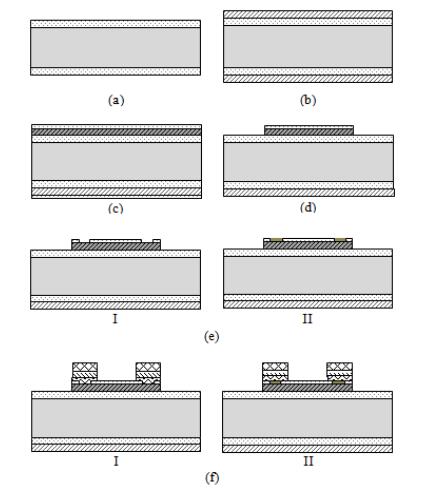

The Ti/Pt/Au metallization system has an advantage of resisting KOH or TMAH solution etching. To form a good ohmic contact, the Ti/Pt/Au metallization system must be alloyed at 400℃. However, the process temperatures of typical MEMS packaging technologies, such as anodic bonding, glass solder bonding and eutectic bonding, generally exceed 400℃. It is puzzling if the Ti/Pt/Au system is destroyed during the subsequent packaging process. In the present work, the resistance of doped polysilicon resistors contacted by the Ti/Pt/Au metallization system that have undergone different temperatures and time are measured. The experimental results show that the ohmic contacts will be destroyed if heated to 500℃. But if a 20 nm Pt film is sputtered on heavily doped polysilicon and alloyed at 700℃ before sputtering Ti/Pt/Au films, the Pt5Si2-Ti/Pt/Au metallization system has a higher service temperature of 500℃, which exceeds process temperatures of most typical MEMS packaging technologies.-

Keywords:

- Ti/Pt/Au metallization system,

- packaging,

- ohmic contacts,

- MEMS

-

References

[1] Card H C. Aluminum-silicon Schottky barriers and ohmic contacts in integrated circuits. IEEE Trans Electron Devices, 1976, 23(6):538 doi: 10.1109/T-ED.1976.18449[2] Mayumi S, Umemoto T, Shishino M, et al. The effect of Cu addition to Al-Si interconnects on stress induced open-circuit failures. Reliab Phys Symp, 1987:15 https://www.mendeley.com/research-papers/effect-cu-addition-alsi-interconnects-stress-induced-opencircuit-failures/[3] Kanamori S, Sudo H. Effects of titanium layer as diffusion barrier in Ti/Pt/Au beam lead metallization on polysilicon. IEEE Trans Compon, 1982, 5(3):318 http://ieeexplore.ieee.org/document/1135973/[4] Sozza A, Dua C, Kerlain A, et al. Long-term reliability of Ti-Pt-Au metallization system for Schottky contact and first-level metallization on SiC MESFET. Microelectron Reliab, 2004, 44(7):1109 doi: 10.1016/j.microrel.2004.01.017[5] Zhou J, Xia G, Li B, et al, Structural and electrical properties of Au/Pt/Ti ohmic contacts to degenerated doped n-GaAS. Appl Phys A, 2003, 76(6):939 doi: 10.1007/s00339-002-1439-z[6] Wang G H, Liu Z M, Dai J L. Application of Ti-Pt-Au multi-layer metallized syetem to semiconductor devices. J Harbin Institute Technol, 1985, (4):26 http://en.cnki.com.cn/Article_en/CJFDTotal-HEBX198504004.htm[7] Wu Z W, Chen D Y, Xia S H. Research on the failed mechanism of anodic bonding of silicon to glass. Micronanoelectron Technol, 2010, 10:619 http://en.cnki.com.cn/Article_en/CJFDTOTAL-BDTQ201010008.htm[8] Xu W, Wang Y C, Luo L. Wafer-level hermetic packaging of MEMS by glass solder at low temperature. J Func Mater Devices, 2005, 11:343 http://en.cnki.com.cn/Article_en/CJFDTOTAL-GNCQ200503016.htm[9] Liu B W, Zhang Z H, Tan Z M, et al. Au-Si eutectic bonding technology for MEMS device. Semicond Technol, 2006, 12:896 http://en.cnki.com.cn/Article_en/CJFDTOTAL-BDTJ200612004.htm[10] Zhong B F. An approach to PtSi contact alloying. Microelectronics, 1988, 18:1 http://en.cnki.com.cn/Article_en/CJFDTotal-MINI198804000.htm[11] Xiong P, Liao S R. Study on the formation of PtSi with Pt-Si alloy. Semicond Optoelectron, 1992, 13:359 http://en.cnki.com.cn/Article_en/CJFDTotal-BDTG199204012.htm[12] Yin J H, Cai W, Wang M G, et al Surface and interface characteristic of sputtered nanometer PtSi film. J Semicond, 2003, 24(S1):74 http://ieeexplore.ieee.org/document/4963291/[13] Wang Q, Ding J N, Wang W X, et al. Fabrication of a pressure sensor gauge chip based on SIMOX. J Semicond, 2005, 26:1595 http://www.oalib.com/paper/1519655[14] Yin Y, Rioux R M, Erdonmez C K, et al. Formation of hollow nanocrystals through the nanoscale Kirkendall effect. Science, 2004, 304(5671):711 doi: 10.1126/science.1096566[15] Campbell S A. Fabrication engineering at the micro and nanoscale. 3th ed. Beijing: Publishing House of Electronics Industry, 2008[16] Wu D F, Yan B D. Metallurgical basis of ohmic contacts. Principle, measurement and process of ohmic contact at metal-semiconductor interface. Shanghai:Profile of Shanghai Jiao Tong University Press, 1989 -

Proportional views

DownLoad:

DownLoad: