| Citation: |

Caihong Yao, Chenwei Wang, Xinhuan Niu, Yan Wang, Shengjun Tian, Zichao Jiang, Yuling Liu. The stability of a novel weakly alkaline slurry of copper interconnection CMP for GLSI[J]. Journal of Semiconductors, 2018, 39(2): 026002. doi: 10.1088/1674-4926/39/2/026002

****

C H Yao, C W Wang, X H Niu, Y Wang, S J Tian, Z C Jiang, Y L Liu. The stability of a novel weakly alkaline slurry of copper interconnection CMP for GLSI[J]. J. Semicond., 2018, 39(2): 026002. doi: 10.1088/1674-4926/39/2/026002.

|

The stability of a novel weakly alkaline slurry of copper interconnection CMP for GLSI

DOI: 10.1088/1674-4926/39/2/026002

More Information

-

Abstract

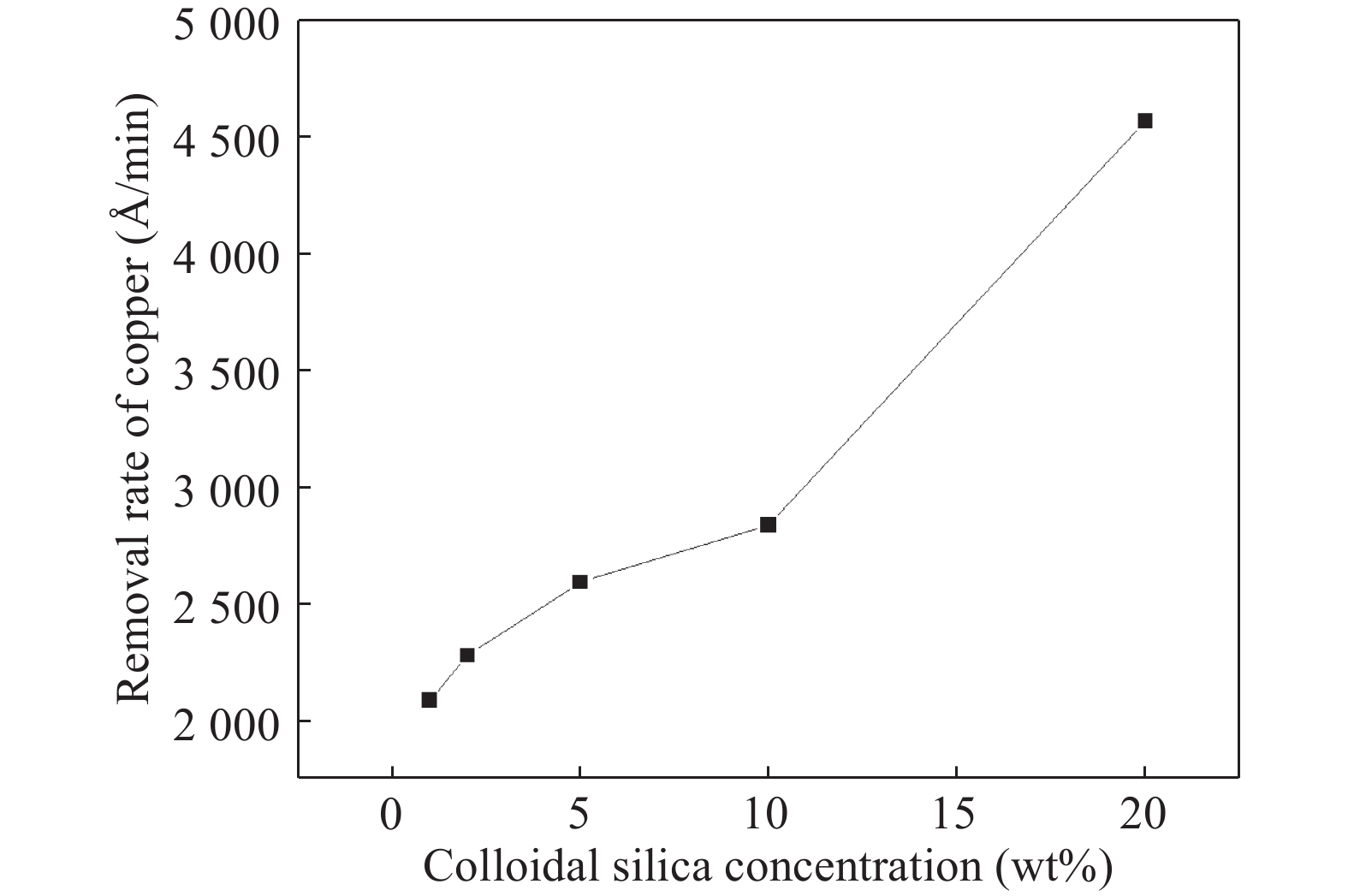

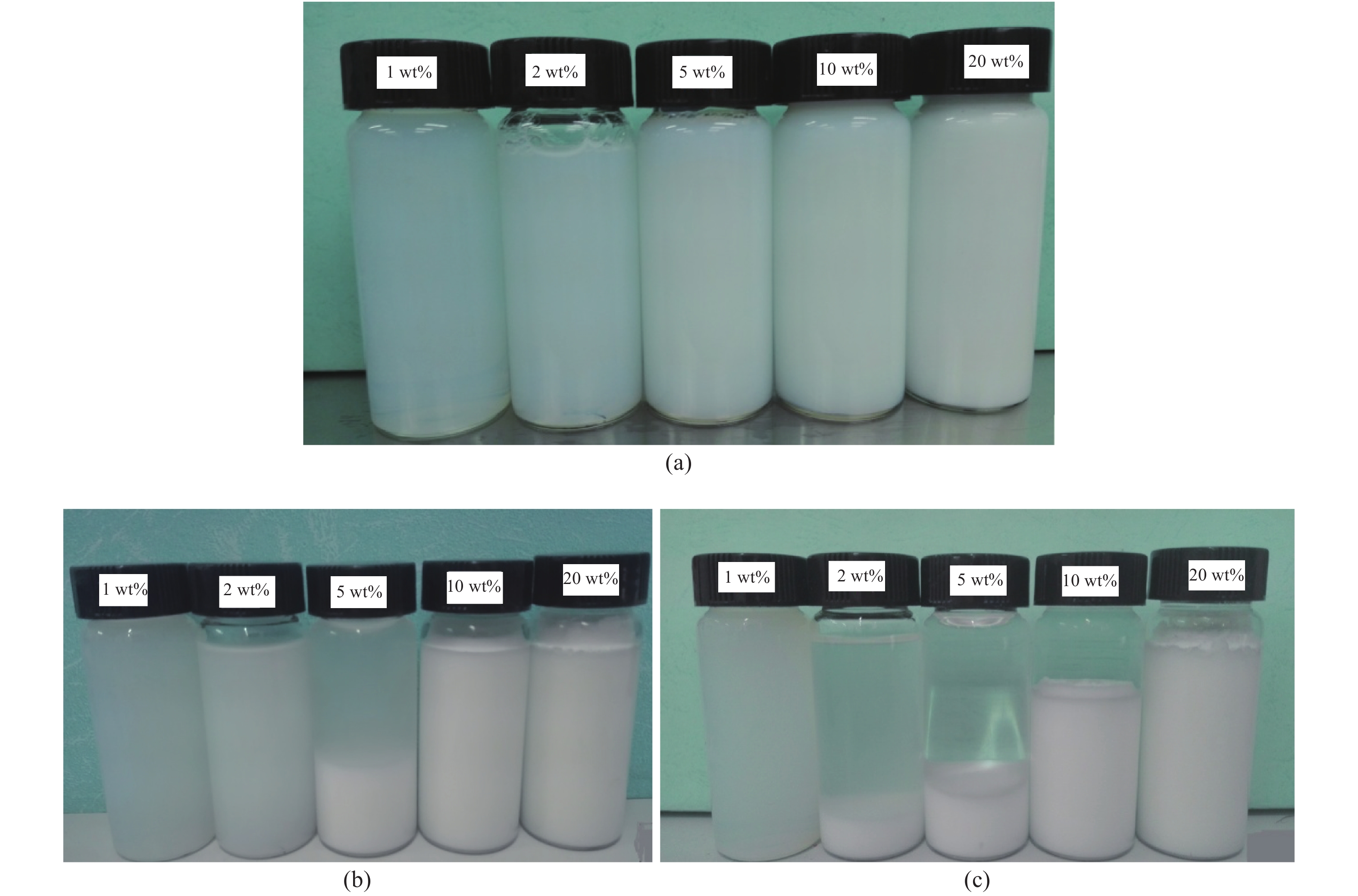

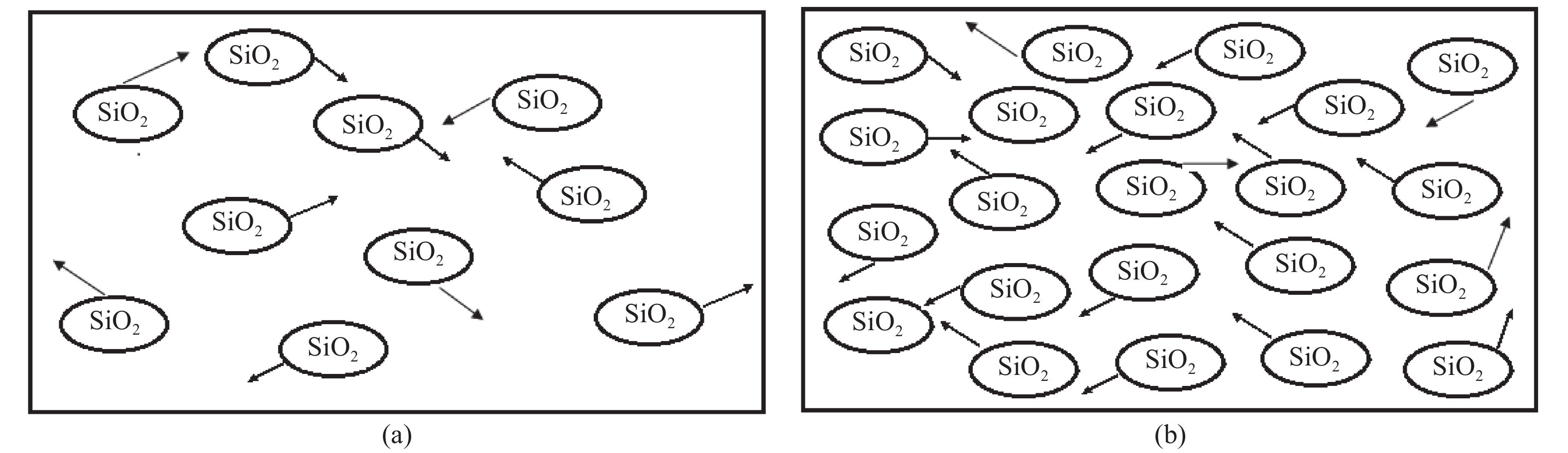

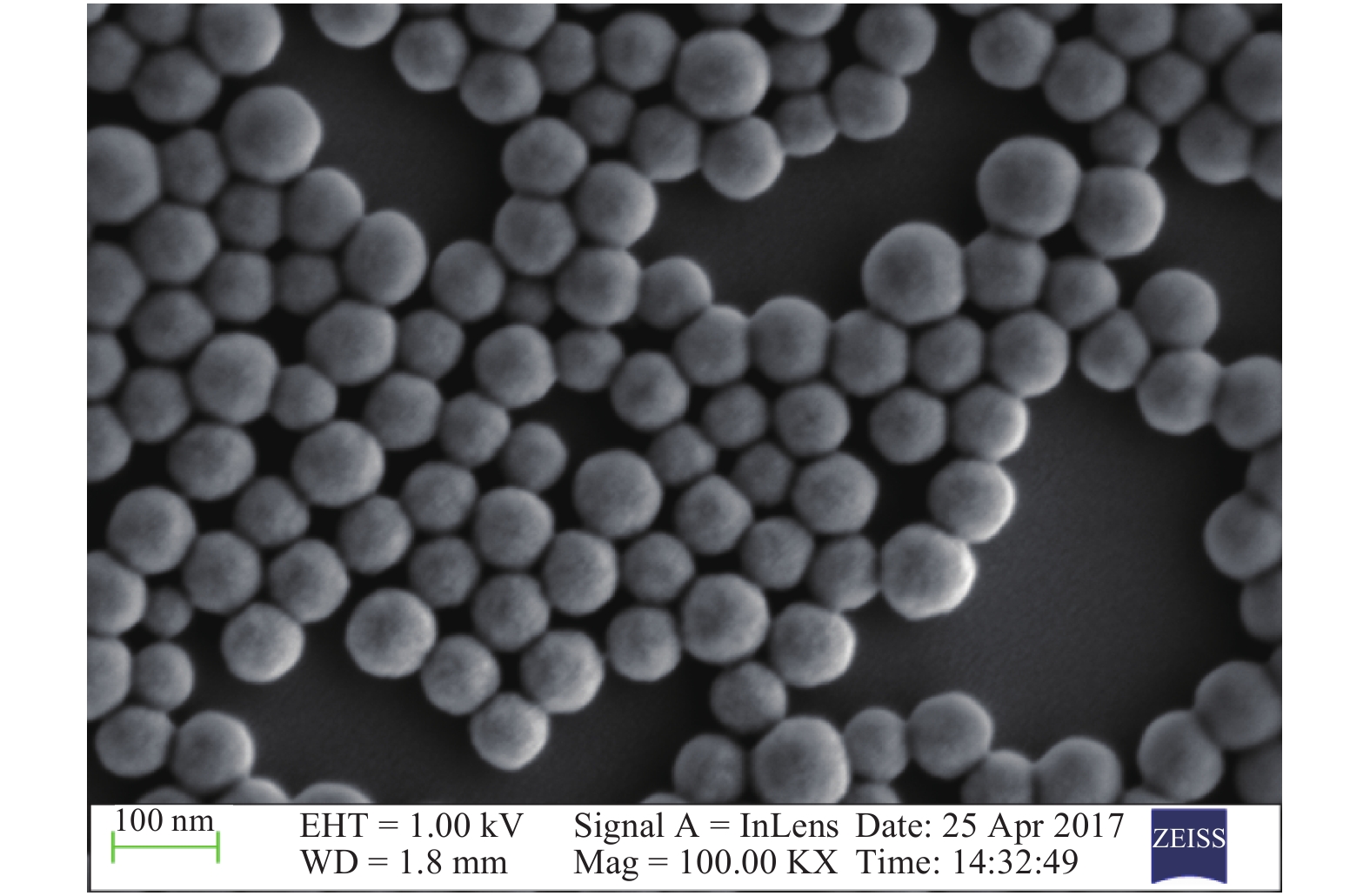

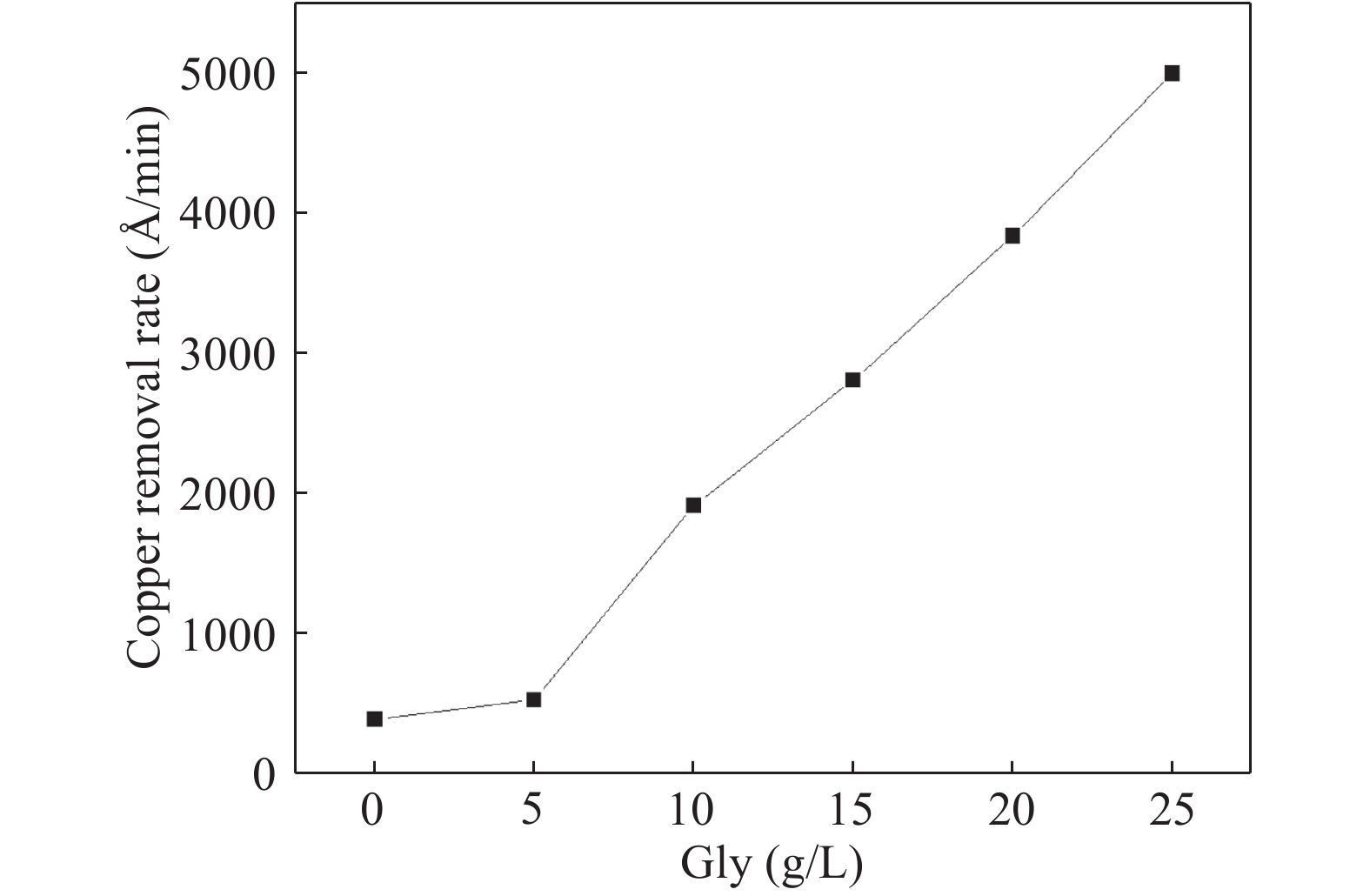

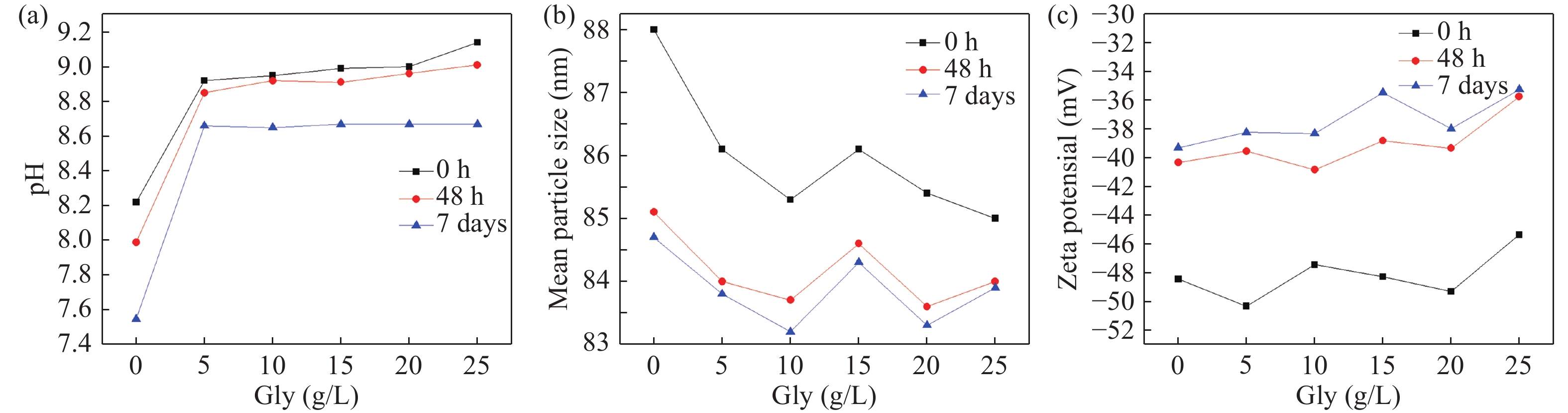

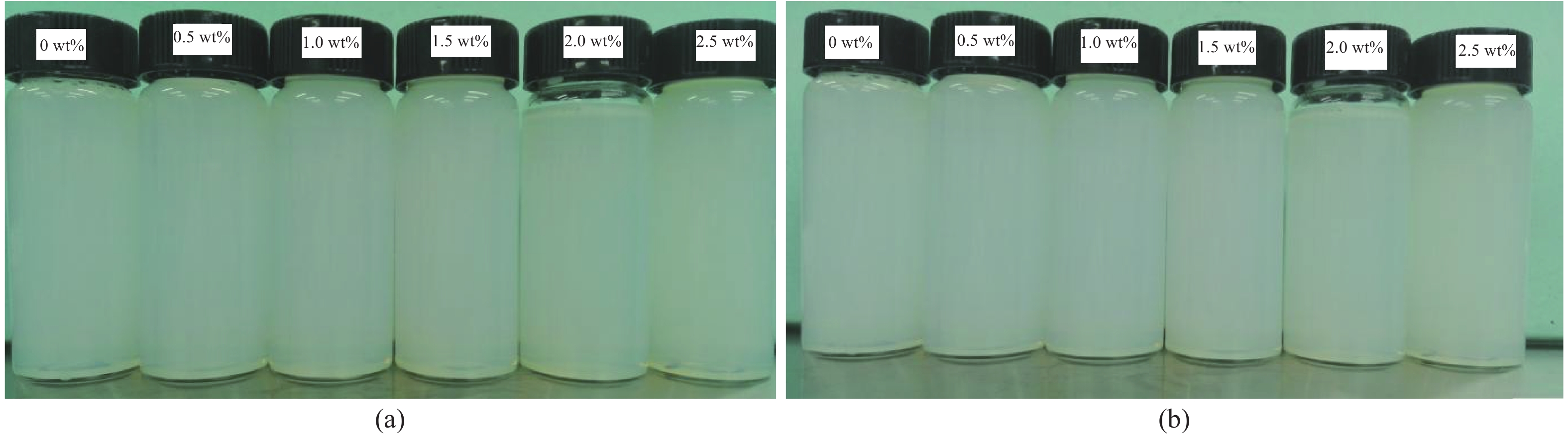

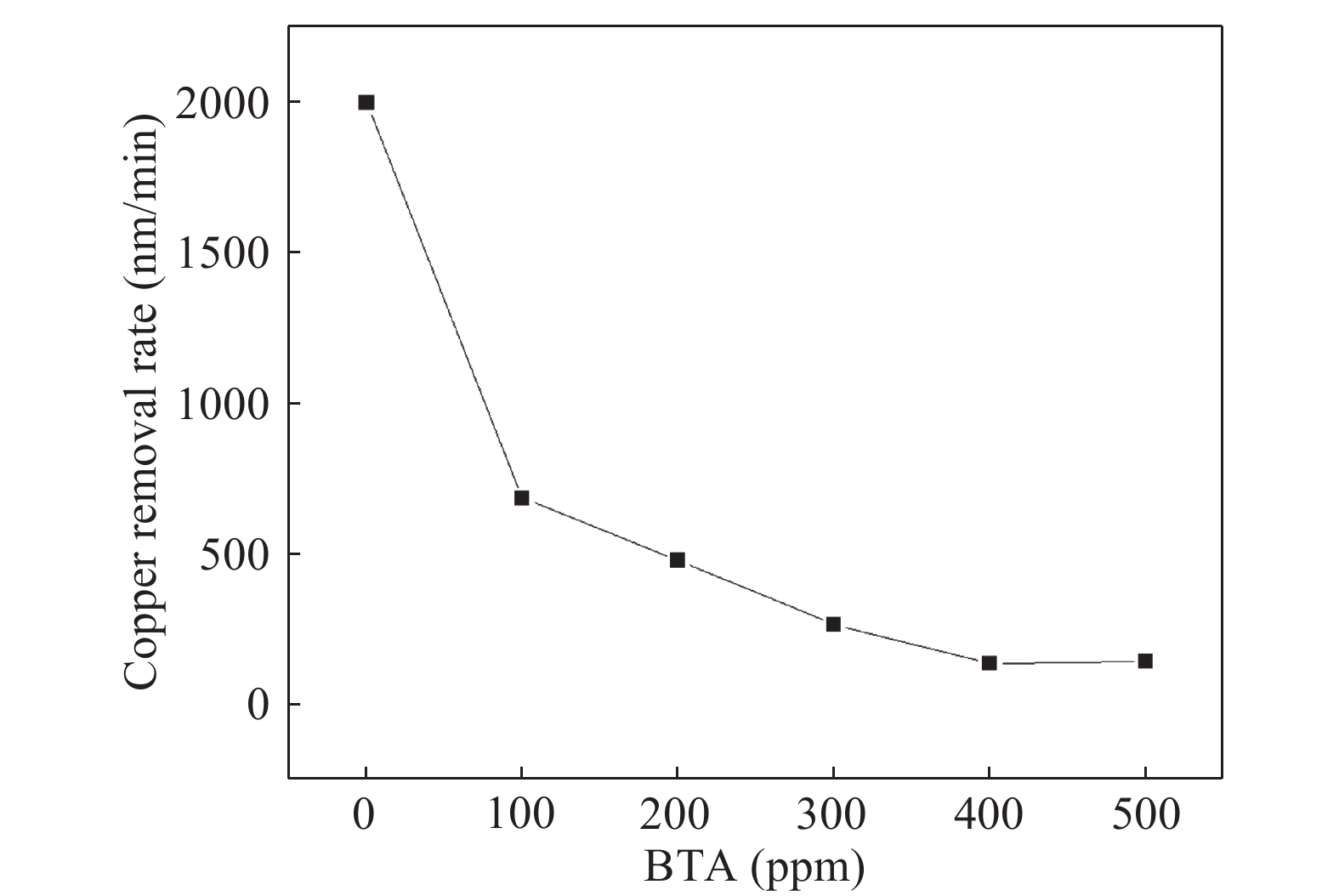

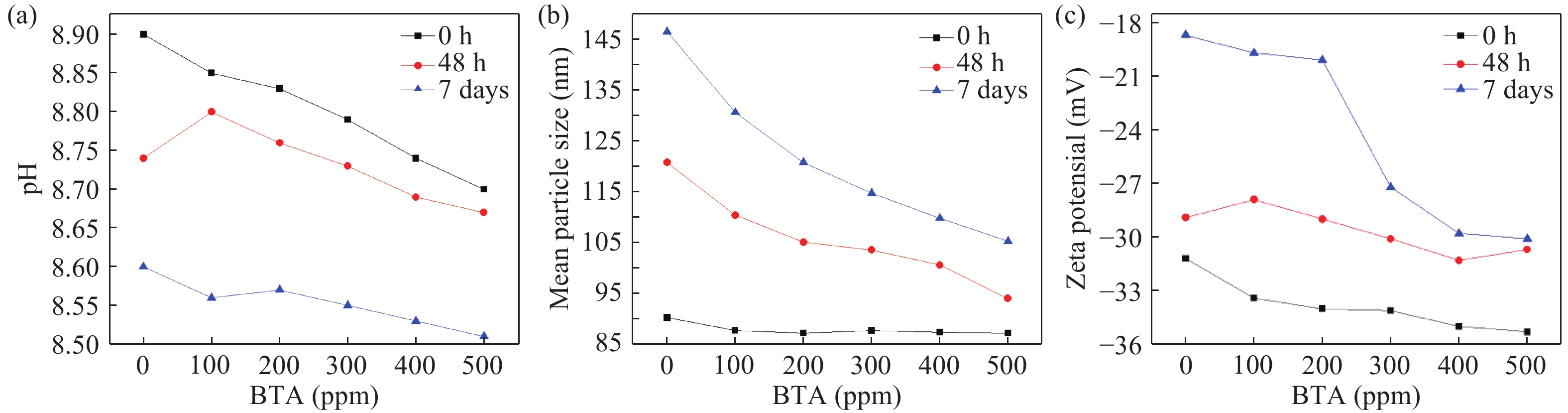

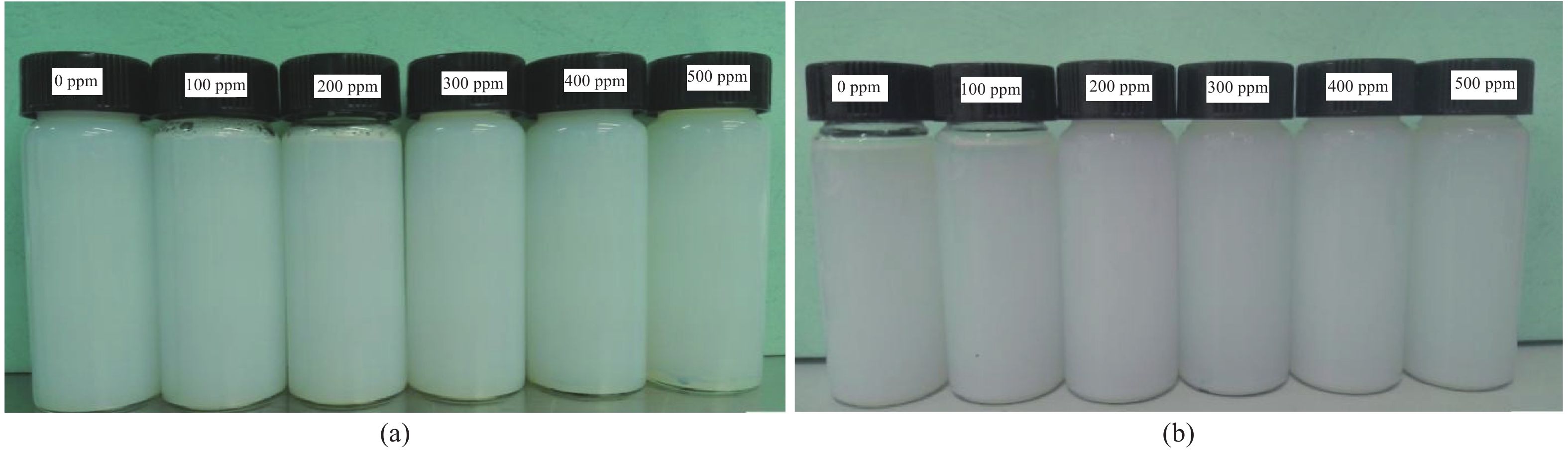

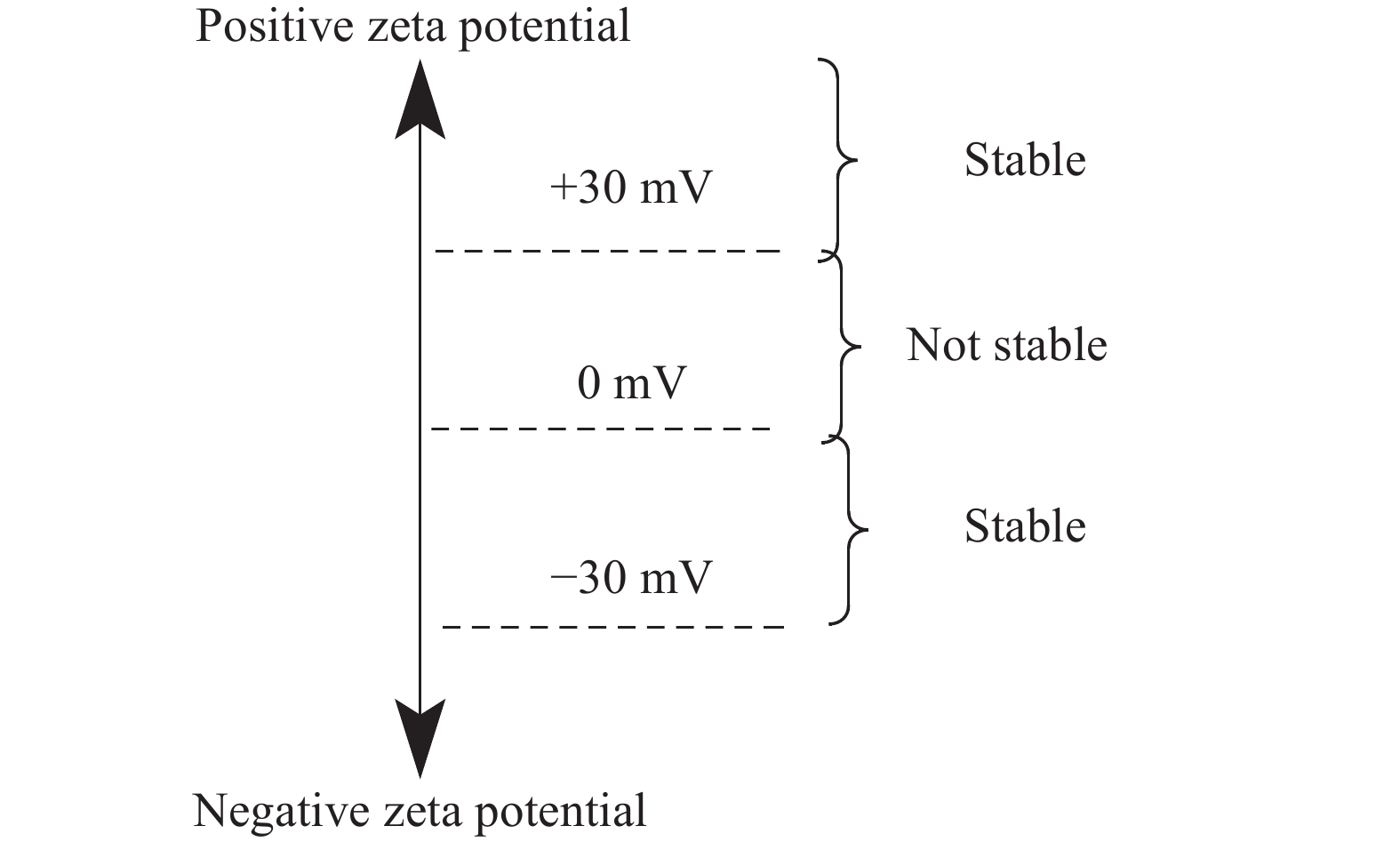

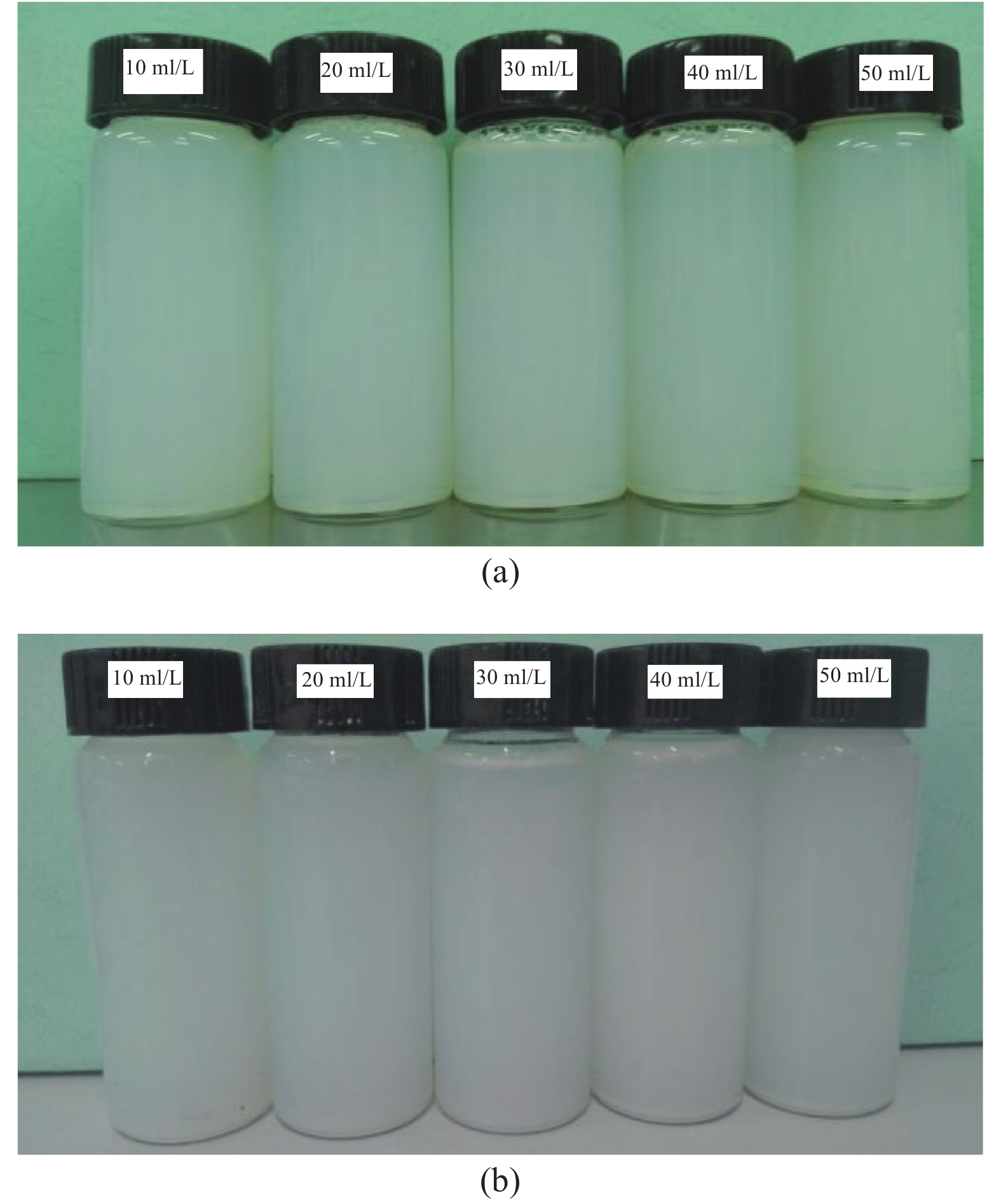

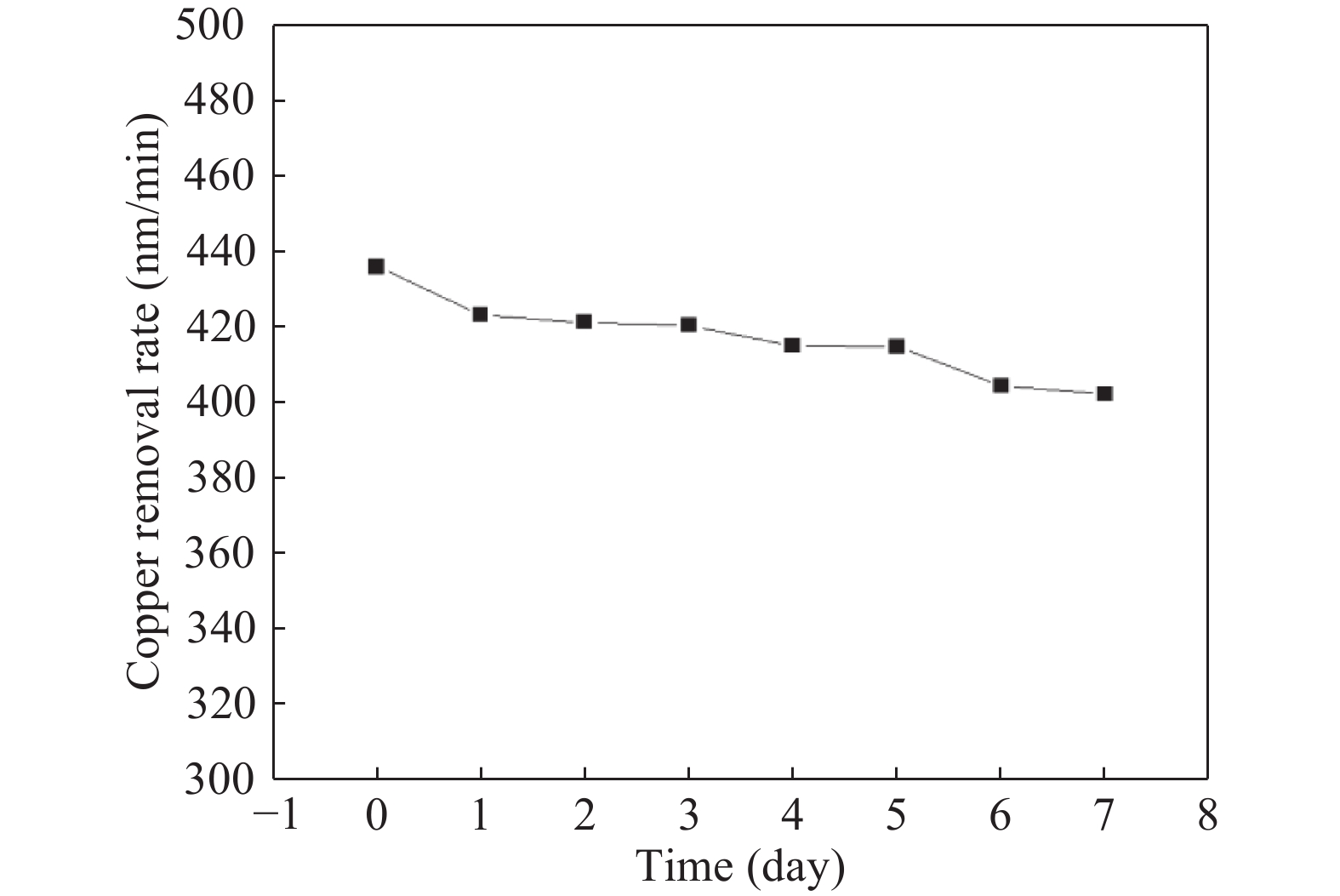

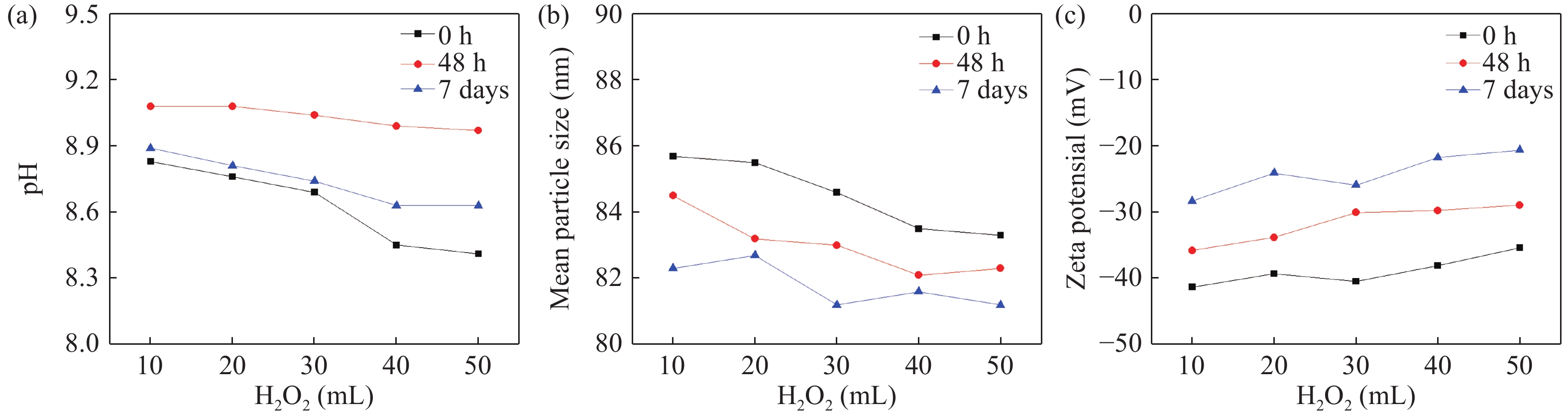

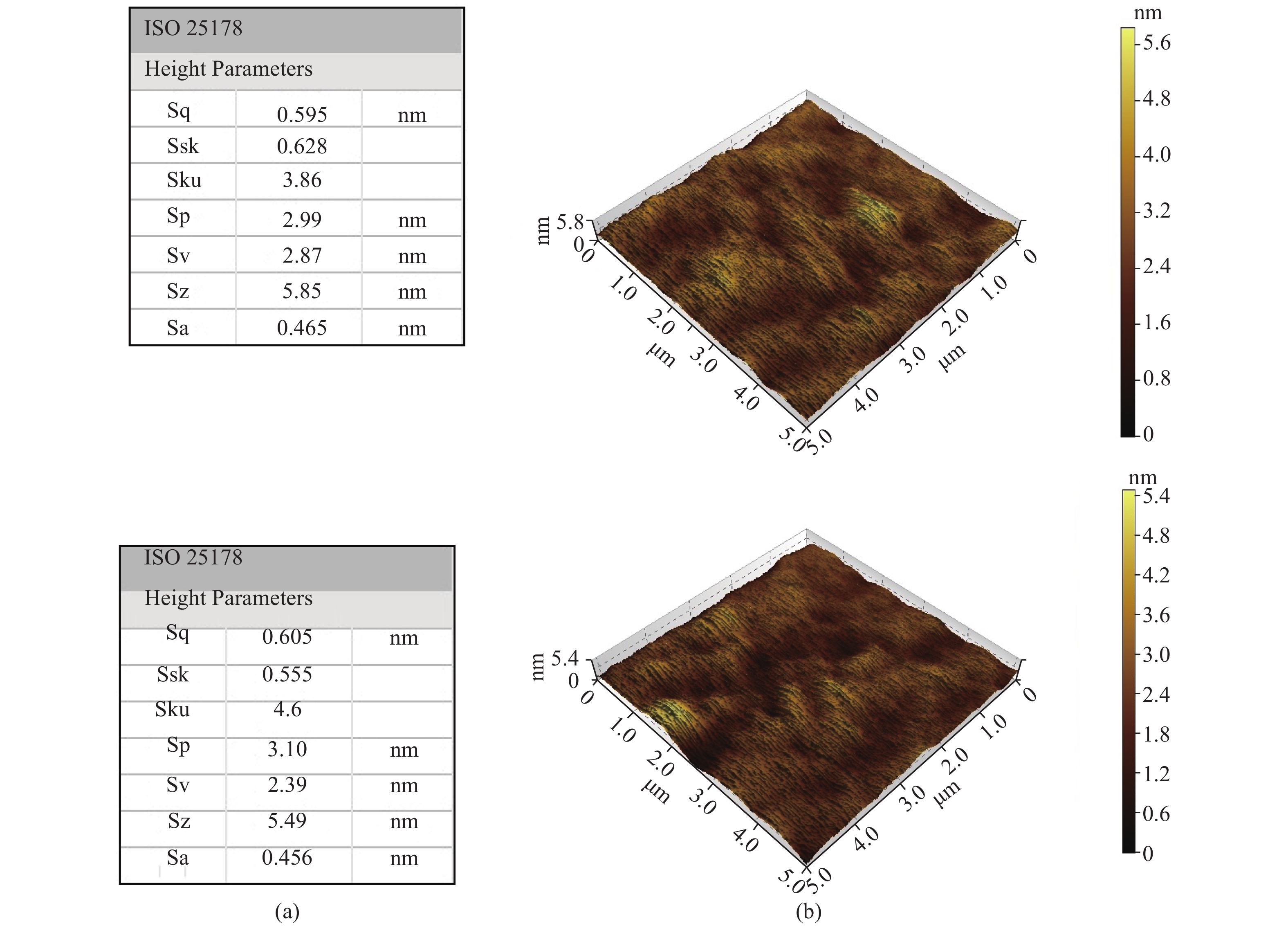

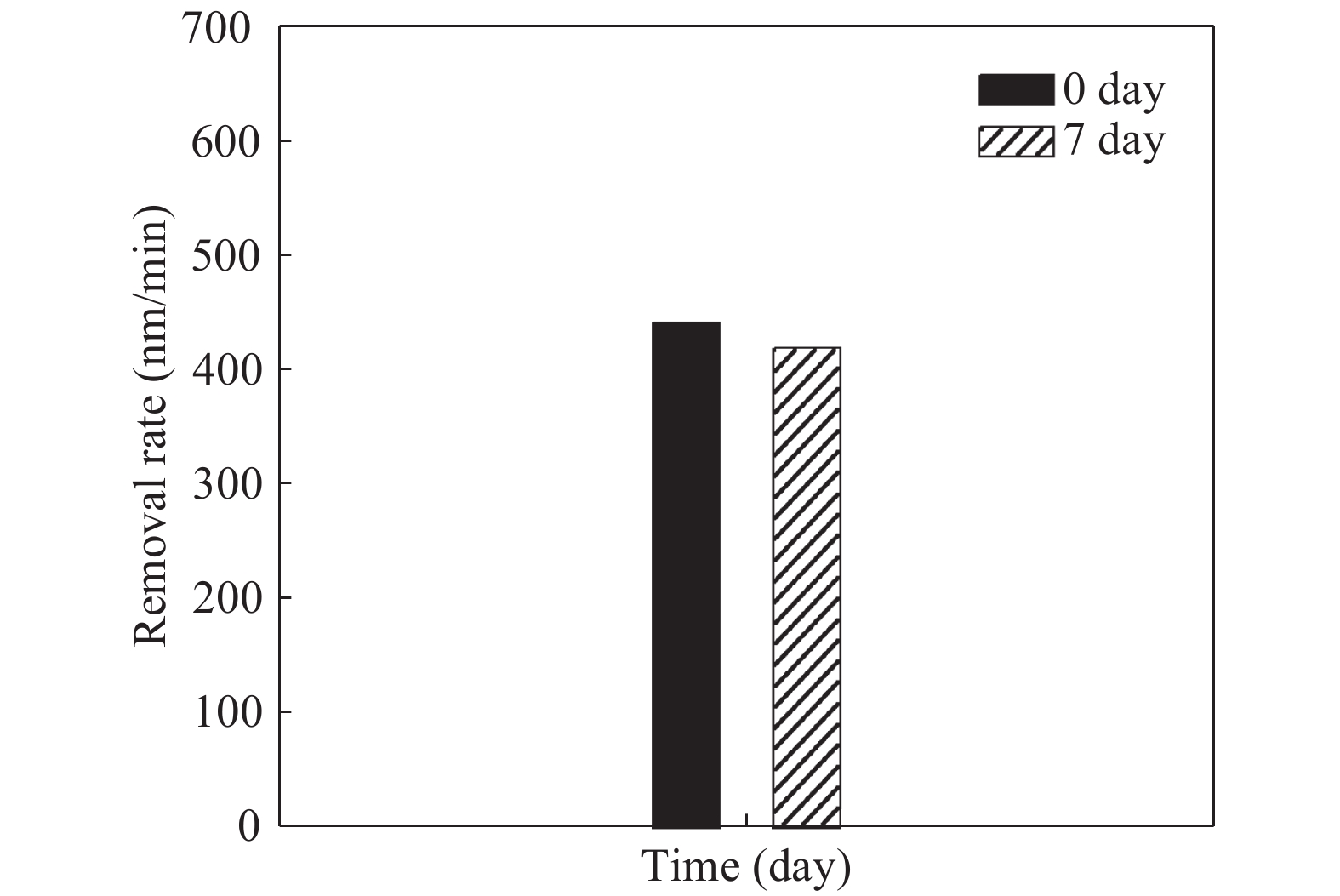

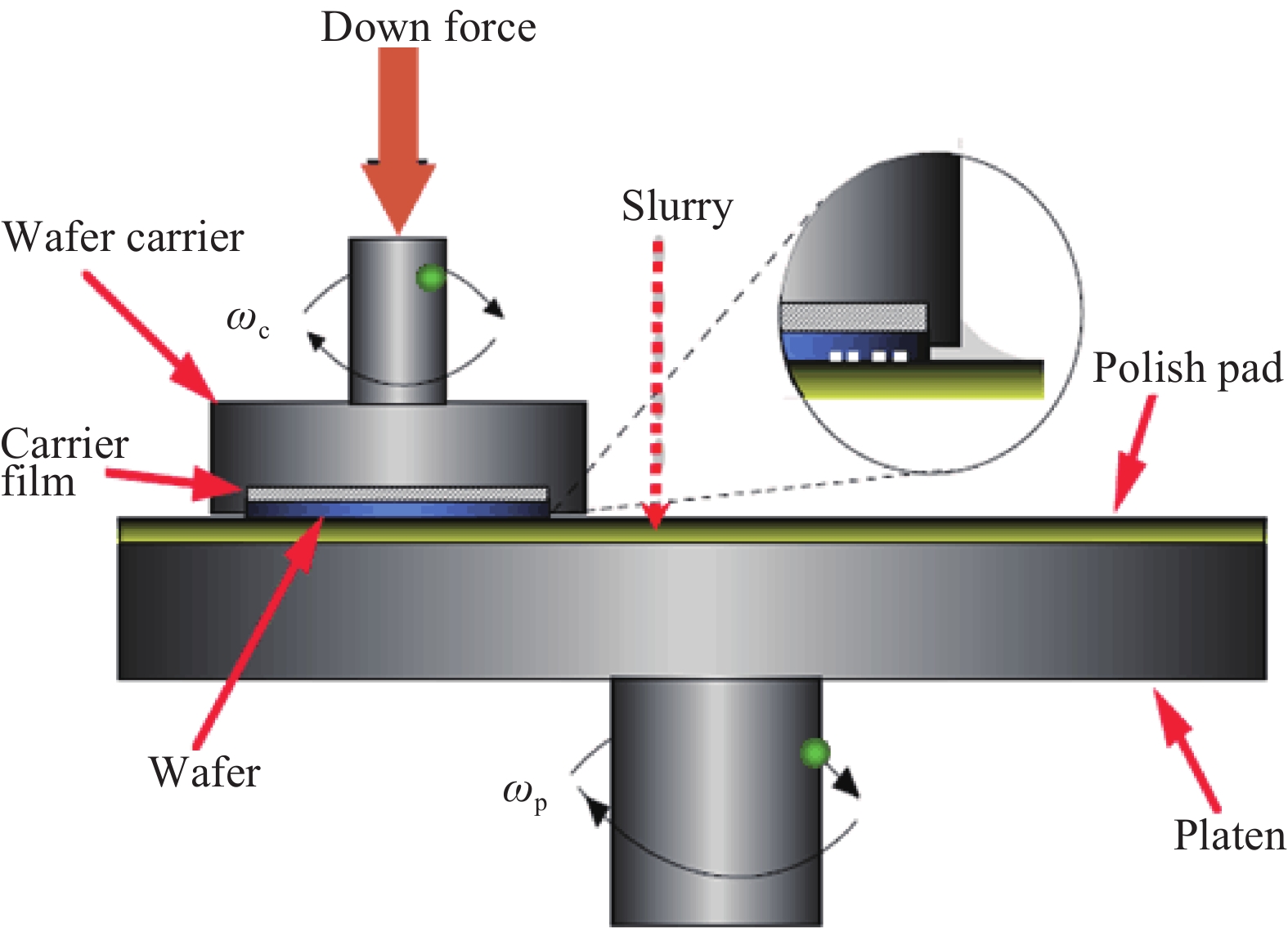

Chemical mechanical polishing (CMP) is one of the important machining procedures of multilayered copper interconnection for GLSI, meanwhile polishing slurry is a critical factor for realizing the high polishing performance such as high planarization efficiency, low surface roughness. The effect of slurry components such as abrasive (colloidal silica), complexing agent (glycine), inhibitor (BTA) and oxidizing agent (H2O2) on the stability of the novel weakly alkaline slurry of copper interconnection CMP for GLSI was investigated in this paper. First, the synergistic and competitive relationship of them in a peroxide-based weakly alkaline slurry during the copper CMP process was studied and the stability mechanism was put forward. Then 1 wt% colloidal silica, 2.5 wt% glycine, 200 ppm BTA, 20 mL/L H2O2 had been selected as the appropriate concentration to prepare copper slurry, and using such slurry the copper blanket wafer was polished. From the variations of copper removal rate, root-mean square roughness (Sq) value with the setting time, it indicates that the working-life of the novel weakly alkaline slurry can reach more than 7 days, which satisfies the requirement of microelectronics further development.-

Keywords:

- stability,

- weakly alkaline slurry,

- CMP,

- copper interconnection

-

References

[1] Yan C Q, Liu Y L, Zhang J, et al. Synergistic effect of glycine and BTA on step height reduction efficiency after copper CMP in weakly alkaline slurry. ECS J Solid State Sci Technol, 2017, 6(1): 1[2] Rao C, Wang T Q, Wang J, et al. Improvement of via dishing and non-uniformity in TSV chemical mechanical planarization. Microelectron Eng, 2016, 151: 38 doi: 10.1016/j.mee.2015.12.004[3] Hu Y, Li Y, Liu Y L, et al. Planarization effect evaluation of acid and alkaline slurries in the copper interconnect process. J Semicond, 2015, 6(3): 036001[4] Zhang J, Liu YL, Yan C Q, et al. Defectivity control of aluminum chemical mechanical planarization in replacement metal gate process of MOSFET. J Semicond, 2016, 37(4): 046001 doi: 10.1088/1674-4926/37/4/046001[5] Cheng J, Wang T Q, He Y Y, et al. Material removal mechanism of copper chemical mechanical polishing in a periodate-based slurry. Appl Surf Sci, 2015, 337: 130 doi: 10.1016/j.apsusc.2015.02.076[6] Wang Y G, Zhang L C, Biddut A, et al. Chemical effect on the material removal rate in the CMP of silicon wafers. Wear, 2011, 270: 312 doi: 10.1016/j.wear.2010.11.006[7] Hong J, Niu X H, Liu Y L, et al. Effect of a novel chelating agent on defect removal during post-CMP cleaning. Appl Surf Sci, 2016, 378: 239 doi: 10.1016/j.apsusc.2016.03.230[8] Li Y L, Liu Y L, Wang C W, et al. Synergetic effect of chelating agent and nonionic surfactant for benzotriazole removal on post Cu-CMP cleaning. J Semicond, 2016, 37(8): 086001 doi: 10.1088/1674-4926/37/8/086001[9] Xu Q, Chen L, Fang J, et al. A chemical mechanical planarization model for aluminum gate structures. Microelectron Eng, 2015, 131: 58 doi: 10.1016/j.mee.2014.09.023[10] Zantye P B, Kumar A, Sikder A K. Chemical mechanical planarization for microelectronics applications. Mater Sci Eng R, 2004, 45(3–6): 89 doi: 10.1016/j.mser.2004.06.002[11] Kim H J, Bohra G, Yang H, et al. , Study of the cross contamination effect on post CMP in situ cleaning process. Microelectron Eng, 2015, 136: 36 doi: 10.1016/j.mee.2015.03.033[12] Chen G D, Liu Y L, Wang C W, et al. Stability for a novel low-pH alkaline slurry during the copper chemical mechanical planarization. J Semicond, 2014, 35(8): 086001 doi: 10.1088/1674-4926/35/8/086001[13] Zhang J, Liu Y L, Yan C Q, et al. Investigation on chemical mechanical planarization performance of the replacement metal gate aluminum polishing slurry. ECS J Solid State Sci Technol, 2016, 5(7): 446 doi: 10.1149/2.0291607jss[14] Lin F, Nolan L, Xu Z, et al. A study of the colloidal stability of mixed abrasive slurries and their role in CMP. J Electrochem Soc, 2012, 159(5): H482 doi: 10.1149/2.jes113470[15] Jiang L, He Y Y, Niu X Y, et al. Synergetic effect of benzotriazole and non-ionic surfactant on copper chemical mechanical polishing in KIO4-based slurries. Thin Solid Films, 2014, 558: 272 doi: 10.1016/j.tsf.2014.01.086[16] Jiang L, He Y Y, Li Y, et al. Synergetic effect of H2O2 and glycine on cobalt CMP in weakly alkaline slurry. Microelectron Eng, 2014, 122: 82 doi: 10.1016/j.mee.2014.02.002 -

Proportional views

DownLoad:

DownLoad: