| Citation: |

Lei Tang, Kwong-Hoi Tsui, Siu-Fung Leung, Qianpeng Zhang, Matthew Kam, Hsin-Ping Wang, Jr-Hau He, Zhiyong Fan. Large-scale, adhesive-free and omnidirectional 3D nanocone anti-reflection films for high performance photovoltaics[J]. Journal of Semiconductors, 2019, 40(4): 042601. doi: 10.1088/1674-4926/40/4/042601

****

L Tang, K H Tsui, S F Leung, Q P Zhang, M Kam, H P Wang, J H He, Z Y Fan, Large-scale, adhesive-free and omnidirectional 3D nanocone anti-reflection films for high performance photovoltaics[J]. J. Semicond., 2019, 40(4): 042601. doi: 10.1088/1674-4926/40/4/042601.

|

Large-scale, adhesive-free and omnidirectional 3D nanocone anti-reflection films for high performance photovoltaics

DOI: 10.1088/1674-4926/40/4/042601

More Information

-

Abstract

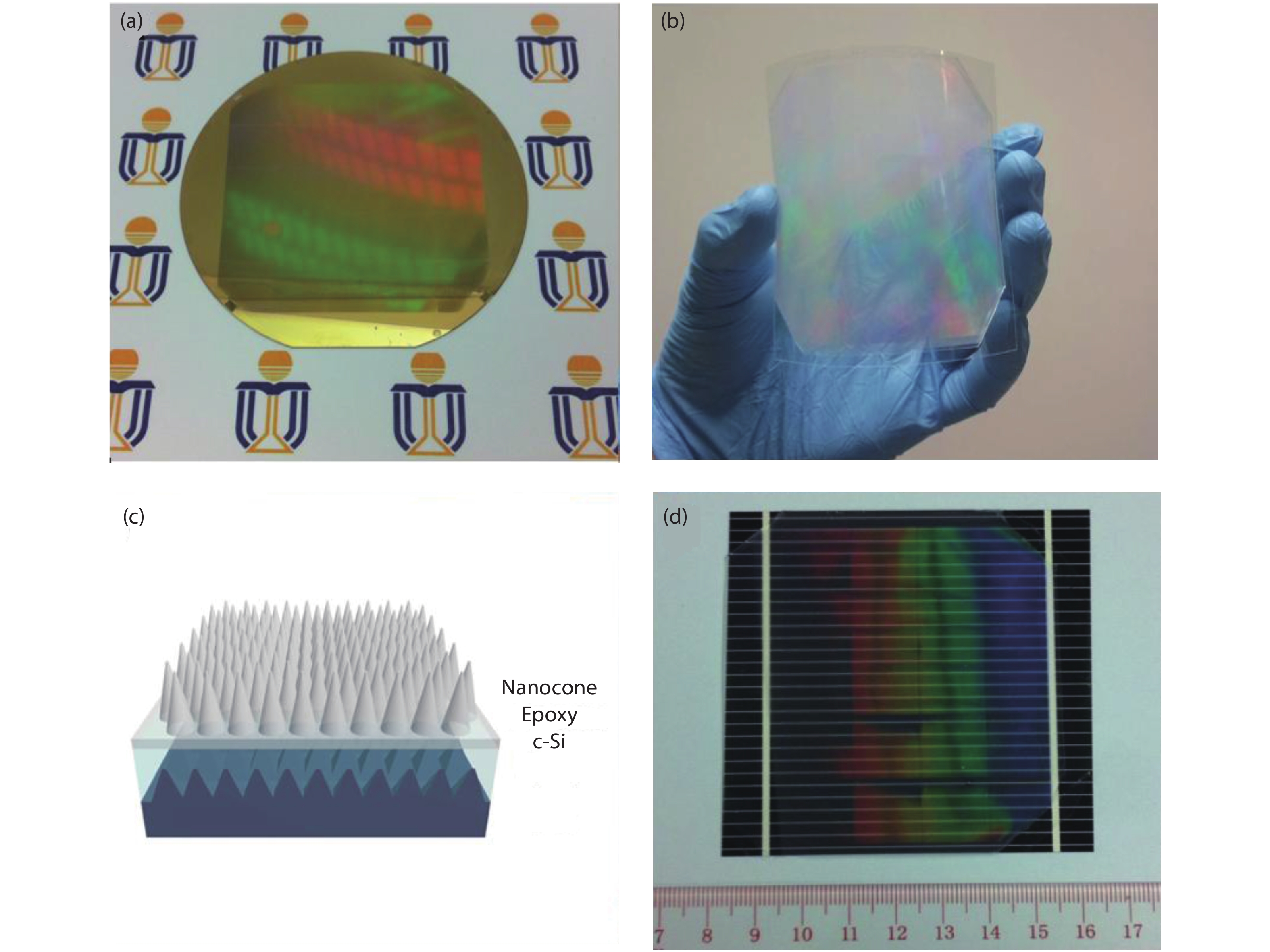

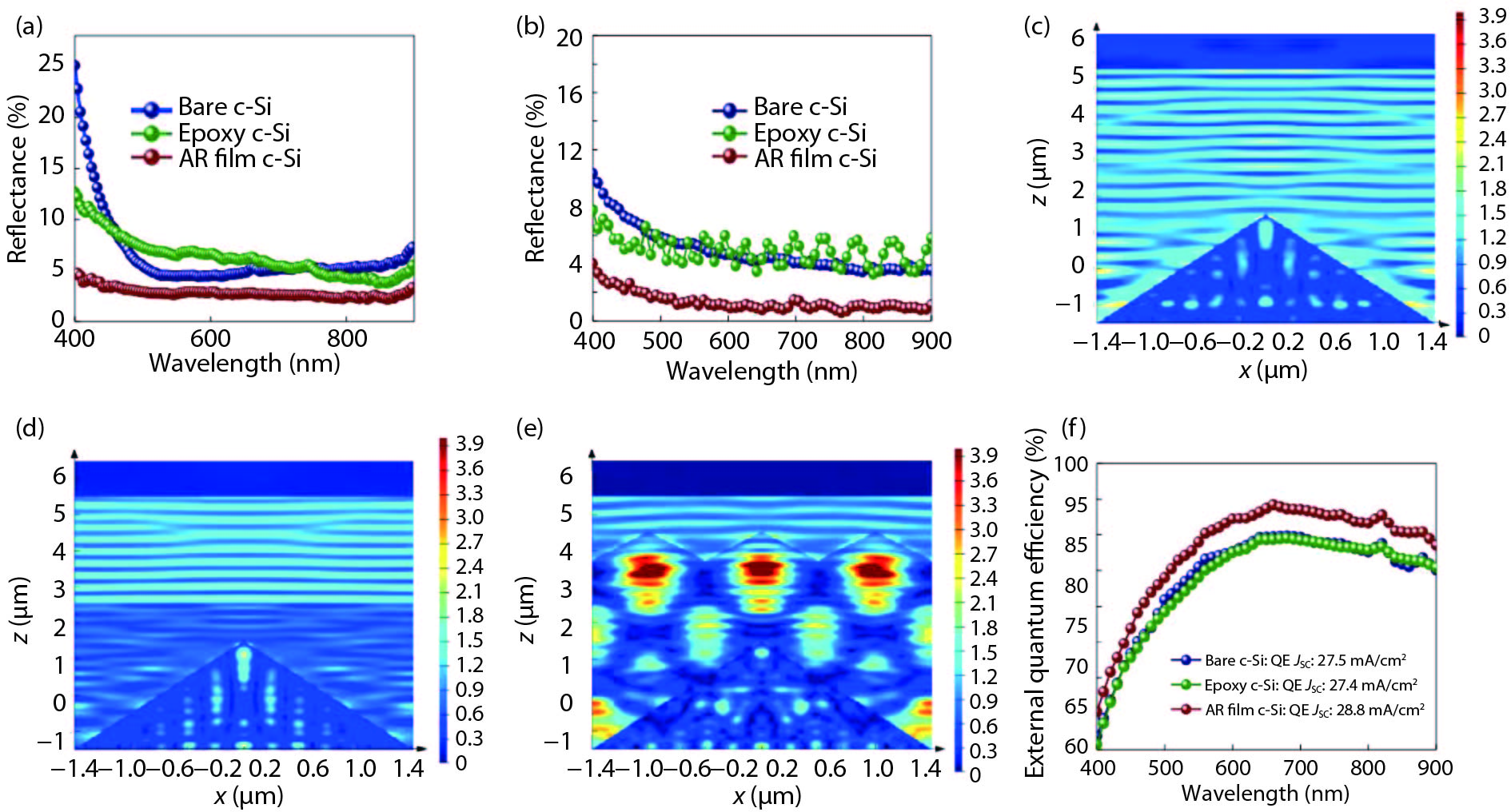

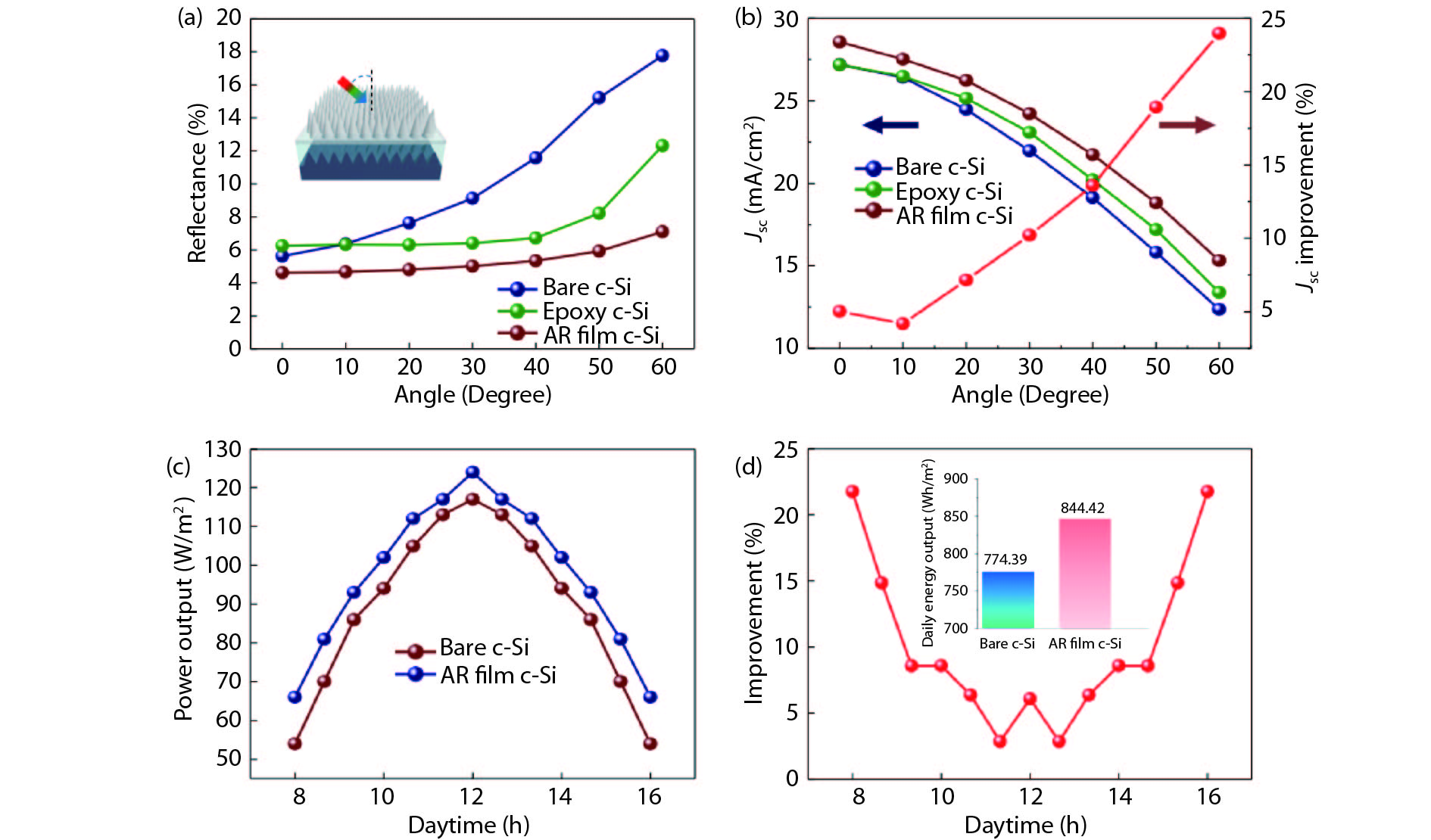

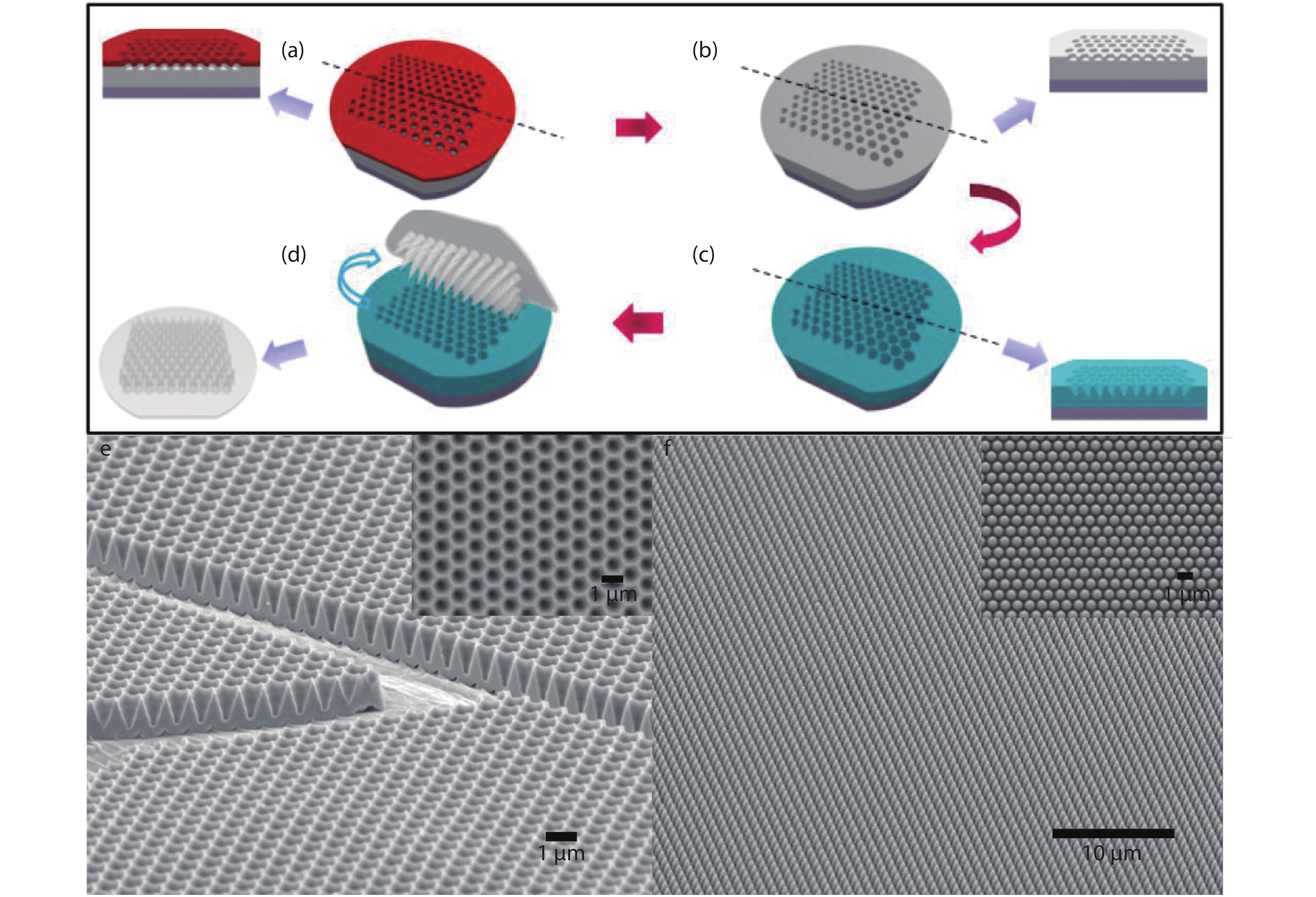

An effective and low-cost front-side anti-reflection (AR) technique has long been sought to enhance the performance of highly efficient photovoltaic devices due to its capability of maximizing the light absorption in photovoltaic devices. In order to achieve high throughput fabrication of nanostructured flexible and anti-reflection films, large-scale, nano-engineered wafer molds were fabricated in this work. Additionally, to gain in-depth understanding of the optical and electrical performance enhancement with AR films on polycrystalline Si solar cells, both theoretical and experimental studies were performed. Intriguingly, the nanocone structures demonstrated an efficient light trapping effect which reduced the surface reflection of a solar cell by 17.7% and therefore enhanced the overall electric output power of photovoltaic devices by 6% at normal light incidence. Notably, the output power improvement is even more significant at a larger light incident angle which is practically meaningful for daily operation of solar panels. The application of the developed AR films is not only limited to crystalline Si solar cells explored here, but also compatible with any types of photovoltaic technology for performance enhancement.-

Keywords:

- antireflection,

- crystalline Si solar cells,

- flexible film

-

References

[1] Klampaftis E, Richards B S. Improvement in multi-crystalline silicon solar cell efficiency via addition of luminescent material to EVA encapsulation layer. Prog Photovoltaics Res Appl, 2011, 19, 345 doi: 10.1002/pip.1019[2] Pern F J, Glick D H, Czanderna A W. Review of the photothermal stability of EVA pottants: effects of formulation on the discoloration rate and mitigation methods. AIP Conference Proceedings, 1996, 353, 1 doi: 10.1063/1.58004[3] Miller D C, Muller M T, Kempe M D, et al. Durability of polymeric encapsulation materials for concentrating photovoltaic systems. Prog Photovoltaics Res Appl, 2013, 21, 631 doi: 10.1002/pip.1241[4] Ramrakhiani M. Recent advances in photovoltaics. Millersville, PA: Materials Research Forum, 2017[5] Chen J, Zhou L, Ou Q, et al. Enhanced light harvesting in organic solar cells featuring a biomimetic active layer and a self‐cleaning antireflective coating. Adv Energy Mater, 2014, 4, 1301777 doi: 10.1002/aenm.201301777[6] Eisele C, Nebel C E, Stutzmann M. Periodic light coupler gratings in amorphous thin film solar cells. J Appl Phys, 2001, 89, 7722 doi: 10.1063/1.1370996[7] Nelson J. The physics of solar cells. London: Imperial College Press, 2003[8] Gwon H, Park Y, Moon C, et al. Superhydrophobic and antireflective nanograss-coated glass for high performance solar cells Nano Research, 2014, 7, 670 doi: 10.1007/s12274-014-0427-x[9] Deubener J, Helsch G, Moiseev A, et al. Glasses for solar energy conversion systems. J Eur Ceram Soc, 2009, 29, 1203 doi: 10.1016/j.jeurceramsoc.2008.08.009[10] Li X, He J, Liu W. Broadband anti-reflective and water-repellent coatings on glass substrates for self-cleaning photovoltaic cells. Mater Res Bull, 2013, 48, 2522 doi: 10.1016/j.materresbull.2013.03.017[11] Wang H, Periyanagounder D, Li A, et al. Fabrication of silicon hierarchical structures for solar cell applications. IEEE Access, 2019, 7, 19395 doi: 10.1109/ACCESS.2018.2885169[12] Lim S, Um D, Ha M, et al. Broadband omnidirectional light detection in flexible and hierarchical ZnO/Si heterojunction photodiodes. Nano Res, 2017, 10, 22 doi: 10.1007/s12274-016-1263-y[13] Tavakoli M M, Lin Q, Leung S, et al. Efficient, flexible and mechanically robust perovskite solar cells on inverted nanocone plastic substrates. Nanoscale, 2016, 8, 4276 doi: 10.1039/C5NR08836D[14] Zheng X, Wei Z, Chen H, et al. Designing nanobowl arrays of mesoporous TiO2 as an alternative electron transporting layer for carbon cathode-based perovskite solar cells. Nanoscale, 2016, 8, 6393 doi: 10.1039/C5NR06715D[15] Fan Z, Ruebusch D, Rathore A, et al. Challenges and prospects of nanopillar-based solar cells. Nano Res, 2009, 2, 829 doi: 10.1007/s12274-009-9091-y[16] Yu M, Long Y, Sun B, et al. Recent advances in solar cells based on one-dimensional nanostructure arrays. Nanoscale, 2012, 4, 9 doi: 10.1039/c2nr30437f[17] Das S, Hossain M J, Leung S, et al. A leaf-inspired photon management scheme using optically tuned bilayer nanoparticles for ultra-thin and highly efficient photovoltaic devices Nano Energy, 2019, 58, 47 doi: 10.1016/j.nanoen.2018.12.072[18] Jiang S, Wang K, Zhang H, et al. Macromolecular Reaction Engineering, 2015, 9, 5 doi: 10.1002/mren.201400065[19] Tsui K H, Lin Q, Chou H, et al. Low-cost, flexible and self-cleaning three-dimensional anti-reflection nanocone arrays for high efficiency photovoltaics. Adv Mater, 2014, 26, 2805 doi: 10.1002/adma.v26.18[20] Lin Q, Leung S, Tsui K, et al. Programmable nanoengineering templates for fabrication of three-dimensional nanophotonic structures. Nanoscale Res Lett, 2013, 8, 1 doi: 10.1186/1556-276X-8-1[21] McIntosh K R, Powell N E, Norris A W, et al. The effect of damp-heat and UV aging tests on the optical properties of silicone and EVA encapsulants. Prog Photovoltaics Res Appl, 2011, 19, 294 doi: 10.1002/pip.1025[22] Qiu Y, Leung S, Zhang Q, et al. Efficient photoelectrochemical water splitting with ultrathin films of hematite on three-dimensional nanophotonic structures. Nano Lett, 2014, 14, 2123 doi: 10.1021/nl500359e[23] Leung S F, Gu L, Zhang Q, et al. Roll-to-roll fabrication of large scale and regular arrays of three-dimensional nanospikes for high efficiency and flexible photovoltaics. Sci Rep, 2014, 4 doi: 10.1038/srep04243[24] Leung S, Yu M, Lin Q, et al. Efficient photon capturing with ordered three-dimensional nanowell arrays. Nano Lett, 2012, 12, 3682 doi: 10.1021/nl3014567[25] Choi J, Wehrspohn R B, Gösele U. Moiré pattern formation on porous alumina arrays using nanoimprint lithography. Adv Mater. 2003, 15, 1531 doi: 10.1002/(ISSN)1521-4095[26] Galliano A, Bistac S, Schultz J. Adhesion and friction of PDMS networks: molecular weight effects. J Colloid Interface Sci. 2003, 265, 372 doi: 10.1016/S0021-9797(03)00458-2[27] Crawford R J, Ivanova E P. Superhydrophobic surfaces. Amsterdam, Netherlands: Elsevier, 2015[28] Tsui K, Li X, Tsoi J K H, et al. Low-cost, flexible, disinfectant-free and regular-array three-dimensional nanopyramid antibacterial films for clinical applications. Nanoscale. 2018, 10, 10436. doi: 10.1039/C8NR01968A[29] Tsai M, Tu W, Tang L, et al. Efficiency enhancement of silicon heterojunction solar cells via photon management using graphene quantum dot as downconverters. Nano Lett, 2016, 16, 309 doi: 10.1021/acs.nanolett.5b03814[30] Lin Y, Lai K Y, Wang H, et al. Slope-tunable sinanorod arrays with enhanced antireflection and self-cleaning properties. Nanoscale. 2010, 2, 2765 doi: 10.1039/c0nr00402b[31] Cai J, Qi L. Recent advances in antireflective surfaces based on nanostructure arrays. Mater Horiz, 2014, 2, 37 doi: 10.1039/c4mh00140k -

Supplements

19010025supp.pdf

19010025supp.pdf

-

Proportional views

DownLoad:

DownLoad: