| Citation: |

Peng Wang, Gaofei Li, Miao Wang, Hong Li, Jing Zheng, Liyou Yang, Yigang Chen, Dongdong Li, Linfeng Lu. Numerical study of mono-crystalline silicon solar cells with passivated emitter and rear contact configuration for the efficiency beyond 24% based on mass production technology[J]. Journal of Semiconductors, 2020, 41(6): 062701. doi: 10.1088/1674-4926/41/6/062701

****

P Wang, G F Li, M Wang, H Li, J Zheng, L Y Yang, Y G Chen, D D Li, L F Lu, Numerical study of mono-crystalline silicon solar cells with passivated emitter and rear contact configuration for the efficiency beyond 24% based on mass production technology[J]. J. Semicond., 2020, 41(6): 062701. doi: 10.1088/1674-4926/41/6/062701.

|

Numerical study of mono-crystalline silicon solar cells with passivated emitter and rear contact configuration for the efficiency beyond 24% based on mass production technology

DOI: 10.1088/1674-4926/41/6/062701

More Information

-

Abstract

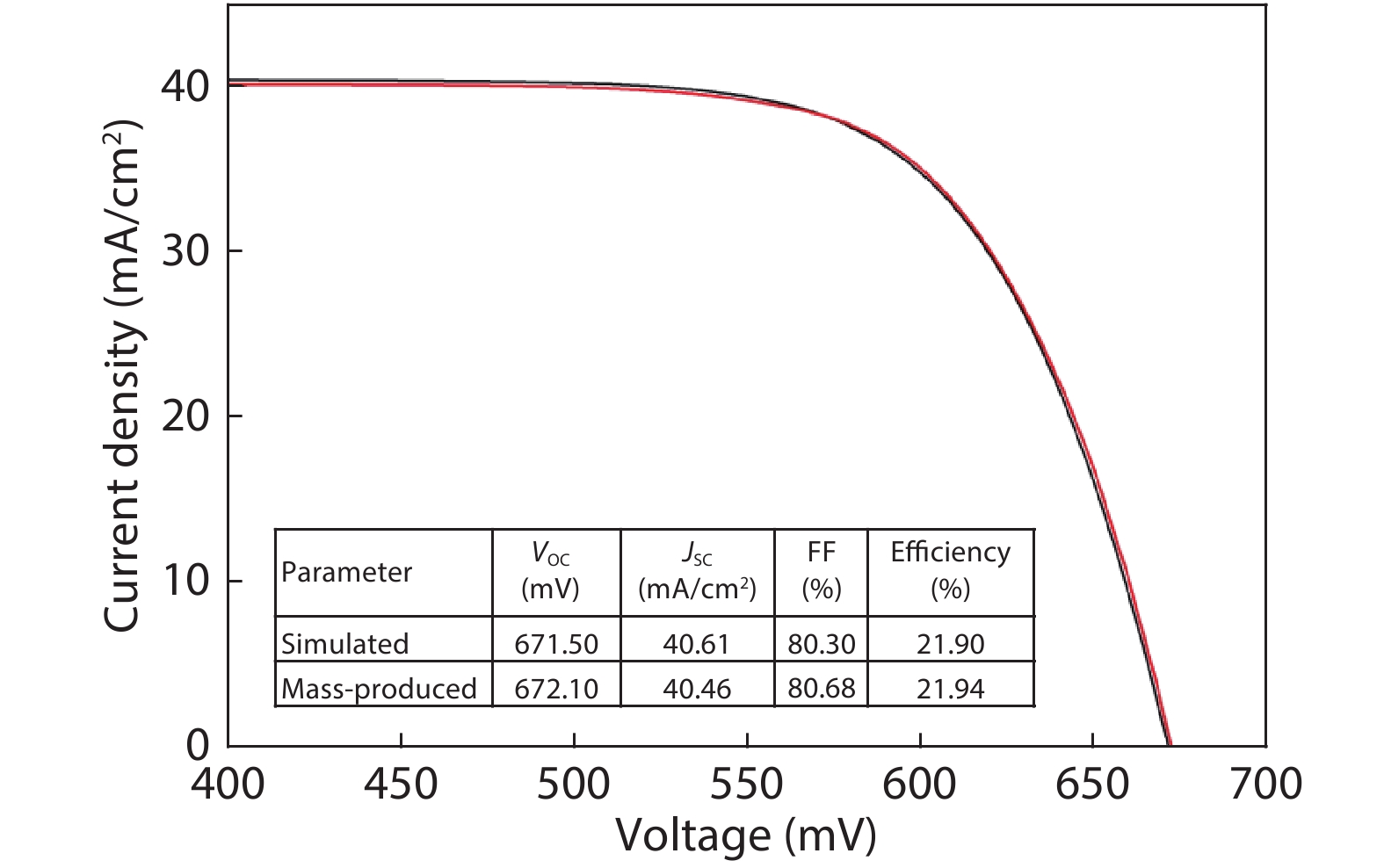

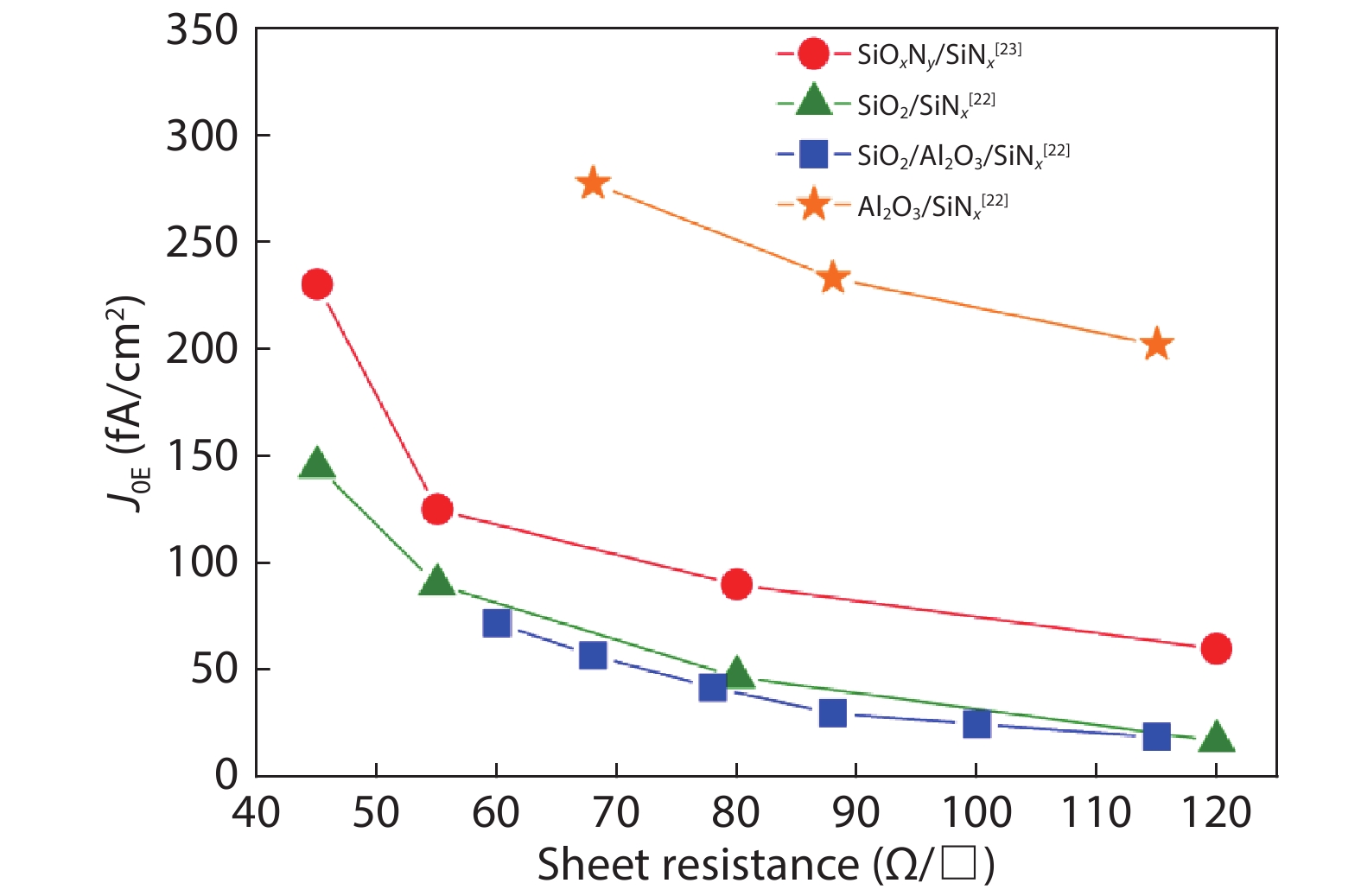

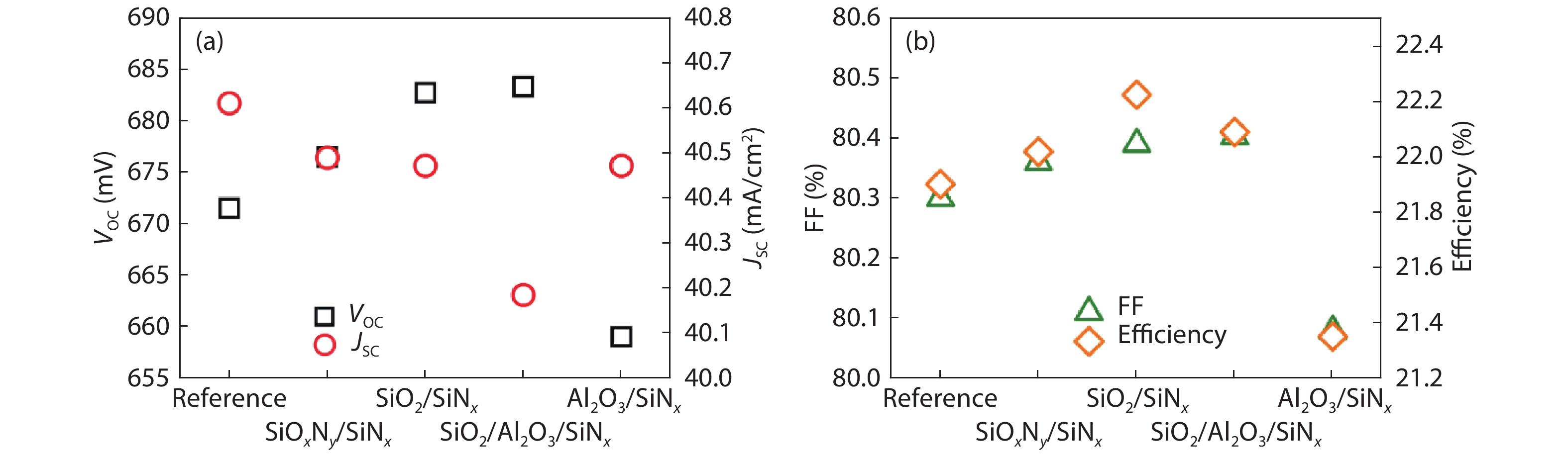

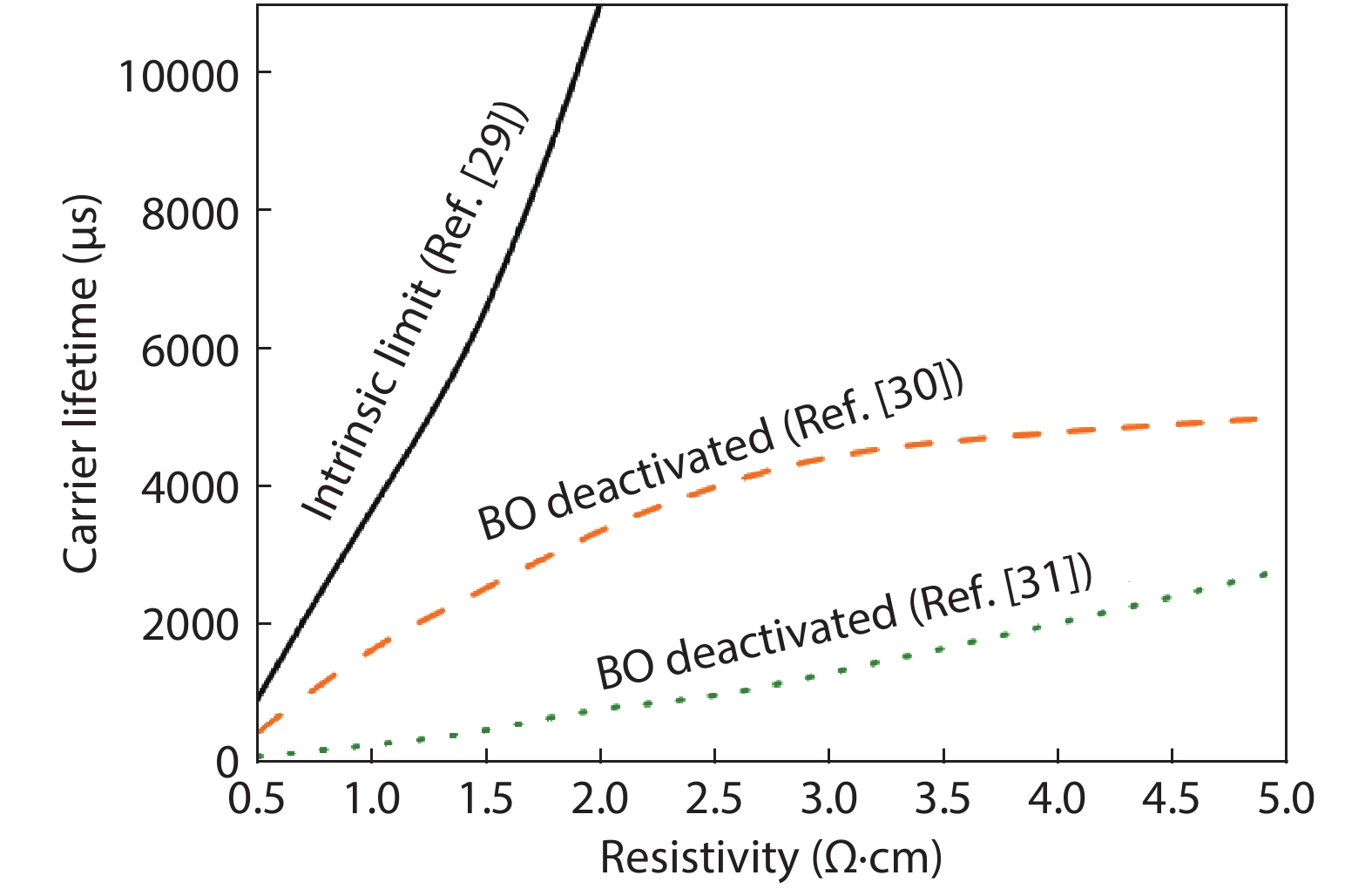

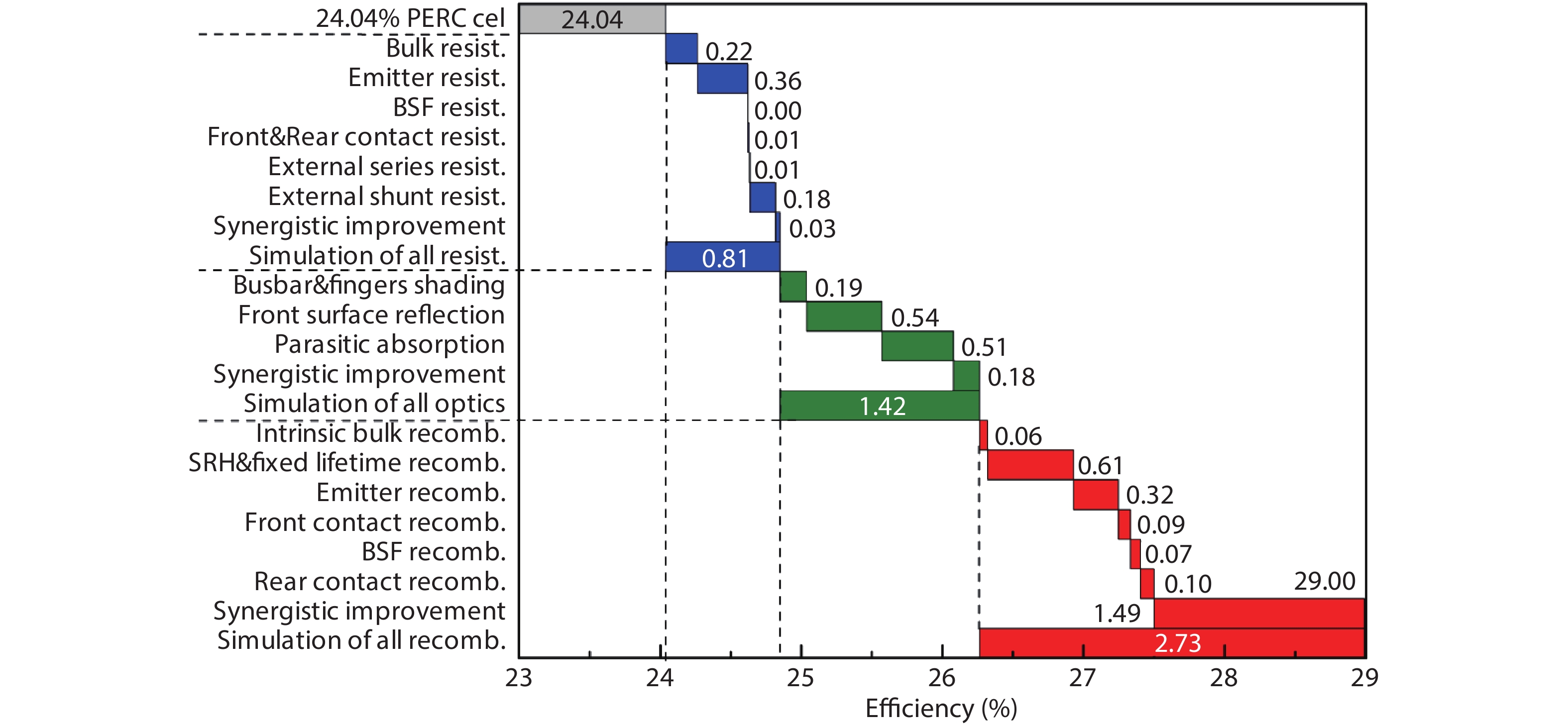

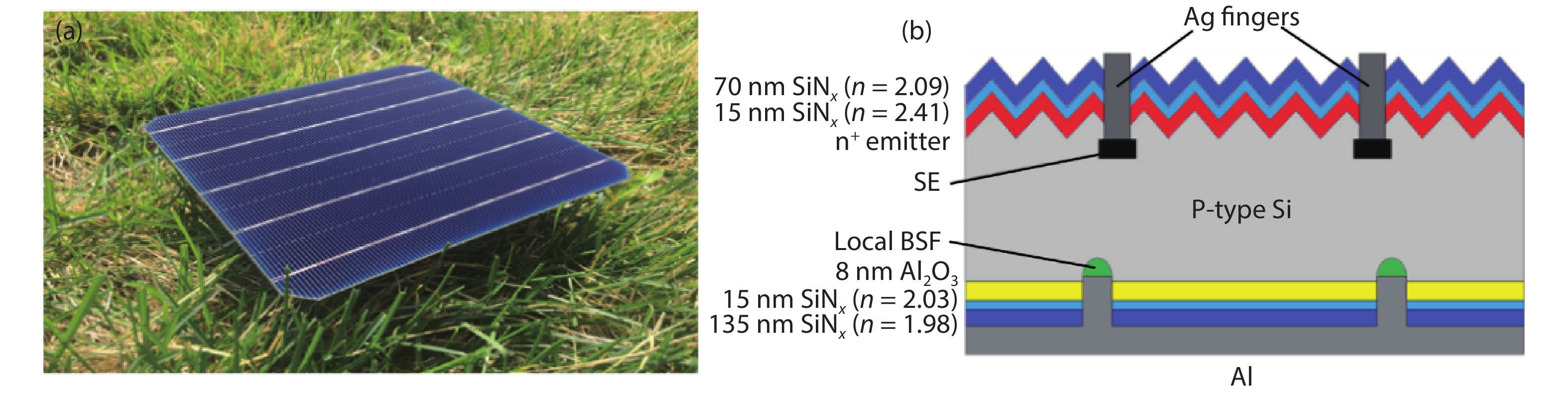

Mono-crystalline silicon solar cells with a passivated emitter rear contact (PERC) configuration have attracted extensive attention from both industry and scientific communities. A record efficiency of 24.06% on p-type silicon wafer and mass production efficiency around 22% have been demonstrated, mainly due to its superior rear side passivation. In this work, the PERC solar cells with a p-type silicon wafer were numerically studied in terms of the surface passivation, quality of silicon wafer and metal electrodes. A rational way to achieve a 24% mass-production efficiency was proposed. Free energy loss analyses were adopted to address the loss sources with respect to the limit efficiency of 29%, which provides a guideline for the design and manufacture of a high-efficiency PERC solar cell. -

References

[1] Blakers A W, Wang A, Milne A M, et al. 22.8% efficient silicon solar cell. Appl Phys Lett, 1989, 55(13), 1363 doi: 10.1063/1.101596[2] Joonwichien S, Utsunomiya S, Kida Y, et al. Improved rear local contact formation using Al paste containing Si for industrial PERC solar cell. IEEE J Photovolt, 2018, 8(1), 54 doi: 10.1109/JPHOTOV.2017.2767604[3] Albadri A M. Characterization of Al2O3 surface passivation of silicon solar cells. TSF, 2014, 562, 451 doi: 10.1016/j.tsf.2014.03.071[4] Pawlik M, Vilcot J P, Halbwax M, et al. Electrical and chemical studies on Al2O3 passivation activation process. Energy Procedia, 2014, 60, 85 doi: 10.1016/j.egypro.2014.12.347[5] Inns D, Poplavskyy D. Measurement of metal induced recombination in solar cells. IEEE 42nd Photovoltaic Specialist Conference (PVSC), 2015, 1[6] Inns D. Understanding metal induced recombination losses in silicon solar cells with screen printed silver contacts. Energy Procedia, 2016, 98, 23 doi: 10.1016/j.egypro.2016.10.077[7] Chen N, Ebong A. Towards 20% efficient industrial Al-BSF silicon solar cell with multiple busbars and fine gridlines. Sol Energy Mater Sol Cells, 2016, 146, 107 doi: 10.1016/j.solmat.2015.11.020[8] Urueña A, John J, Eyben P, et al. Studying local aluminum back surface field (Al-BSF) contacts through scanning spreading resistance microscopy (SSRM). 26th European Photovoltaic Solar Energy Conference (EU PVSEC), 2011[9] Hallam B, Herguth A, Hamer P, et al. Eliminating light-induced degradation in commercial p-type Czochralski silicon solar cells. Appl Sci, 2018, 8(1), 10 doi: 10.3390/app8010010[10] Herguth A, Hahn G. Kinetics of the boron-oxygen related defect in theory and experiment. J Appl Phys, 2010, 108(11), 114509 doi: 10.1063/1.3517155[11] Herguth A, Schubert G, Kaes M, et al. Avoiding boron-oxygen related degradation in highly boron doped Cz silicon. 21st European Photovoltaic Solar Energy Conference (EU PVSEC), 2006, 530[12] Ye F, Deng W, Guo W, et al. 22.13% efficient industrial p-type mono PERC solar cell. IEEE 43rd Photovoltaic Specialists Conference (PVSC), 2016, 3360[13] Müller M, Fischer G, Bitnar B, et al. Loss analysis of 22% efficient industrial PERC solar cells. Energy Procedia, 2017, 124, 131 doi: 10.1016/j.egypro.2017.09.322[14] LONGi Solar sets new bifacial mono-PERC solar cell world record at 24.06 percent. https://www.prnewswire.com/in/news-releases/longi-solar-sets-new-bifacial-mono-perc-solar-cell-world-record-at-24-06-percent-875820879.html[15] Fell A. A free and fast three-dimensional/two-dimensional solar cell simulator featuring conductive boundary and quasi-neutrality approximations. IEEE Trans Electron Devices, 2013, 60(2), 733 doi: 10.1109/TED.2012.2231415[16] Del Alamo J A, Swanson R M. The physics and modeling of heavily doped emitters. IEEE Trans Electron Devices, 1984, 31(12), 1878 doi: 10.1109/T-ED.1984.21805[17] Swanson R M J S C. Point-contact solar cells: modeling and experiment. Sol Cells, 1986, 17(1), 85 doi: 10.1016/0379-6787(86)90061-X[18] Brendel R. Modeling solar cells with the dopant-diffused layers treated as conductive boundaries. Prog Photovolt: Res Appl, 2012, 20(1), 31 doi: 10.1002/pip.954[19] Module ray tracer from PV lighthouse, sunsolve. https://www.pvlighthouse.com.au/sunsolve[20] Fell A, Mcintosh K R, Altermatt P P, et al. Input parameters for the simulation of silicon solar cells in 2014. IEEE J Photovolt, 2017, 5(4), 1250 doi: 10.1109/JPHOTOV.2015.2430016[21] Min B, Müller M, Wagner H, et al. A roadmap toward 24% efficient PERC solar cells in industrial mass production. IEEE J Photovolt, 2017, 7(6), 1541 doi: 10.1109/JPHOTOV.2017.2749007[22] Ernst M, Walter D, Fell A, et al. Efficiency potential of p-type Al passivated perc solar cells with locally laser-doped rear contacts. IEEE J Photovolt, 2016, 6(3), 1 doi: 10.1109/JPHOTOV.2016.2551079[23] Shockley W. The theory of p−n junctions in semiconductors and p−n junction transistors. Bell Syst Tech J, 1949, 28(3), 435 doi: 10.1002/j.1538-7305.1949.tb03645.x[24] Würfel P. Physics of solar cells: from principles to new concepts. Berlin: Wiley-vch, 2005[25] Huang H, Modanese C, Sun S, et al. Effective passivation of p+ and n+ emitters using SiO2/Al2O3/SiNx stacks: Surface passivation mechanisms and application to industrial p-PERT bifacial Si solar cells. Sol Energy Mater Sol Cells, 2018, 186, 356 doi: 10.1016/j.solmat.2018.07.007[26] Kimmerle A, Rahman M M, Werner S, et al. Precise parameterization of the recombination velocity at passivated phosphorus doped surfaces. J Appl Phys, 2016, 119(2), 025706 doi: 10.1063/1.4939960[27] Dingemans G, Kessels W. Status and prospects of Al2O3-based surface passivation schemes for silicon solar cells. J Vac Sci Technol A, 2012, 30(4), 040802 doi: 10.1116/1.4728205[28] Glunz S W, Feldmann F. SiO2 surface passivation layers–a key technology for silicon solar cells. Sol Energy Mater Sol Cells, 2018, 185, 260 doi: 10.1016/j.solmat.2018.04.029[29] Zhuo Z, Sannomiya Y, Kanetani Y, et al. Interface properties of SiOxNy layer on Si prepared by atmospheric-pressure plasma oxidation-nitridation. Nanoscale Res Lett, 2013, 8(1), 201 doi: 10.1186/1556-276X-8-201[30] Richter A, Glunz S W, Werner F, et al. Improved quantitative description of Auger recombination in crystalline silicon. Phys Rev B, 2012, 86(16), 4172 doi: 10.1103/PhysRevB.86.165202[31] Shockley W, Read W Jr. Statistics of the recombinations of holes and electrons. Phys Rev, 1952, 87(5), 835 doi: 10.1103/PhysRev.87.835[32] Hall R. Germanium rectifier characteristics. Phys Rev, 1951, 83(1), 228[33] Richter A, Werner F, Cuevas A, et al. Improved parameterization of Auger recombination in silicon. Energy Procedia, 2012, 27(27), 88 doi: 10.1016/j.egypro.2012.07.034[34] Walter D C, Lim B, Schmidt J. Realistic efficiency potential of next-generation industrial Czochralski-grown silicon solar cells after deactivation of the boron–oxygen-related defect center. Prog Photovolt: Res Appl, 2016, 24(7), 920 doi: 10.1002/pip.2731[35] Schmidt J, Lim B, Walter D, et al. Impurity-related limitations of next-generation industrial silicon solar cells. IEEE J Photovolt, 2013, 3(1), 114 doi: 10.1109/JPHOTOV.2012.2210030[36] Wolny F, Weber T, Müller M, et al. Light induced degradation and regeneration of high efficiency Cz PERC cells with varying base resistivity. Energy Procedia, 2013, 38, 523 doi: 10.1016/j.egypro.2013.07.312[37] Woehl R, Hörteis M, Glunz S. Analysis of the optical properties of screen-printed and aerosol-printed and plated fingers of silicon solar cells. Adv OptoElectron, 2008, 759340 doi: 10.1155/2008/759340[38] Blakers A. Shading losses of solar-cell metal grids. J Appl Phys, 1992, 71(10), 5237 doi: 10.1063/1.350580[39] Braun S, Micard G, Hahn G. Solar cell improvement by using a multi busbar design as front electrode. Energy Procedia, 2012, 27(7), 227 doi: 10.1016/j.egypro.2012.07.056[40] Walter J, Tranitz M, Volk M, et al. Multi-wire interconnection of busbar-free solar cells. Energy Procedia, 2014, 55, 380 doi: 10.1016/j.egypro.2014.08.109[41] Rehman A U, Lee S H. Review of the potential of the Ni/Cu plating technique for crystalline silicon solar cells. Materials, 2014, 7(2), 1318 doi: 10.3390/ma7021318[42] Shockley W, Queisser H J. Detailed balance limit of efficiency of p–n junction solar cells. J Appl Phys, 1961, 32(3), 510 doi: 10.1063/1.1736034[43] Kerr M J, Cuevas A, Campbell P. Limiting efficiency of crystalline silicon solar cells due to Coulomb-enhanced Auger recombination. Prog Photovolt: Res Appl Math, 2003, 11(2), 97 doi: 10.1002/pip.464[44] Richter A, Hermle M, Glunz S W. Reassessment of the limiting efficiency for crystalline silicon solar cells. IEEE J Photovolt, 2013, 3(4), 1184 doi: 10.1109/JPHOTOV.2013.2270351 -

Proportional views

DownLoad:

DownLoad: