| Citation: |

Xing Fan, Dechun Zou, Liming Ding. Fiber-like solar cells[J]. Journal of Semiconductors, 2021, 42(5): 050202. doi: 10.1088/1674-4926/42/5/050202

****

X Fan, D C Zou, L M Ding, Fiber-like solar cells[J]. J. Semicond., 2021, 42(5): 050202. doi: 10.1088/1674-4926/42/5/050202.

|

-

References

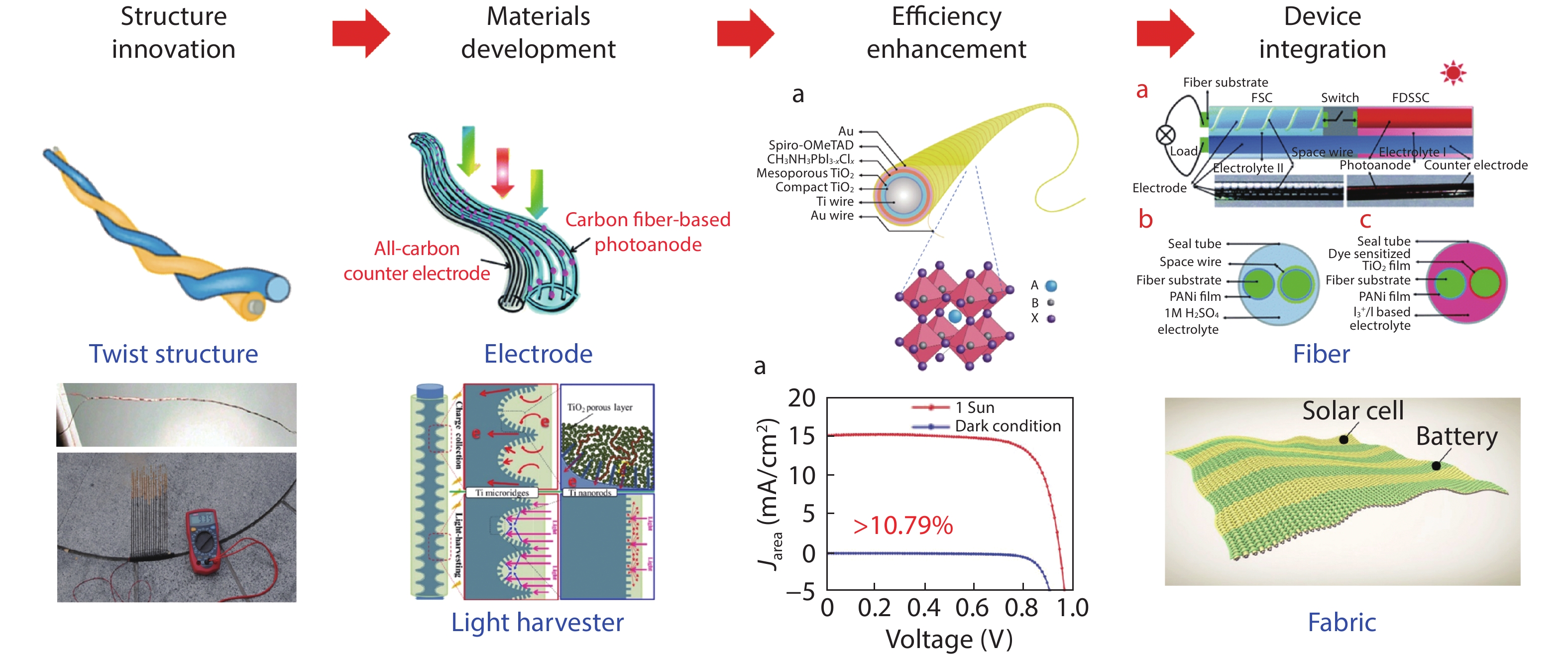

[1] Fan X, Chu Z, Wang F, et al. Wire-shaped flexible dye-sensitized solar cells. Adv Mater, 2008, 20, 592 doi: 10.1002/adma.200701249[2] Fan X, Chu Z, Chen L, et al. Fibrous flexible solid-type dye-sensitized solar cells without transparent conducting oxide. Appl Phys Lett, 2008, 92, 113510 doi: 10.1063/1.2891051[3] Zou D, Wang D, Chu Z, et al. Fiber-shaped flexible solar cells. Coordin Chem Rev, 2010, 254, 1169 doi: 10.1016/j.ccr.2010.02.012[4] Yu J, Wang D, Huang Y, et al. A cylindrical core-shell-like TiO2 nanotube array anode for flexible fiber-type dye-sensitized solar cells. Nanoscale Res Lett, 2011, 6, 94 doi: 10.1186/1556-276X-6-94[5] Wang D, Hou S, Wu H, et al. Fiber-shaped all-solid state dye sensitized solar cell with remarkably enhanced performance via substrate surface engineering and TiO2 film modification. J Mater Chem, 2011, 21, 6383 doi: 10.1039/c1jm00016k[6] Fan X, Zhang X, Zhang N, et al. Wet-process fabrication of low-cost all-solid wire-shaped solar cells on manganese-plated electrodes. Electrochim Acta, 2015, 161, 358 doi: 10.1016/j.electacta.2015.02.092[7] Cai X, Hou S, Wu H, et al. All-carbon electrode-based fiber-shaped dye-sensitized solar cells. Phys Chem Chem Phys, 2012, 14, 125 doi: 10.1039/C1CP22613D[8] Cai X, Wu H, Hou S, et al. Dye-sensitized solar cells with vertically aligned TiO2 nanowire arrays grown on carbon fibers. ChemSusChem, 2014, 7, 474 doi: 10.1002/cssc.201301020[9] Fu Y, Hou S, Cai X, et al. Transparent conductive oxide-less, flexible, and highly efficient dye-sensitized solar cells with commercialized carbon fiber as the counter electrode. J Mater Chem, 2011, 21, 13776 doi: 10.1039/c1jm12056e[10] Hou S, Lv Z, Wu H, et al. Flexible conductive threads for wearable dye-sensitized solar cells. J Mater Chem, 2012, 22, 6549 doi: 10.1039/c2jm16773e[11] Peng M, Cai X, Fu Y, et al. Facial synthesis of SnO2 nanoparticle film for efficient fiber-shaped dye-sensitized solar cells. J Power Sources, 2014, 247, 249 doi: 10.1016/j.jpowsour.2013.08.075[12] Wang W, Zhao Q, Li H, et al. Transparent, double-sided, ITO-free, flexible dye-sensitized solar sells based on metal wire/ZnO nanowire arrays. Adv Funct Mater, 2012, 22, 2775 doi: 10.1002/adfm.201200168[13] Dong B, Hu J, Xiao X, et al. High-efficiency fiber-shaped perovskite solar cell by vapor-assisted deposition with a record efficiency of 10.79%. Adv Mater Technol, 2019, 4, 1900131 doi: 10.1002/admt.201900131[14] Fu Y, Lv Z, Hou S, et al. Conjunction of fiber solar cells with groovy micro-reflectors as highly efficient energy harvesters. Energy Environ Sci, 2011, 4, 3379 doi: 10.1039/c1ee01427g[15] Liu G, Wang M, Wang H, et al. Hierarchically structured photoanode with enhanced charge collection and light harvesting abilities for fiber-shaped dye-sensitized solar cells. Nano Energy, 2018, 49, 95 doi: 10.1016/j.nanoen.2018.04.037[16] Fu Y, Cai X, Wu H, et al. Fiber supercapacitors utilizing pen ink for flexible/wearable energy storage. Adv Mater, 2012, 24, 5713 doi: 10.1002/adma.201202930[17] Fu Y, Wu H, Ye S, et al. Integrated power fiber for energy conversion and storage. Energy Environ Sci, 2013, 6, 805 doi: 10.1039/c3ee23970e[18] Yu X, Fu Y, Cai X, et al. Flexible fiber-type zinc –carbon battery based on carbon fiber electrodes. Nano Energy, 2013, 2, 1242 doi: 10.1016/j.nanoen.2013.06.002[19] Zhang N, Huang F, Zhao S, et al. Photo-rechargeable fabrics as sustainable and robust power sources for wearable bioelectronics. Matter, 2020, 2, 1260 doi: 10.1016/j.matt.2020.01.022 -

Proportional views

DownLoad:

DownLoad: