| Citation: |

Rongfeng Tang, Tao Chen, Liming Ding. Engineering microstructures for efficient Sb2(S xSe1−x)3 solar cells[J]. Journal of Semiconductors, 2021, 42(7): 070203. doi: 10.1088/1674-4926/42/7/070203

****

R F Tang, T Chen, L M Ding, Engineering microstructures for efficient Sb2(S xSe1−x)3 solar cells[J]. J. Semicond., 2021, 42(7): 070203. doi: 10.1088/1674-4926/42/7/070203.

|

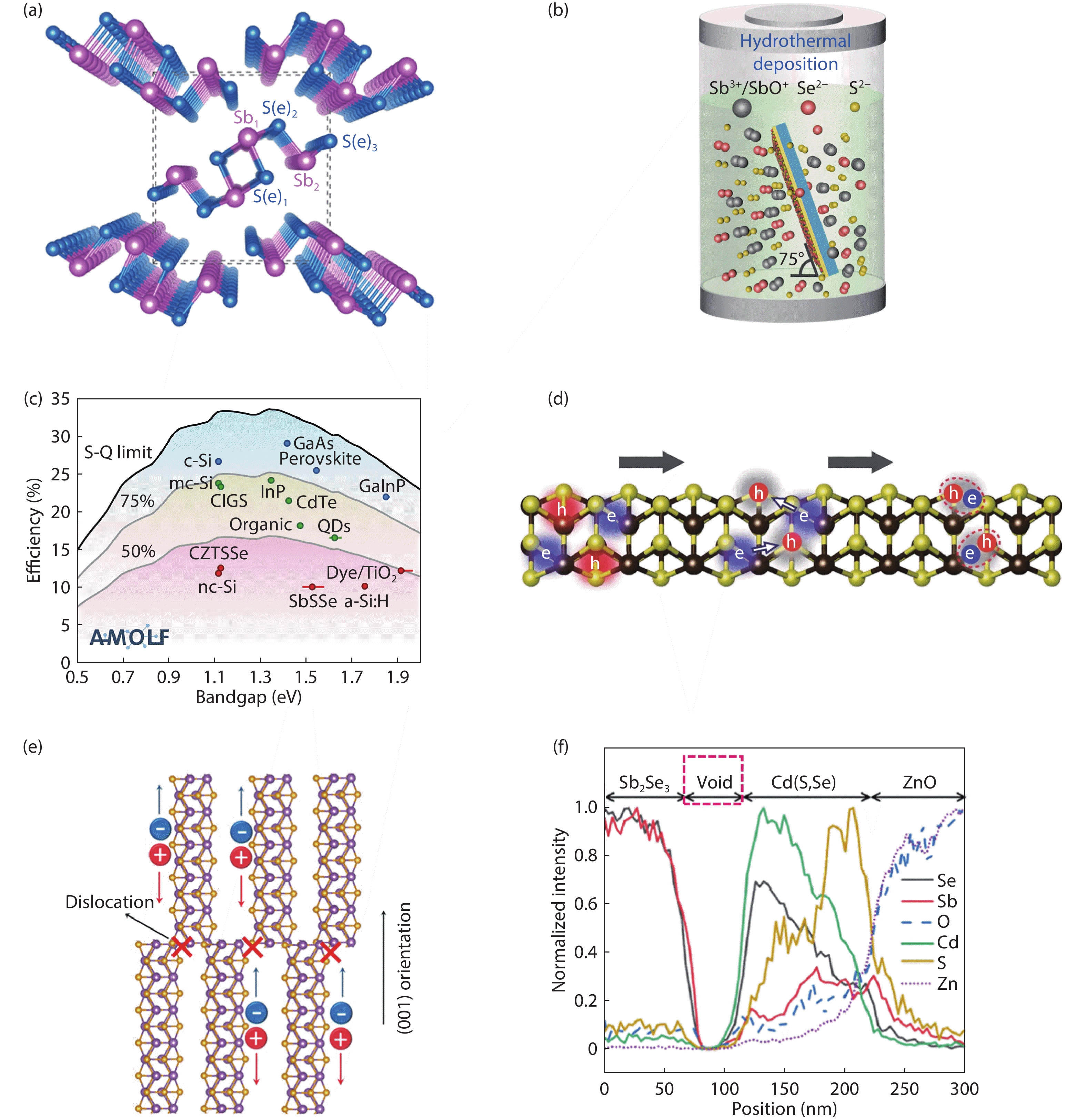

Engineering microstructures for efficient Sb2(S xSe1−x)3 solar cells

DOI: 10.1088/1674-4926/42/7/070203

More Information

-

References

[1] Lei H W, Chen J J, Tan Z J, et al. Review of recent progress in antimony chalcogenide-based solar cells: materials and devices. Sol RRL, 2019, 3, 1900026 doi: 10.1002/solr.201900026[2] Deng H, Zeng Y Y, Ishaq M, et al. Quasiepitaxy strategy for efficient full-inorganic Sb2S3 solar cells. Adv Funct Mater, 2019, 29, 1901720 doi: 10.1002/adfm.201901720[3] Wu C Y, Lian W T, Zhang L J, et al. Water additive enhanced solution processing of alloy Sb2(S1– xSex)3-based solar cells. Sol RRL, 2020, 4, 1900582 doi: 10.1002/solr.201900582[4] Wang L, Li D B, Li K H, et al. Stable 6%-efficient Sb2Se3 solar cells with a ZnO buffer layer. Nat Energy, 2017, 2, 17046 doi: 10.1038/nenergy.2017.46[5] Tang R F, Wang X M, Lian W T, et al. Hydrothermal deposition of antimony selenosulfide thin films enables solar cells with 10% efficiency. Nat Energy, 2020, 5, 587 doi: 10.1038/s41560-020-0652-3[6] Wang X M, Tang R F, Jiang C H, et al. Manipulating the electrical properties of Sb2(S, Se)3 film for high-efficiency solar cell. Adv Energy Mater, 2020, 10, 2002341 doi: 10.1002/aenm.202002341[7] Wen X X, Chen C, Lu S C, et al. Vapor transport deposition of antimony selenide thin film solar cells with 7.6% efficiency. Nat Commun, 2018, 9, 2179 doi: 10.1038/s41467-018-04634-6[8] Li Z Q, Liang X Y, Li G, et al. 9.2%-efficient core-shell structured antimony selenide nanorod array solar cells. Nat Commun, 2019, 10, 125 doi: 10.1038/s41467-018-07903-6[9] Zhou Y, Wang L, Chen S Y, et al. Thin-film Sb2Se3 photovoltaics with oriented one-dimensional ribbons and benign grain boundaries. Nat Photonics, 2015, 9, 409 doi: 10.1038/nphoton.2015.78[10] Yang Z L, Wang X M, Chen Y Z, et al. Ultrafast self-trapping of photoexcited carriers sets the upper limit onantimony trisulfide photovoltaic devices. Nat Commun, 2019, 10, 4540 doi: 10.1038/s41467-019-12445-6[11] Li J J, Huang J L, Li K H, et al. Defect-resolved effective majority carrier mobility in highly anisotropic antimony chalcogenide thin-film solar cells. Sol RRL, 2021, 5, 2000693 doi: 10.1002/solr.202000693[12] Williams R E, Ramasse Q M, McKenna K P, et al. Evidence for self-healing benign grain boundaries and a highly defective Sb2Se3-CdS interfacial layer in Sb2Se3 thin-film photovoltaics. ACS Appl Mater Interfaces, 2020, 12, 21730 doi: 10.1021/acsami.0c03690[13] Chen C, Tang J. Open-circuit voltage loss of antimony chalcogenide solar cells: status, origin, and possible solutions. ACS Energy Lett, 2020, 5, 2294 doi: 10.1021/acsenergylett.0c00940[14] Maiti A, Chatterjee S, Pal A J. Sulfur-vacancy passivation in solution-processed Sb2S3 thin films: Influence on photovoltaic interfaces. ACS Appl Energy Mater, 2020, 3, 810 doi: 10.1021/acsaem.9b01951[15] Ayala-Mató F, Vigil-Galán O, Nicolás-Marín M M, et al. Study of loss mechanisms on Sb2(S1– xSex)3 solar cell with n-i-p structure: Toward an efficiency promotion. Appl Phys Lett, 2021, 118, 73903 doi: 10.1063/5.0032867 -

Proportional views

DownLoad:

DownLoad: