| Citation: |

Tieshi Wei, Xuefei Li, Zhiyun Li, Wenxian Yang, Yuanyuan Wu, Zhiwei Xing, Shulong Lu. Interfacial dynamics of GaP/Si(100) heterostructure grown by molecular beam epitaxy[J]. Journal of Semiconductors, 2022, 43(12): 122101. doi: 10.1088/1674-4926/43/12/122101

****

T S Wei, X F Li, Z Y Li, W X Yang, Y Y Wu, Z W Xing, S L Lu. Interfacial dynamics of GaP/Si(100) heterostructure grown by molecular beam epitaxy[J]. J. Semicond, 2022, 43(12): 122101. doi: 10.1088/1674-4926/43/12/122101

|

Interfacial dynamics of GaP/Si(100) heterostructure grown by molecular beam epitaxy

DOI: 10.1088/1674-4926/43/12/122101

More Information

-

Abstract

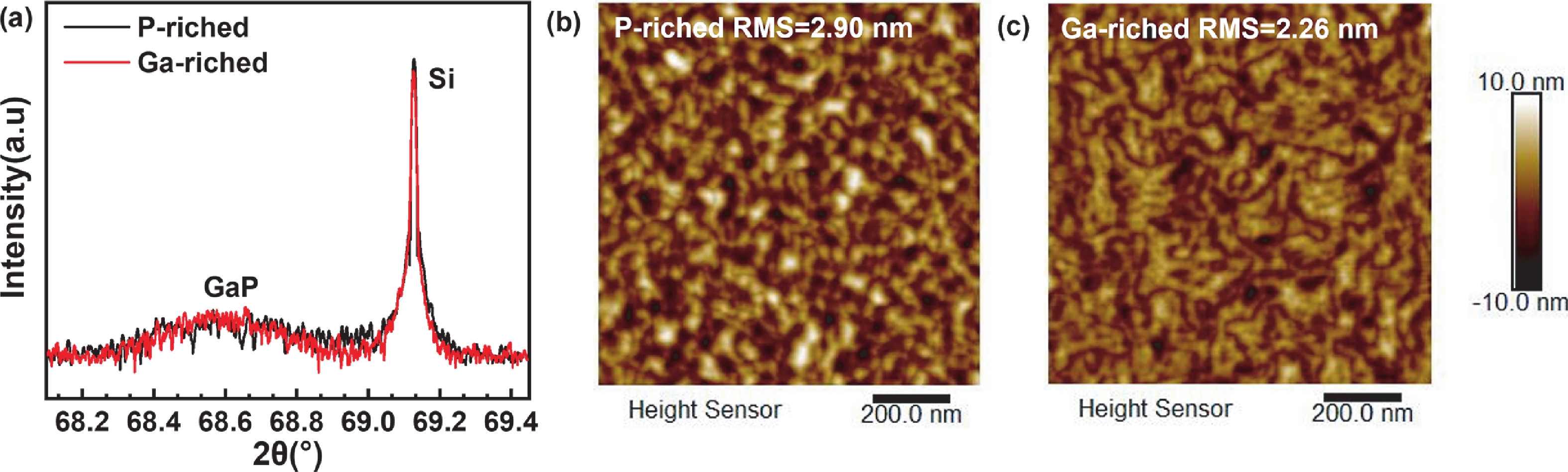

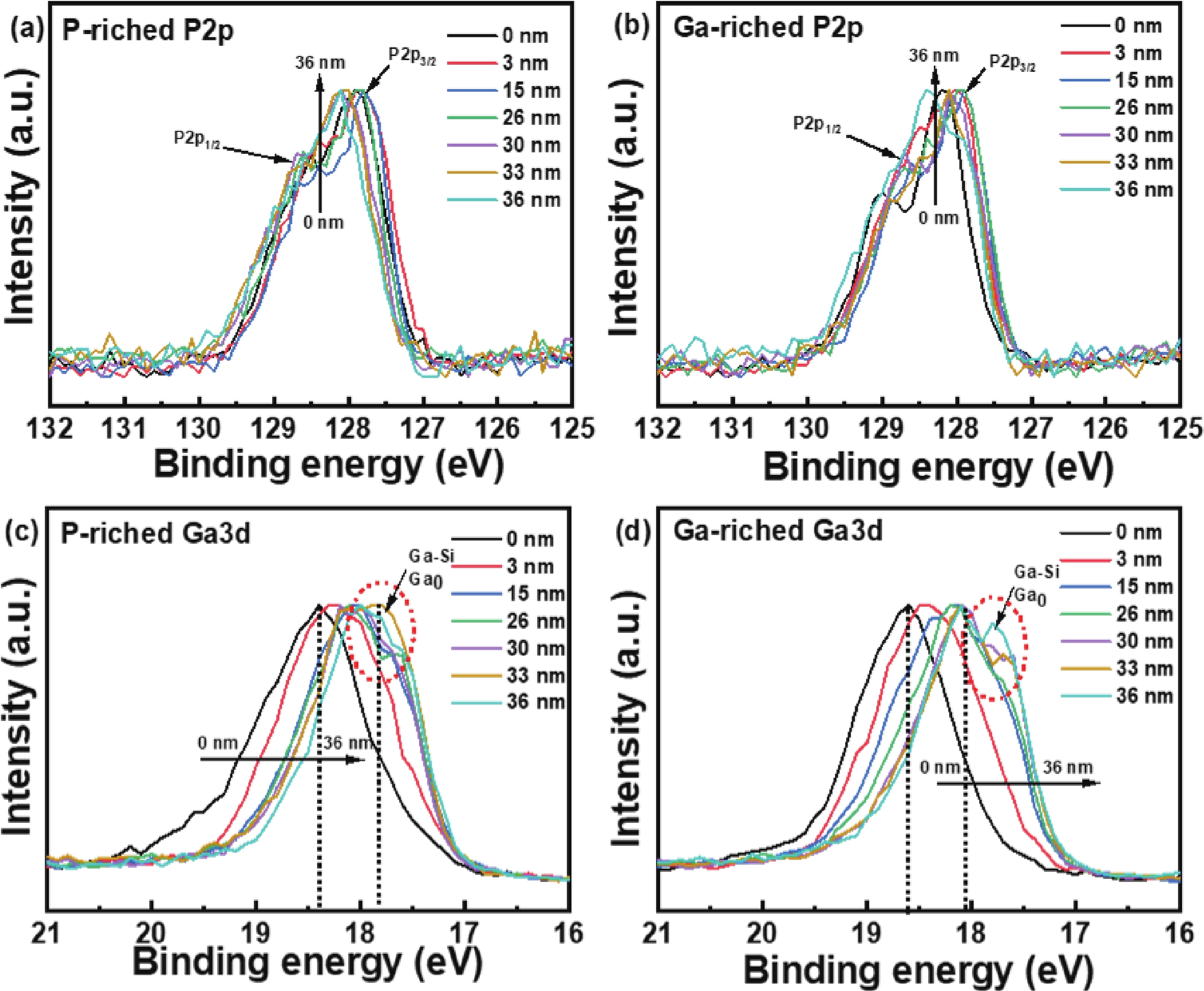

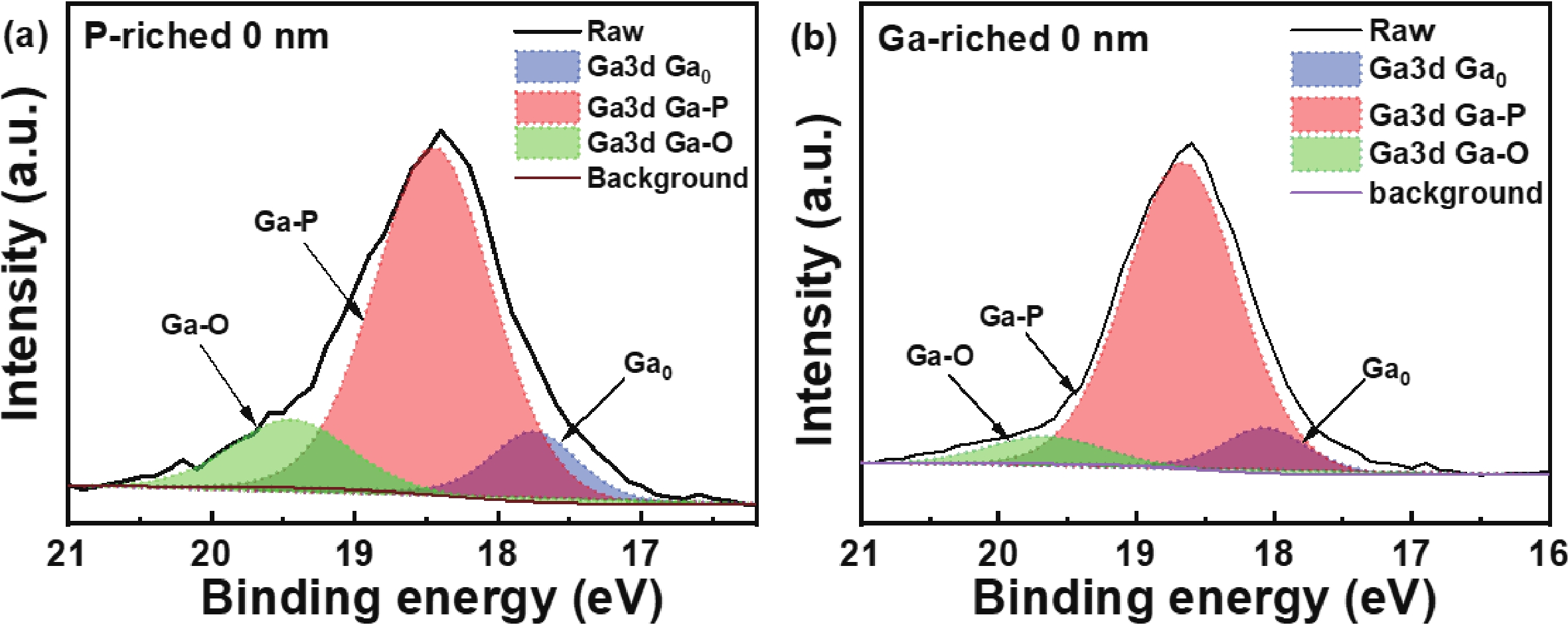

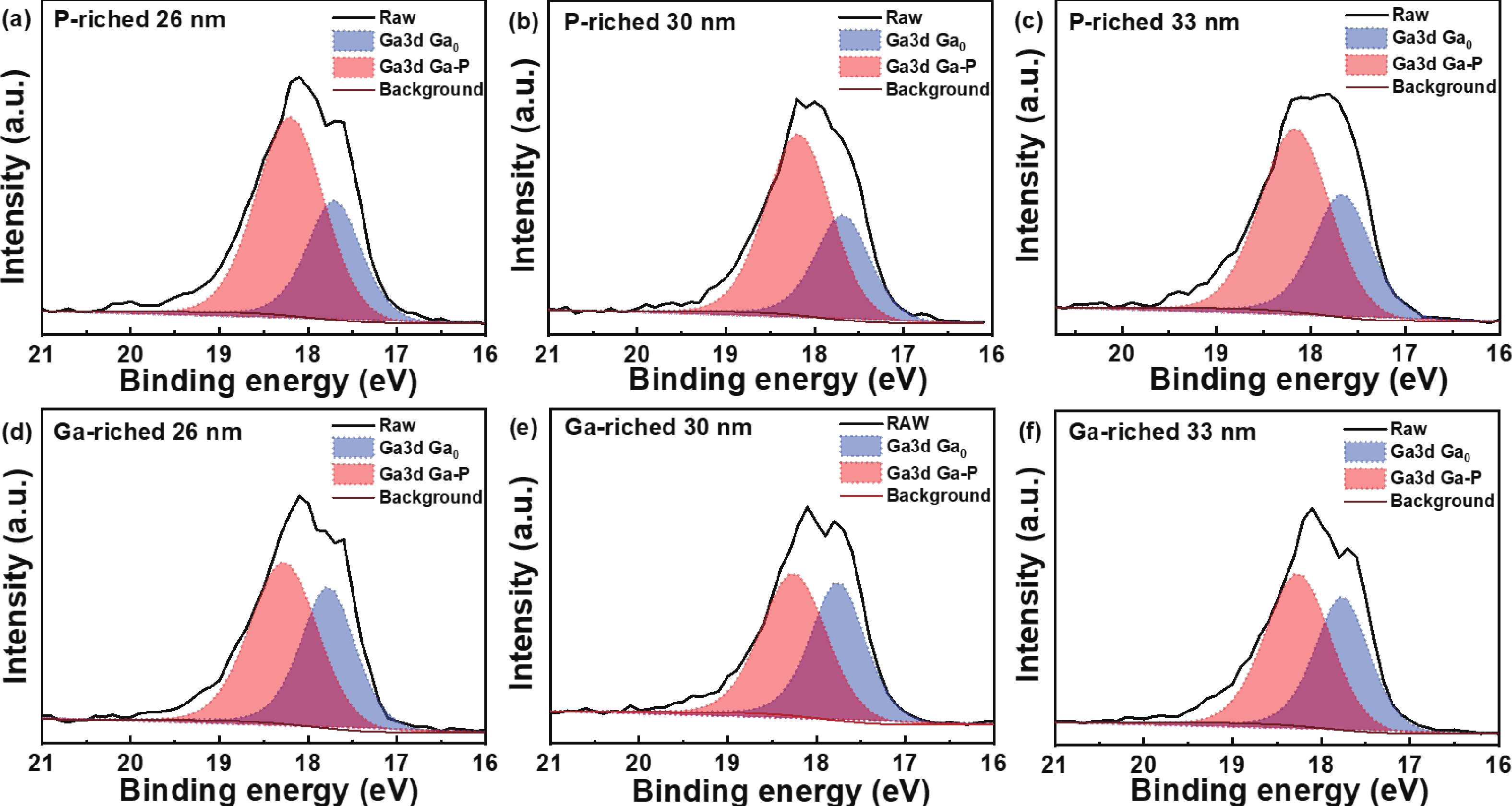

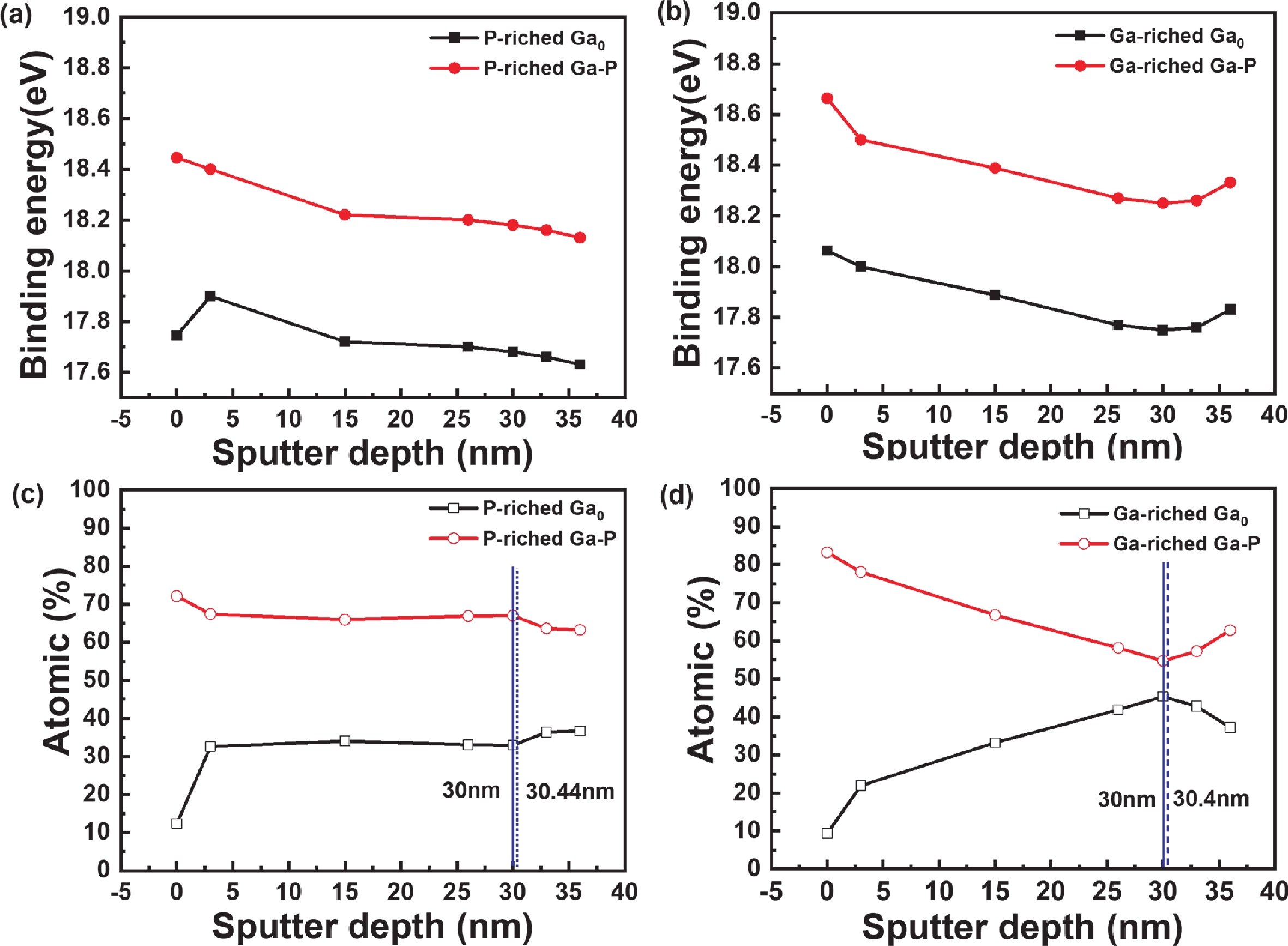

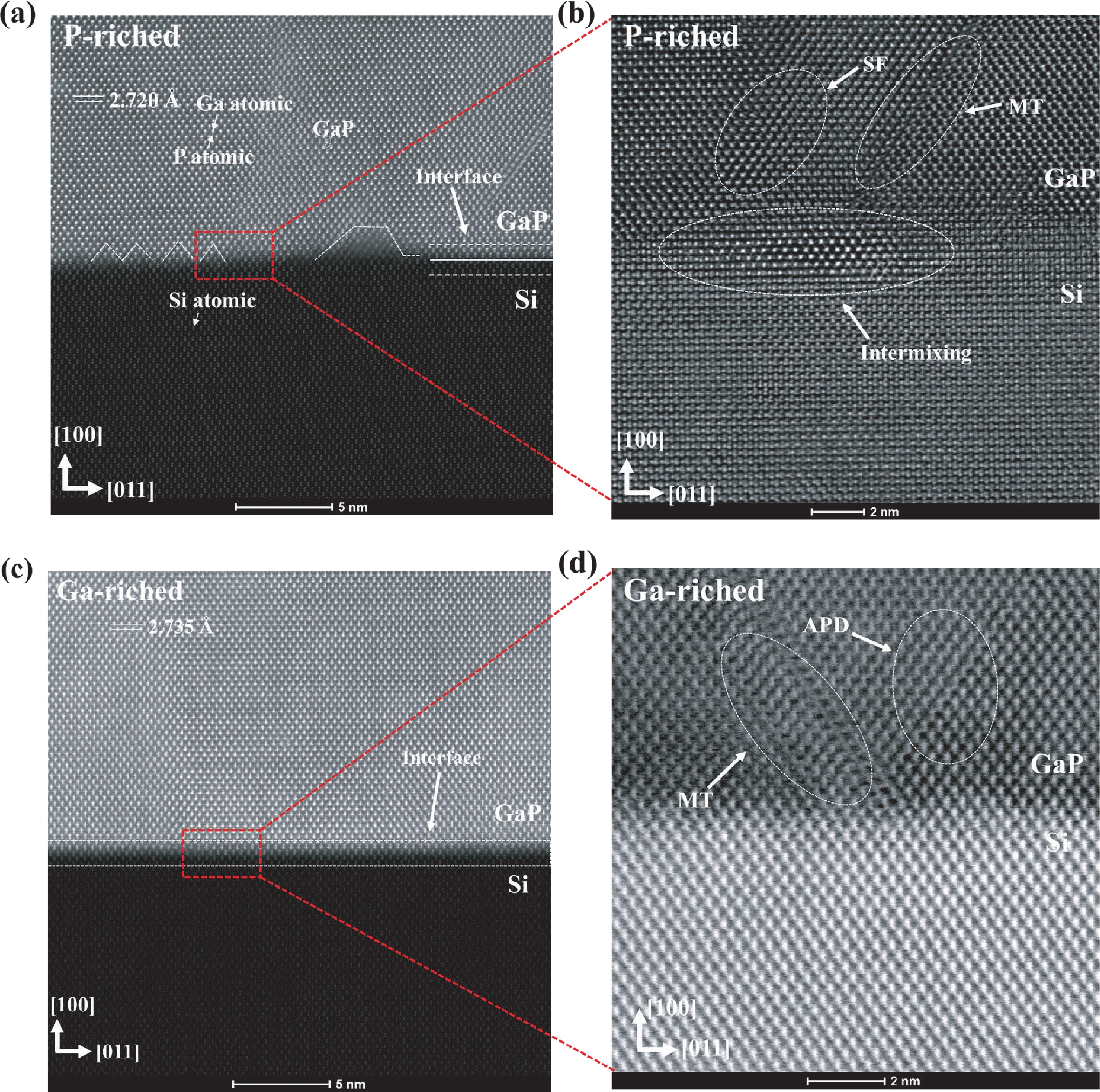

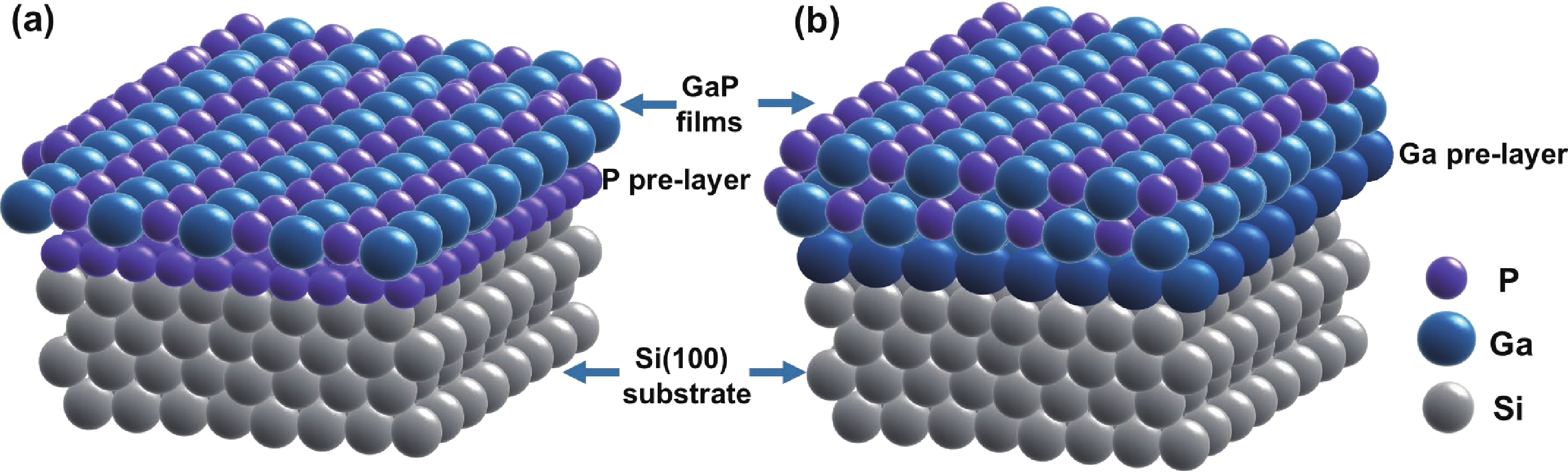

The atomic structure and surface chemistry of GaP/Si(100) heterostructure with different pre-layers grown by molecular beam epitaxy are studied. It is found that GaP epilayer with Ga-riched pre-layers on Si(100) substrate has regular surface morphology and stoichiometric abrupt heterointerfaces from atomic force microscopes (AFMs) and spherical aberration-corrected transmission electron microscopes (ACTEMs). The interfacial dynamics of GaP/Si(100) heterostructure is investigated by X-ray photoelectron spectroscopy (XPS) equipped with an Ar gas cluster ion beam, indicating that Ga pre-layers can lower the interface formation energy and the bond that is formed is more stable. These results suggest that Ga-riched pre-layers are more conducive to the GaP nucleation as well as the epitaxial growth of GaP material on Si(100) substrate.-

Keywords:

- XPS,

- interfacial dynamics,

- GaP/Si(100) heterostructure,

- MBE

-

References

[1] Boley A, Luna E, Zhang C, et al. Interfacial intermixing and anti-phase boundaries in GaP/Si(001) heterostructures. J Cryst Growth, 2021, 562, 126059 doi: 10.1016/j.jcrysgro.2021.126059[2] Boyer J T, Blumer A N, Blumer Z H, et al. Reduced dislocation lntroduction in III–V/Si heterostructures with glide-enhancing compressively strained superlattices. Cryst Growth Des, 2020, 20, 6939 doi: 10.1021/acs.cgd.0c00992[3] Zhang C, Vadiee E, Dahal S, et al. Developing high performance GaP/Si heterojunction solar cells. J Vis Exp, 2018, 141, 58292 doi: 10.3791/58292[4] Gutowski P, Sankowska I, Słupinski T, et al. Optimization of MBE growth conditions of In0.52Al0.48As waveguide layers for InGaAs/InAlAs/InP quantum cascade lasers. Materials, 2019, 12, 1621 doi: 10.3390/ma12101621[5] Han Y, Ng W K, Xue Y, et al. Room temperature III–V nanolasers with distributed bragg reflectors epitaxially grown on (001) silicon-on-insulators. Photonics Res, 2019, 7, 1081 doi: 10.1364/PRJ.7.001081[6] Kawanami H. Heteroepitaxial technologies of III–V on Si. Sol Energy Mater Sol Cells, 2001, 66, 479 doi: 10.1016/S0927-0248(00)00209-9[7] Fang S F, Adomi K, Lyer S, et al. Gallium arsenide and other compound semiconductors on silicon. J Appl Phys, 1990, 68, R31 doi: 10.1063/1.346284[8] Supplie O, Romanyuk O, Koppka C, et al. Metalorganic vapor phase epitaxy of III–V-on-silicon: experiment and theory. Prog Cryst Growth Charact Mater, 2018, 64, 103 doi: 10.1016/j.pcrysgrow.2018.07.002[9] Feifel M, Ohlmann J, France R M, et al. Electron channeling contrast imaging investigation of stacking fault pyramids in GaP on Si nucleation layers. J Cryst Growth, 2020, 532, 125422 doi: 10.1016/j.jcrysgro.2019.125422[10] Harrison W A, Kraut E A, Waldrop J R, et al. Polar heterojunction interfaces. Phys Rev B, 1978, 18, 4402 doi: 10.1103/PhysRevB.18.4402[11] Zhang C, Boley A, Faleev N, et al. Investigation of defect creation in GaP/Si(001) epitaxial structures. J Cryst Growth, 2018, 503, 36 doi: 10.1016/j.jcrysgro.2018.09.020[12] Grassman T J, Brenner M R, Rajagopalan S, et al. Control and elimination of nucleation-related defects in GaP/Si(001) heteroepitaxy. Appl Phys Lett, 2009, 94, 232106 doi: 10.1063/1.3154548[13] Lucci I, Charbonnier S, Vallet M, et al. A stress-free and textured GaP template on silicon for solar water splitting. Adv Funct Mater, 2018, 28, 1801585 doi: 10.1002/adfm.201801585[14] Hool R D, Chai Y, Sun Y, et al. Relaxed GaP on Si with low threading dislocation density. Appl Phys Lett, 2020, 116, 042102 doi: 10.1063/1.5141122[15] Romanyuk O, Gordeev I, Paszuk A, et al. GaP/Si(001) interface study by XPS in combination with Ar gas cluster ion beam sputtering. Appl Surf Sci, 2020, 514, 145903 doi: 10.1016/j.apsusc.2020.145903[16] Doscher H, Bruckner S, Dobrich A, et al. Surface preparation of Si(100) by thermal oxide removal in a chemical vapor environment. J Cryst Growth, 2011, 315, 10 doi: 10.1016/j.jcrysgro.2010.07.017[17] Nandy M, Paszuk A, Feifel M, et al. A route to obtaining low-defect III–V epilayers on Si (100) utilizing MOCVD. Cryst Growth Des, 2021, 21, 5603 doi: 10.1021/acs.cgd.1c00410[18] D. Keith Bowen and Tanner. B K, High resolution X-ray diffractometry and topography. Abingdon, Taylor & Francis e-Library, 1998[19] Chadi D J. Stabilities of single-layer and bilayer steps on Si (001) surfaces. Phys Rev Lett, 1987, 59, 1691 doi: 10.1103/PhysRevLett.59.1691[20] Curson N J, Schofield S R, Simmons M Y, et al. STM characterization of the Si-P heterodimer. Phys Rev B, 2004, 69, 195303 doi: 10.1103/PhysRevB.69.195303[21] Brenner M R. GaP/Si heteroepitaxy (suppression of nucleation related defects). Ohio, The Ohio State University, 2009[22] Suzuki Y, Sanada N, Shimomura M, et al. High-resolution XPS analysis of GaP(001), (111)A, and (111)B surfaces passivated by (NH4)2S x solution. Appl Surf Sci, 2004, 235, 260 doi: 10.1016/j.apsusc.2004.05.099[23] Supplie O, May M M, Steinbach G, et al. Time-resolved in Situ spectroscopy during formation of the GaP/Si(100) heterointerface. J Phys Chem Lett, 2015, 6, 464 doi: 10.1021/jz502526e[24] Liu K Z, Suzuki Y, Fukuda Y. AES and XPS studies of a GaP(001) surface treated by S2Cl2 and P2S5/(NH4)2S x. Appl Surf Sci, 2004, 237, 627 doi: 10.1016/j.apsusc.2004.06.135[25] Beyer A, Stegmüller A, Oelerich J O, et al. Pyramidal structure formation at the lnterface between III/V semiconductors and silicon. Chem Mater, 2016, 28, 3265 doi: 10.1021/acs.chemmater.5b04896[26] Nagano M, Yamada S, Akita S, et al. Low-damage sputtering of GaAs and GaP using size-selected Ar cluster ion beams. Jpn J Appl Phys, 2005, 44, 164 doi: 10.1143/JJAP.44.L164[27] Romanyuk O, Hannappel T, Grosse F. Atomic and electronic structure of GaP/Si(111), GaP/Si(110), and GaP/Si(113) interfaces and superlattices studied by density functional theory. Phys Rev B, 2013, 88, 115312 doi: 10.1103/PhysRevB.88.115312[28] Baira M, Bekhti-Siad A, Hebali K, et al. Charge compensation mechanisms in favor of the incorporation of the Eu3+ ion into the ZnO host lattice. Phys B, 2018, 537, 296 doi: 10.1016/j.physb.2018.02.035[29] Romanyuk O, Grosse F, Braun W. Stoichiometry and bravais lattice diversity: Anab initiostudy of the GaSb(001) surface. Phys Rev B, 2009, 79, 235330 doi: 10.1103/PhysRevB.79.235330[30] Doscher H, Supplie O, Bruckner S, et al. Indirect in situ characterization of Si(100) substrates at the initial stage of III–V heteroepitaxy. J Cryst Growth, 2011, 315, 16 doi: 10.1016/j.jcrysgro.2010.08.017[31] P Farin, H Eisele, Dähne M. From surface data to bulk properties: a case study for antiphase boundaries in GaP on Si (001). J Phys D, 2021, 54, 205302 doi: 10.1088/1361-6463/abdff1[32] Volz K, Beyer A, Witte W, et al. GaP-nucleation on exact Si (001) substrates for III/V device integration. J Cryst Growth, 2011, 315, 37 doi: 10.1016/j.jcrysgro.2010.10.036 -

Proportional views

DownLoad:

DownLoad: