| Citation: |

Yabao Zhang, Jun Zheng, Peipei Ma, Xueyi Zheng, Zhi Liu, Yuhua Zuo, Chuanbo Li, Buwen Cheng. Growth and characterization of β-Ga2O3 thin films grown on off-angled Al2O3 substrates by metal-organic chemical vapor deposition[J]. Journal of Semiconductors, 2022, 43(9): 092801. doi: 10.1088/1674-4926/43/9/092801

****

Y B Zhang, J Zheng, P P Ma, X Y Zheng, Z Liu, Y H Zuo, C B Li, B W Cheng. Growth and characterization of β-Ga2O3 thin films grown on off-angled Al2O3 substrates by metal-organic chemical vapor deposition[J]. J. Semicond, 2022, 43(9): 092801. doi: 10.1088/1674-4926/43/9/092801

|

Growth and characterization of β-Ga2O3 thin films grown on off-angled Al2O3 substrates by metal-organic chemical vapor deposition

DOI: 10.1088/1674-4926/43/9/092801

More Information

-

Abstract

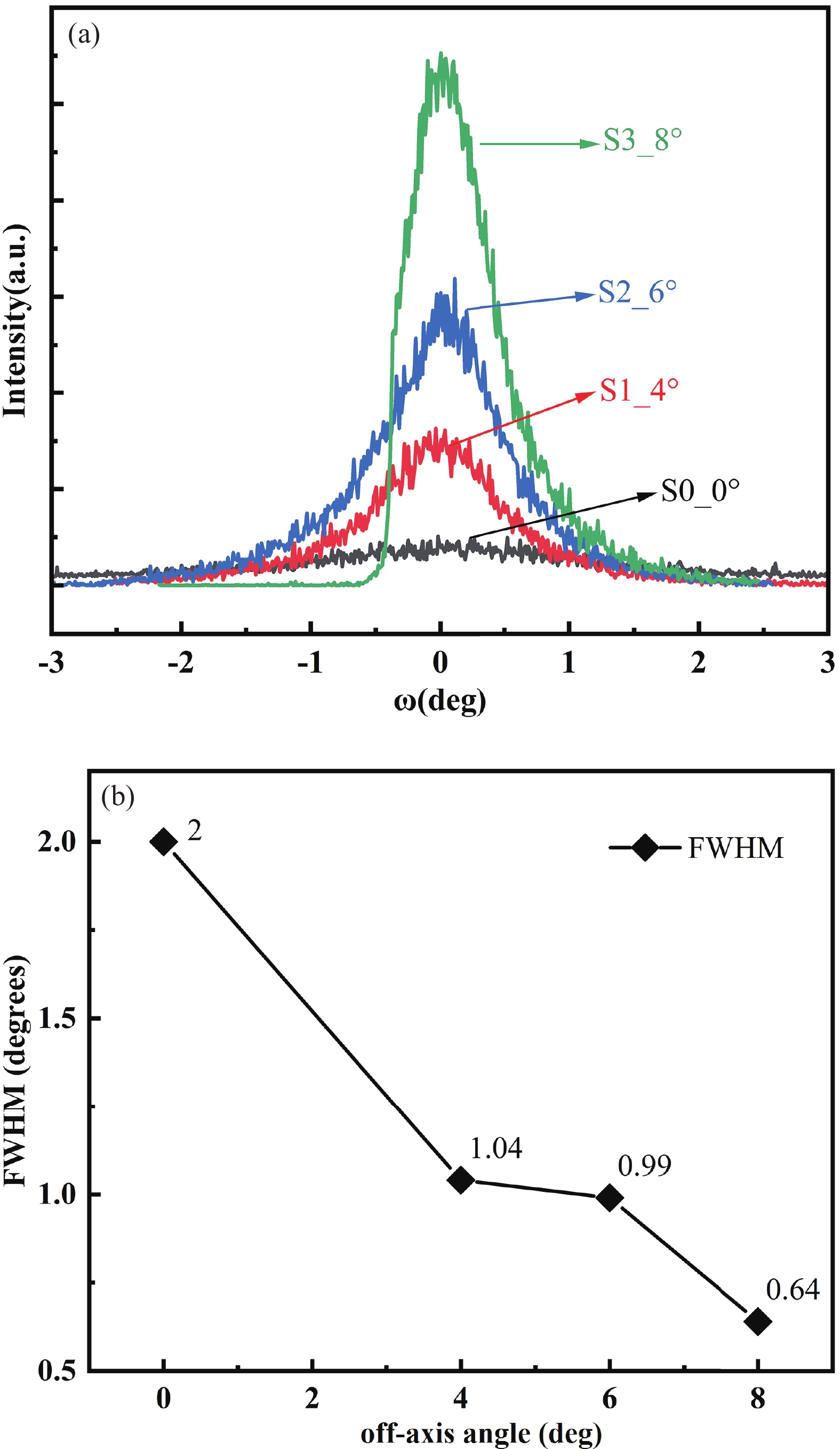

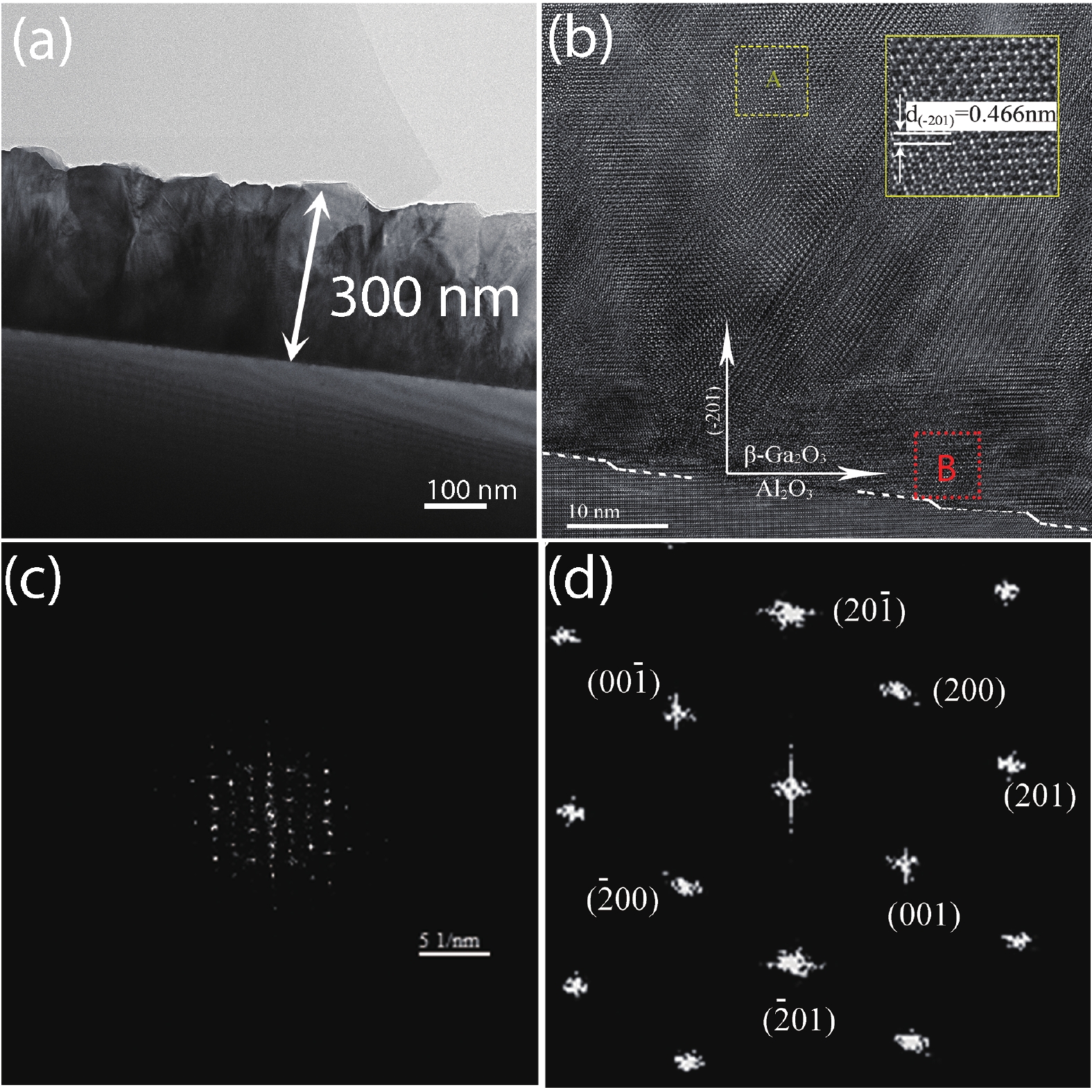

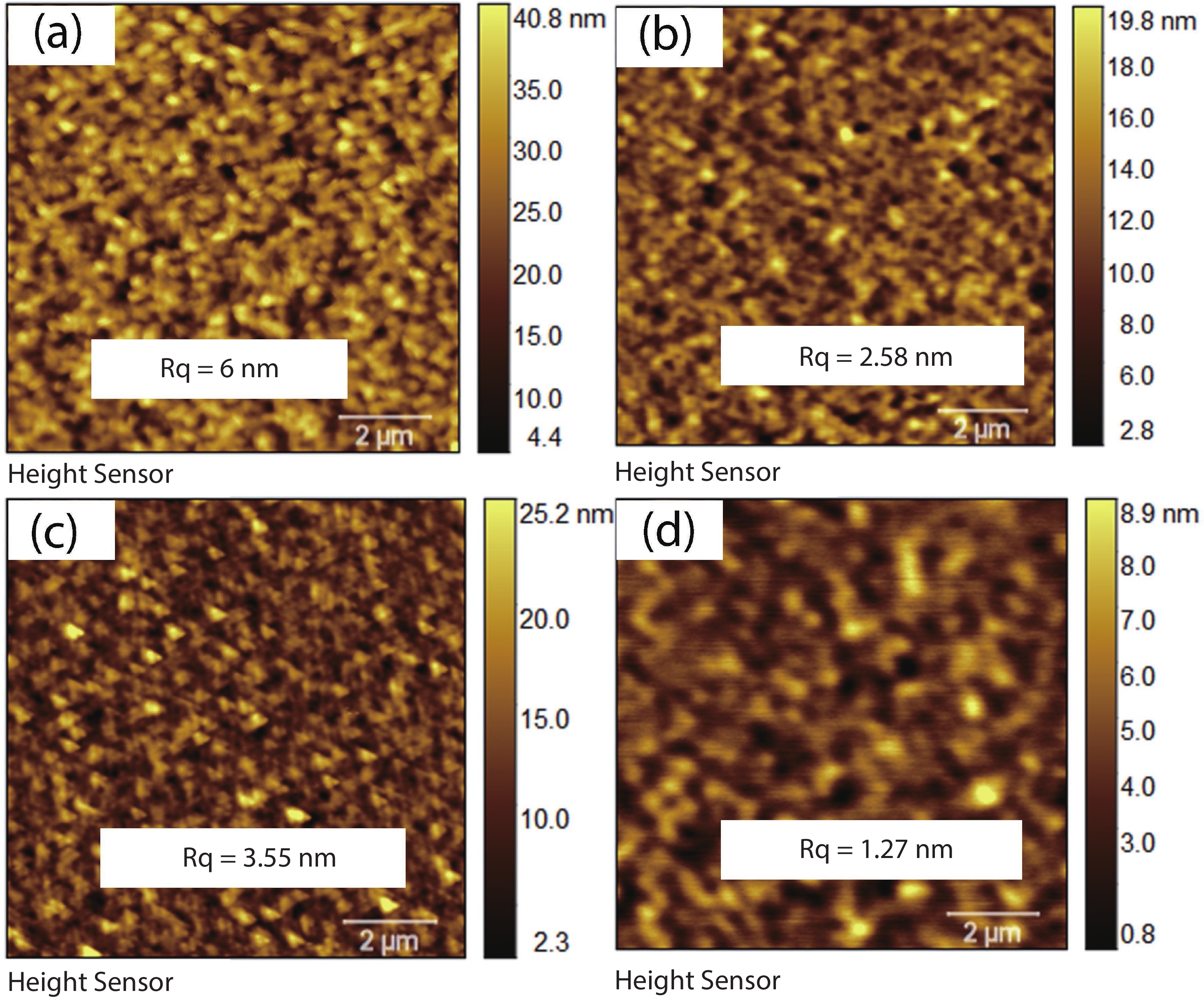

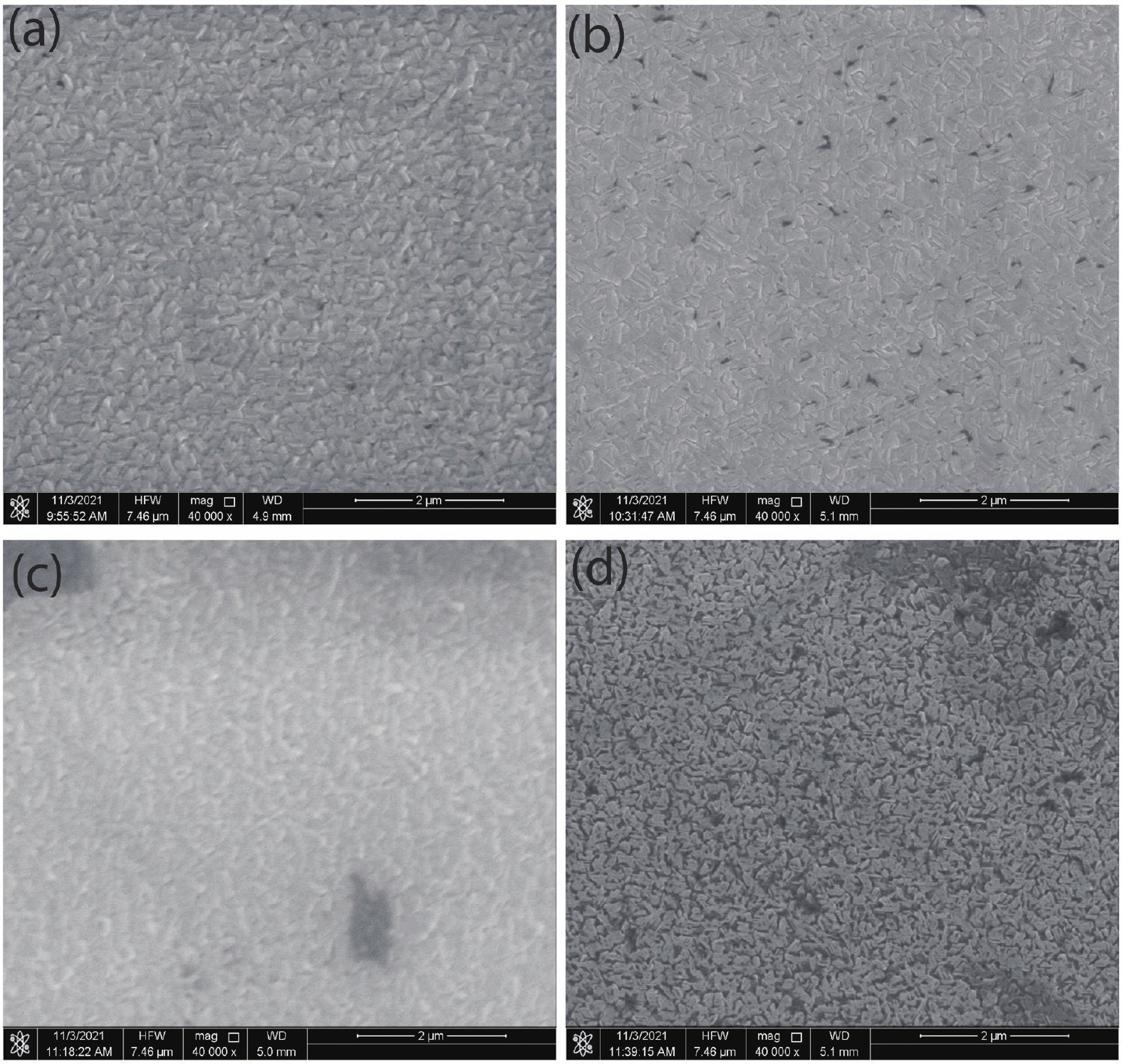

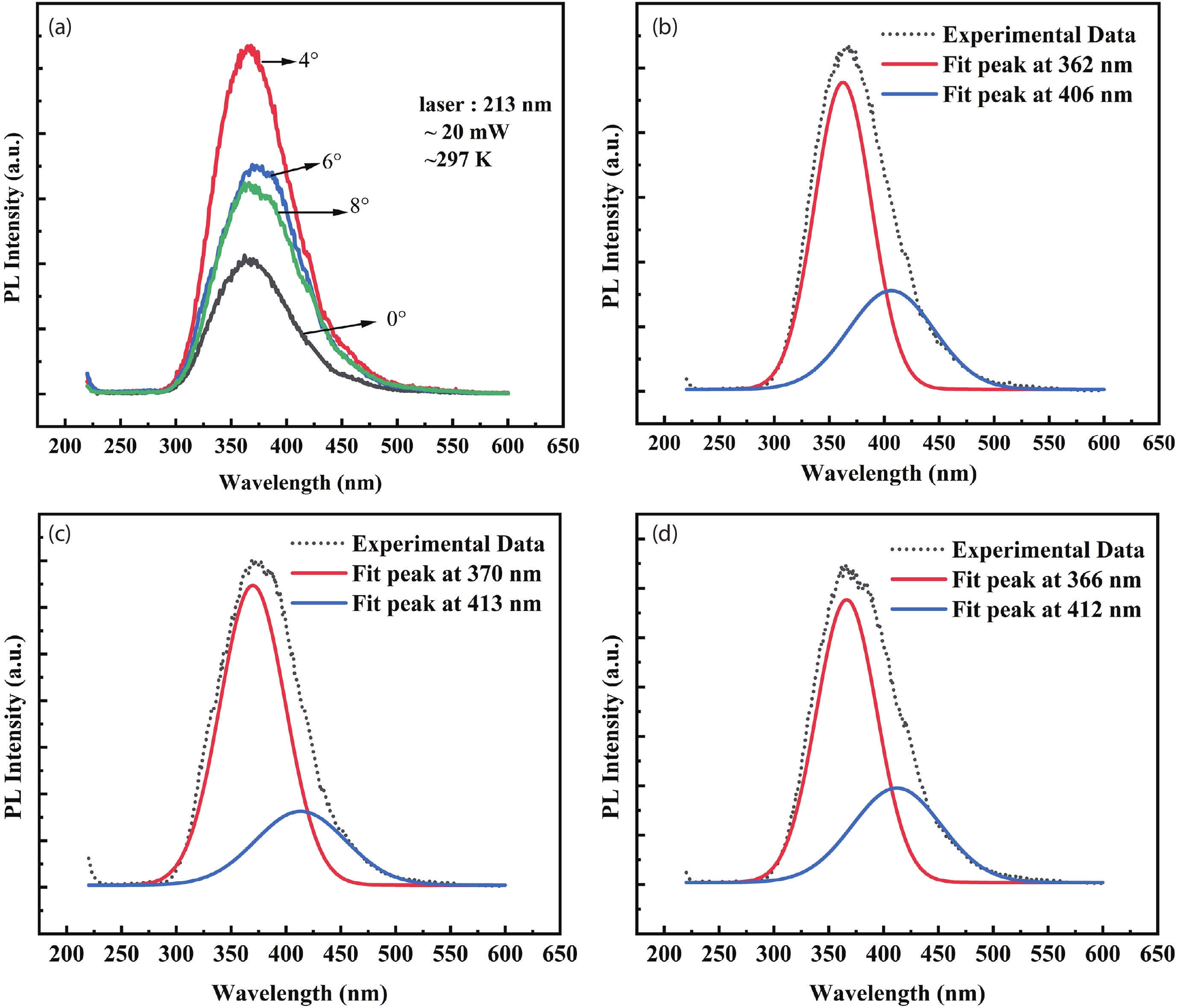

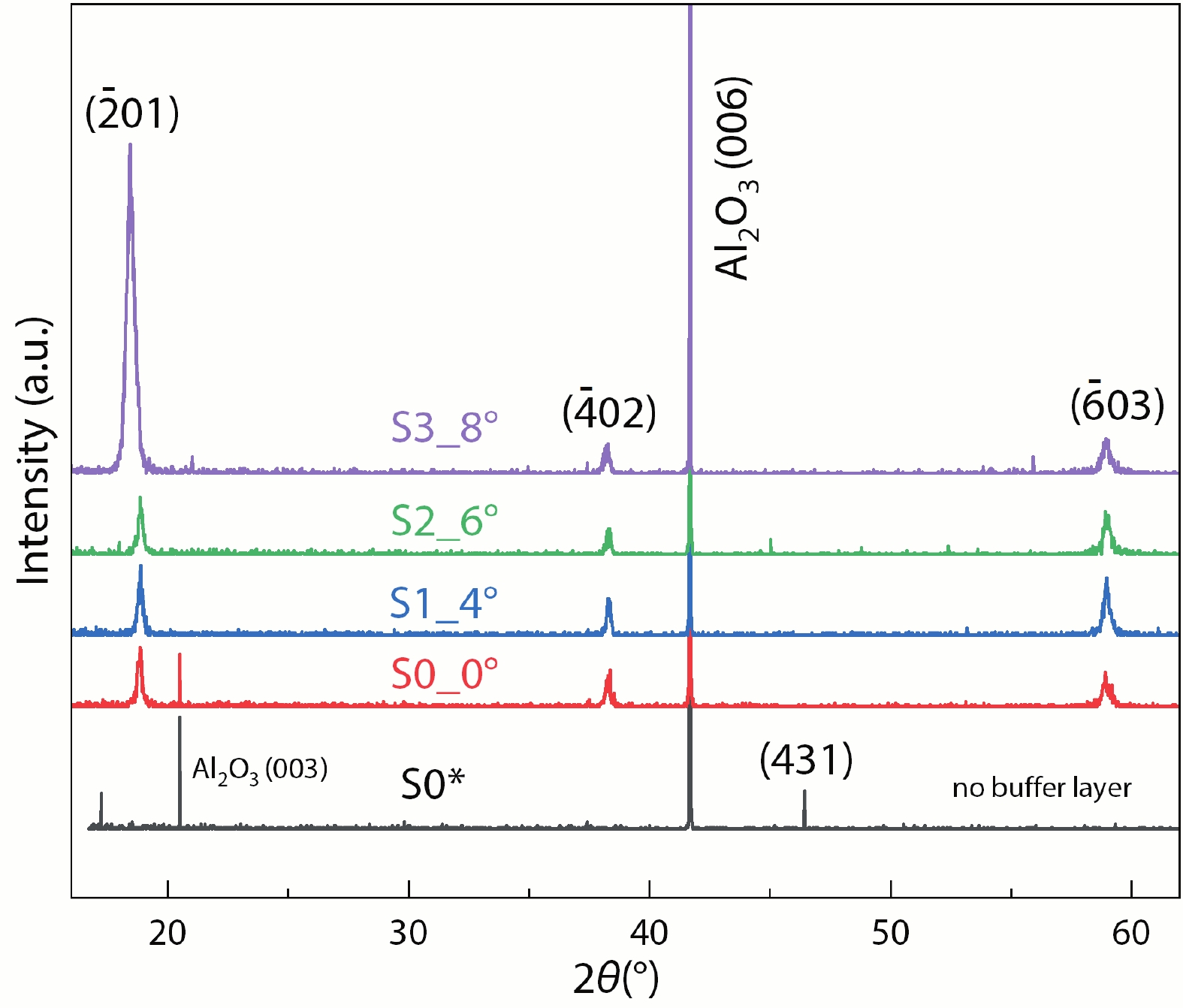

Beta-gallium oxide (β-Ga2O3) thin films were deposited on c-plane (0001) sapphire substrates with different mis-cut angles along <$11\bar{2}0$ > by metal-organic chemical vapor deposition (MOCVD). The structural properties and surface morphology of as-grown β-Ga2O3 thin films were investigated in detail. It was found that by using thin buffer layer and mis-cut substrate technology, the full width at half maximum (FWHM) of the ($ \bar{2}01$ ) diffraction peak of the β-Ga2O3 film is decreased from 2° on c-plane (0001) Al2O3 substrate to 0.64° on an 8° off-angled c-plane (0001) Al2O3 substrate. The surface root-mean-square (RMS) roughness can also be improved greatly and the value is 1.27 nm for 8° off-angled c-plane (0001) Al2O3 substrate. Room temperature photoluminescence (PL) was observed, which was attributed to the self-trapped excitons formed by oxygen and gallium vacancies in the film. The ultraviolet–blue PL intensity related with oxygen and gallium vacancies is decreased with the increasing mis-cut angle, which is in agreement with the improved crystal quality measured by high resolution X-ray diffraction (HR-XRD). The present results provide a route for growing high quality β-Ga2O3 film on Al2O3 substrate.-

Keywords:

- β-Ga2O3,

- heteroepitaxy,

- mis-cut Al2O3 substrates,

- MOCVD

-

References

[1] Jeong Y J, Yang J Y, Lee C H, et al. Fluorine-based plasma treatment for hetero-epitaxial β-Ga2O3 MOSFETs. Appl Surf Sci, 2021, 558, 149936 doi: 10.1016/j.apsusc.2021.149936[2] Jubu P R, Yam F K. Development and characterization of MSM UV photodetector based on gallium oxide nanostructures. Sens Actuator A, 2020, 312, 112141 doi: 10.1016/j.sna.2020.112141[3] Lv Y J, Zhou X Y, Long S B, et al. Enhancement-mode β-Ga2O3 metal-oxide-semiconductor field-effect transistor with high breakdown voltage over 3000 V realized by oxygen annealing. Phys Status Solidi RRL, 2020, 14, 1900586 doi: 10.1002/pssr.201900586[4] Dong H, Xue H W, He Q M, et al. Progress of power field effect transistor based on ultra-wide bandgap Ga2O3 semiconductor material. J Semicond, 2019, 40, 011802 doi: 10.1088/1674-4926/40/1/011802[5] Tippins H H. Optical absorption and photoconductivity in the band edge of β-Ga2O3. Phys Rev, 1965, 140, A316 doi: 10.1103/PhysRev.140.A316[6] Ueda N, Hosono H, Waseda R, et al. Anisotropy of electrical and optical properties in β-Ga2O3 single crystals. Appl Phys Lett, 1997, 71, 933 doi: 10.1063/1.119693[7] Kohn J A, Broder J D. Characterization of β-Ga2O3 and its alumina isomorph, θ-Al2O3. Am Mineral, 1957, 42, 398[8] Stepanov S I, Nikolaev V I, Bougrov V E, et al. Gallium oxide: Properties and applications - A review. Rev Adv Mater Sci, 2016, 44, 63[9] Pearton S J, Yang J C, Cary P H, et al. A review of Ga2O3 materials, processing, and devices. Appl Phys Rev, 2018, 5, 011301 doi: 10.1063/1.5006941[10] Wang D, He L N, Le Y, et al. Characterization of single crystal β-Ga2O3 films grown on SrTiO3 (100) substrates by MOCVD. Ceram Int, 2020, 46, 4568 doi: 10.1016/j.ceramint.2019.10.185[11] Cao Q, He L N, Xiao H D, et al. β-Ga2O3 epitaxial films deposited on epi-GaN/sapphire (0001) substrates by MOCVD. Mater Sci Semicond Process, 2018, 77, 58 doi: 10.1016/j.mssp.2018.01.010[12] Mi W, Ma J, Luan C N, et al. Characterization of β-Ga2O3 epitaxial films grown on MgO (111) substrates by metal-organic chemical vapor deposition. Mater Lett, 2012, 87, 109 doi: 10.1016/j.matlet.2012.07.106[13] Mi W, Luan C N, Li Z, et al. Ultraviolet-green photoluminescence of β-Ga2O3 films deposited on MgAl6O10 (100) substrate. Opt Mater, 2013, 35, 2624 doi: 10.1016/j.optmat.2013.07.030[14] Qian C, Sun J, Zhang L, et al. Crystal-domain orientation and boundary in highly ordered organic semiconductor thin film. J Phys Chem C, 2015, 119, 14965 doi: 10.1021/acs.jpcc.5b03727[15] Nakagomi S, Kokubun Y. Crystal orientation of β-Ga2O3 thin films formed on c-plane and a-plane sapphire substrate. J Cryst Growth, 2012, 349, 12 doi: 10.1016/j.jcrysgro.2012.04.006[16] Boschi F, Bosi M, Berzina T, et al. Hetero-epitaxy of ε-Ga2O3 layers by MOCVD and ALD. J Cryst Growth, 2016, 443, 25 doi: 10.1016/j.jcrysgro.2016.03.013[17] Zhuo Y, Chen Z M, Tu W B, et al. β-Ga2O3 versus ε-Ga2O3: Control of the crystal phase composition of gallium oxide thin film prepared by metal-organic chemical vapor deposition. Appl Surf Sci, 2017, 420, 802 doi: 10.1016/j.apsusc.2017.05.241[18] Hu D Q, Wang Y, Zhuang S W, et al. Surface morphology evolution and optoelectronic properties of heteroepitaxial Si-doped β-Ga2O3 thin films grown by metal-organic chemical vapor deposition. Ceram Int, 2018, 44, 3122 doi: 10.1016/j.ceramint.2017.11.079[19] Wu J W, Mi W, Yang Z C, et al. Influence of annealing on the structural and optical properties of gallium oxide films deposited on c-sapphire substrate. Vacuum, 2019, 167, 6 doi: 10.1016/j.vacuum.2019.05.034[20] Wei J Q, Kim K, Liu F, et al. β-Ga2O3 thin film grown on sapphire substrate by plasma-assisted molecular beam epitaxy. J Semicond, 2019, 40, 012802 doi: 10.1088/1674-4926/40/1/012802[21] Oshima Y, Vίllora E G, Shimamura K. Quasi-heteroepitaxial growth of β-Ga2O3 on off-angled sapphire (0001) substrates by halide vapor phase epitaxy. J Cryst Growth, 2015, 410, 53 doi: 10.1016/j.jcrysgro.2014.10.038[22] Xu W L, Shi J C, Li Y W, et al. Study of β-Ga2O3 films hetero-epitaxially grown on off-angled sapphire substrates by halide vapor phase epitaxy. Mater Lett, 2021, 289, 129411 doi: 10.1016/j.matlet.2021.129411[23] Rafique S, Han L, Neal A T, et al. Towards high-mobility heteroepitaxial β-Ga2O3 on sapphire–dependence on the substrate off-axis angle. Phys Status Solidi A, 2018, 215, 1700467 doi: 10.1002/pssa.201700467[24] Zhang T, Hu Z G, Li Y F, et al. Investigation on the β-Ga2O3 deposited on off-angled sapphire (0001) substrates. J Lumin, 2021, 233, 117928 doi: 10.1016/j.jlumin.2021.117928[25] Bryan I, Bryan Z, Mita S, et al. Surface kinetics in AlN growth: A universal model for the control of surface morphology in III-nitrides. J Cryst Growth, 2016, 438, 81 doi: 10.1016/j.jcrysgro.2015.12.022[26] Xie M H, Cheung S H, Zheng L X, et al. Step bunching of vicinal GaN(0001) surfaces during molecular beam epitaxy. Phys Rev B, 2000, 61, 9983 doi: 10.1103/PhysRevB.61.9983[27] Varley J B, Janotti A, Franchini C, et al. Role of self-trapping in luminescence andp-type conductivity of wide-band-gap oxides. Phys Rev B, 2012, 85, 081109 doi: 10.1103/PhysRevB.85.081109[28] Ho C H, Tseng C Y, Tien L C. Thermoreflectance characterization of beta-Ga2O3 thin-film nanostrips. Opt Express, 2010, 18, 16360 doi: 10.1364/OE.18.016360 -

Proportional views

DownLoad:

DownLoad: