| Citation: |

Bryan Siu Ting Tam, Shou-Cheng Dong, Ching W. Tang. Low-temperature conformal vacuum deposition of OLED devices using close-space sublimation[J]. Journal of Semiconductors, 2023, 44(9): 092602. doi: 10.1088/1674-4926/44/9/092602

****

B S T Tam, S C Dong, C W Tang. Low-temperature conformal vacuum deposition of OLED devices using close-space sublimation[J]. J. Semicond, 2023, 44(9): 092602. doi: 10.1088/1674-4926/44/9/092602

|

Low-temperature conformal vacuum deposition of OLED devices using close-space sublimation

DOI: 10.1088/1674-4926/44/9/092602

More Information

-

Abstract

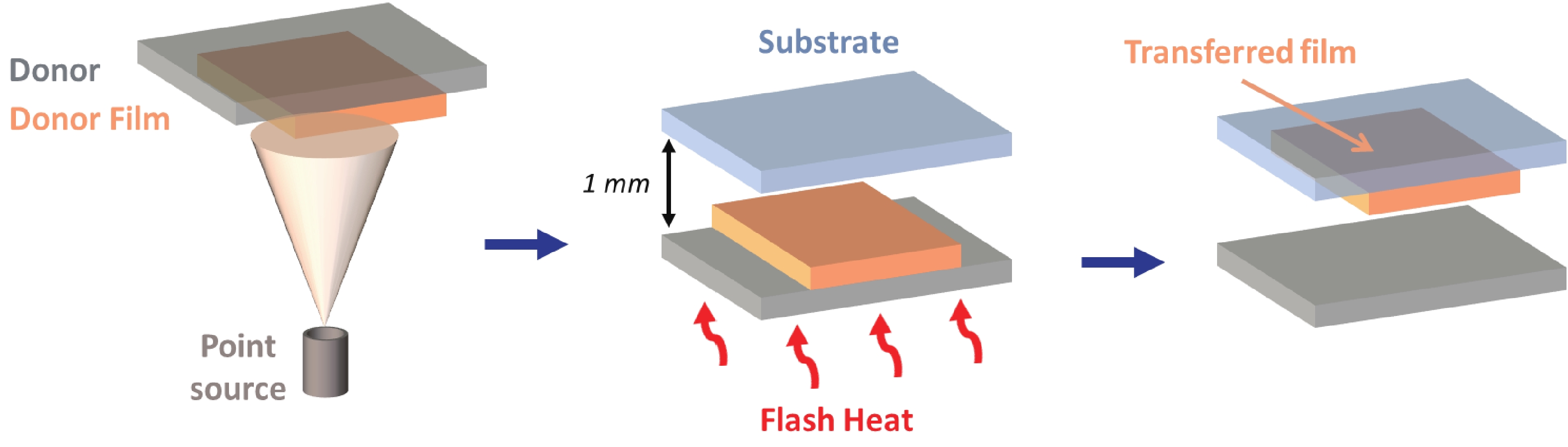

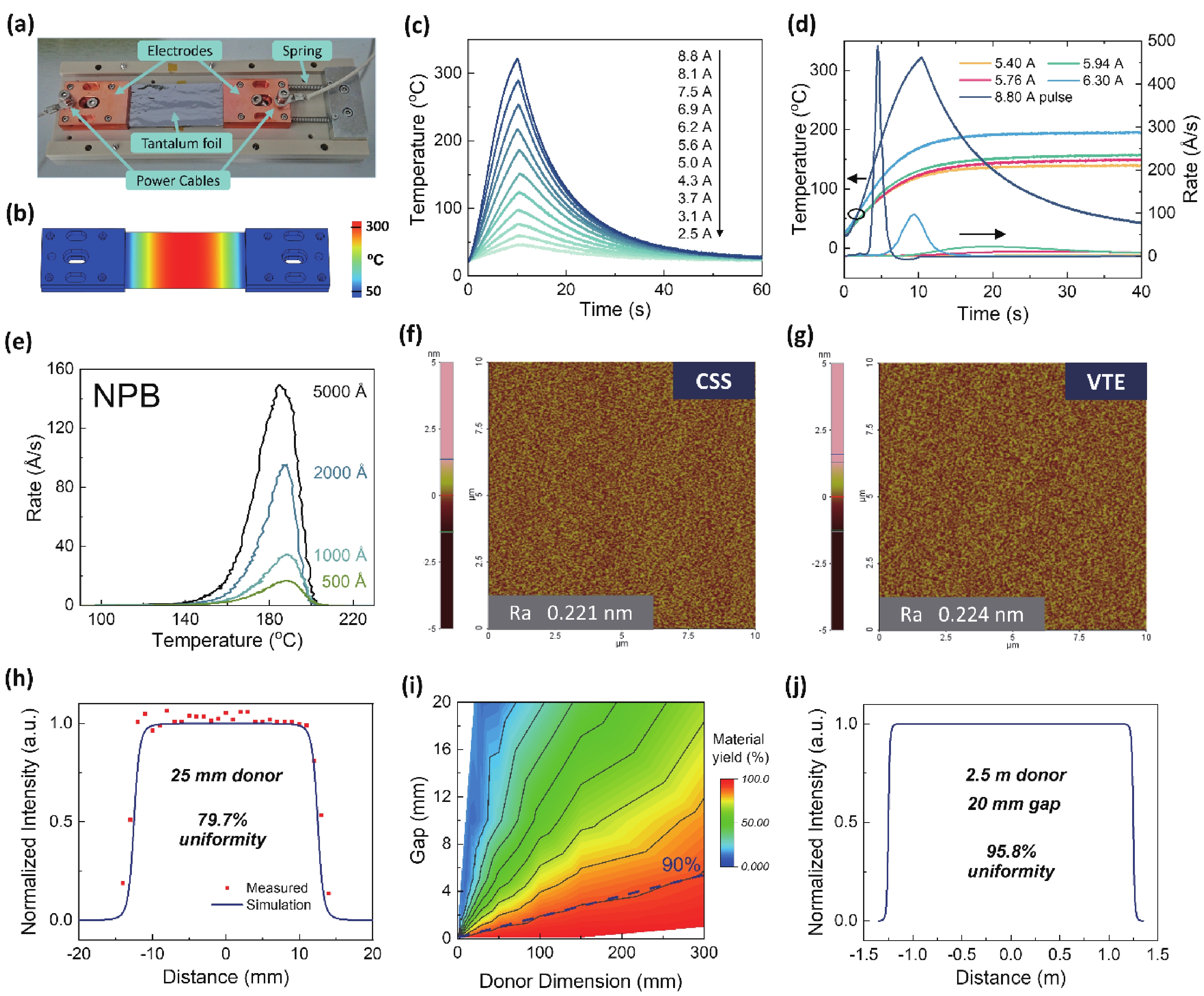

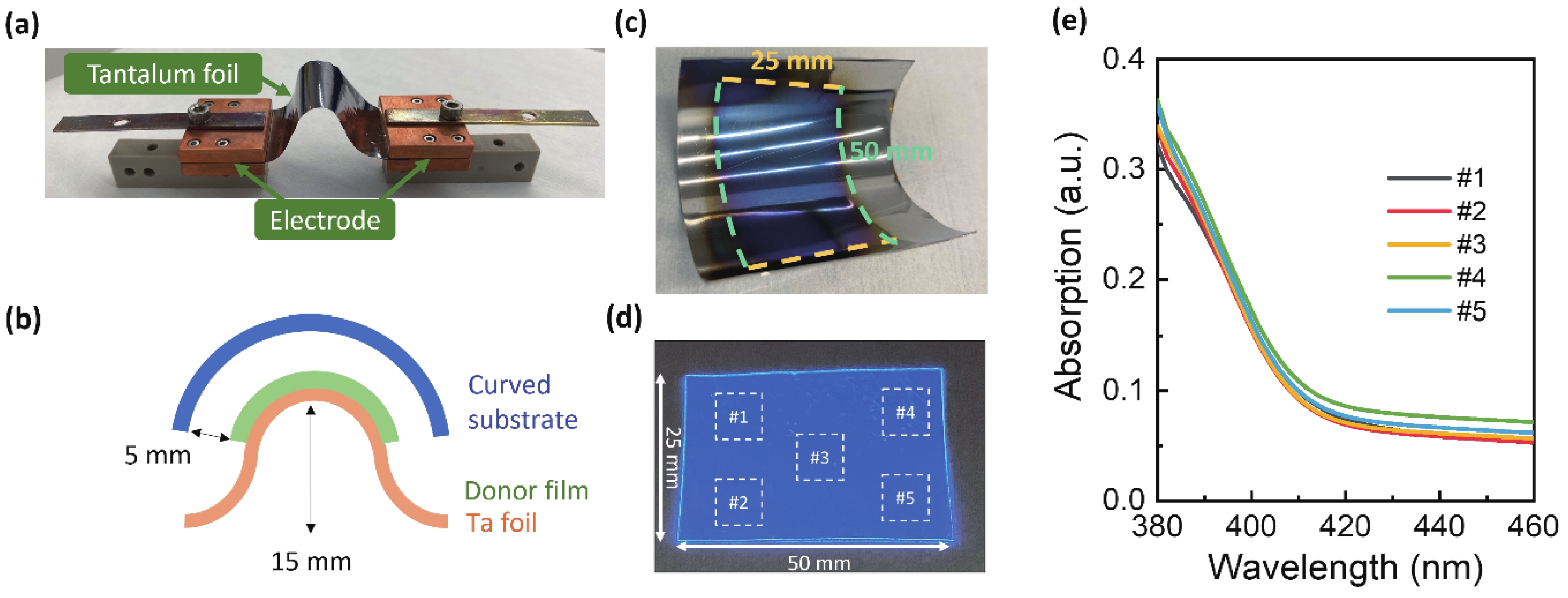

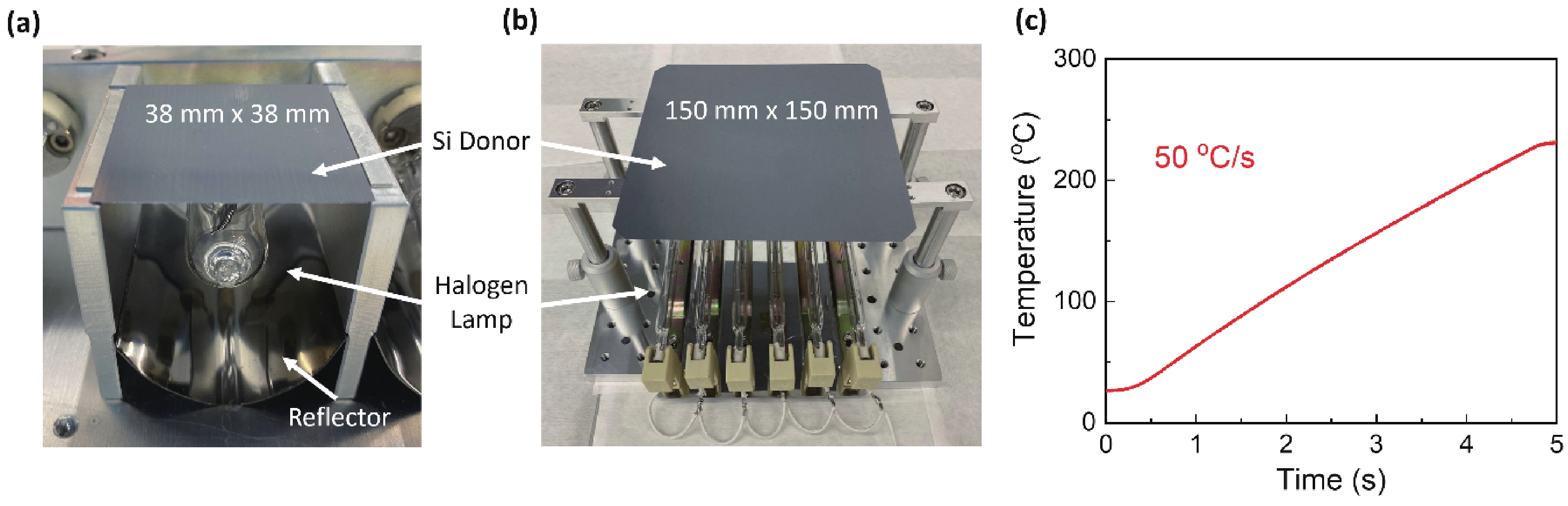

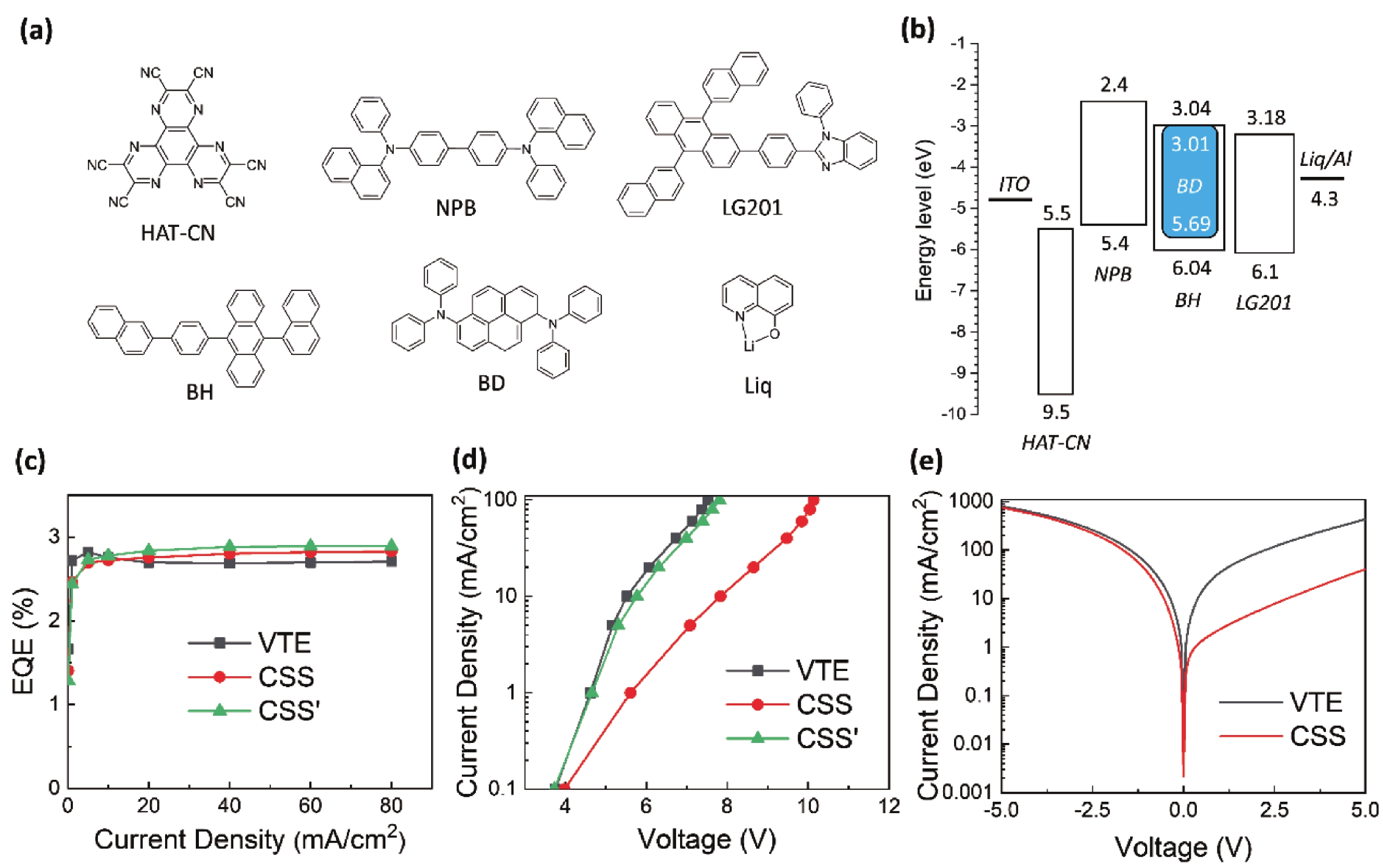

Close-space sublimation (CSS) has been demonstrated as an alternative vacuum deposition technique for fabricating organic light-emitting diodes (OLEDs). CSS utilizes a planar donor plate pre-coated with organic thin films as an area source to rapidly transfer the donor film to a device substrate at temperatures below 200 °C. CSS is also conformal and capable of depositing on odd-shaped substrates using flexible donor media. The evaporation behaviors of organic donor films under CSS were fully characterized using model OLED materials and CSS-deposited films exhibited comparable device performances in an OLED stack to films deposited by conventional point sources. The low temperature and conformal nature of CSS, along with its high material utilization and short process time, make it a promising method for fabricating flexible OLED displays.-

Keywords:

- close-space sublimation,

- OLED,

- thin film,

- low temperature,

- vacuum deposition

-

References

[1] Hwang C, Im Y, Kim J J, et al. Plane source evaporation for new patterning technique of high resolution AMOLEDs. IMID 2015 Digest, 2016, 272[2] Hwang C, Kim S S, Lee H, et al. Plane source evaporation techniques for super ultra high resolution flexible AMOLED. SID Symp Dig Tech Pap, 2017, 48, 523 doi: 10.1002/sdtp.11690[3] Hwang C, Kim S S, Bang S W, et al. Novel plane source FMM evaporation techniques for manufacturing of 2250ppi flexible AMOLEDs. SID Symp Dig Tech Pap, 2018, 49, 1003 doi: 10.1002/sdtp.12222[4] Hwang C, Kim S S, Bang S W, et al. Unique belt plane source evaporation techniques for the mass production of 2250ppi AMOLED and 77” QD OLED TV. SID Symp Dig Tech Pap, 2019, 50, 949 doi: 10.1002/sdtp.13082[5] Lee S T, Chin B D, Kim M H, et al. A novel patterning method for full-color organic light-emitting devices: Laser induced thermal imaging (LITI). SID Symp Dig Tech Pap, 2004, 35, 1008 doi: 10.1889/1.1821308[6] Cho S H, Suh M C, Kim J W. The operating voltage behavior of green fluorescent organic light emitting diode with blue common layer structure during laser imaging process. Org Electron, 2012, 13, 2945 doi: 10.1016/j.orgel.2012.08.013[7] Suh M C, Kang T M, Cho S W, et al. 53.2: Invited paper: Large-area color-patterning technology for AMOLED. SID Symp Dig Tech Pap, 2009, 40, 794 doi: 10.1889/1.3256909[8] Boroson M, Tutt L, Nguyen K, et al. 16.5L: Late-news-paper: Non-contact OLED color patterning by radiation-induced sublimation transfer (RIST). SID Symp Dig Tech Pap, 2005, 36, 972 doi: 10.1889/1.2036612[9] Hirano T, Matsuo K, Kohinata K, et al. 53.2: Distinguished paper: Novel laser transfer technology for manufacturing large-sized OLED displays. SID Symp Dig Tech Pap, 2007, 38, 1592 doi: 10.1889/1.2785623[10] Fardel R, Nagel M, Nüesch F, et al. Fabrication of organic light-emitting diode pixels by laser-assisted forward transfer. Applied Physics Letters, 2007, 91, 061103 doi: 10.1063/1.2759475[11] Long M, Bruce E K, Neil P R, et al. Enabling high-throughput, low-cost manufacturing of OLED display and lighting panels. MRS Online Proc Libr, 2010, 1212, 706 doi: 10.1557/PROC-1212-S06-06-C07-06[12] Tam S T. Organic light emitting diode devices fabricated by close-space sublimation. MPhil Thesis, Hong Kong University of Science and Technology, 2019[13] Tam S T. Investigation of organic light-emitting diodes fabricated by close-space sublimation. PhD Thesis, Hong Kong University of Science and Technology, 2022[14] Tam S T, Dong S C, Tang C W. Close-space sublimation of OLED materials via electrical heating of metal foils. SID Symp Dig Tech Pap, 2018, 49, 737 doi: 10.1002/sdtp.12830[15] Tam B S T, Dong S C, Tang C W. Blue OLEDs fabricated by close-space sublimation. SID Symp Dig Tech Pap, 2019, 50, 153 doi: 10.1002/sdtp.12878[16] Dong H J, Tam B S T, Ding L, et al. Low-temperature vacuum deposition of green phosphorescent OLED devices using close-space sublimation of spirobifluorene hosts. J Lumin, 2022, 252, 119360 doi: 10.1016/j.jlumin.2022.119360[17] Shim S, Kim J T, Shin E J, et al. Phase behaviors of NPB molecule under vacuum. Mater Res Bull, 2016, 82, 67 doi: 10.1016/j.materresbull.2016.01.054 -

Proportional views

DownLoad:

DownLoad:

Bryan Siu Ting Tam:is a Postdoctoral Fellow with the Department of Electronic and Computer Engineering at HKUST. He received his BE in 2017, MPhil in 2019, and PhD in 2022, all from HKUST. His research is focused on deposition and patterning methods for high-resolution OLED displays and the degradation mechanism of blue OLEDs

Bryan Siu Ting Tam:is a Postdoctoral Fellow with the Department of Electronic and Computer Engineering at HKUST. He received his BE in 2017, MPhil in 2019, and PhD in 2022, all from HKUST. His research is focused on deposition and patterning methods for high-resolution OLED displays and the degradation mechanism of blue OLEDs Shou-Cheng Dong:is a Research Assistant Professor with the Department of Electronic and Computer Engineering and an IAS Junior Fellow at HKUST. He received his PhD in 2011 from Wuhan University, China. He conducted postdoctoral research at Soochow University and the City University of Hong Kong before joining HKUST in 2014. His research is focused on blue OLED lifetime deposition and patterning methods for high-resolution OLED displays, and color conversion technologies

Shou-Cheng Dong:is a Research Assistant Professor with the Department of Electronic and Computer Engineering and an IAS Junior Fellow at HKUST. He received his PhD in 2011 from Wuhan University, China. He conducted postdoctoral research at Soochow University and the City University of Hong Kong before joining HKUST in 2014. His research is focused on blue OLED lifetime deposition and patterning methods for high-resolution OLED displays, and color conversion technologies Ching W. Tang:was the IAS Bank of East Asia Professor at the Hong Kong University of Science and Technology from 2013 to 2023 and the Doris Johns Cherry Professor of Chemical Engineering at the University of Rochester from 2006 to 2013. He is currently an Emeritus Professor at the University of Rochester. Prof Tang received his B.S. from the University of British Columbia and his Ph.D. from Cornell University. Before academia, he spent almost 30 years in the Kodak Research Laboratories in Rochester, NY, where he pioneered the field of organic electronics with the inventions of OLED and OPV. Prof. Tang holds fellowships at many distinguished organizations, such as the U.S. National Academy of Engineering and the Academy of Sciences of Hong Kong. He received numerous prestigious awards for his invention of OLED, including the Kyoto Prize, the Wolf Prize, and the SID Fellow. His recent research has been focused on OLED lifetime and fabrication techniques for high-resolution OLED displays

Ching W. Tang:was the IAS Bank of East Asia Professor at the Hong Kong University of Science and Technology from 2013 to 2023 and the Doris Johns Cherry Professor of Chemical Engineering at the University of Rochester from 2006 to 2013. He is currently an Emeritus Professor at the University of Rochester. Prof Tang received his B.S. from the University of British Columbia and his Ph.D. from Cornell University. Before academia, he spent almost 30 years in the Kodak Research Laboratories in Rochester, NY, where he pioneered the field of organic electronics with the inventions of OLED and OPV. Prof. Tang holds fellowships at many distinguished organizations, such as the U.S. National Academy of Engineering and the Academy of Sciences of Hong Kong. He received numerous prestigious awards for his invention of OLED, including the Kyoto Prize, the Wolf Prize, and the SID Fellow. His recent research has been focused on OLED lifetime and fabrication techniques for high-resolution OLED displays