| Citation: |

Jianzhong Liao, Fangzhou Wu, Jiwen Xu, Guisheng Zhu, Fei Shang, Huarui Xu. Sintering and electrical characteristics of In2O3-based targets doped with multiple components for solar cells[J]. Journal of Semiconductors, 2025, In Press. doi: 10.1088/1674-4926/24090038

****

J Z Liao, F Z Wu, J W Xu, G S Zhu, F Shang, and H R Xu, Sintering and electrical characteristics of In2O3-based targets doped with multiple components for solar cells[J]. J. Semicond., 2025, accepted doi: 10.1088/1674-4926/24090038

|

Sintering and electrical characteristics of In2O3-based targets doped with multiple components for solar cells

DOI: 10.1088/1674-4926/24090038

CSTR: 32376.14.1674-4926.24090038

More Information-

Abstract

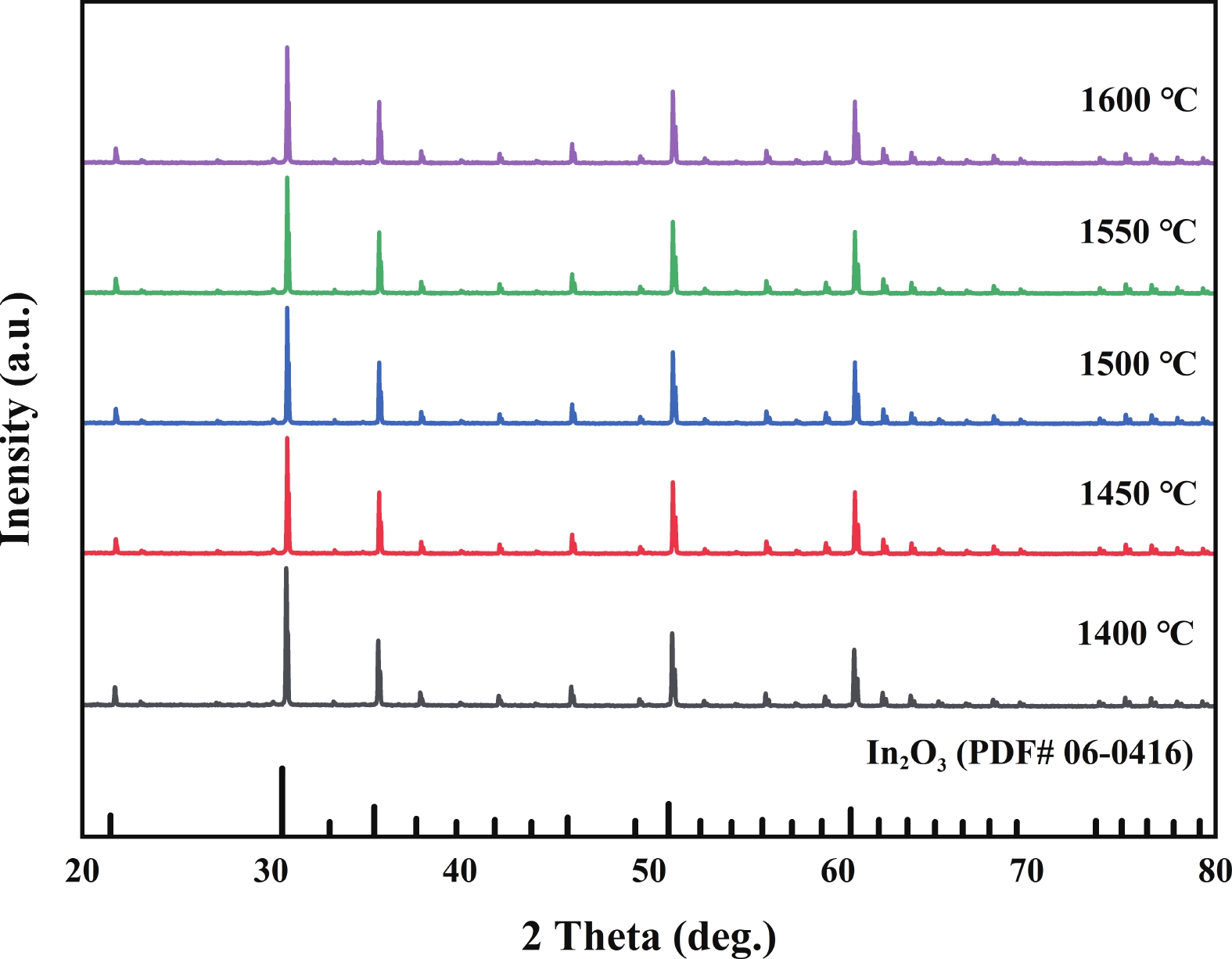

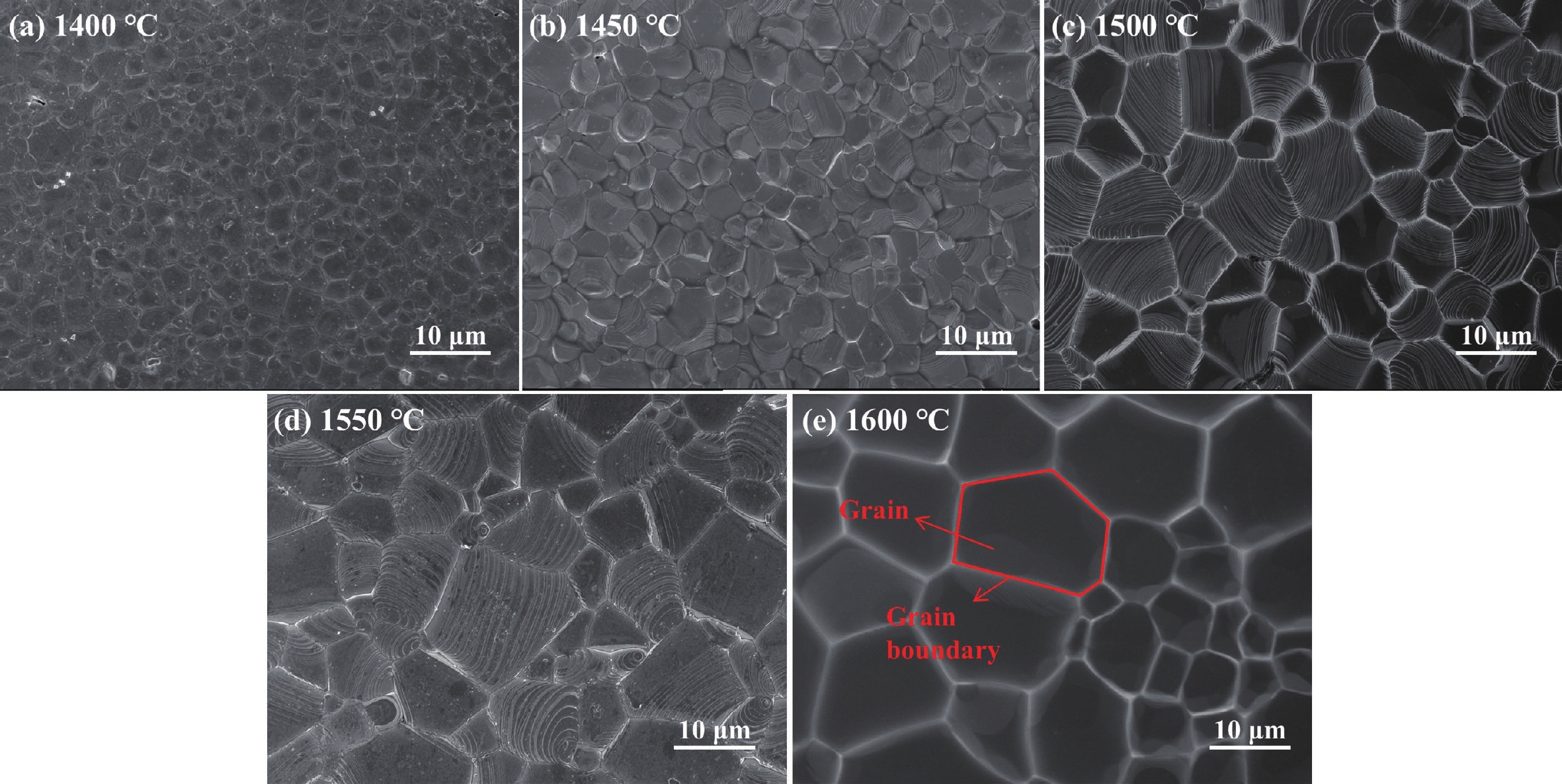

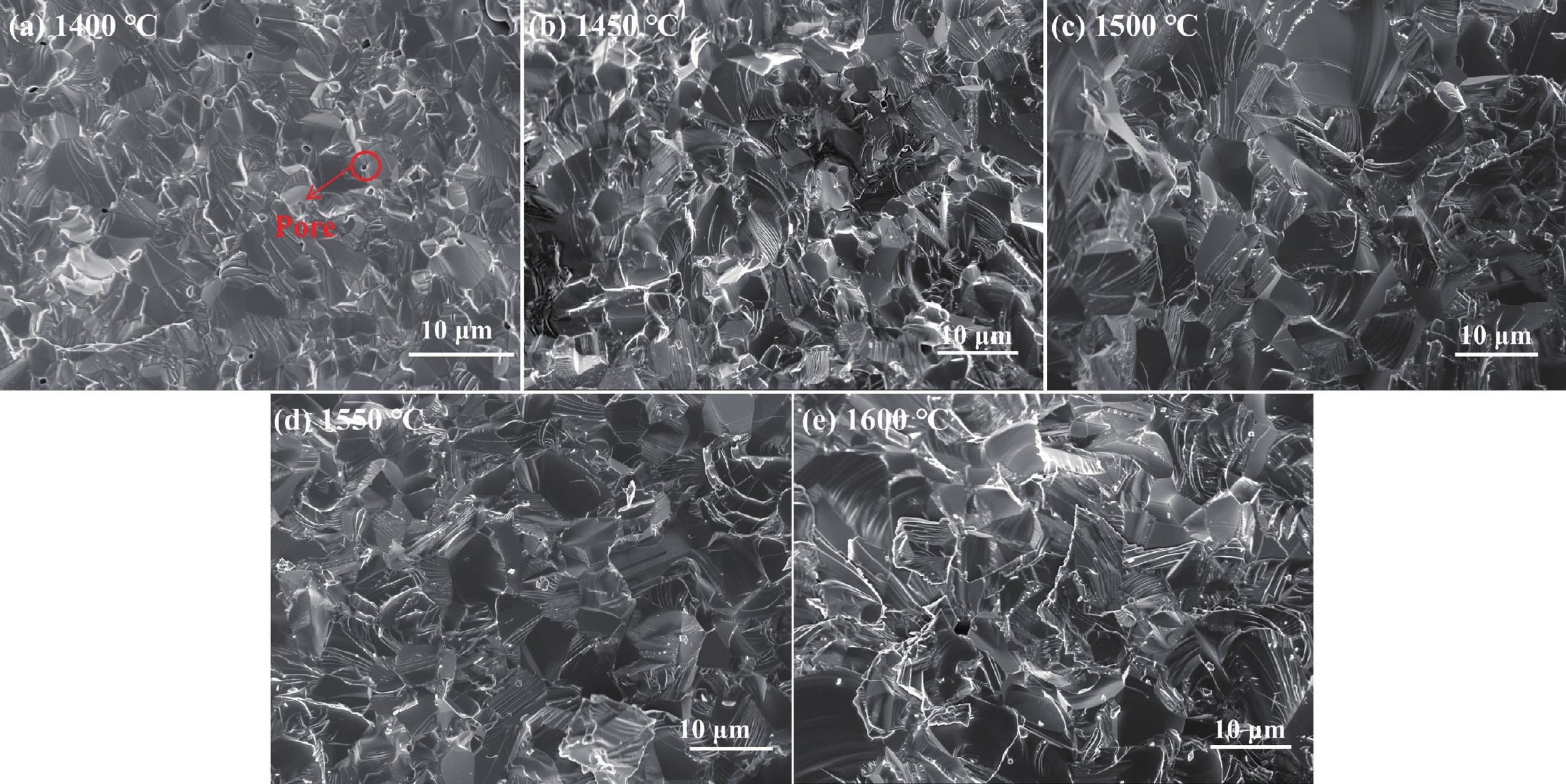

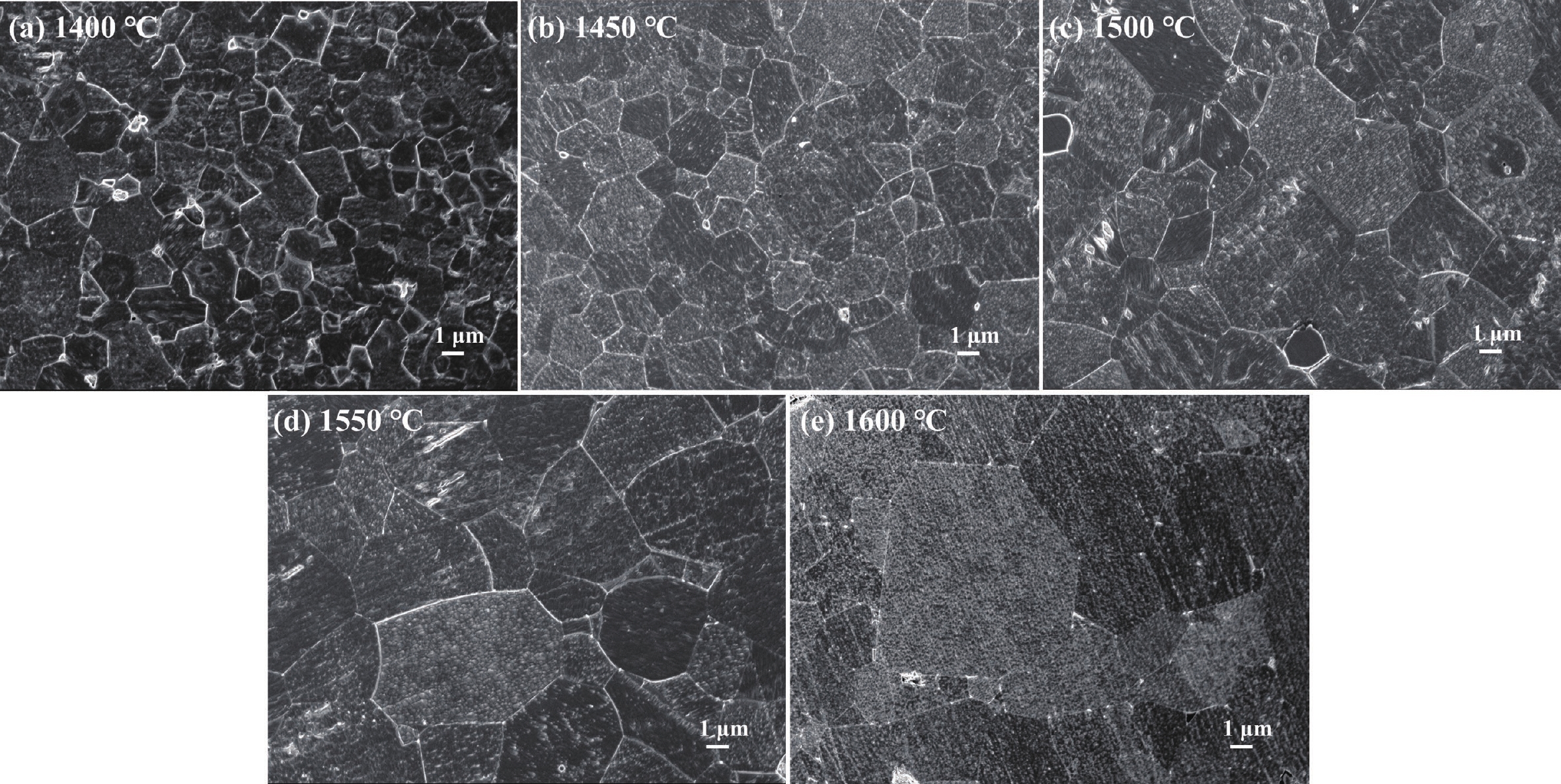

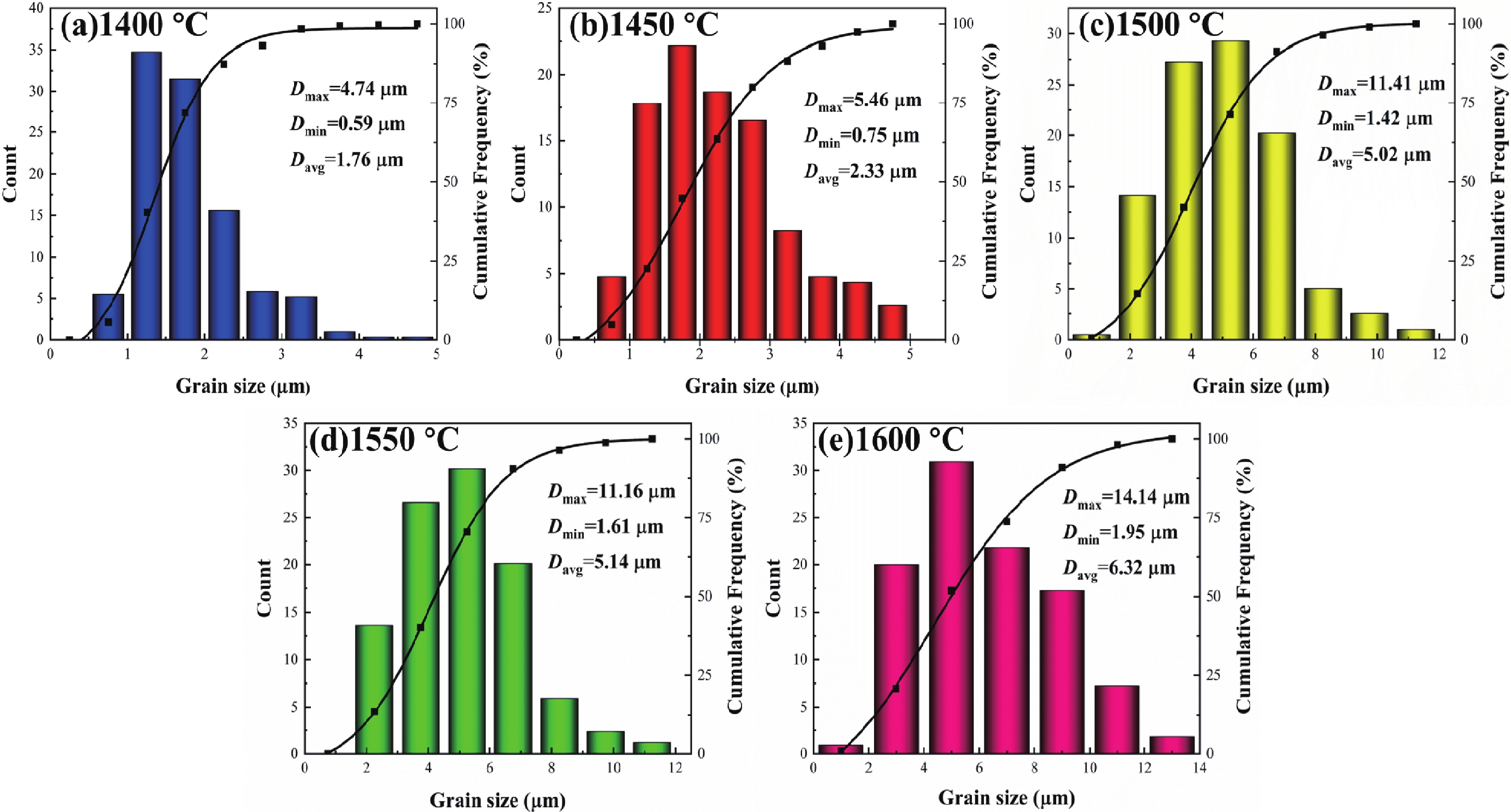

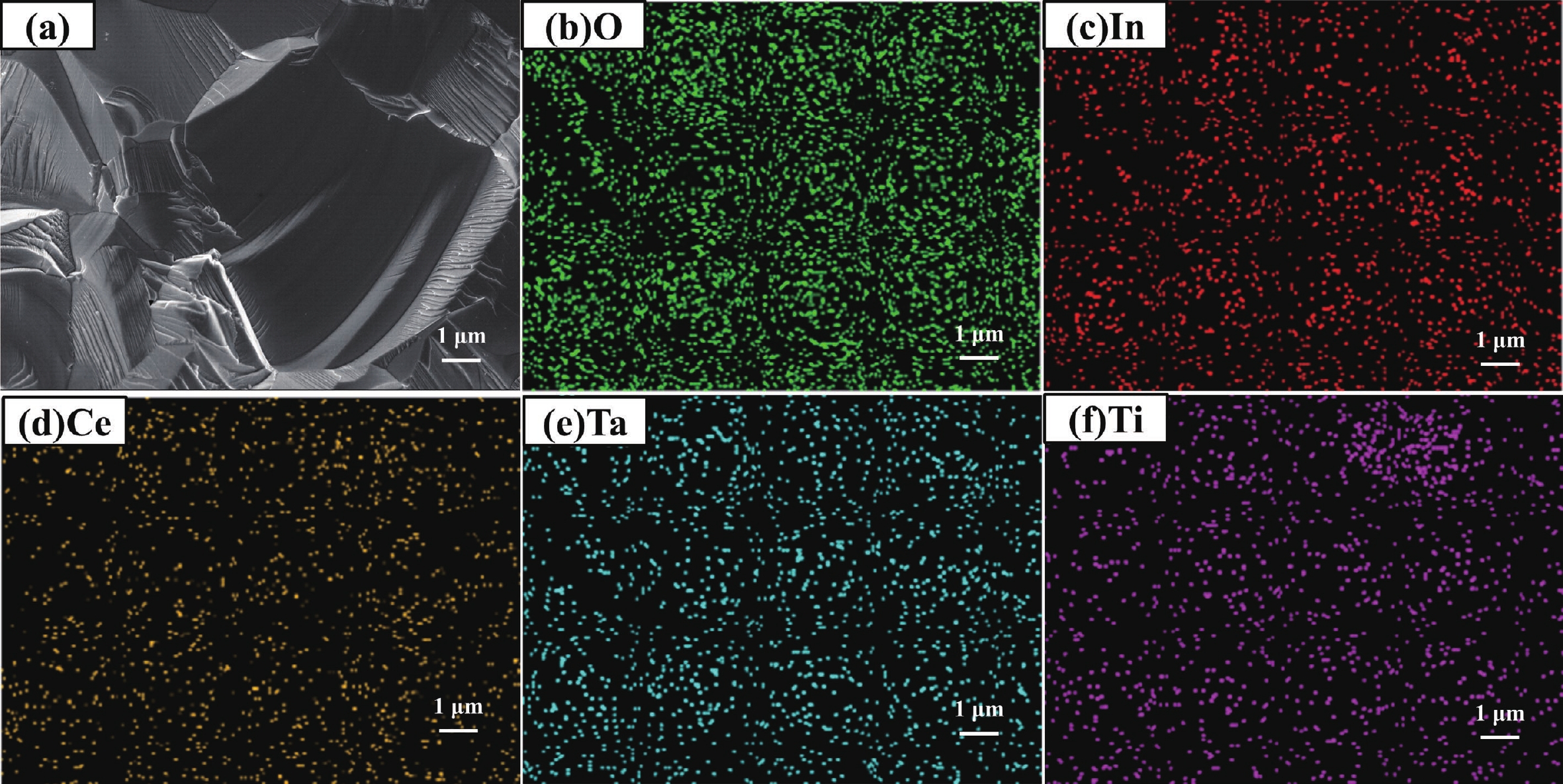

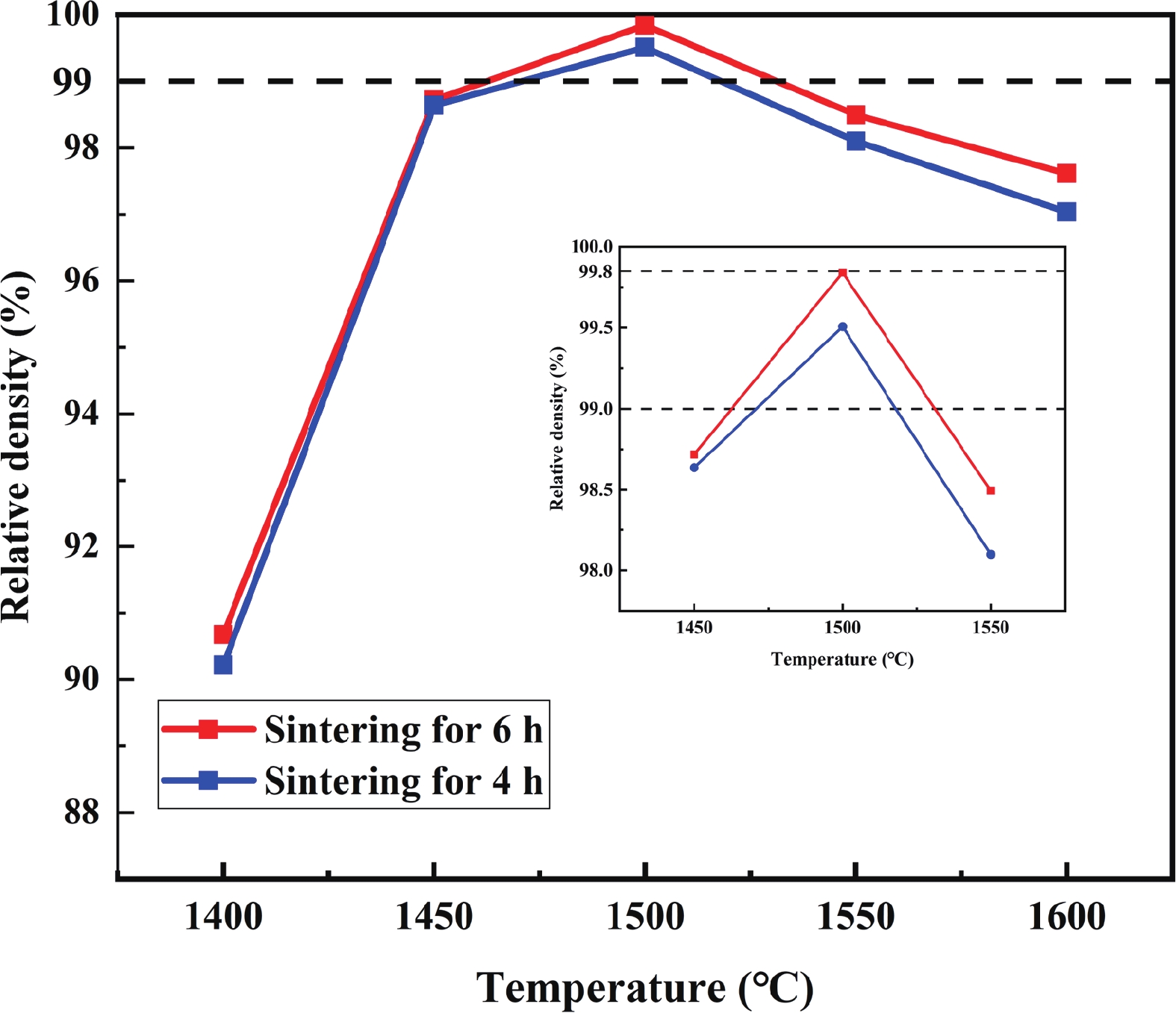

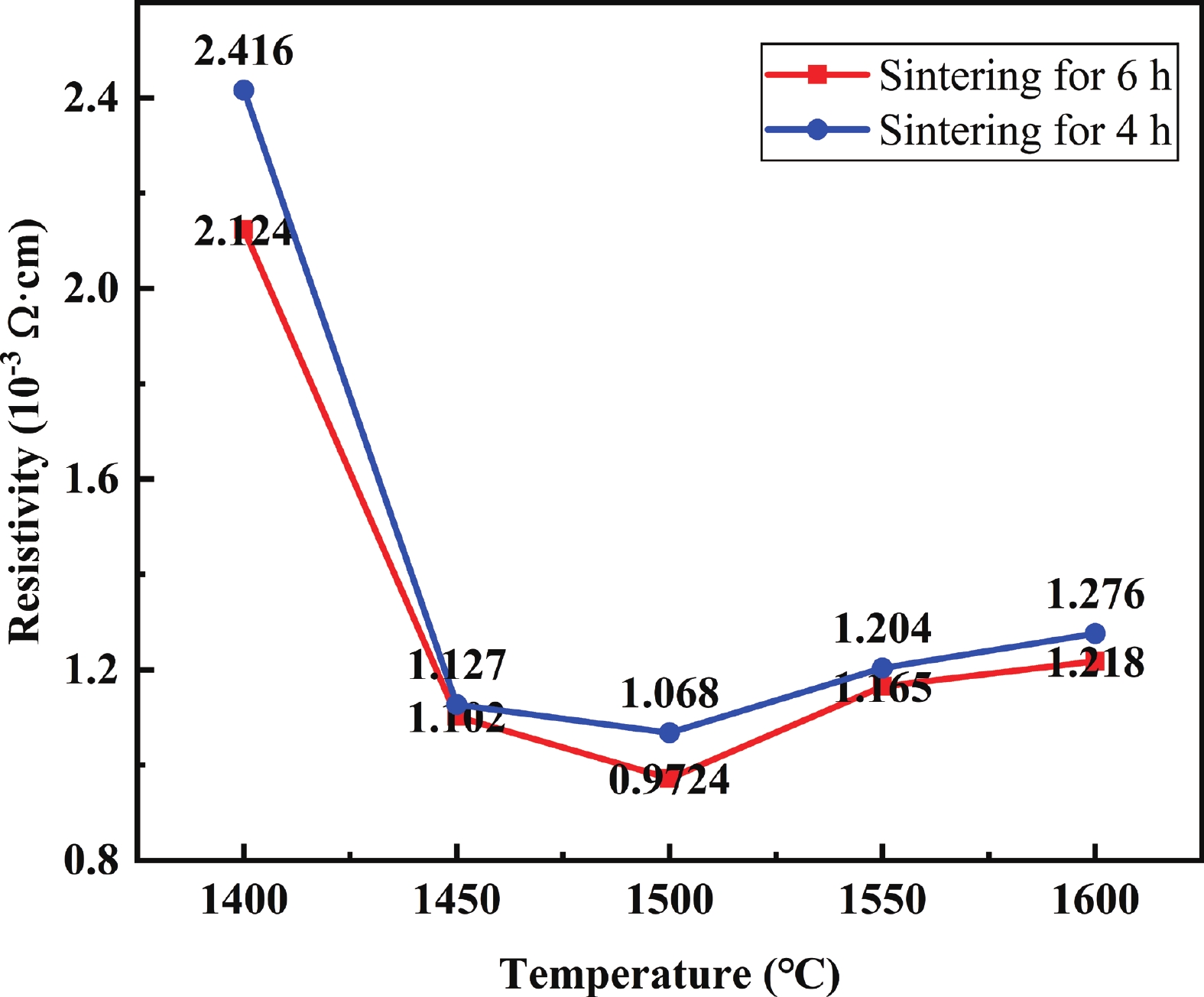

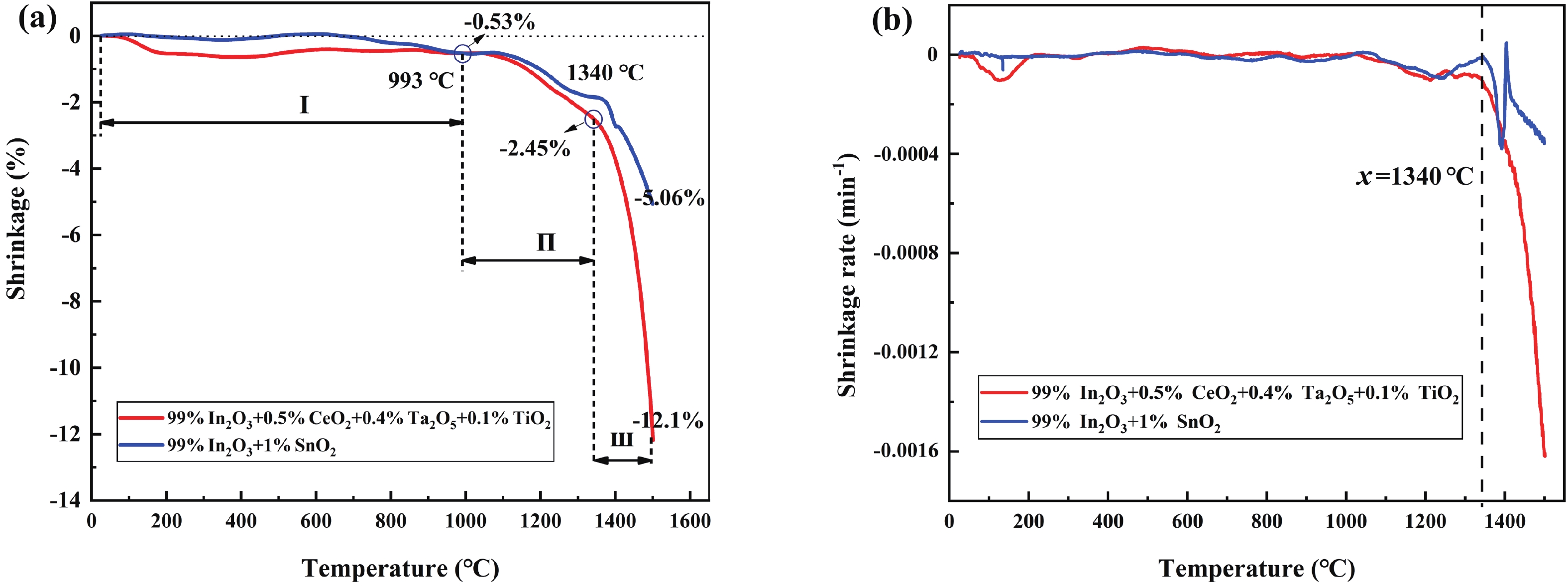

To address the escalating demand for high-mobility transparent and conductive oxide (TCO) films in heterojunction solar cells, multiple components doped In2O3 targets were proposed. The In2O3 targets incorporating 1 wt.% CeO2, Ta2O5 and TiO2 were sintered under different sintering temperatures and times. All the targets show the cubic bixbyite phase of In2O3. The microstructure illustrates densely packed fine grains and uniform elemental distribution. Notably, increasing the sintering temperature and holding time contributes to effective pore elimination within the targets. A relative density of greater than 99.5% is obtained for the targets sintered at 1500 °C for 4 and 6 h, and the corresponding optimum resistivity decreases from 1.068×10−³ Ω·cm to 9.73×10−4 Ω·cm. These results provide the experimental basis of fabricating In2O3-based targets for depositing high mobility TCO films by magnetron sputtering.-

Keywords:

- high mobility,

- multi-component,

- In2O3,

- sintering,

- density

-

References

[1] Patel J, Sharme R K, Quijada M A, et al. A review of transparent conducting films (TCFs): Prospective ITO and AZO deposition methods and applications. Nanomaterials, 2024, 14(24), 2013 doi: 10.3390/nano14242013[2] Sun Z Q, Chen X Q, He Y C, et al. Toward efficiency limits of crystalline silicon solar cells: Recent progress in high-efficiency silicon heterojunction solar cells. Adv Energy Mater, 2022, 12(23), 2200015 doi: 10.1002/aenm.202200015[3] Du G L, Bai Y H, Huang J, et al. Surface passivation of ITO on heterojunction solar cells with enhanced cell performance and module reliability. ECS J Solid State Sci Technol, 2021, 10(3), 035008 doi: 10.1149/2162-8777/abeece[4] Chavan G T, Kim Y, Khokhar M Q, et al. A brief review of transparent conducting oxides (TCO): The influence of different deposition techniques on the efficiency of solar cells. Nanomaterials, 2023, 13(7), 1226 doi: 10.3390/nano13071226[5] Yuan C, Liu X X, Ge C Y, et al. Stable indium tin oxide with high mobility. ACS Appl Mater Interfaces, 2022, 14(44), 49937 doi: 10.1021/acsami.2c13312[6] Kim Y J, Jin S B, Kim S I, et al. Study on the electrical properties of ITO films deposited by facing target sputter deposition. J Phys D: Appl Phys, 2009, 42(7), 075412 doi: 10.1088/0022-3727/42/7/075412[7] Gong W B, Wang G H, Gong Y B, et al. Investigation of In2O3: SnO2 films with different doping ratio and application as transparent conducting electrode in silicon heterojunction solar cell. Sol Energy Mater Sol Cells, 2022, 234, 111404 doi: 10.1016/j.solmat.2021.111404[8] Koida T, Ueno Y, Shibata H. In2 O3-based transparent conducting oxide films with high electron mobility fabricated at low process temperatures. Phys Status Solidi Appl Res, 2018, 215(7), 1700506 doi: 10.1002/pssa.201700506[9] Krishnan R R, Sreedharan R S, Sudheer S K, et al. Effect of tantalum doping on the structural and optical properties of RF magnetron sputtered indium oxide thin films. Mater Sci Semicond Process, 2015, 37, 112 doi: 10.1016/j.mssp.2015.02.033[10] Yao Z, Duan W, Steuter P, et al. Influence of oxygen on sputtered titanium‐doped indium oxide thin films and their application in silicon heterojunction solar cells. Solar RRL, 2021, 5(1), 2000501. doi: 10.1002/solr.202000501[11] Bhachu D S, Scanlon D O, Sankar G, et al. Origin of high mobility in molybdenum-doped indium oxide. Chem Mater, 2015, 27(8), 2788 doi: 10.1021/cm503896h[12] Yang M, Feng J H, Li G F, et al. Tungsten-doped In2O3 transparent conductive films with high transmittance in near-infrared region. J Cryst Growth, 2008, 310(15), 3474 doi: 10.1016/j.jcrysgro.2008.05.012[13] Grew B, Bowers J W, Lisco F, et al. High mobility titanium-doped indium oxide for use in tandem solar cells deposited via pulsed DC magnetron sputtering. Energy Procedia, 2014, 60, 148 doi: 10.1016/j.egypro.2014.12.357[14] Koida T, Fujiwara, H, Kondo, M. Hydrogen-doped In2O3 as high-mobility transparent conductive oxide. Jpn J Appl Phys, 2007, 46(25/28), L685[15] Warmsingh C, Yoshida Y, Readey D W, et al. High-mobility transparent conducting Mo-doped In2O3 thin films by pulsed laser deposition. J Appl Phys, 2004, 95(7), 3831 doi: 10.1063/1.1646468[16] Gupta R K, Ghosh K, Mishra S R, et al. High mobility, transparent, conducting Gd-doped In2O3 thin films by pulsed laser deposition. Thin Solid Films, 2008, 516(10), 3204 doi: 10.1016/j.tsf.2007.09.012[17] Shi J H, Meng F Y, Bao J, et al. Surface scattering effect on the electrical mobility of ultrathin Ce doped In2O3 film prepared at low temperature. Mater Lett, 2018, 225, 54 doi: 10.1016/j.matlet.2018.04.102[18] Nakashima K, Kumahara Y. Effect of tin oxide dispersion on nodule formation in ITO sputtering. Vacuum, 2002, 66(3/4), 221[19] Liu W, Lai Z, Wu W, et al. Application progress of hot isostatic pressing technology in transparent ceramics. Adv Ceram, 2023, 44(2), 117[20] Son J W, Kim D Y, Boch P. Enhanced densification of In2O3 ceramics by presintering with low pressure (5 MPa). J Am Ceram Soc, 1998, 81(9), 2489 doi: 10.1111/j.1151-2916.1998.tb02650.x[21] Liu Y Y, Meng F Y, Shi J H, et al. High mobility Ti, Zr and Ga-codoping In2O3 transparent conductive oxide films prepared at low temperatures. J Mater Sci Mater Electron, 2021, 32(3), 3201 doi: 10.1007/s10854-020-05068-x[22] Muraoka M, Suzuki M, Sawada Y, et al. Sintering of tin-doped indium oxide (Indium-Tin-Oxide, ITO) with Bi2O3 additive. J Mater Sci, 1998, 33(23), 5621 doi: 10.1023/A:1004420416545[23] Suzuki M, Maeda Y, Muraoka M, et al. ITO films sputter-deposited using an ITO target sintered with vanadium oxide additive. Mater Sci Eng B, 1998, 54(1/2), 43[24] Zhai X, Zhang X, Ma Y, et al. Influence of Bi2O3, TiO2 additives and sintering process on the performance of ITO target based on normal pressure sintering method. Trans Indian Ceram Soc, 2019, 78(2), 83 doi: 10.1080/0371750X.2019.1605935[25] Nadaud N, Boch P. Influence of TiO2 additives on the microstructure of In2O2 ceramics. Ceram Int, 1996, 22(3), 207 doi: 10.1016/0272-8842(95)00082-8[26] Chen D, Jiang C X, Sun H L, et al. Sintering study of ITO using a ZnO-doped and microwave hybrid sintering approach. J Asian Ceram Soc, 2014, 2(1), 57[27] Liang F, Liu J X. Sintering, microstructure and electricity properties of ITO targets with Bi2O3–Nb2O5 addition. Ceram Int, 2017, 43(8), 5856 doi: 10.1016/j.ceramint.2017.02.009[28] Huang J W, Yuan T C, Mei F S, et al. Effects of cerium oxide doping on the microstructure and properties of ITO targets and the photoelectric properties of the films. J Mater Sci Mater Electron, 2019, 30(16), 15469 doi: 10.1007/s10854-019-01923-8[29] Liu T, Jiang Z C, Liu J X. Achieving high relative density and low resistivity in indium tin oxide targets via Bi2O3-CeO2 additive. J Alloys Compd, 2023, 968, 171998 doi: 10.1016/j.jallcom.2023.171998[30] Kim B C, Lee J H, Kim J J, et al. Densification of nanocrystalline ITO powders in fast firing: Effect of specimen mass and sintering atmosphere. Mater Res Bull, 2005, 40(2), 395 doi: 10.1016/j.materresbull.2004.10.006[31] Yang S M, Sun B S, Liu Y, et al. Effect of ITO target crystallinity on the properties of sputtering deposited ITO films. Ceram Int, 2020, 46(5), 6342 doi: 10.1016/j.ceramint.2019.11.110[32] Liu C, Liu J X, Wang Y. Preparation of indium tin oxide targets with a high density and single phase structure by normal pressure sintering process. Rare Met, 2011, 30(2), 126 doi: 10.1007/s12598-011-0210-z[33] Mei F S, Yuan T C, Li R D. Effects of second-phase particles and elemental distributions of ITO targets on the properties of deposited ITO films. Ceram Int, 2017, 43(12), 8866 doi: 10.1016/j.ceramint.2017.04.021[34] Yu J K, Kang S G, Jung K C, et al. Fabrication of nano-sized ITO powder from waste ITO target by spray pyrolysis process. Mater Trans, 2007, 48(2), 249 doi: 10.2320/matertrans.48.249[35] Utsumi K, Matsunaga O, Takahata T. Low resistivity ITO film prepared using the ultra high density ITO target. Thin Solid Films, 1998, 334(1/2), 30 -

Supplements

24090038Supplementary_materials.pdf

24090038Supplementary_materials.pdf

-

Proportional views

Jianzhong Liao got his bachelor’s degree from Guangxi University of Science and Technology in 2021. Now he is currently pursuing a master’s degree in Materials Science and Engineering at Guilin University of Electronic Technology. His research primarily focuses on the formulation design and sintering process of In2O3-based ceramic targets for optoelectronics application.

Jianzhong Liao got his bachelor’s degree from Guangxi University of Science and Technology in 2021. Now he is currently pursuing a master’s degree in Materials Science and Engineering at Guilin University of Electronic Technology. His research primarily focuses on the formulation design and sintering process of In2O3-based ceramic targets for optoelectronics application. Jiwen Xu received his doctoral degree from Shaanxi Normal University, Xian, China, in 2014. He is currently a professor in School of Materials Science and Engineering, Guilin University of Electronic Technology, Guilin, China. His current research interests include oxide powders, ceramic targets, and transparent and conducting films.

Jiwen Xu received his doctoral degree from Shaanxi Normal University, Xian, China, in 2014. He is currently a professor in School of Materials Science and Engineering, Guilin University of Electronic Technology, Guilin, China. His current research interests include oxide powders, ceramic targets, and transparent and conducting films.

DownLoad:

DownLoad: