| Citation: |

Kangda Yin, Shengli Wang, Yuling Liu, Chenwei Wang, Xiang Li. Evaluation of planarization capability of copper slurry in the CMP process[J]. Journal of Semiconductors, 2013, 34(3): 036002. doi: 10.1088/1674-4926/34/3/036002

****

K D Yin, S L Wang, Y L Liu, C W Wang, X Li. Evaluation of planarization capability of copper slurry in the CMP process[J]. J. Semicond., 2013, 34(3): 036002. doi: 10.1088/1674-4926/34/3/036002.

|

Evaluation of planarization capability of copper slurry in the CMP process

DOI: 10.1088/1674-4926/34/3/036002

More Information

-

Abstract

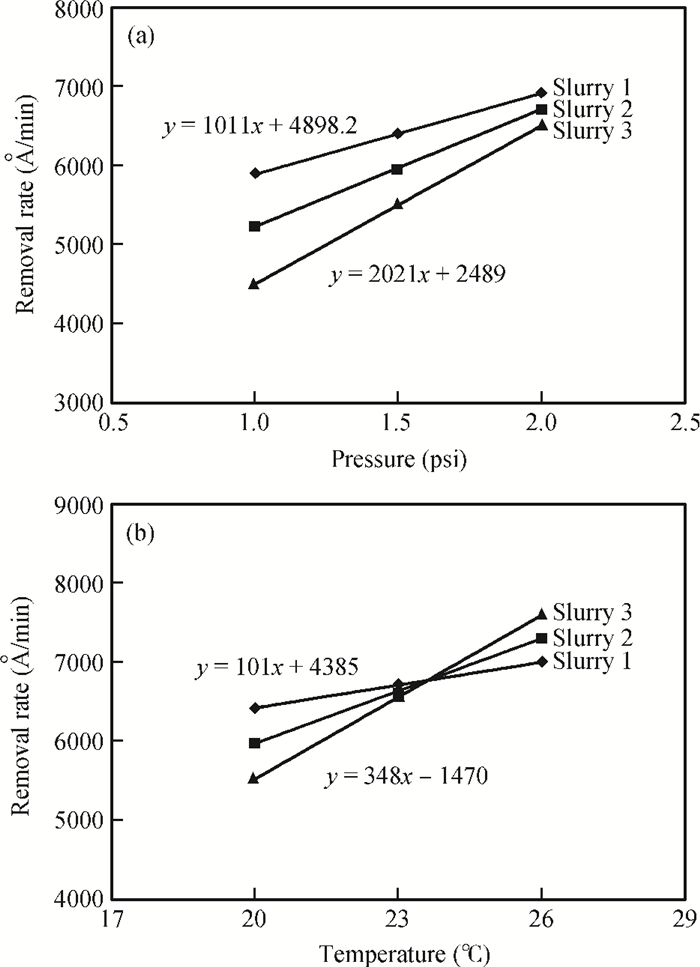

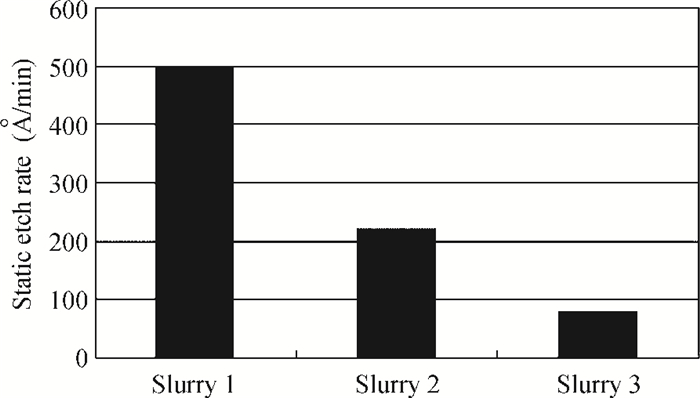

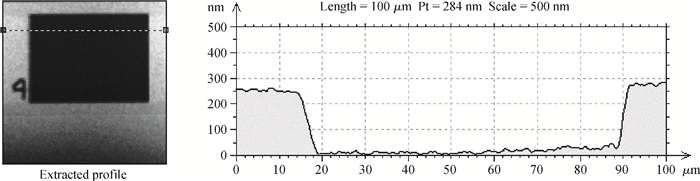

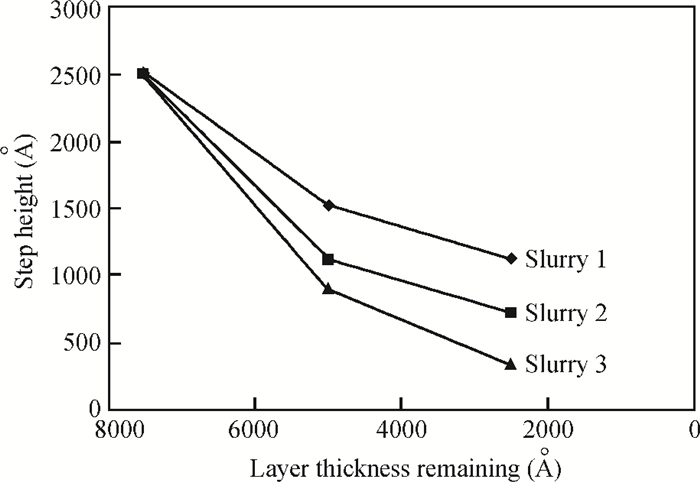

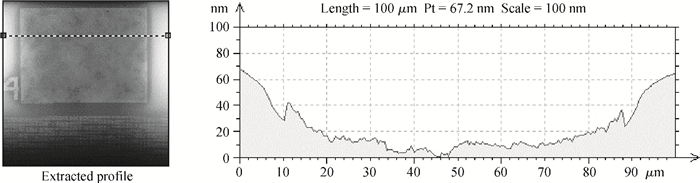

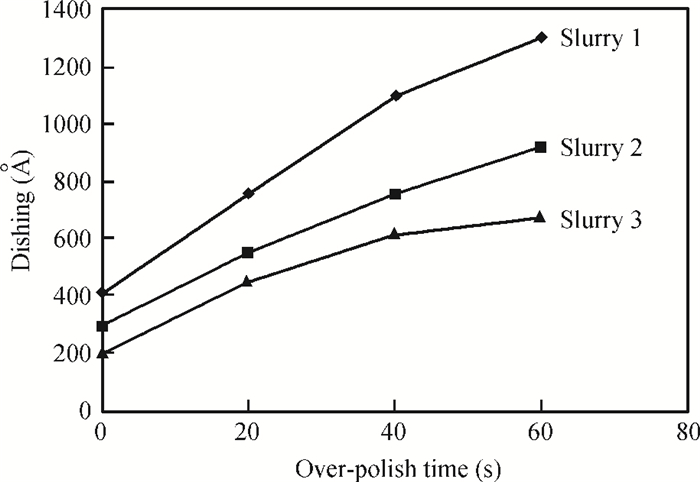

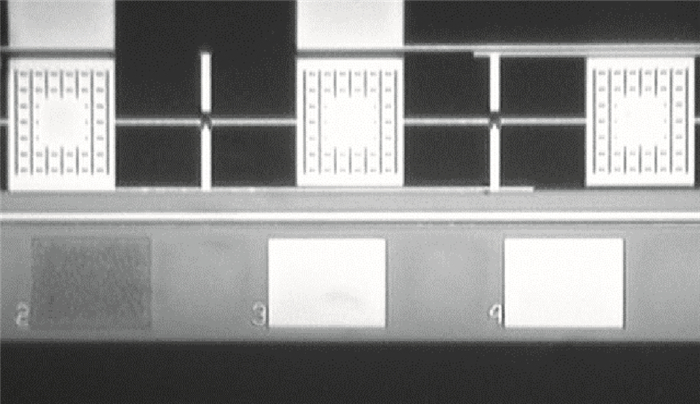

The evaluation methods of planarization capability of copper slurry are investigated. Planarization capability and material removal rate are the most essential properties of slurry. The goal of chemical mechanical polishing (CMP) is to achieve a flat and smooth surface. Planarization capability is the elimination capability of the step height on the copper pattern wafer surface, and reflects the passivation capability of the slurry to a certain extent. Through analyzing the planarization mechanism of the CMP process and experimental results, the planarization capability of the slurry can be evaluated by the following five aspects:pressure sensitivity, temperature sensitivity, static etch rate, planarization efficiency and saturation properties. -

References

[1] Fayolle M, Romagna F. Copper CMP evaluation:planarization issues. Microelectron Eng, 1997, 37/38:135 doi: 10.1016/S0167-9317(97)00104-4[2] Pandija S, Roy D, Babu S V. Chemical mechanical planarization of copper using abrasive-free solutions of oxalic acid and hydrogen peroxide. Mater Chem Phys, 2007, 102:141 http://cat.inist.fr/?aModele=afficheN&cpsidt=18617785[3] Price D T, Gutmann R J, Murarka S P. Damascene copper interconnects with polymer ILDs. Thin Solid Films, 1997, 308/309:523 doi: 10.1016/S0040-6090(97)00479-3[4] Kriz J, Angelkort C, Czekalla M, et al. Overview of dual damascene integration schemes in Cu BEOL integration. Microelectron Eng, 2008, 85:2128 doi: 10.1016/j.mee.2008.05.034[5] Ruan W B, Chen L, Li Z G, et al. Effects of pattern characteristics on copper CMP. Journal of Semiconductors, 2009, 30:046001 doi: 10.1088/1674-4926/30/4/046001[6] Nguyen V H, Daamen R, Hoofman R. Impact of different slurry and polishing pad choices on the planarization efficiency of a copper CMP process. Microelectron Eng, 2004, 76:95 doi: 10.1016/j.mee.2004.07.019[7] Su J X, Du J X, Ma L J, et al. Material removal rate of 6H-SiC crystal substrate CMP using an alumina (Al2O3) abrasive. Journal of Semiconductors, 2012, 33:106003 doi: 10.1088/1674-4926/33/10/106003[8] Zeidler D, Plötner M, Drescher K. Endpoint detection method for CMP of copper. Microelectron Eng, 2000, 50:411 doi: 10.1016/S0167-9317(99)00309-3[9] Nguyen V, VanKranenburg H, Woerlee P. Dependency of dishing on polish time and slurry chemistry in Cu CMP. Microelectron Eng, 2000, 50:403 doi: 10.1016/S0167-9317(99)00308-1[10] Noh K, Saka N, Chun J H. Effect of slurry selectivity on dielectric erosion and copper dishing in copper chemical-mechanical polishing. Cirp Ann-Manuf Tech, 2004, 53:463 doi: 10.1016/S0007-8506(07)60740-9[11] Lee H, Park B, Jeong H. Mechanical effect of process condition and abrasive concentration on material removal rate profile in copper chemical mechanical planarization. J Mater Process Technol, 2009, 209:1729 doi: 10.1016/j.jmatprotec.2008.04.021[12] Pandija S, Roy D, Babu S V. Achievement of high planarization efficiency in CMP of copper at a reduced down pressure. Microelectron Eng, 2009, 86:367 doi: 10.1016/j.mee.2008.11.047[13] Wang C W, Liu Y L, Niu X H, et al. An advanced alkaline slurry for barrier chemical mechanical planarization on patterned wafers. Journal of Semiconductors, 2012, 33:046001 doi: 10.1088/1674-4926/33/4/046001 -

Proportional views

DownLoad:

DownLoad: