| Citation: |

Haobo Yuan, Yuling Liu, Mengting Jiang, Weijuan Liu, Guodong Chen. Effect of chelating agent concentration in alkaline Cu CMP process under the condition of different applied pressures[J]. Journal of Semiconductors, 2014, 35(11): 116005. doi: 10.1088/1674-4926/35/11/116005

****

H B Yuan, Y L Liu, M T Jiang, W J Liu, G D Chen. Effect of chelating agent concentration in alkaline Cu CMP process under the condition of different applied pressures[J]. J. Semicond., 2014, 35(11): 116005. doi: 10.1088/1674-4926/35/11/116005.

|

Effect of chelating agent concentration in alkaline Cu CMP process under the condition of different applied pressures

DOI: 10.1088/1674-4926/35/11/116005

More Information

-

Abstract

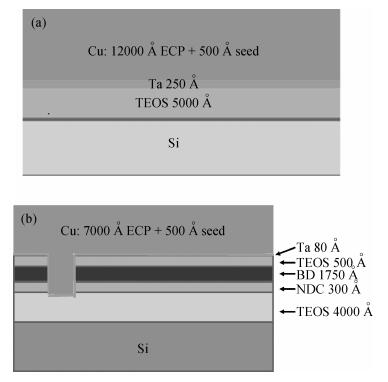

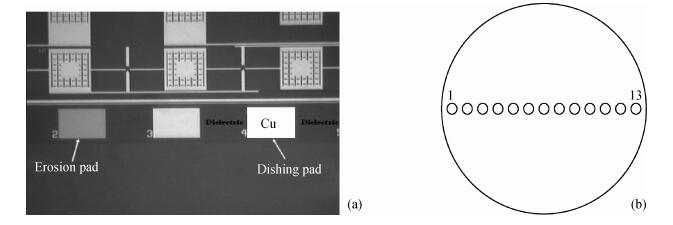

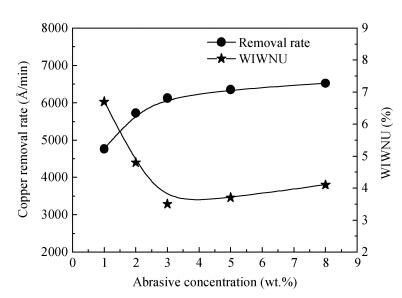

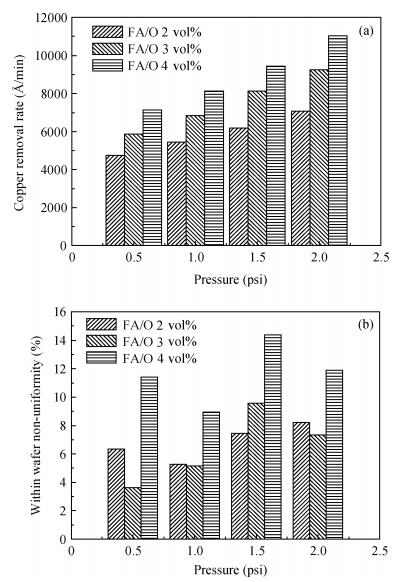

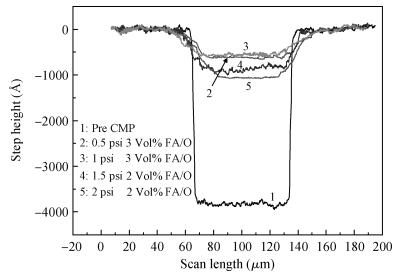

We propose the action mechanism of Cu chemical mechanical planarization (CMP) in an alkaline solution. Meanwhile, the effect of abrasive mass fraction on the copper removal rate and within wafer non-uniformity (WIWNU) have been researched. In addition, we have also investigated the synergistic effect between the applied pressure and the FA/O chelating agent on the copper removal rate and WIWNU in the CMP process. Based on the experimental results, we chose several concentrations of the FA/O chelating agent, which added in the slurry can obtain a relatively high removal rate and a low WIWNU after polishing, to investigate the planarization performance of the copper slurry under different applied pressure conditions. The results demonstrate that the copper removal rate can reach 6125 Å/min when the abrasive concentration is 3 wt.%. From the planarization experimental results, we can see that the residual step height is 562 Å after excessive copper of the wafer surface is eliminated. It denotes that a good polishing result is acquired when the FA/O chelating agent concentration and applied pressure are fixed at 3 vol% and 1 psi, respectively. All the results set forth here are very valuable for the research and development of alkaline slurry.-

Keywords:

- alkaline slurry,

- Cu CMP,

- synergistic effect,

- planarization,

- step height

-

References

[1] Ma T, Chen L, Ruan W B. An interconnect sheet resistance model considering CMP pattern effects in 45 nm process. Physics Procedia, 2012, 25:110 doi: 10.1016/j.phpro.2012.03.058[2] Takaya Y, Kishida H, Hayashi T. Chemical mechanical polishing of patterned copper wafer surface using water-soluble fullerenol slurry. CIRP Annals-Manufacturing Technology, 2011, 60(1):567 doi: 10.1016/j.cirp.2011.03.068[3] Li Y, Liu Y L, Niu X H. Application of a macromolecular chelating agent in chemical mechanical polishing of copper film under the condition of low pressure and low abrasive concentration. Journal of Semiconductors, 2014, 35(1):016001 doi: 10.1088/1674-4926/35/1/016001[4] Hu Y, Liu Y L, Liu X Y. Effect of alkaline slurry on the electric character of the pattern Cu wafer. Journal of Semiconductors, 2011, 32(7):076002 doi: 10.1088/1674-4926/32/7/076002[5] Wang C W, Ma S H, Liu Y L. CMP process optimization using alkaline bulk copper slurry on a 300 mm applied materials reflexion LK system. Journal of Semiconductors, 2013, 34(12):126001 doi: 10.1088/1674-4926/34/12/126001[6] Wang C W, Liu Y L, Tian J Y. A study on the comparison of CMP performance between a novel alkaline slurry and a commercial slurry for barrier removal. Microelectron Eng, 2012, 98(2):29[7] Wang C W, Gao J J, Tian J Y. Chemical mechanical planarization of barrier layers by using a weakly alkaline slurry. Microelectron Eng, 2013, 108:71 doi: 10.1016/j.mee.2013.04.001[8] Yin K D, Wang S L, Liu Y L. Evaluation of planarization capability of copper slurry in the CMP process. Journal of Semiconductors, 2013, 34(3):036002 doi: 10.1088/1674-4926/34/3/036002[9] Chen R, Kang J, Liu Y L. A new weakly alkaline slurry for copper planarization at a reduced down pressure. Journal of Semiconductors, 2014, 35(2):026005 doi: 10.1088/1674-4926/35/2/026005[10] Liu X Y, Liu Y L, Liang Y. Effect of slurry components on chemical mechanical polishing of copper at low down pressure and a chemical kinetics model. Thin Solid Films, 2011, 520(1):400 doi: 10.1016/j.tsf.2011.06.050 -

Proportional views

DownLoad:

DownLoad: