| Citation: |

Kh. S. Karimov, M. Mahroof-Tahir, M. Saleem, M. Tariq Saeed Chani, A. Khan Niaz. Temperature sensor based on composite film of vanadium complex (VO2(3-fl)) and CNT[J]. Journal of Semiconductors, 2015, 36(7): 073004. doi: 10.1088/1674-4926/36/7/073004

****

Kh. S. Karimov, M. Mahroof-Tahir, M. Saleem, M. T. S. Chani, A. K. Niaz. Temperature sensor based on composite film of vanadium complex (VO2(3-fl)) and CNT[J]. J. Semicond., 2015, 36(7): 073004. doi: 10.1088/1674-4926/36/7/073004.

|

Temperature sensor based on composite film of vanadium complex (VO2(3-fl)) and CNT

DOI: 10.1088/1674-4926/36/7/073004

More Information

-

Abstract

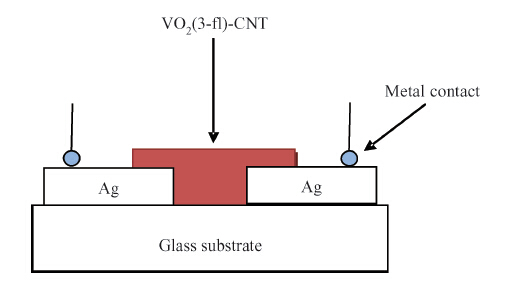

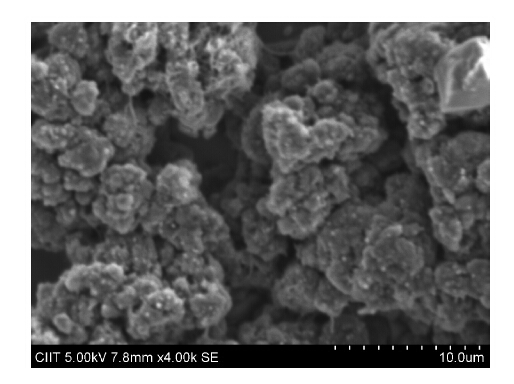

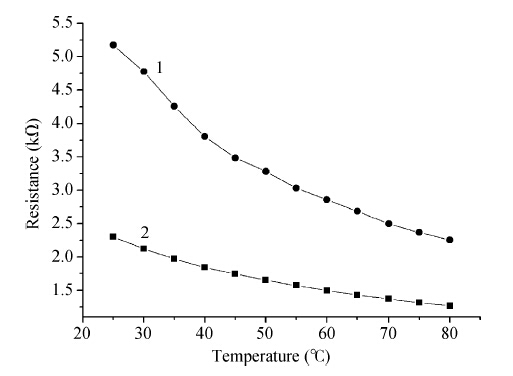

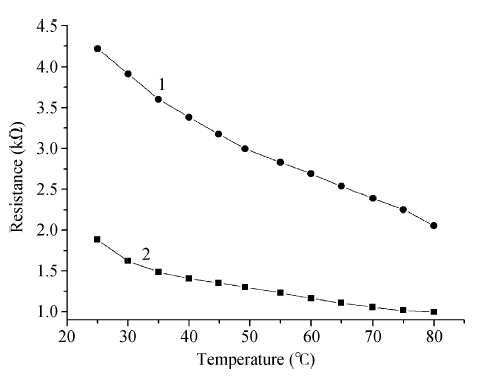

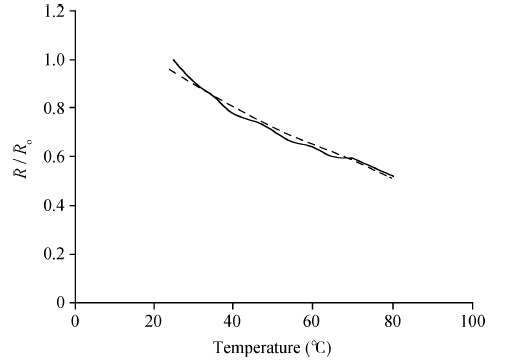

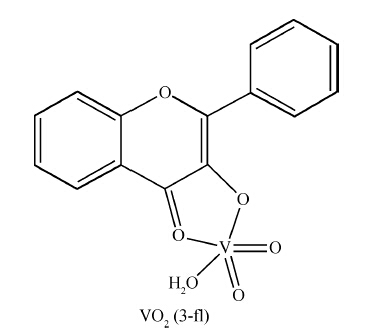

A vanadium complex (VO2(3-fl)) and CNT composite film based temperature sensor is reported in this study. Surface-type silver electrodes were deposited on the glass substrates. A thin film of VO2(3-fl) and CNT composite was coated as a temperature-sensing material on the top of the pre-patterned Ag electrodes. The temperature-sensing principle of the sensor was based on the conductivity change of the coated sensing element upon heating or cooling processes. DC and AC (100 Hz) resistances of the temperature sensor decreased quasi-linearly with increasing the temperature in the range of 25-80 ℃. The overall resistance of the sensor decreases by 1.8-2.1 and 1.9-2.0 times at DC and AC voltage, respectively. The resistance temperature coefficients of the sensor were in the range of -(0.9-1.3)% and -(1.1-1.3)% at DC and AC voltage, respectively. The properties of the sensor studied in this work, make it beneficial to be used in the instruments for environmental monitoring of temperature.-

Keywords:

- CNT,

- vanadium complex,

- film,

- temperature sensor,

- resistance

-

References

[1] [2] [3] [4] [5] [6] [7] [8] [9] [10] [11] [12] [13] [14] [15] [16] [17] [18] [19] [20] [21] [22] [23] [24] [25] [26] [27] [28] [29] [30] [31] [32] [33] [34] [35] [36] [37] [38] [39] [40] -

Proportional views

DownLoad:

DownLoad: