| Citation: |

Dongyan Tao, Yu Cheng, Jingming Liu, Jie Su, Tong Liu, Fengyun Yang, Fenghua Wang, Kewei Cao, Zhiyuan Dong, Youwen Zhao. Chemical and electrical properties of (NH4)2S passivated GaSb surface[J]. Journal of Semiconductors, 2015, 36(7): 073006. doi: 10.1088/1674-4926/36/7/073006

****

D Y Tao, Y Cheng, J M Liu, J Su, T Liu, F Y Yang, F H Wang, K W Cao, Z Y Dong, Y W Zhao. Chemical and electrical properties of (NH4)2S passivated GaSb surface[J]. J. Semicond., 2015, 36(7): 073006. doi: 10.1088/1674-4926/36/7/073006.

|

Chemical and electrical properties of (NH4)2S passivated GaSb surface

DOI: 10.1088/1674-4926/36/7/073006

More Information

-

Abstract

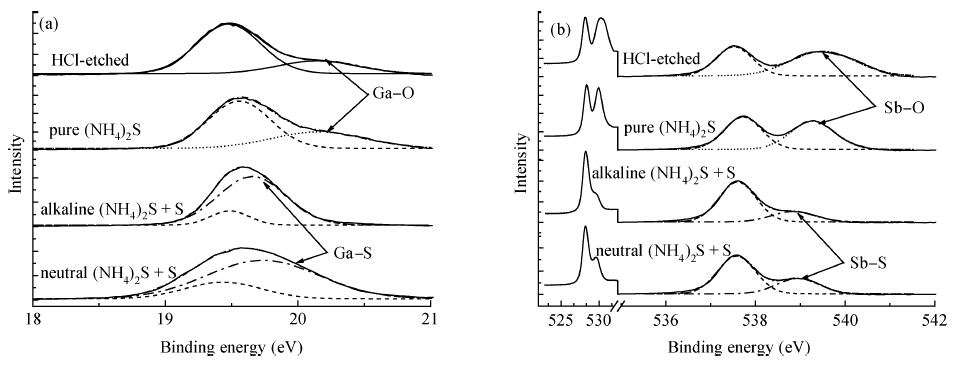

The surface chemical properties of gallium antimonide (GaSb) after ammonium sulfide ((NH4)2S) solution passivation have been studied by X-ray photoelectron spectroscopy (XPS), time of flight secondary ion mass spectroscopy (TOF-SIMS) and I-V measurement. An advantage of neutral (NH4)2S + S solution over pure (NH4)2S solution and alkaline (NH4)2S + S solution has been found in the ability to passivate the GaSb surface by contrast and comparison. It has been found that alkaline (NH4)2S + S solution passivation effectively removes oxides of the GaSb surface and forms sulfide products to improve device performance. TOF-SIMS complementally demonstrates that pure (NH4)2S passivation did form sulfide products, which are too soluble to really exist. The lowest roughness determined using a 3D optical profilometer and the highest improved SBD quality proved that neutral (NH4)2S + S solution passivation worked much better in improving the surface properties of GaSb.-

Keywords:

- surface passivation,

- GaSb,

- XPS,

- TOF-SIMS

-

References

[1] [2] [3] [4] [5] [6] [7] [8] [9] [10] [11] [12] [13] [14] [15] -

Proportional views

DownLoad:

DownLoad: