| Citation: |

Luqi Tao, Danyang Wang, Song Jiang, Ying Liu, Qianyi Xie, He Tian, Ningqin Deng, Xuefeng Wang, Yi Yang, Tianling Ren. Fabrication techniques and applications of flexible graphene-based electronic devices[J]. Journal of Semiconductors, 2016, 37(4): 041001. doi: 10.1088/1674-4926/37/4/041001

****

L Q Tao, D Y Wang, S Jiang, Y Liu, Q Y Xie, H Tian, N Q Deng, X F Wang, Y Yang, T L Ren. Fabrication techniques and applications of flexible graphene-based electronic devices[J]. J. Semicond., 2016, 37(4): 041001. doi: 10.1088/1674-4926/37/4/041001.

|

Fabrication techniques and applications of flexible graphene-based electronic devices

DOI: 10.1088/1674-4926/37/4/041001

More Information

-

Abstract

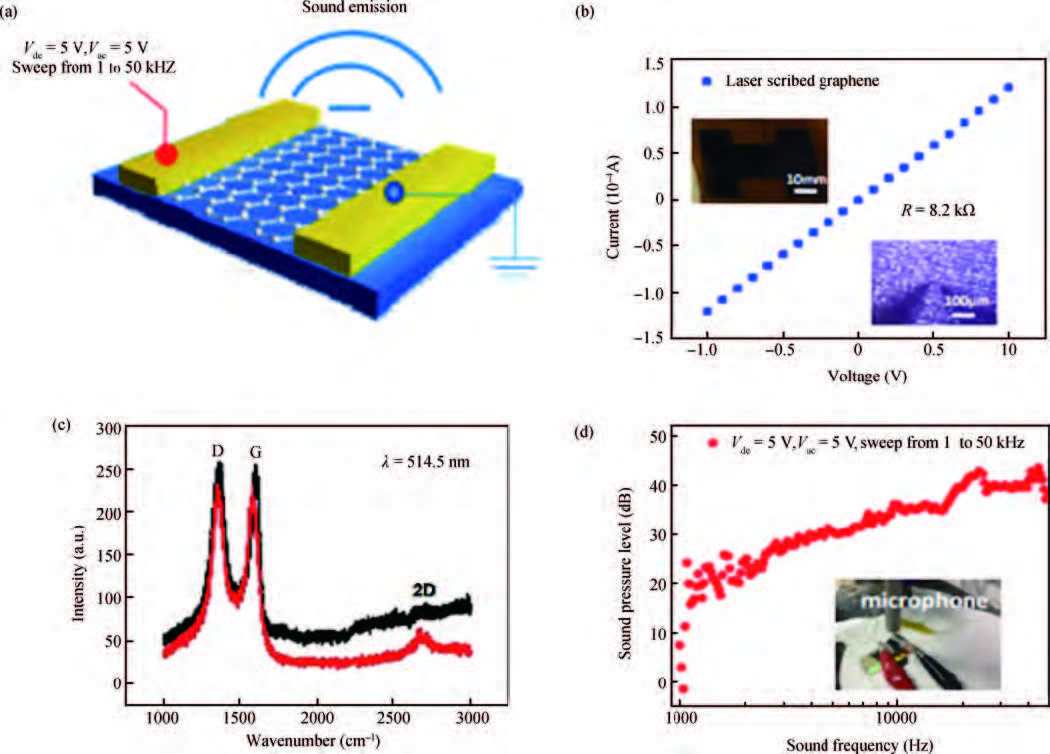

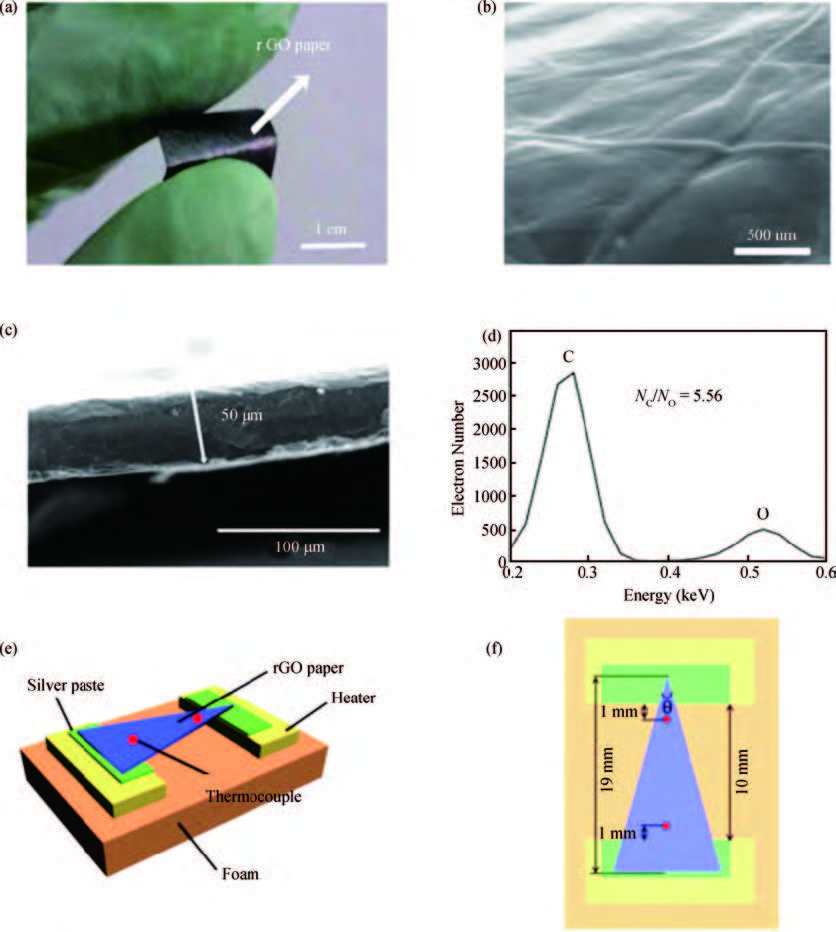

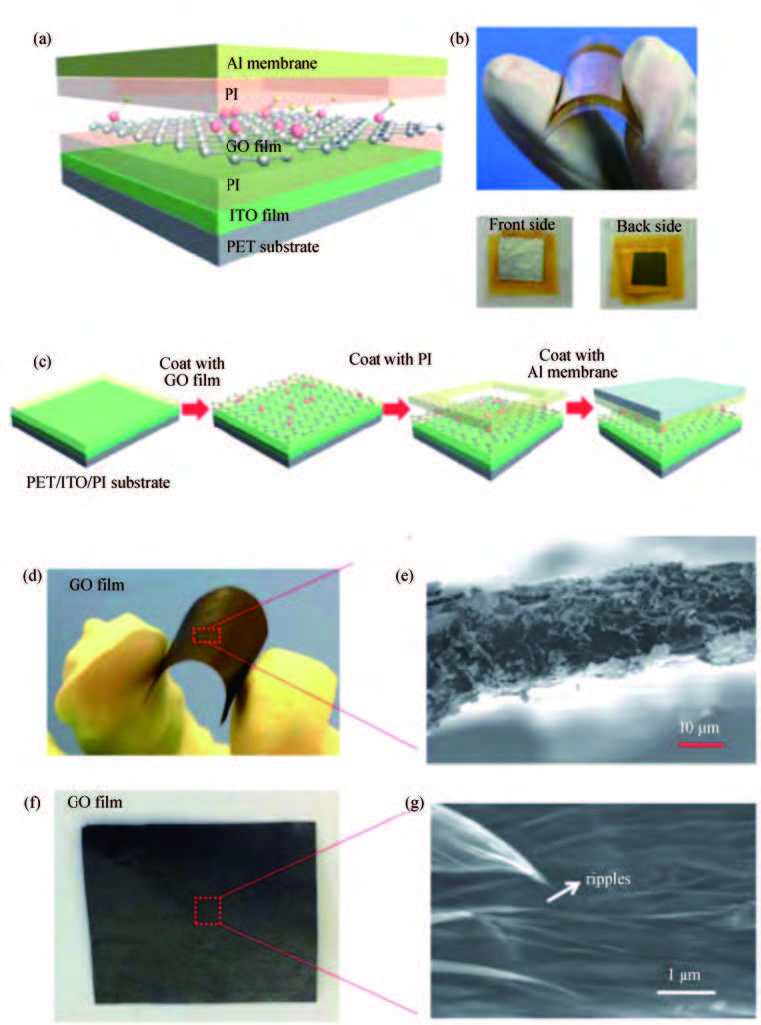

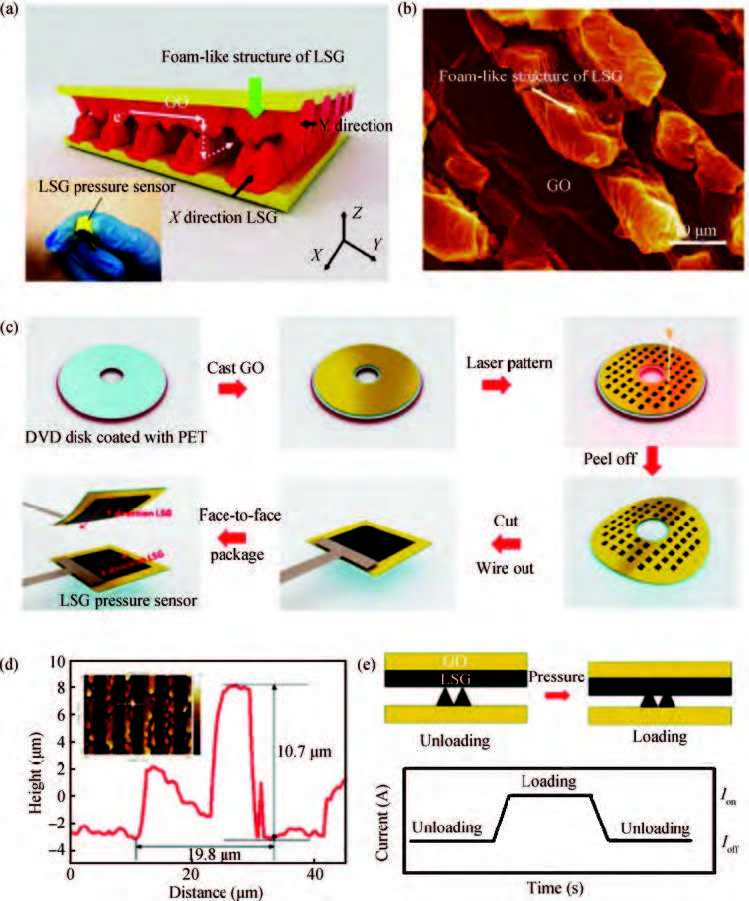

In recent years, flexible electronic devices have become a hot topic of scientific research. These flexible devices are the basis of flexible circuits, flexible batteries, flexible displays and electronic skins. Graphene-based materials are very promising for flexible electronic devices, due to their high mobility, high elasticity, a tunable band gap, quantum electronic transport and high mechanical strength. In this article, we review the recent progress of the fabrication process and the applications of graphene-based electronic devices, including thermal acoustic devices, thermal rectifiers, graphene-based nanogenerators, pressure sensors and graphene-based light-emitting diodes. In summary, although there are still a lot of challenges needing to be solved, graphene-based materials are very promising for various flexible device applications in the future.-

Keywords:

- flexible electronic devices,

- fabrication process,

- graphene

-

References

[1] [2] [3] [4] [5] [6] [7] [8] [9] [10] [11] [12] [13] [14] [15] [16] [17] [18] [19] [20] [21] [22] [23] [24] [25] [26] [27] [28] [29] [30] [31] [32] [33] [34] [35] [36] [37] [38] [39] [40] [41] [42] [43] [44] [45] [46] [47] [48] [49] [50] [51] [52] [53] [54] [55] [56] [57] [58] [59] [60] [61] [62] [63] [64] [65] [66] [67] [68] [69] [70] [71] [72] [73] [74] [75] [76] [77] [78] [79] [80] [81] [82] [83] [84] [85] [86] [87] [88] [89] [90] [91] [92] [93] [94] [95] [96] [97] [98] [99] [100] [101] [102] [103] [104] -

Proportional views

DownLoad:

DownLoad: