| Citation: |

Zhaoguo Xue, Taige Dong, Zhimin Zhu, Yaolong Zhao, Ying Sun, Linwei Yu. Engineering in-plane silicon nanowire springs for highly stretchable electronics[J]. Journal of Semiconductors, 2018, 39(1): 011001. doi: 10.1088/1674-4926/39/1/011001

****

Z G Xue, T G Dong, Z M Zhu, Y L Zhao, Y Sun, L W Yu, Engineering in-plane silicon nanowire springs for highly stretchable electronics[J]. J. Semicond., 2018, 39(1): 011001. doi: 10.1088/1674-4926/39/1/011001.

|

Engineering in-plane silicon nanowire springs for highly stretchable electronics

DOI: 10.1088/1674-4926/39/1/011001

More Information

-

Abstract

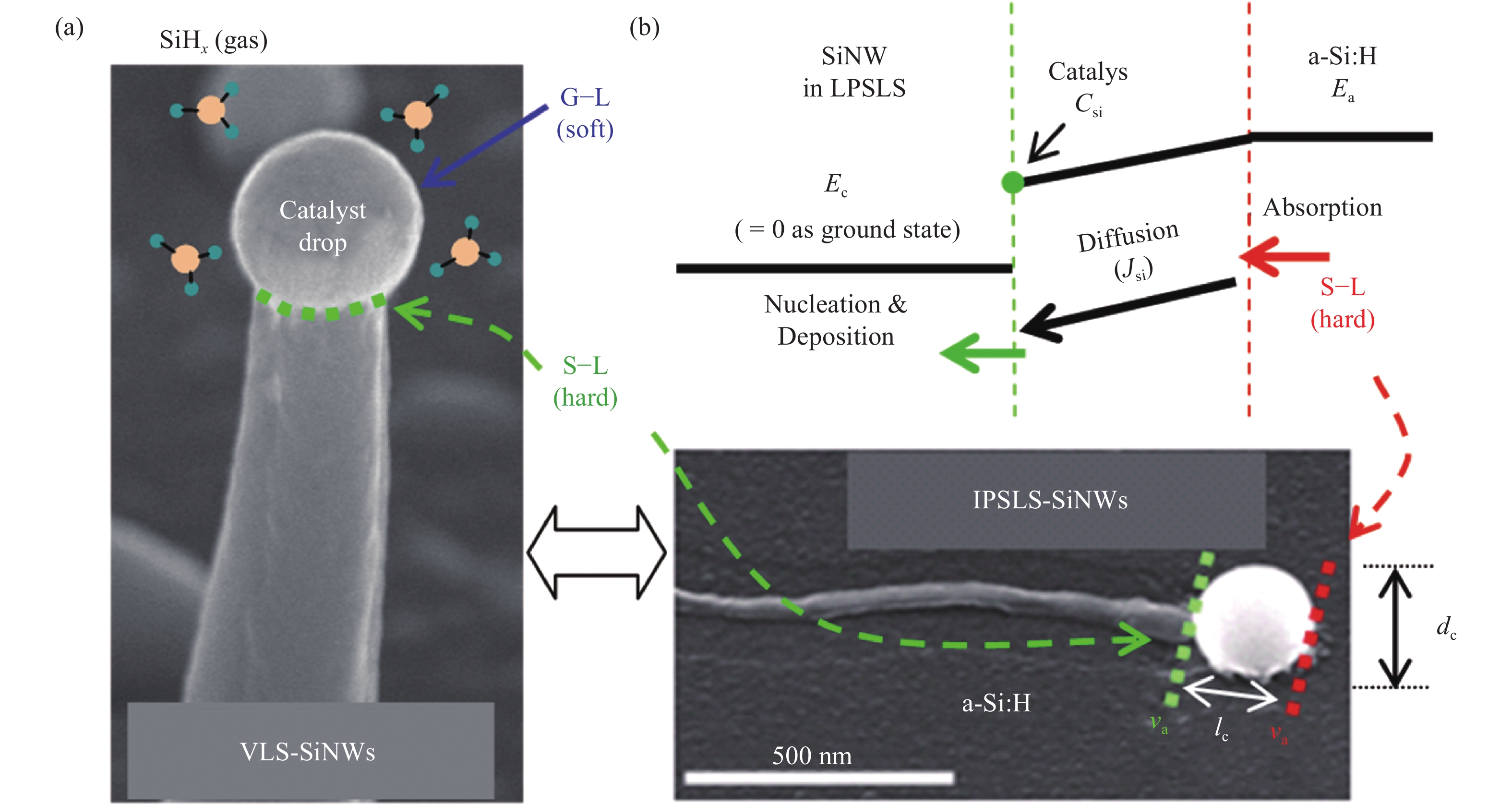

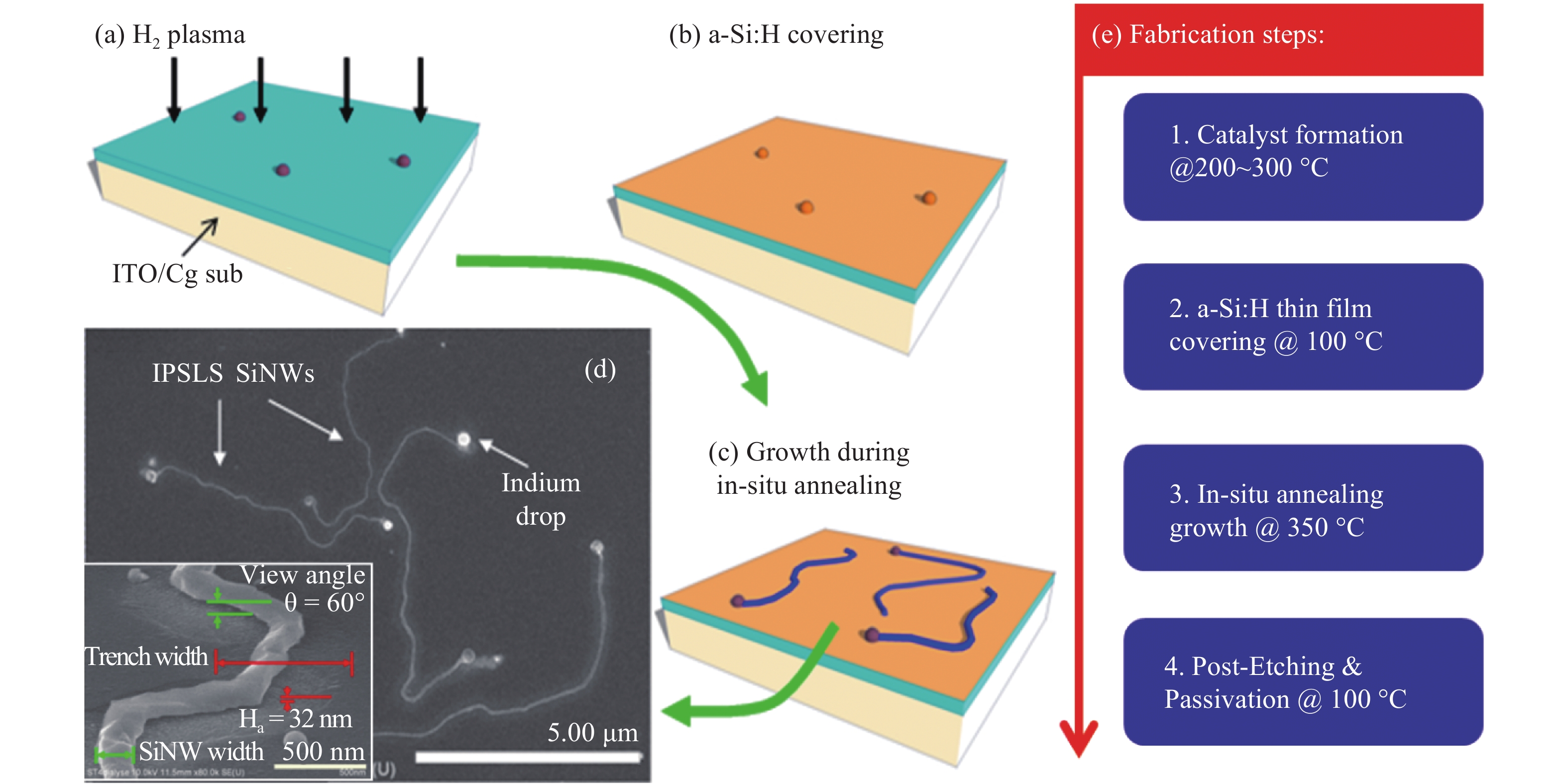

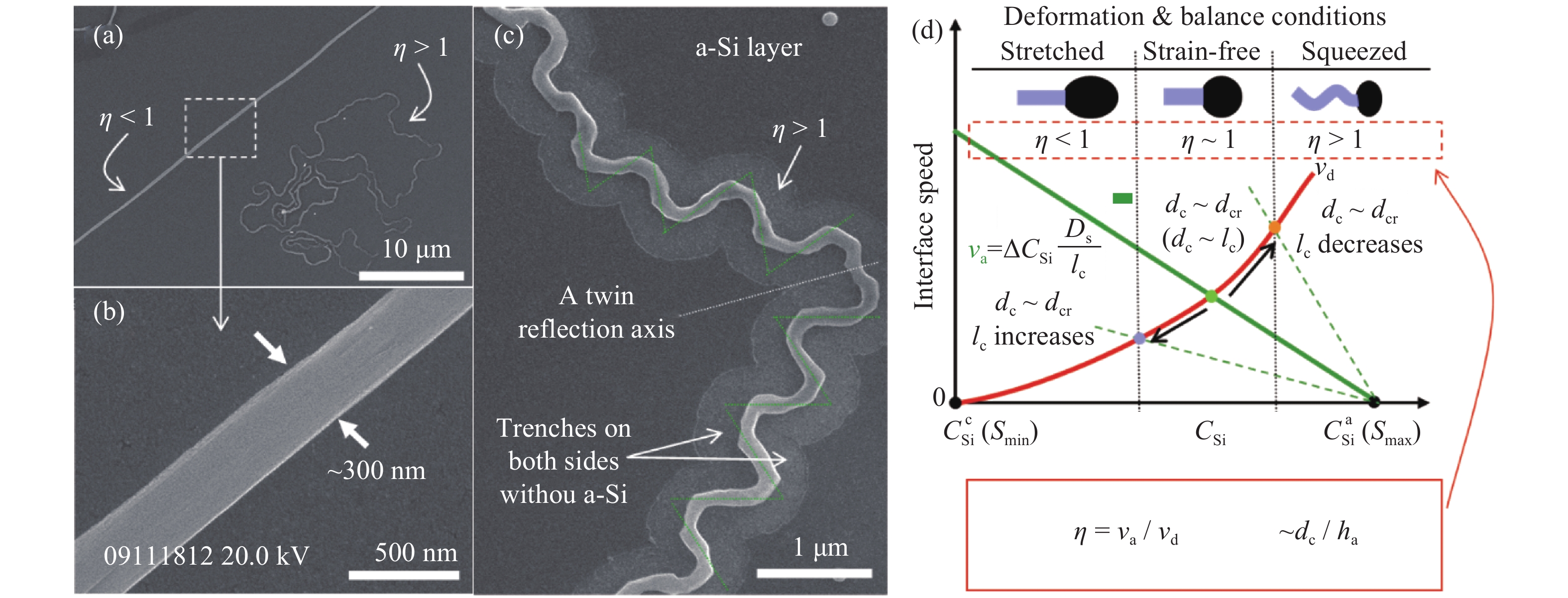

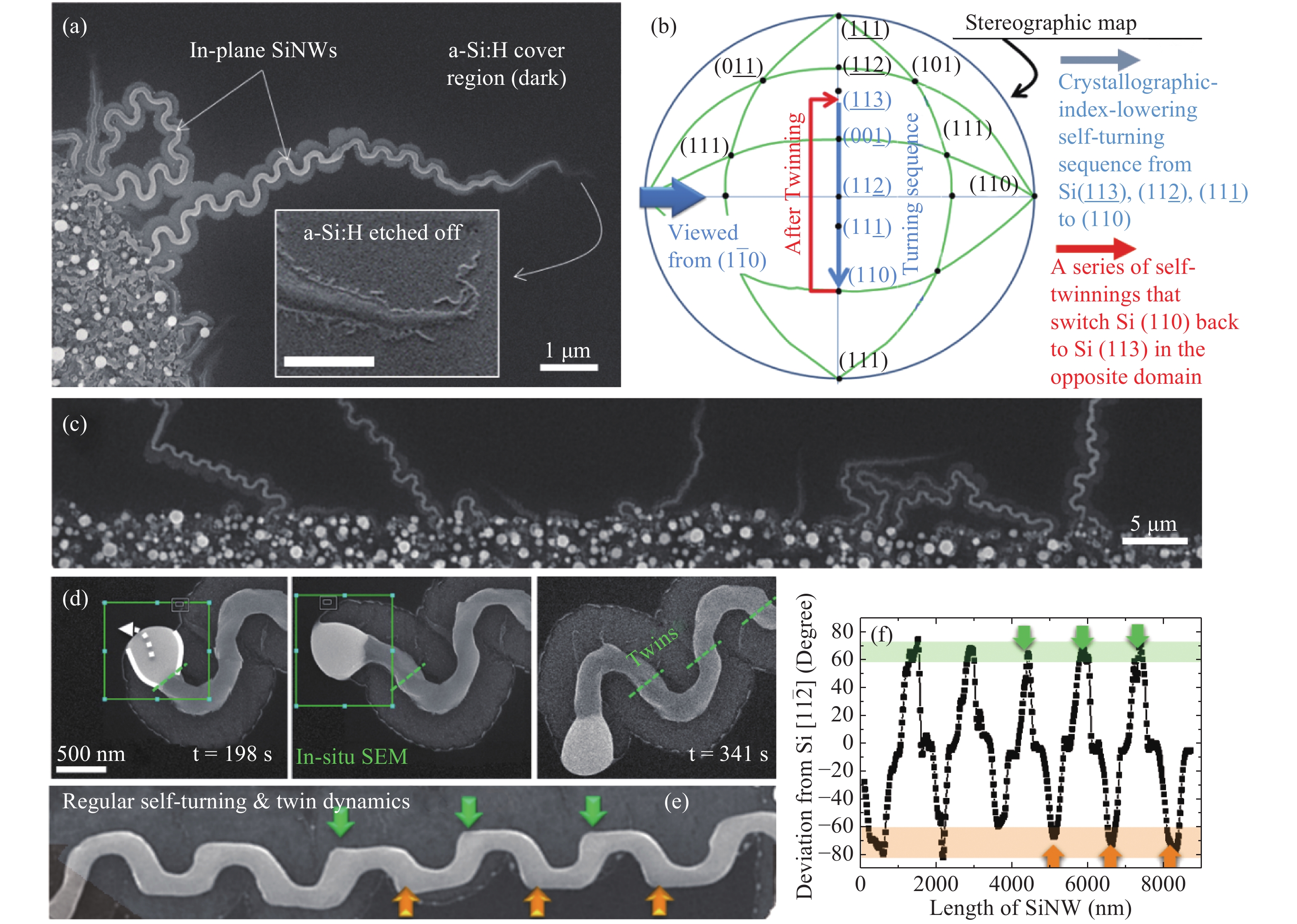

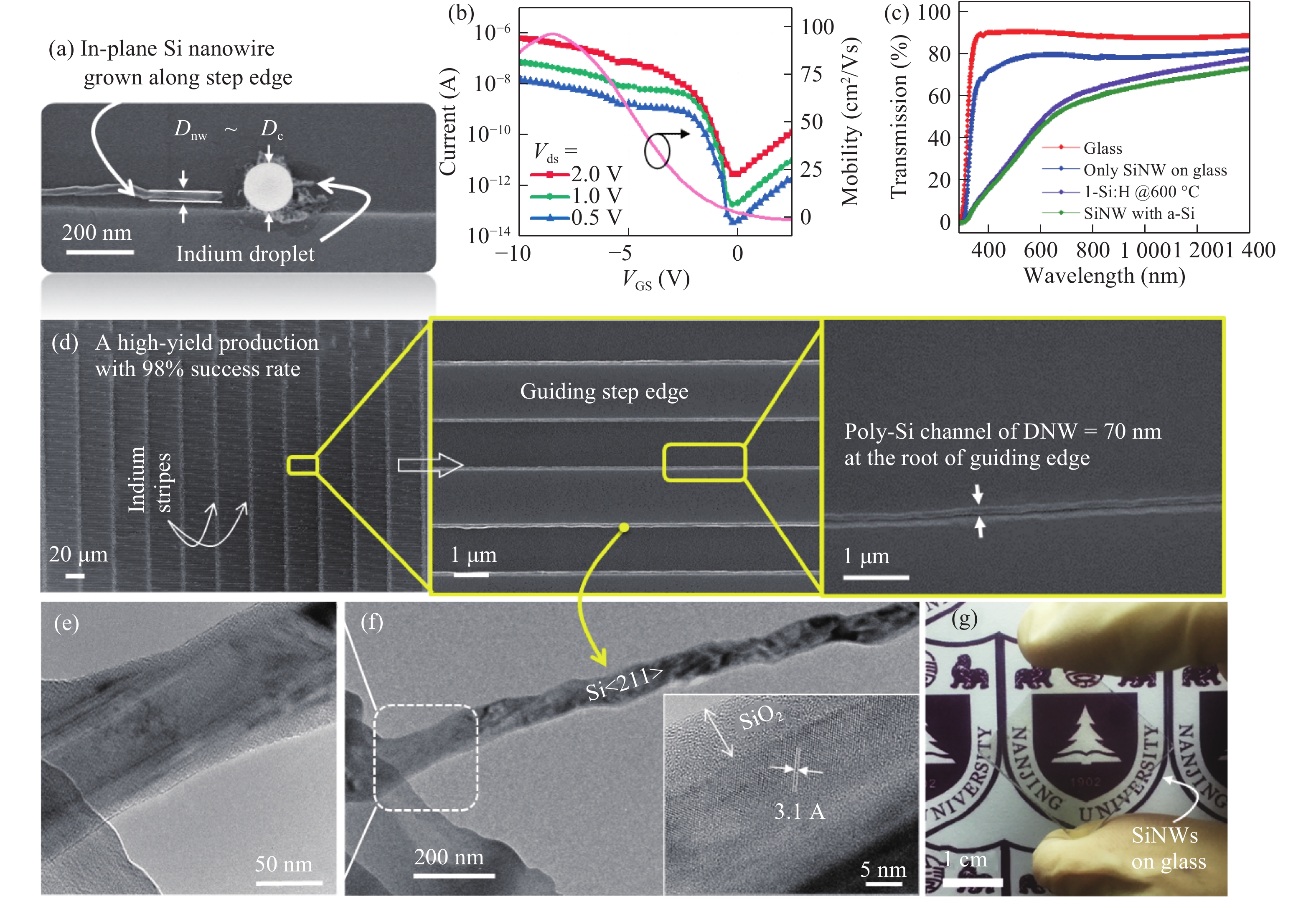

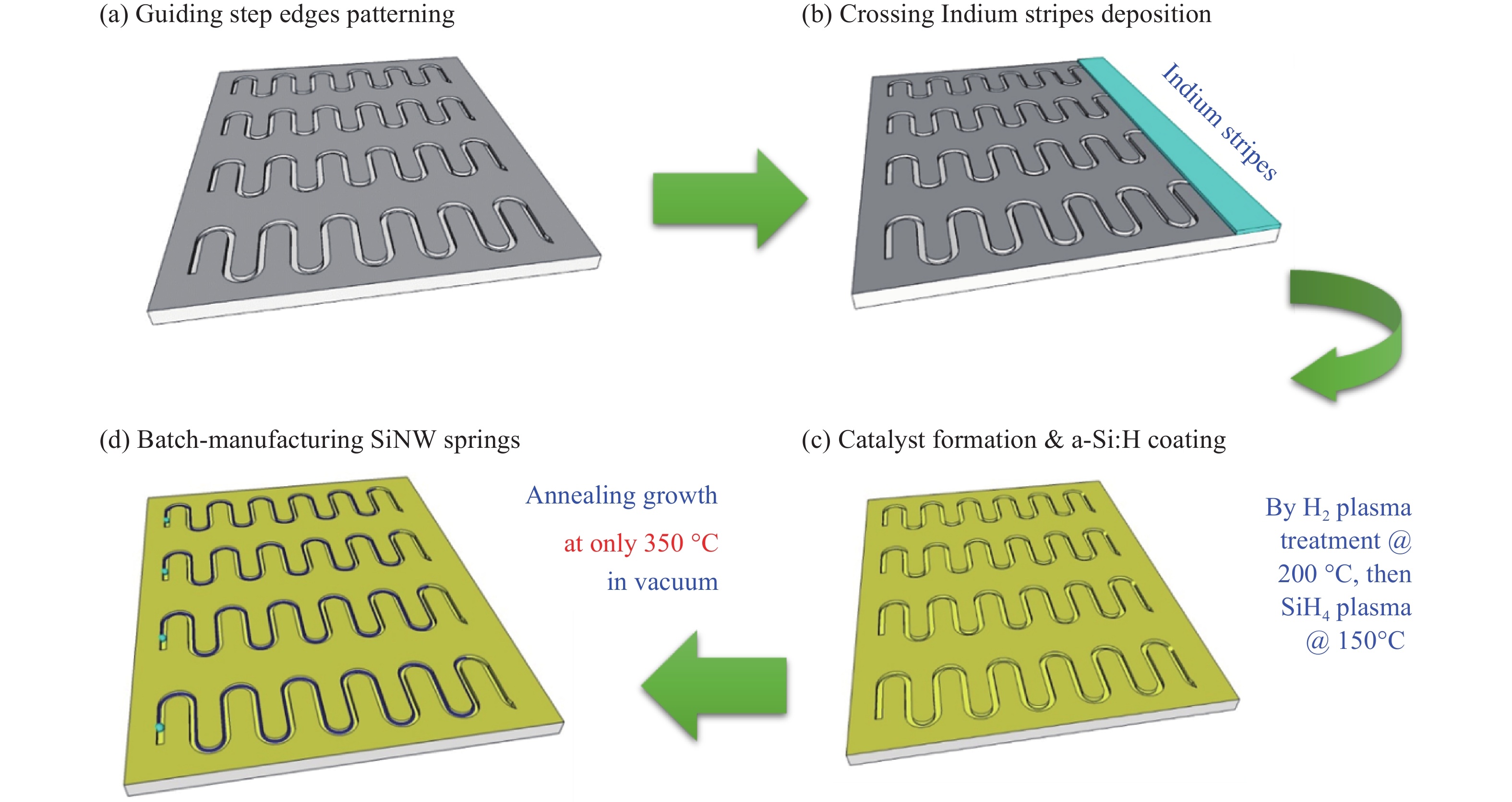

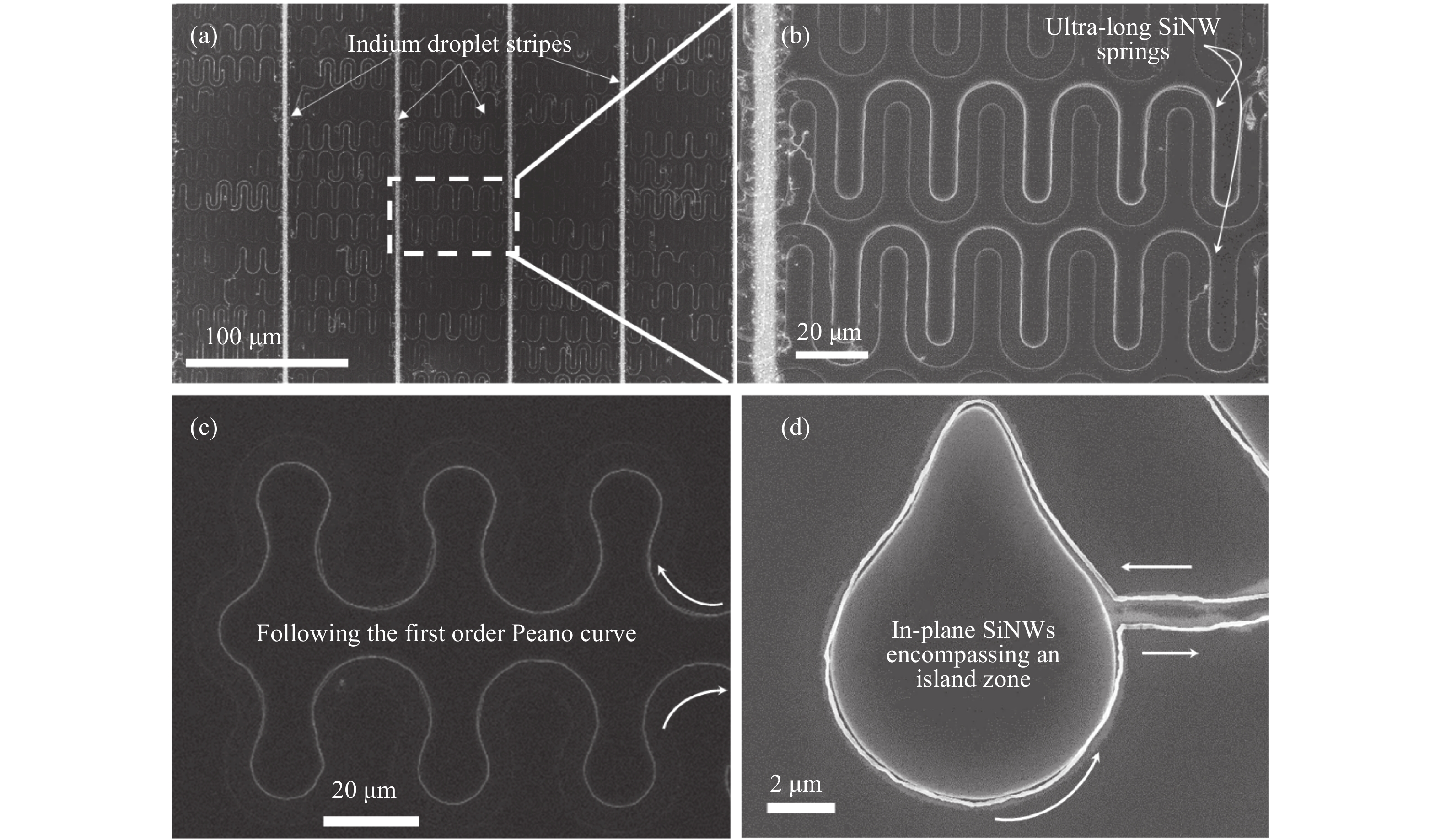

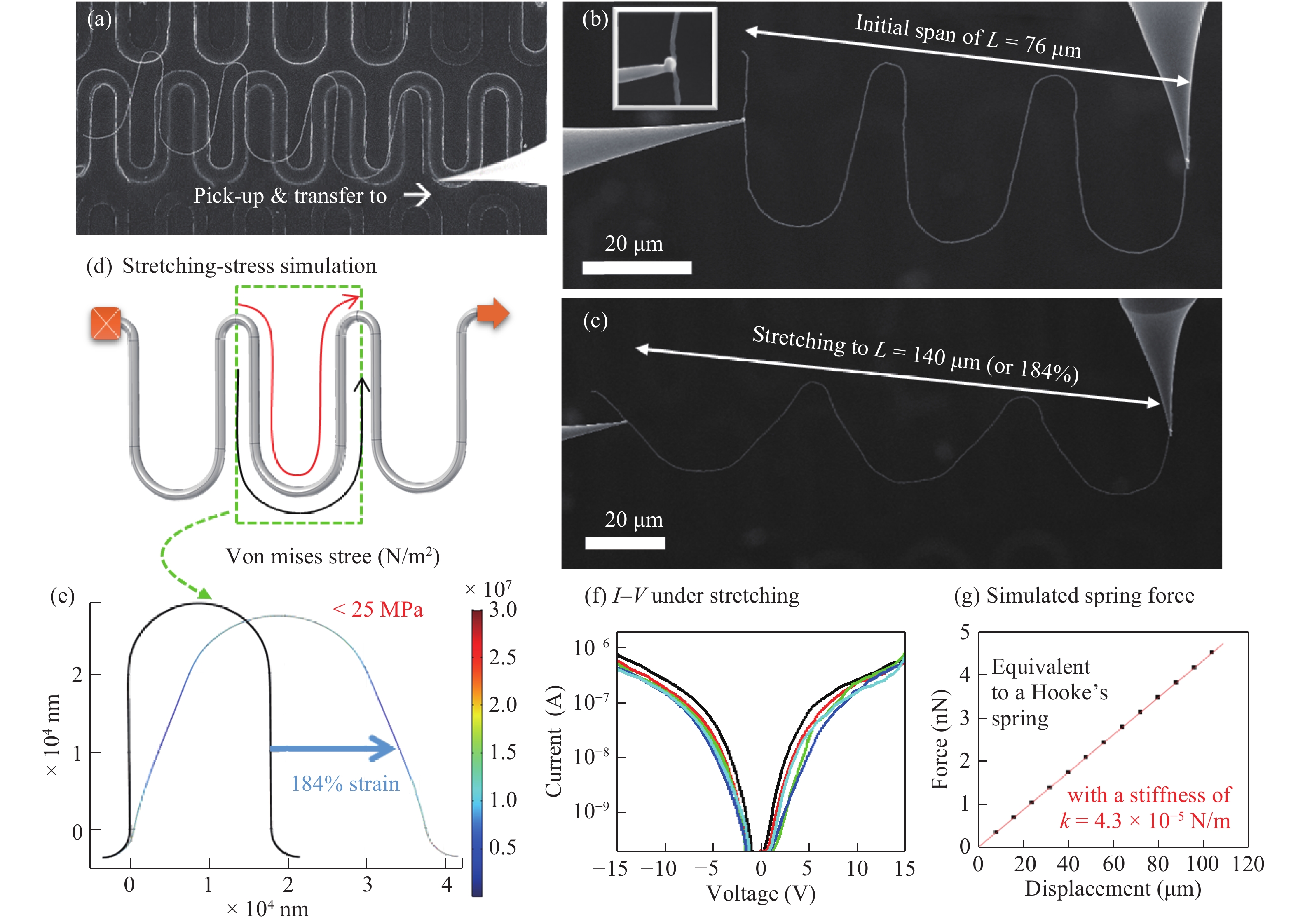

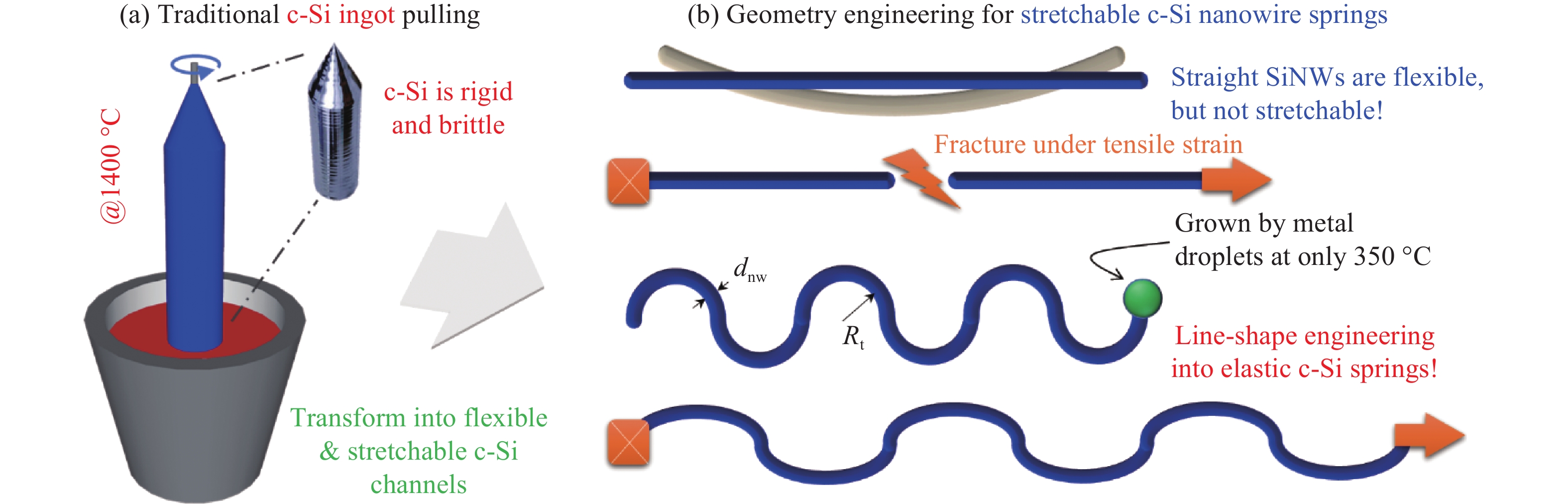

Crystalline silicon (c-Si) is unambiguously the most important semiconductor that underpins the development of modern microelectronics and optoelectronics, though the rigid and brittle nature of bulk c-Si makes it difficult to implement directly for stretchable applications. Fortunately, the one-dimensional (1D) geometry, or the line-shape, of Si nanowire (SiNW) can be engineered into elastic springs, which indicates an exciting opportunity to fabricate highly stretchable 1D c-Si channels. The implementation of such line-shape-engineering strategy demands both a tiny diameter of the SiNWs, in order to accommodate the strains under large stretching, and a precise growth location, orientation and path control to facilitate device integration. In this review, we will first introduce the recent progresses of an in-plane self-assembly growth of SiNW springs, via a new in-plane solid-liquid-solid (IPSLS) mechanism, where mono-like but elastic SiNW springs are produced by surface-running metal droplets that absorb amorphous Si thin film as precursor. Then, the critical growth control and engineering parameters, the mechanical properties of the SiNW springs and the prospects of developing c-Si based stretchable electronics, will be addressed. This efficient line-shape-engineering strategy of SiNW springs, accomplished via a low temperature batch-manufacturing, holds a strong promise to extend the legend of modern Si technology into the emerging stretchable electronic applications, where the high carrier mobility, excellent stability and established doping and passivation controls of c-Si can be well inherited. -

References

[1] Kim J, Salvatore G A, Araki H, et al. Stretchable optoelectronic systems for wireless optical characterization of the skin. Sci Adv, 2016, 2: e1600418 doi: 10.1126/sciadv.1600418[2] Xu B, Rogers J A. Mechanics-driven approaches to manufacturing—A perspective. Extrem Mech Lett, 2016, 7: 44 doi: 10.1016/j.eml.2015.12.012[3] Kim D H, Ghaffari R, Lu N, et al. Flexible and stretchable electronics for biointegrated devices. Ann Rev Biomed Eng, 2012, 14: 113 doi: 10.1146/annurev-bioeng-071811-150018[4] Hussain A M, Hussain M M. CMOS-technology-enabled flexible and stretchable electronics for internet of everything applications. Adv Mater, 2016, 28: 4219 doi: 10.1002/adma.v28.22[5] Hammock M L, Chortos A, Tee B C K, et al. The evolution of electronic skin (e-skin): a brief history, design considerations, and recent progress. Adv Mater, 2013, 25: 5997 doi: 10.1002/adma.201302240[6] Cheng T, Zhang Y, Lai. Stretchable thin-film electrodes for flexible electronics with high deformability and stretchability. Adv Mater, 2015, 27: 3349 doi: 10.1002/adma.v27.22[7] Wang Y, Zhu C, Pfattner R, et al. A highly stretchable, transparent, and conductive polymer. Sci Adv, 2017, 3: e1602076 doi: 10.1126/sciadv.1602076[8] Roberts M E, Mannsfeld S C B, Stoltenberg R M, et al. Flexible, plastic transistor-based chemical sensors. Org Electron, 2009, 10: 377 doi: 10.1016/j.orgel.2008.12.001[9] Sokolov A N, Roberts M E, Bao Z. Fabrication of low-cost electronic biosensors. Mater Today, 2009, 12: 12 doi: 10.1016/S1369-7021(09)70247-0[10] Arias A C, MacKenzie J D, McCulloch I, et al. Materials and applications for large area electronics: solution-based approaches. Chem Rev, 2010, 110: 3 doi: 10.1021/cr900150b[11] Lei Z, Wang Q, Sun S, et al. A bioinspired mineral hydrogel as a self-healable, mechanically adaptable ionic skin for highly sensitive pressure sensing. Adv Mater, 2017, 29: 1700321 doi: 10.1002/adma.201700321[12] Lin P, Yan F. Organic thin-film transistors for chemical and biological sensing. Adv Mater, 2012, 24: 34 doi: 10.1002/adma.201103334[13] Wang L, Liu P, Guan P, et al. In situ atomic-scale observation of continuous and reversible lattice deformation beyond the elastic limit. Nat Commun, 2013, 4: 2413 doi: 10.1038/ncomms3413[14] Wang L, Zheng K, Zhang Z, et al. Direct atomic-scale imaging about the mechanisms of ultralarge bent straining in Si nanowires. Nano Lett, 2011, 11: 2382 doi: 10.1021/nl200735p[15] Zheng K, Han X, Wang L, et al. Atomic mechanisms governing the elastic limit and the incipient plasticity of bending Si nanowires. Nano Lett, 2009, 9: 2471 doi: 10.1021/nl9012425[16] Zhu Y, Xu F, Qin Q, et al. Mechanical properties of vapor-liquid-solid synthesized silicon nanowires. Nano Lett, 2009, 9: 3934 doi: 10.1021/nl902132w[17] Khang D Y, Jiang H, Huang Y, et al. A stretchable form of single-crystal silicon for high-performance electronics on rubber substrates. Science, 2006, 311: 208 doi: 10.1126/science.1121401[18] Kim H W, Shim S H. Helical nanostructures of SiOx synthesized through the heating of Co-coated substrates. Appl Surf Sci, 2007, 253: 3664 doi: 10.1016/j.apsusc.2006.07.083[19] Zhang H F, Wang C M, Buck E C, et al. Synthesis, characterization, and manipulation of helical SiO2 nanosprings. Nano Lett, 2003, 3: 577 doi: 10.1021/nl0341180[20] Swain B S, Lee S S, Lee S H, et al. Transformation of silicon nanowires to nanocoils by annealing in reducing atmosphere. J Cryst Growth, 2011, 327: 276 doi: 10.1016/j.jcrysgro.2011.06.018[21] Tang Y H, Zhang Y F, Wang N, et al. Morphology of Si nanowires synthesized by high-temperature laser ablation. J Appl Phys, 1999, 85: 7981 doi: 10.1063/1.369389[22] Tian B, Xie P, Kempa T J, et al. Single-crystalline kinked semiconductor nanowire superstructures. Nat Nano, 2009, 4: 824 doi: 10.1038/nnano.2009.304[23] Lugstein A, Steinmair M, Hyun Y J, et al. Pressure-induced orientation control of the growth of epitaxial silicon nanowires. Nano Lett, 2008, 8: 2310 doi: 10.1021/nl8011006[24] Musin I R, Filler M A. Chemical control of semiconductor nanowire kinking and superstructure. Nano Lett, 2012, 12: 3363 doi: 10.1021/nl204065p[25] Schmidt V, Wittemann J V, Senz S, et al. Silicon nanowires: a review on aspects of their growth and their electrical properties. Adv Mater, 2009, 21: 2681 doi: 10.1002/adma.200803754[26] Wagner R S, Ellis W C. Vapor-liquid-solid mechanism of single crystal growth. Appl Phys Lett, 1964, 4: 89 doi: 10.1063/1.1753975[27] Xu F, Lu W, Zhu Y. Controlled 3D buckling of silicon nanowires for stretchable electronics. ACS Nano, 2011, 5: 672 doi: 10.1021/nn103189z[28] Kim D H, Ahn J H, Choi W M, et al. Stretchable and foldable silicon integrated circuits. Science, 2008, 320: 507 doi: 10.1126/science.1154367[29] Jang K I, Li K, Chung H U, et al. Self-assembled three dimensional network designs for soft electronics. Nat Commun, 2017, 8: 15894[30] Sepulveda A C C, Cordero M S D, Carreño A A A, et al. Stretchable and foldable silicon-based electronics. Appl Phys Lett, 2017, 110: 134103 doi: 10.1063/1.4979545[31] Rojas J P, Arevalo A, Foulds I G, et al. Design and characterization of ultra-stretchable monolithic silicon fabric. Appl Phys Lett, 2014, 105: 154101 doi: 10.1063/1.4898128[32] Kim J, Lee M, Shim H J, et al. Stretchable silicon nanoribbon electronics for skin prosthesis. Nat Commun, 2014, 5: 5747 doi: 10.1038/ncomms6747[33] Pevzner A, Engel Y, Elnathan R, et al. Confinement-guided shaping of semiconductor nanowires and nanoribbons: " writing with nanowires”. Nano Lett, 2012, 12: 7 doi: 10.1021/nl201527h[34] Gonzalez M, Axisa F, Bulcke M V, et al. Design of metal interconnects for stretchable electronic circuits. Microelectron Rel, 2008, 48: 825 doi: 10.1016/j.microrel.2008.03.025[35] Vanfleteren J, Gonzalez M, Bossuyt F, et al. Printed circuit board technology inspired stretchable circuits. MRS Bull, 2012, 37: 254 doi: 10.1557/mrs.2012.48[36] Yu L, Alet P J, Picardi G, et al. An in-plane solid-liquid-solid growth mode for self-avoiding lateral silicon nanowires. Phys Rev Lett, 2009, 102: 125501 doi: 10.1103/PhysRevLett.102.125501[37] Yu L, P Roca i Cabarrocas. Initial nucleation and growth of in-plane solid-liquid-solid silicon nanowires catalyzed by indium. Phys Rev B, 2009, 80: 085313 doi: 10.1103/PhysRevB.80.085313[38] Yu L, P Roca i Cabarrocas. Growth mechanism and dynamics of in-plane solid-liquid-solid silicon nanowires. Phys Rev B, 2010, 81: 085323 doi: 10.1103/PhysRevB.81.085323[39] Scarontich I, Car R, Parrinello M. Amorphous silicon studied by ab initio molecular dynamics: preparation, structure, and properties. Phys Rev B, 1991, 44: 11092 doi: 10.1103/PhysRevB.44.11092[40] Roorda S, Doorn S, Sinke W C, et al. Calorimetric evidence for structural relaxation in amorphous silicon. Phys Rev Lett, 1989, 62: 1880 doi: 10.1103/PhysRevLett.62.1880[41] Yu L P. Morphology control and growth dynamics of in-plane solid–liquid–solid silicon nanowires. Physica E, 2012, 44: 1045 doi: 10.1016/j.physe.2011.06.005[42] Xue Z, Xu M, Li X, et al. In-plane self-turning and twin dynamics renders large stretchability to mono-like zigzag silicon nanowire springs. Adv Func Mater, 2016, 26: 5352 doi: 10.1002/adfm.201600780[43] Xue Z, Xu M, Zhao Y, et al. Engineering island-chain silicon nanowires via a droplet mediated Plateau-Rayleigh transformation. Nat Commun, 2016, 7: 12836 doi: 10.1038/ncomms12836[44] Shin N, Chi M, Howe J Y, et al. Rational defect introduction in silicon nanowires. Nano Lett, 2013, 13: 1928 doi: 10.1021/nl3042728[45] Algra R E, Verheijen M A, Borgstrom M T, et al. Twinning superlattices in indium phosphide nanowires. Nature, 2008, 456: 369 doi: 10.1038/nature07570[46] Li X, Wei X, Xu T, et al. Remarkable and crystal-structure-dependent piezoelectric and piezoresistive effects of InAs nanowires. Adv Mater, 2015, 27: 2852 doi: 10.1002/adma.v27.18[47] Li X, Wei X L, Xu T T, et al. Mechanical properties of individual InAs nanowires studied by tensile tests. Appl Phys Lett, 2014, 104: 103110 doi: 10.1063/1.4868133[48] Xu M, Xue Z, Yu L, et al. Operating principles of in-plane silicon nanowires at simple step-edges. Nanoscale, 2015, 7: 5197 doi: 10.1039/C4NR06531J[49] Yu L, Moustapha O, Oudwan M, et al. Guided growth of in-plane lateral SiNWs led by indium catalysts. Mater Res Soc Symp Proc, 2009, 1178E: AA07[50] Yu L, Oudwan M, Moustapha O, et al. Guided growth of in-plane silicon nanowires. Appl Phys Lett, 2009, 95: 113106 doi: 10.1063/1.3227667[51] Yu L, Chen W, O'Donnell B, et al. Growth-in-place deployment of in-plane silicon nanowires. Appl Phys Lett, 2011, 99: 203104 doi: 10.1063/1.3659895[52] Xu M, Wang J, Xue Z, et al. High performance transparent in-plane silicon nanowire Fin-TFTs via a robust nano-droplet-scanning crystallization dynamics. Nanoscale, 2017, 9: 10350 doi: 10.1039/C7NR02825C[53] Chen W, Yu L, Misra S, et al. Incorporation and redistribution of impurities into silicon nanowires during metal-particle-assisted growth. Nat Commun, 2014, 5: 4134[54] Xue Z, Sun M, Zhao Y, et al. Deterministic line-shape programming of silicon nanowires for extremely stretchable springs and electronics. Nano Lett, 2017, 17: 7638[55] O'Mara W, Herring R B, Hunt L P. Handbook of semiconductor silicon technology. Crest Publishing House, 2007 -

Proportional views

DownLoad:

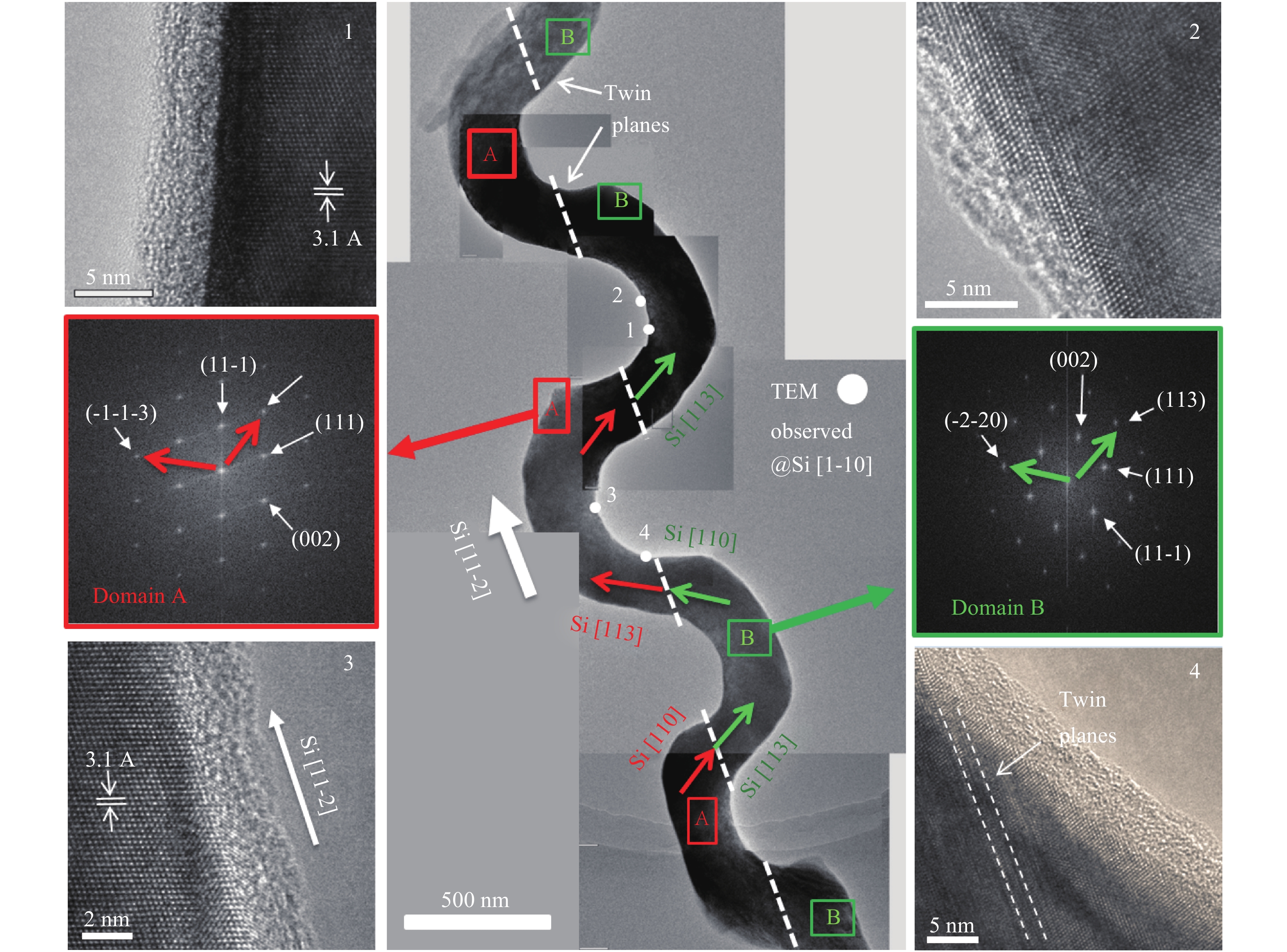

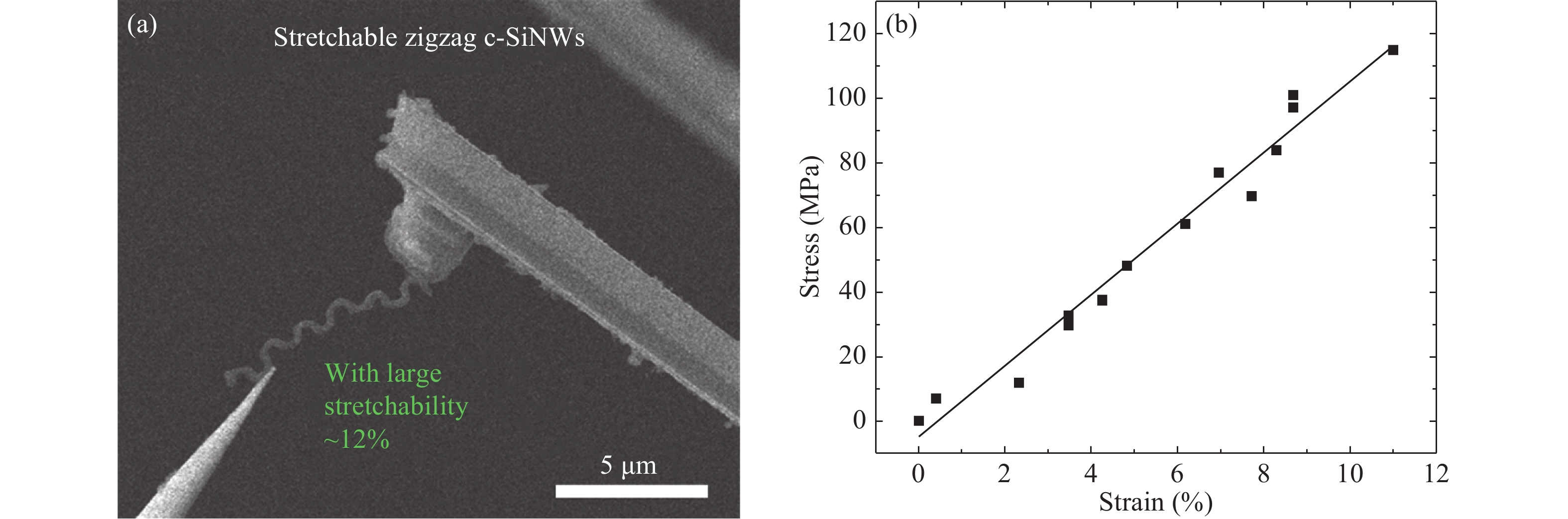

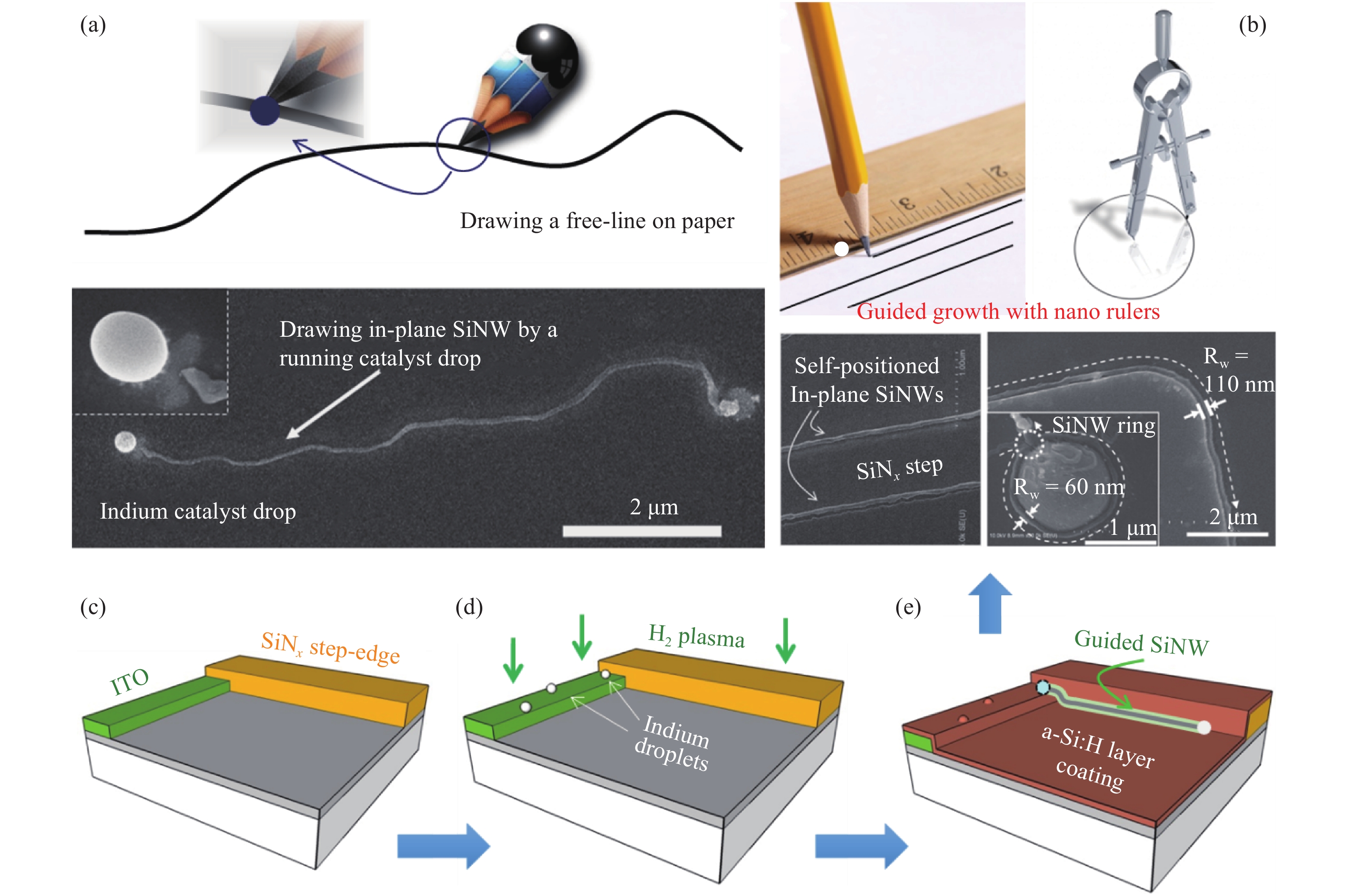

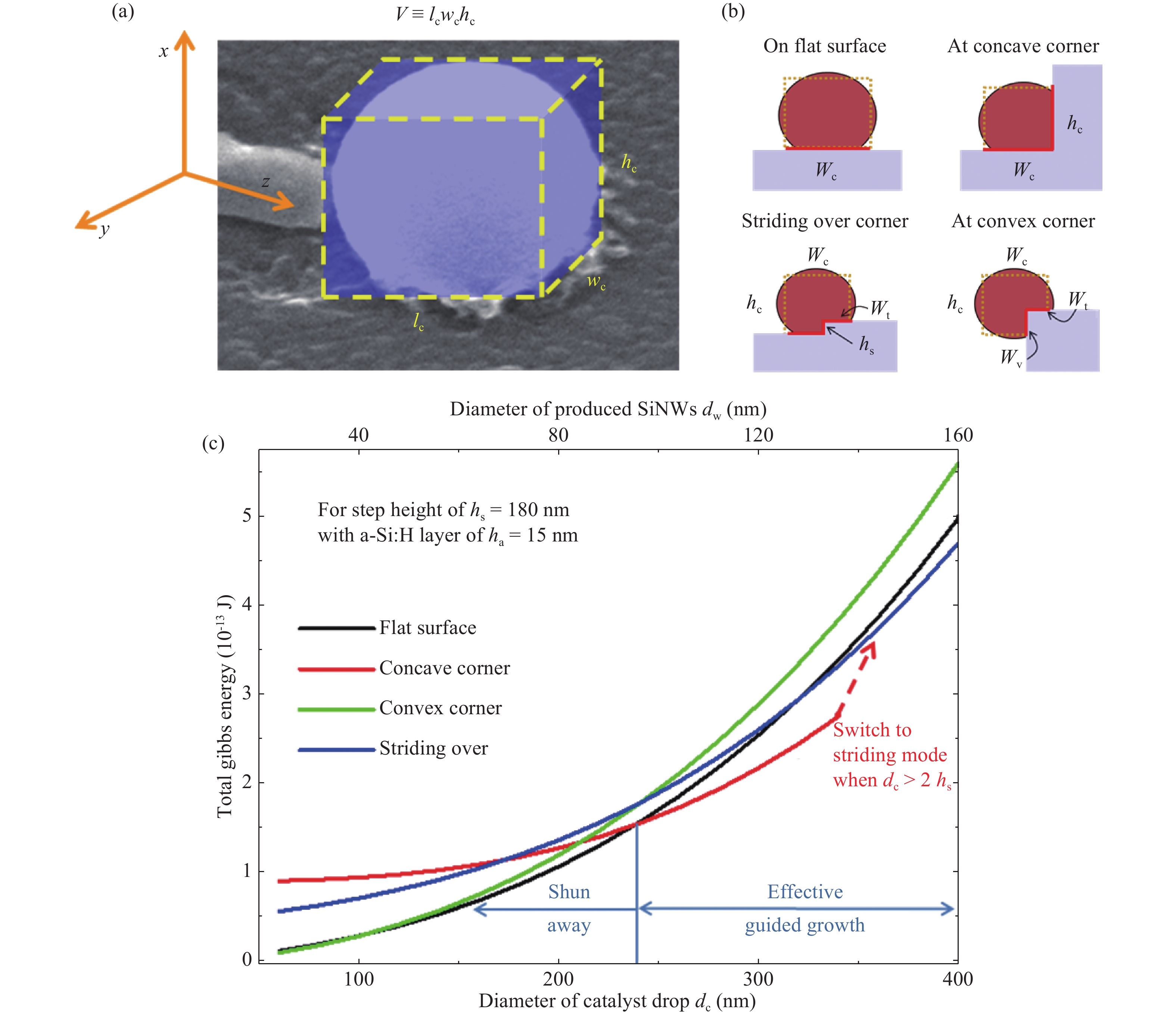

DownLoad: