| Citation: |

Run Tian, Chao Ma, Jingmin Wu, Zhiyu Guo, Xiang Yang, Zhongchao Fan. A review of manufacturing technologies for silicon carbide superjunction devices[J]. Journal of Semiconductors, 2021, 42(6): 061801. doi: 10.1088/1674-4926/42/6/061801

****

R Tian, C Ma, J M Wu, Z Y Guo, X Yang, Z C Fan, A review of manufacturing technologies for silicon carbide superjunction devices[J]. J. Semicond., 2021, 42(6): 061801. doi: 10.1088/1674-4926/42/6/061801.

|

A review of manufacturing technologies for silicon carbide superjunction devices

DOI: 10.1088/1674-4926/42/6/061801

More Information

-

Abstract

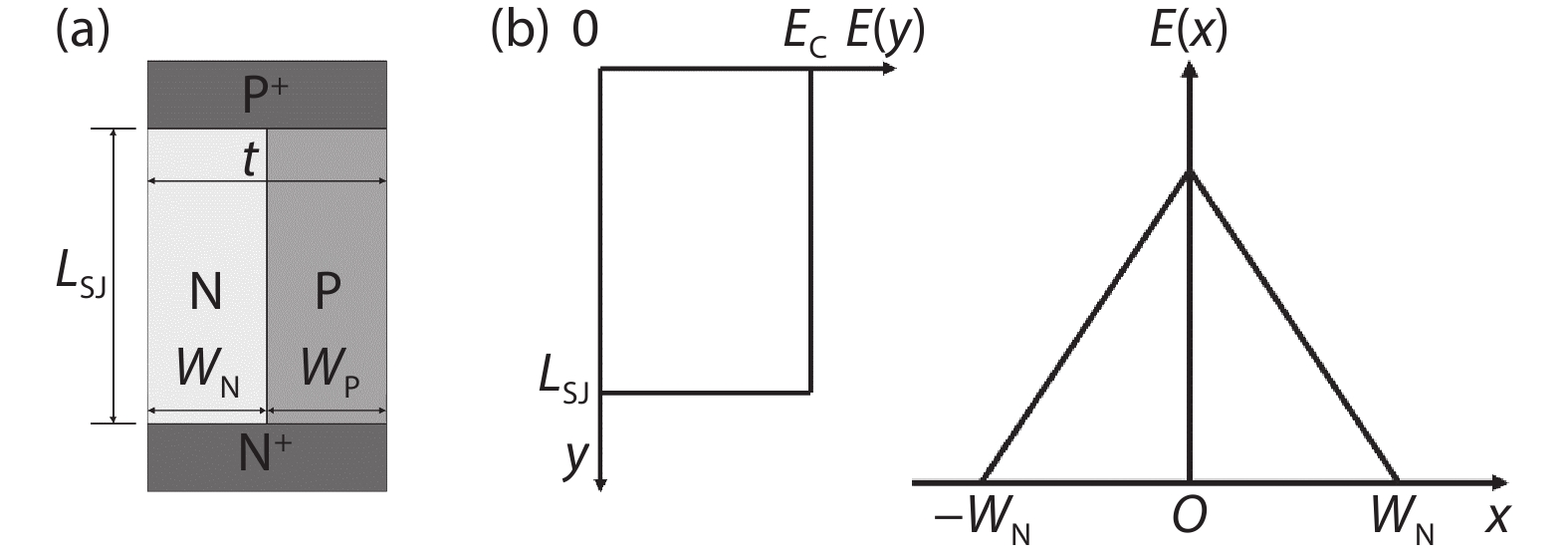

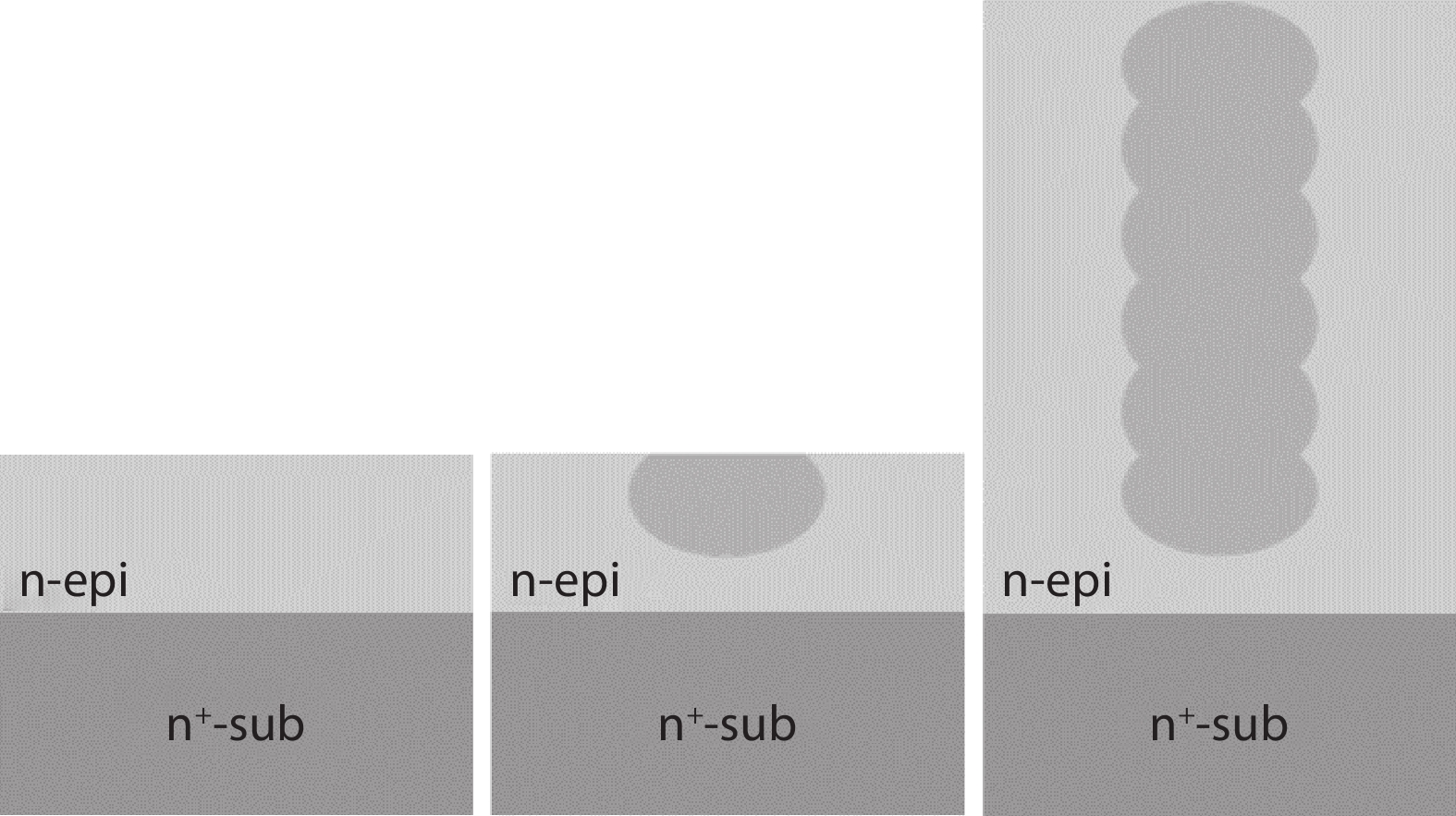

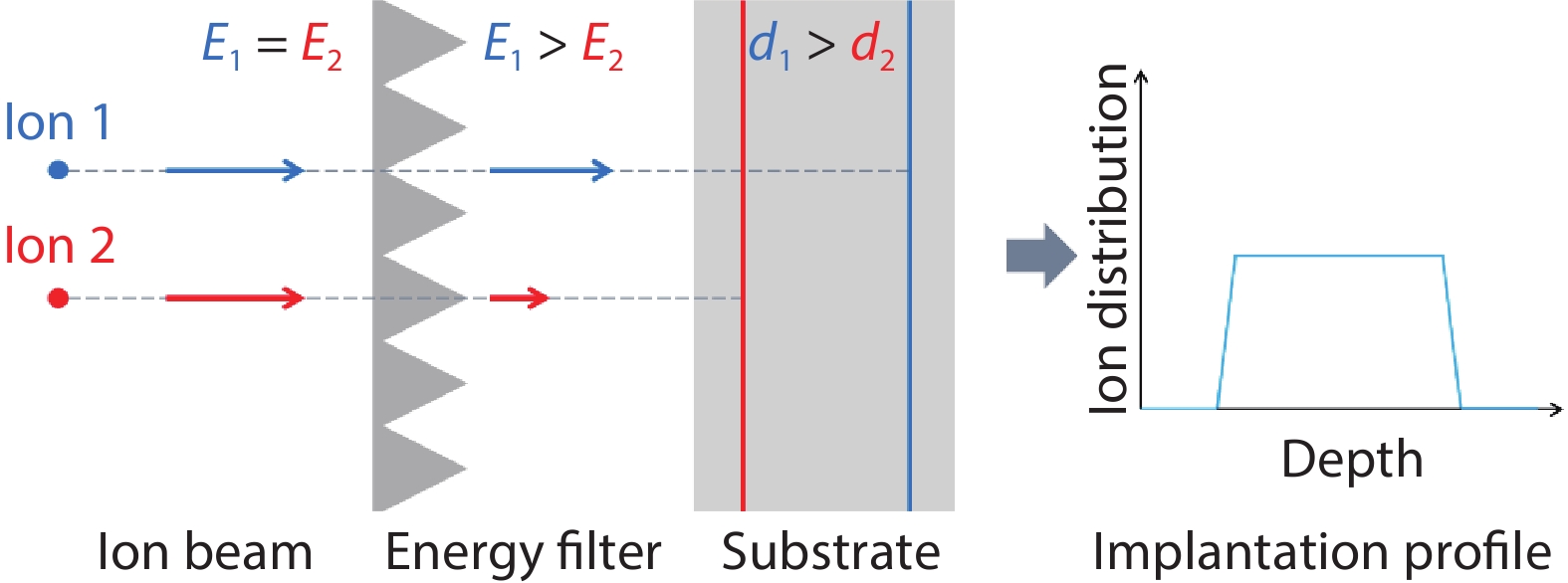

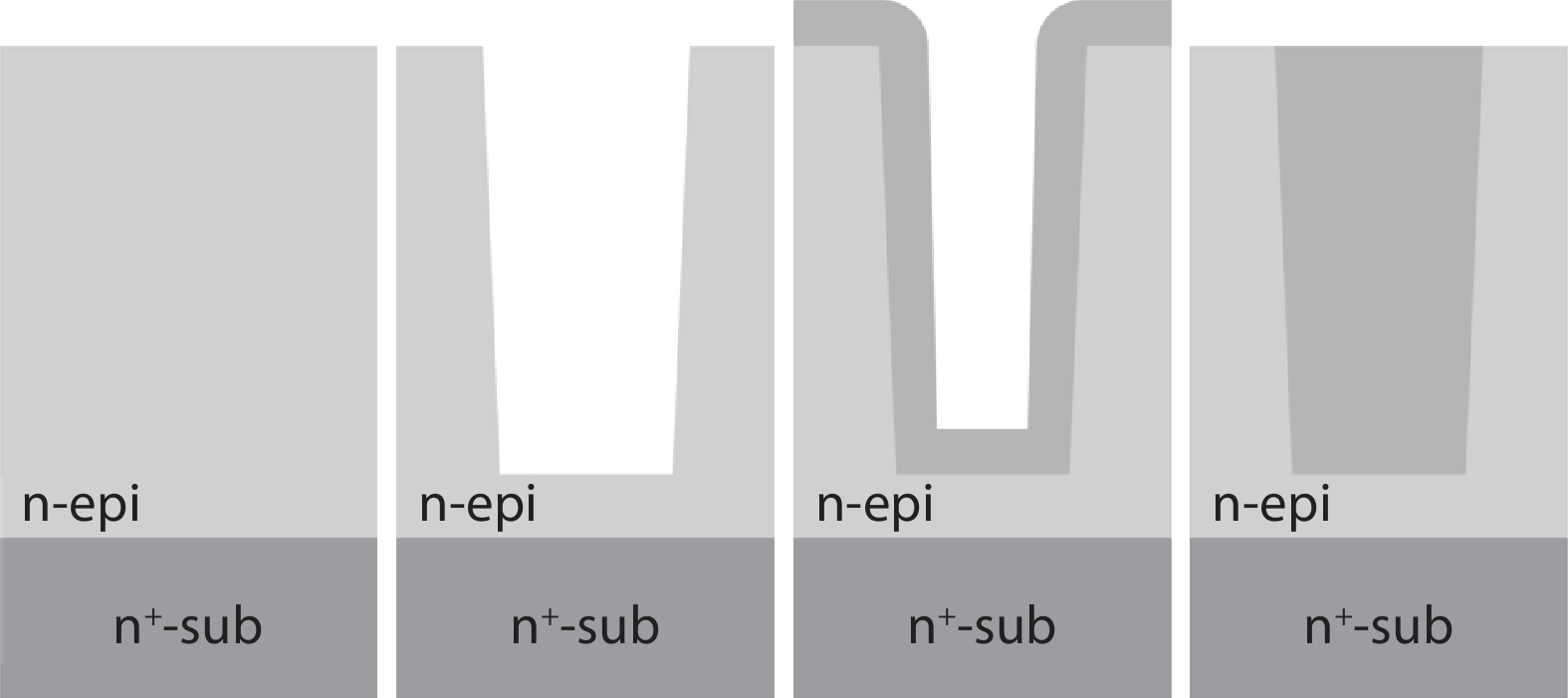

Superjunction technology is believed to reach the optimal specific on-resistance and breakdown voltage trade-off. It has become a mainstream technology in silicon high-voltage metal oxide semiconductor field effect transistor devices. Numerous efforts have been conducted to employ the same concept in silicon carbide devices. These works are summarized here. -

References

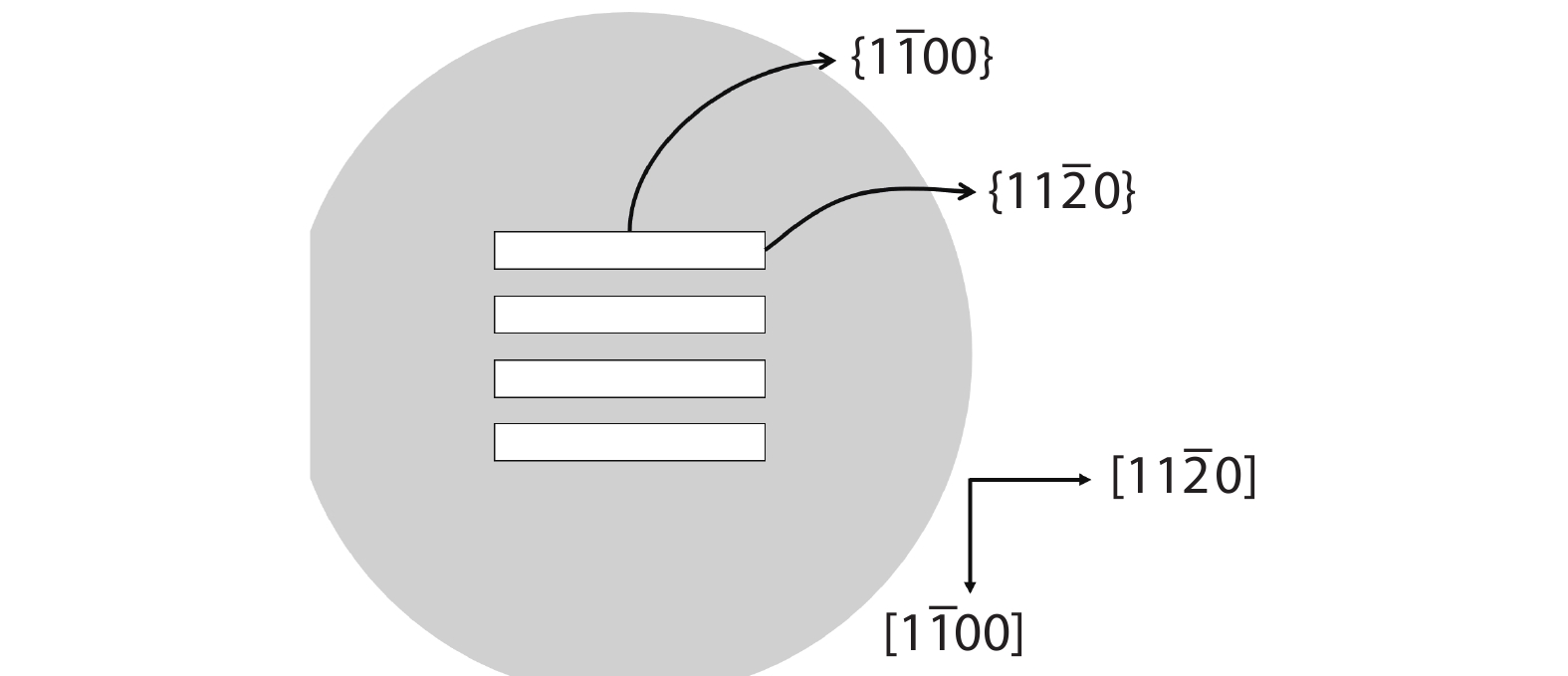

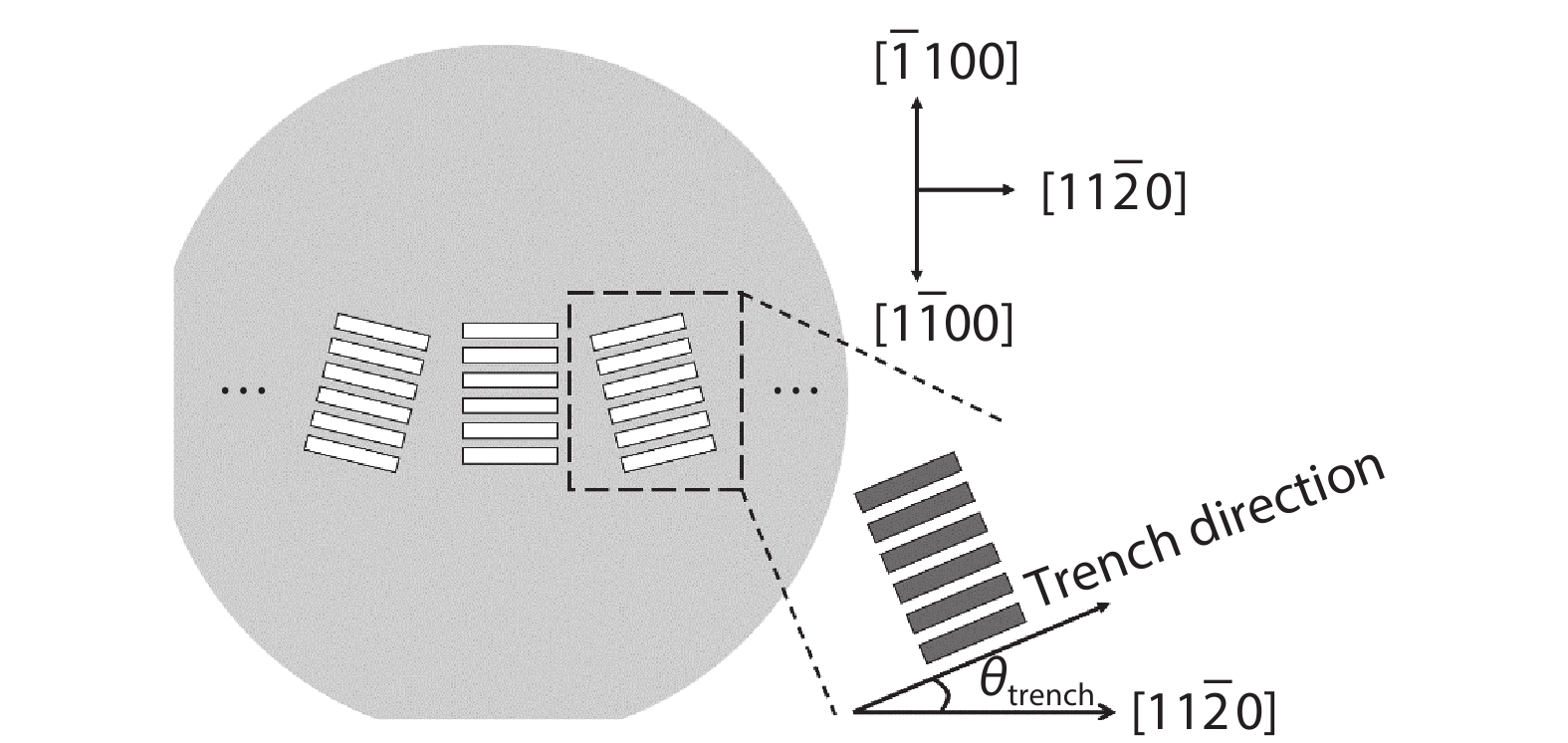

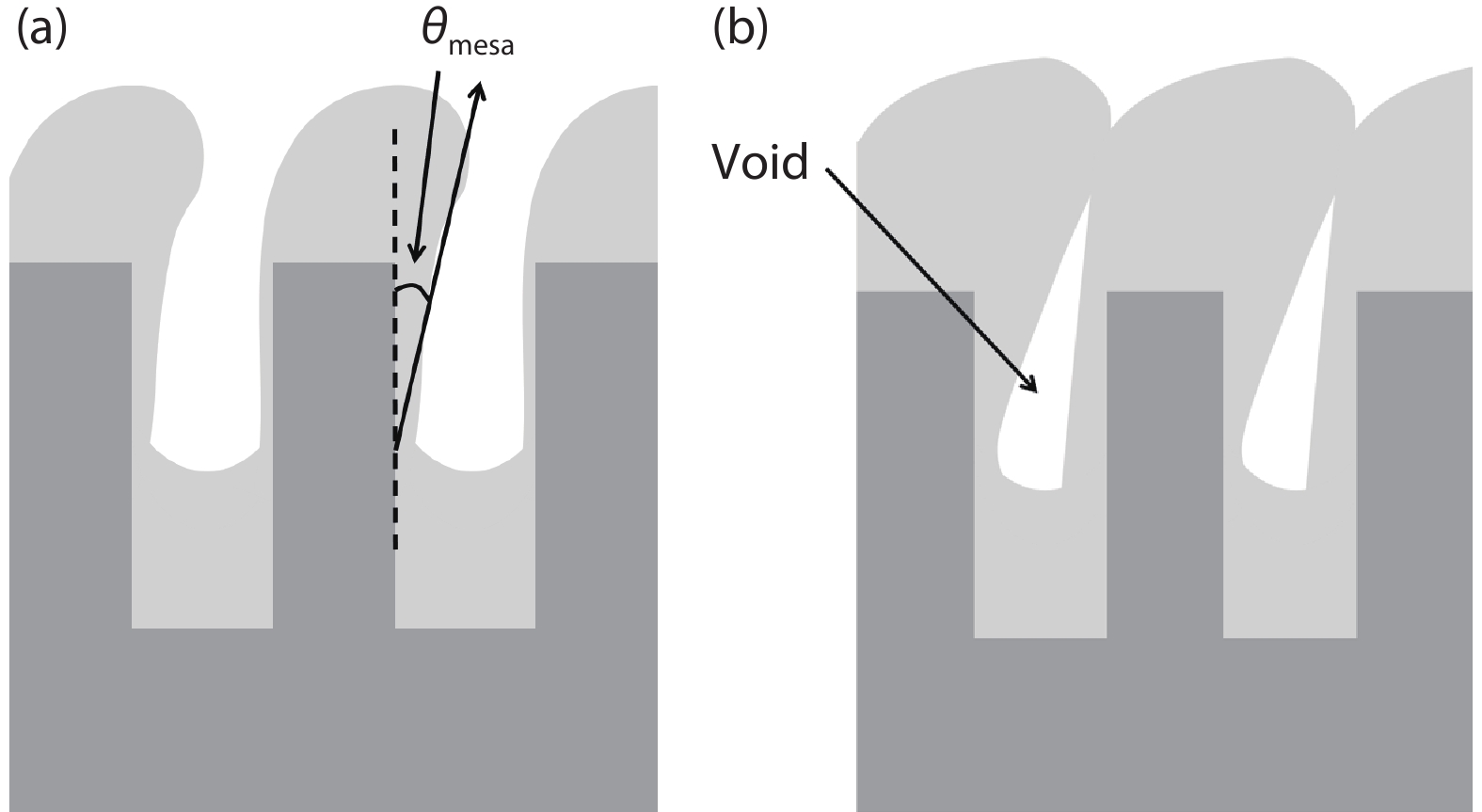

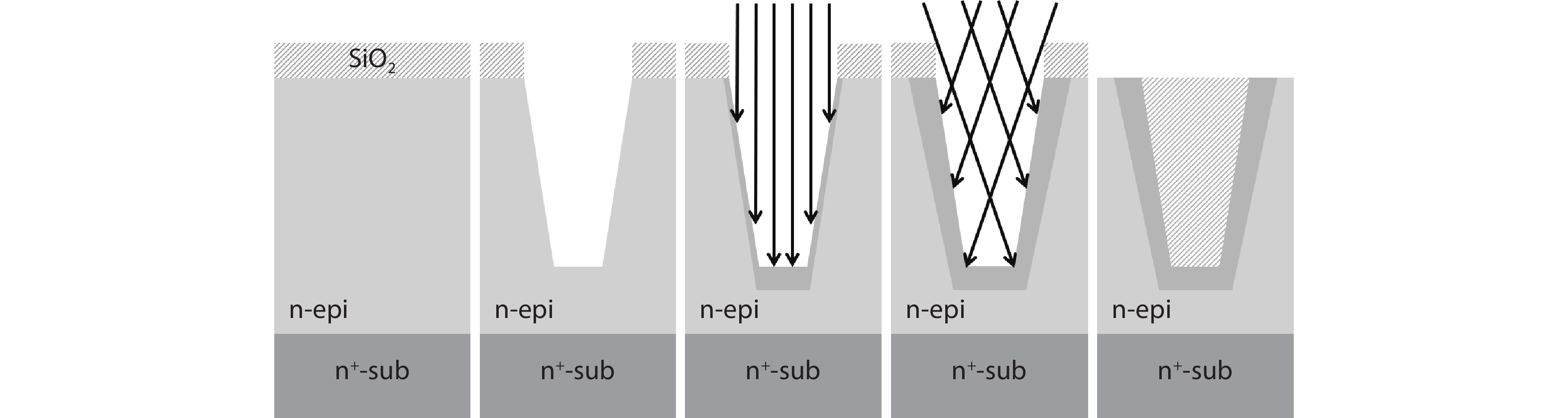

[1] Baliga B J. Trends in power semiconductor devices. IEEE Trans Electron Devices, 1996, 43(10), 1717 doi: 10.1109/16.536818[2] Huang A Q. Power semiconductor devices for smart grid and renewable energy systems. J Proc IEEE, 2017, 105(11), 2019 doi: 10.1109/JPROC.2017.2687701[3] Baliga B J. Fundamentals of power semiconductor devices. New York: Springer Verlag, 2008[4] Kimoto T, Cooper J A. Fundamentals of silicon carbide technology. Singapore: Wiley, 2014[5] Tsuchida H, Kamata I, Jikimoto T, et al. Epitaxial growth of thick 4H-SiC layers in a vertical radiant-heating reactor. J Cryst Growth, 2002, 237–239, 1206 doi: 10.1557/PROC-640-H2.12[6] Onishi Y, Iwamoto S, Sato T, et al. 24 mΩ·cm2 680 V silicon superjunction MOSFET. International Symposium on Power Semiconductor Devices and ICs, 2002, 241[7] Saito W, Omura I, Aida S, et al. A 20 mΩ·cm2 600 V-class Superjunction MOSFET. International Symposium on Power Semiconductor Devices and ICs, 2004, 459[8] Rub M, Bar M, Deboy G, et al. 550 V superjunction 3.9 Ω·mm2 transistor formed by 25 MeV masked boron implantation. International Symposium on Power Semiconductor Devices and ICs, 2004, 455[9] Yamauchi S, Urakami Y, Tuji N, et al. Defect-less trench filling of epitaxial Si growth by H2 annealing. International Symposium on Power Semiconductor Devices and ICs, 2002, 133[10] Iwamoto S, Takahashi K, Kuribayashi H, et al. Above 500 V class Superjunction MOSFETs fabricated by deep trench etching and epitaxial growth. International Symposium on Power Semiconductor Devices and ICs, 2005, 31[11] Sakakibara J, Noda Y, Shibata T, et al. 600 V-class super junction MOSFET with high aspect ratio P/N columns structure. International Symposium on Power Semiconductor Devices and ICs, 2008, 299[12] Udrea F, Deboy G, Fujihira T. Superjunction power devices, history, development, and future prospects. IEEE Trans Electron Devices, 2017, 64(3), 713 doi: 10.1109/TED.2017.2658344[13] Kobayashi Y, Kyogoku S, Morimoto T, et al. High-temperature performance of 1.2 kV-class SiC super junction MOSFET. International Symposium on Power Semiconductor Devices and ICs, 2019, 31[14] Kosugi R, Sakuma Y, Kojima K, et al. First experimental demonstration of SiC super-junction (SJ) structure by multi-epitaxial growth method. International Symposium on Power Semiconductor Devices and ICs, 2014, 346[15] Rueb M. Addressing production of SiC super-junction MOSFETs. J Compd Semicond, 2019, 25(3), 38[16] Ishibashi N, Fukada K, Bandoh A, et al. High-quality 100/150 mm p-type 4H-SiC epitaxial wafer for high-voltage bipolar devices. Mater Sci Forum, 2017, 897, 55 doi: 10.4028/www.scientific.net/MSF.897.55[17] Ding R X, Yang Y T, Han R. Microtrenching effect of SiC ICP etching in SF6/O2 plasma. J Semicond, 2009, 30(1), 016001 doi: 10.1088/1674-4926/30/1/016001[18] Han C, Zhang Y, Song Q, et al. An improved ICP etching for mesa-terminated 4H-SiC P –i –N diodes. IEEE Trans Electron Devices, 2015, 62(4), 1223 doi: 10.1109/TED.2015.2403615[19] Beheim G M, Evans L J. Control of trenching and surface roughness in deep reactive ion etched 4H and 6H SiC. MRS Proc, 2006, 911, 0911 doi: 10.1557/PROC-0911-B10-15[20] Kimoto T, Yamamoto T, Chen Z Y, et al. 4H-SiC (11-20) epitaxial growth. Mater Sci Forum, 2000, 338–342, 189 doi: 10.4028/www.scientific.net/MSF.338-342.189[21] Takeuchi Y, Kataoka M, Kimoto T, et al. SiC migration enhanced embedded epitaxial (ME3) growth technology. Mater Sci Forum, 2006, 527–529, 251 doi: 10.4028/www.scientific.net/MSF.527-529.251[22] Kimoto T, Matsunami H. Surface diffusion lengths of adatoms on 6H-SiC{0001} faces in chemical vapor deposition of SiC. J Appl Phys, 1995, 78(5), 3132 doi: 10.1063/1.359999[23] Ji S, Kojima K, Kosugi R, et al. Influence of growth pressure on filling 4H-SiC trenches by CVD method. Jpn J Appl Phys, 2016, 55(1S), 01AC04 doi: 10.7567/JJAP.55.01AC04[24] Ji S, Kojima K, Kosugi R, et al. Filling 4H-SiC trench towards selective epitaxial growth by adding HCl to CVD process. Appl Phys Express, 2015, 8(6), 065502 doi: 10.7567/APEX.8.065502[25] Kosugi R, Ji S, Mochizuki K, et al. Strong impact of slight trench direction misalignment from [11-20] on deep trench filling epitaxy for SiC super-junction devices. Jpn J Appl Phys, 2017, 56(4S), 04CR05 doi: 10.7567/JJAP.56.04CR05[26] Kosugi R, Sakuma Y, Kojima K, et al. Development of SiC super-junction (SJ) device by deep trench-filling epitaxial growth. Mater Sci Forum, 2013, 740–742, 785 doi: 10.4028/www.scientific.net/MSF.740-742.785[27] Kojima K, Nagata A, Ito S, et al. Filling of deep trench by epitaxial SiC growth. Mater Sci Forum, 2013, 742, 793 doi: 10.4028/www.scientific.net/MSF.740-742.793[28] Zhong X, Wang B, Sheng K. Design and experimental demonstration of 1.35 kV SiC super junction Schottky diode. International Symposium on Power Semiconductor Devices and ICs, 2016, 231 -

Proportional views

DownLoad:

DownLoad: