| Citation: |

Chaowei Si, Yingchun Fu, Guowei Han, Yongmei Zhao, Jin Ning, Zhenyu Wei, Fuhua Yang. A new DRIE cut-off material in SOG MEMS process[J]. Journal of Semiconductors, 2023, 44(4): 044101. doi: 10.1088/1674-4926/44/4/044101

****

C W Si, Y C Fu, G W Han, Y M Zhao, J Ning, Z Y Wei, F H Yang. A new DRIE cut-off material in SOG MEMS process[J]. J. Semicond, 2023, 44(4): 044101. doi: 10.1088/1674-4926/44/4/044101

|

-

Abstract

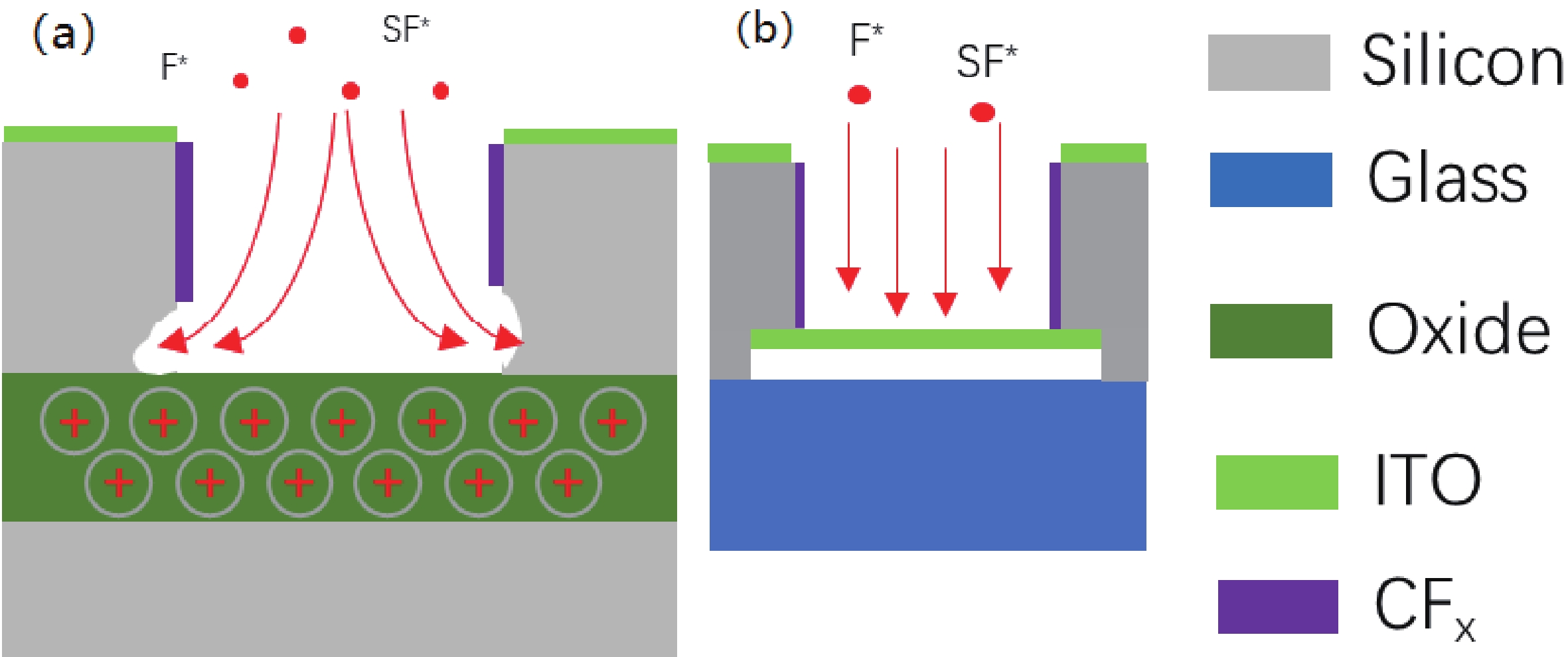

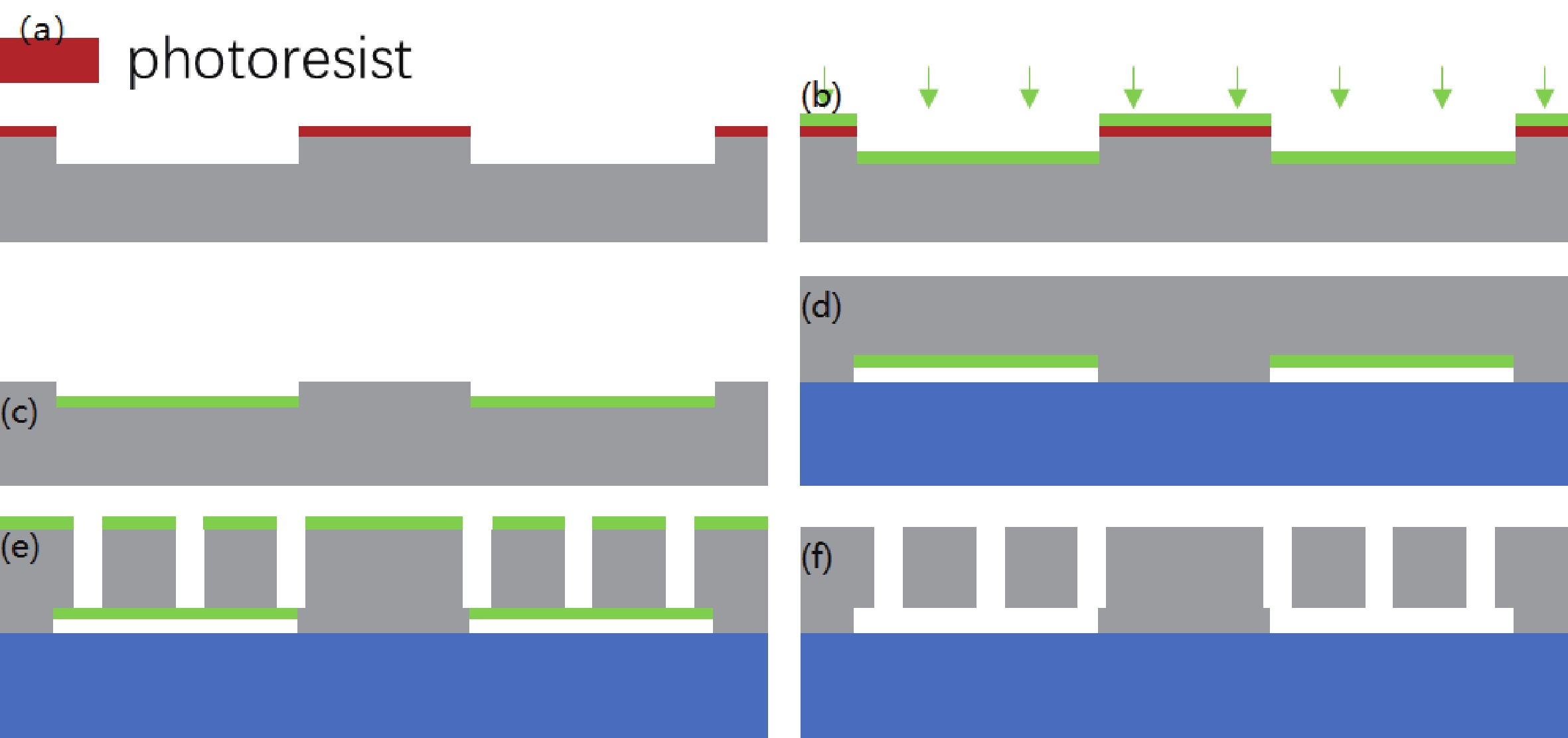

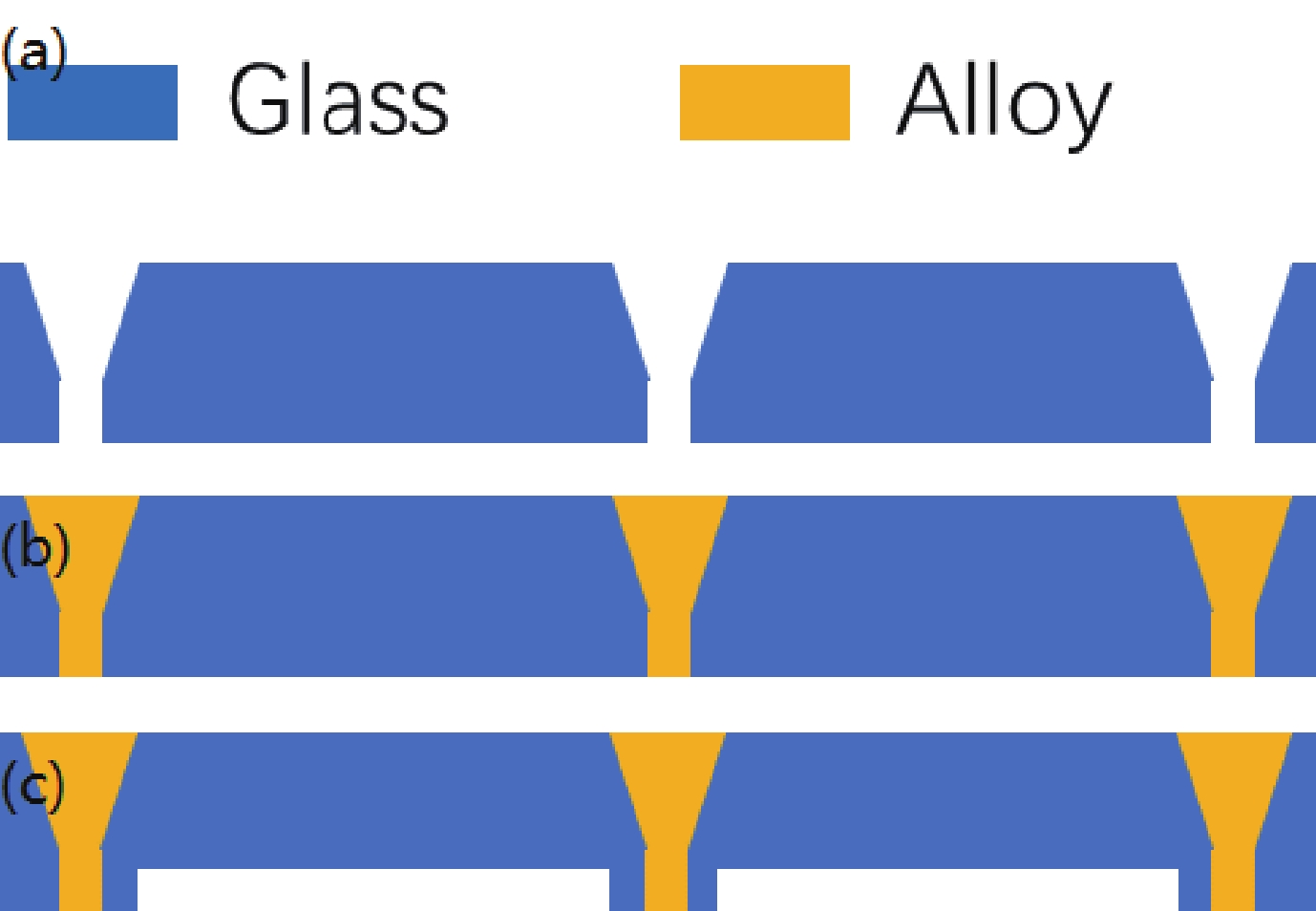

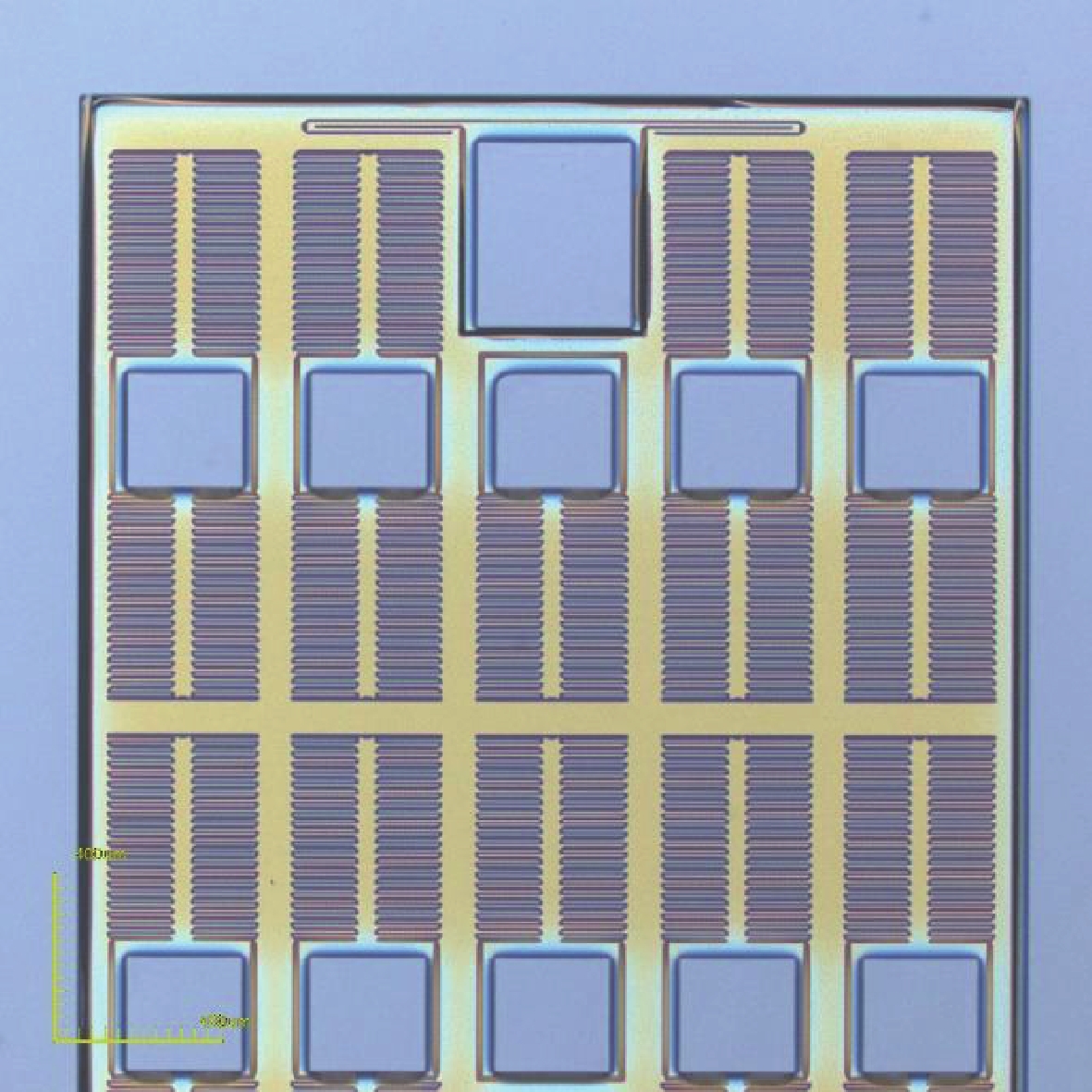

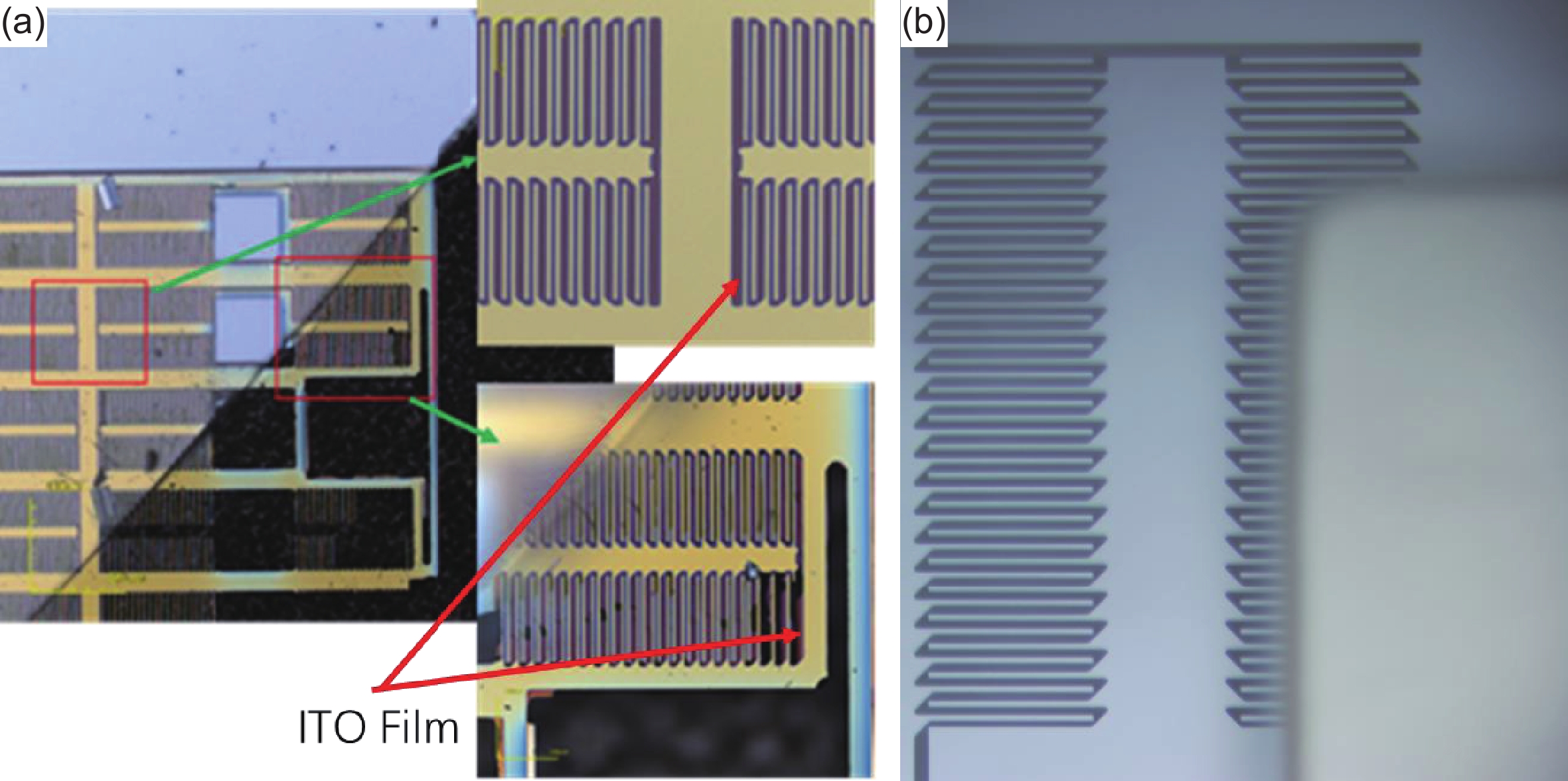

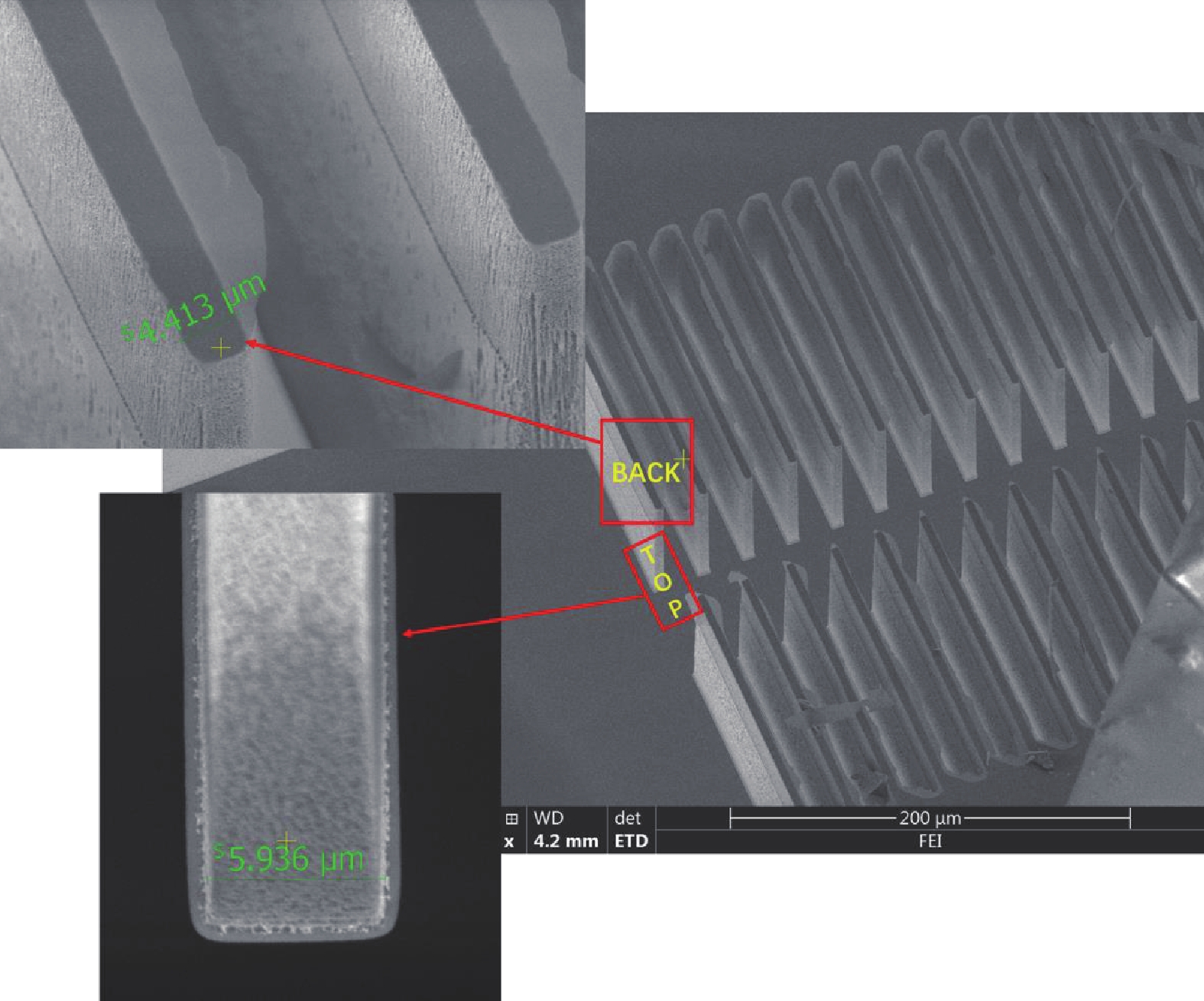

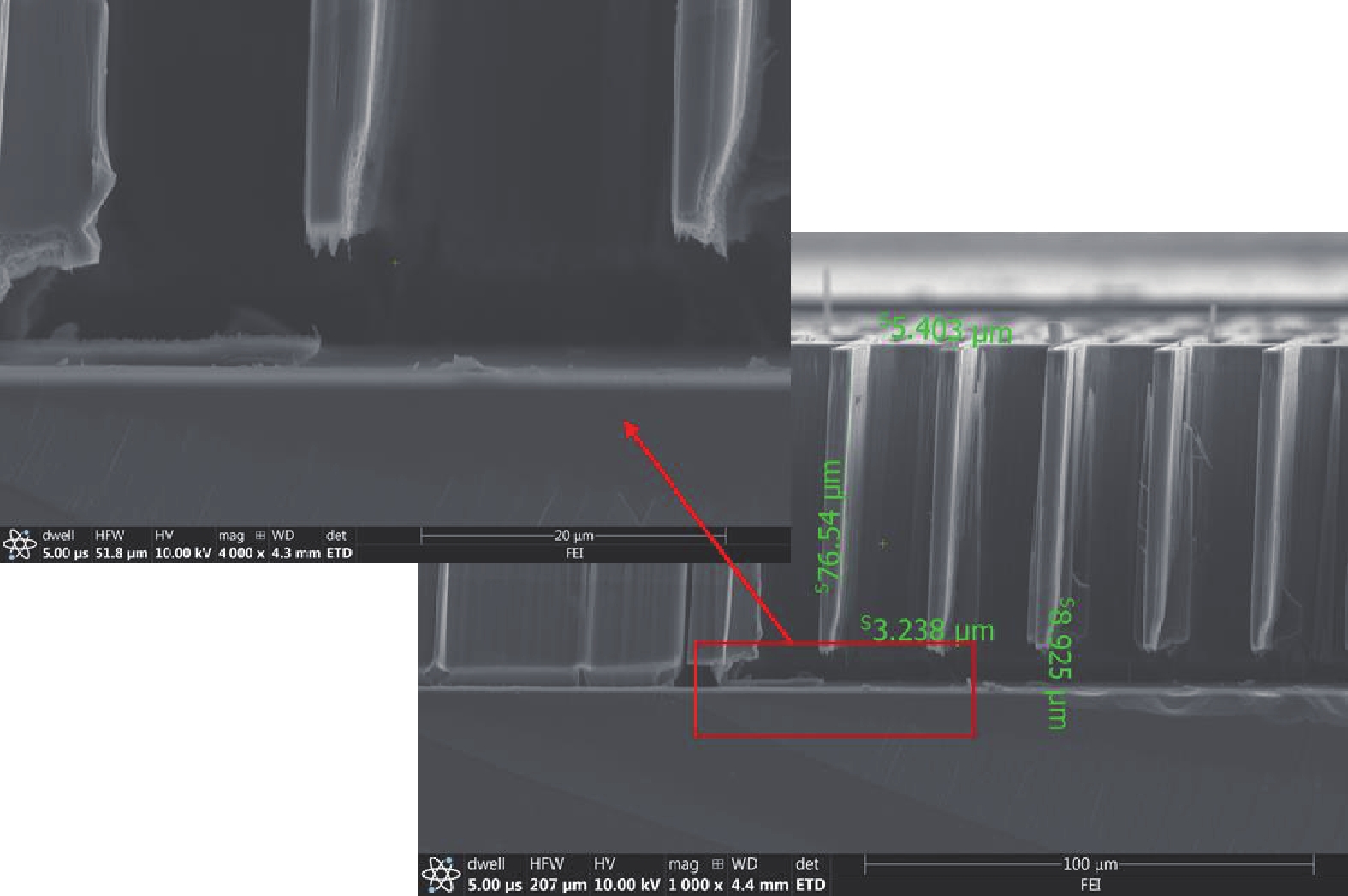

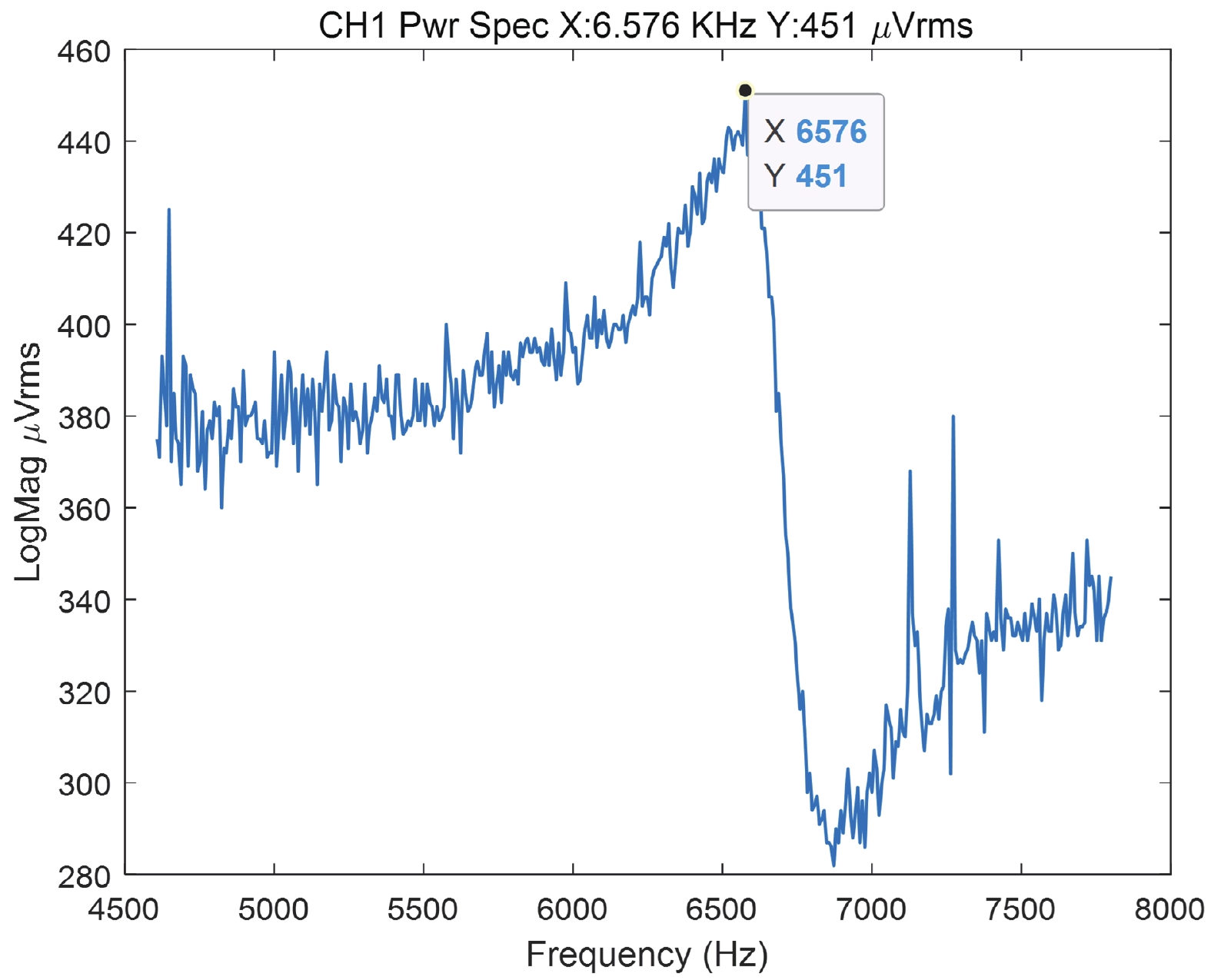

The silicon on glasses process is a common preparation method of micro-electro-mechanical system inertial devices, which can realize the processing of thick silicon structures. This paper proposes that indium tin oxides (ITO) film can serve as a deep silicon etching cut-off layer because ITO is less damaged under the attack of fluoride ions. ITO has good electrical conductivity and can absorb fluoride ions for silicon etching and reduce the reflection of fluoride ions, thus reducing the foot effect. The removal and release of ITO use an acidic solution, which does not damage the silicon structure. Therefore, the selection of the sacrificial layer has an excellent effect in maintaining the shape of the MEMS structure. This method is used in the preparation of MEMS accelerometers with a structure thickness of 100 μm and a feature size of 4 μm. The over-etching of the bottom of the silicon structure caused by the foot effect is negligible. The difference between the simulated value and the designed value of the device characteristic frequency is less than 5%. This indicates that ITO is an excellent deep silicon etch stopper material.-

Keywords:

- SOG process,

- DRIE cut-off layer,

- ITO film,

- foot effect

-

References

[1] Acar C. High-performance 6-Axis MEMS inertial sensor based on through-silicon via technology. 2016 IEEE International Symposium on Inertial Sensors and Systems, 2016, 62 doi: 10.1109/ISISS.2016.7435545[2] Tjulkins F, Nguyen A T T, Hoivik N, et al. 3-axis MEMS accelerometer-based implantable heart monitoring system with novel fixation method. 2013 IEEE 63rd Electronic Components and Technology Conference, 2013, 510 doi: 10.1109/ECTC.2013.6575620[3] Johnson B, Christ K, Endean D, et al. Tuning fork MEMS gyroscope for precision northfinding. 2015 DGON Inertial Sensors and Systems Symposium, 2015, 1[4] Kuisma H. Glass isolated TSVs for MEMS. Proceedings of the 5th Electronics System-integration Technology Conference, 2014, 1 doi: 10.1109/ESTC.2014.6962718[5] Taheri-Tehrani P, Defoort M, Chen Y, et al. Epitaxially-encapsulated quad mass resonator with shaped comb fingers for frequency tuning. 2017 IEEE 30th International Conference on Micro Electro Mechanical Systems, 2017, 1111 doi: 10.1109/MEMSYS.2017.7863608[6] Rödjegård H, Johansson C, Enoksson P, et al. A monolithic three-axis SOI-accelerometer with uniform sensitivity. Sens Actuat A, 2005, 123/124, 50 doi: 10.1016/j.sna.2005.02.032[7] Yang Y, Ng E J, Ahn C H, et al. Mechanical coupling of dual breathe-mode ring resonator. 2013 Transducers Eurosensors XXVII: The 17th International Conference on Solid-State Sensors, Actuators and Microsystems, 2013, 502 doi: 10.1109/Transducers.2013.6626813[8] Senkal D, Askari S, Ahamed M J, et al. 100K Q-factor toroidal ring gyroscope implemented in wafer-level epitaxial silicon encapsulation process. 2014 IEEE 27th International Conference on Micro Electro Mechanical Systems, 2014, 24 doi: 10.1109/MEMSYS.2014.6765564[9] Kim J, Park S, Kwak D, et al. Robust SOI process without footing and its application to ultra high-performance microgyroscopes. Sens Actuat A, 2004, 114, 236 doi: 10.1016/j.sna.2004.01.022[10] Seok S, Lee B, Kim J, et al. A new compensation method for the footing effect in MEMS fabrication. J Micromech Microeng, 2005, 15, 1791 doi: 10.1088/0960-1317/15/10/001/meta[11] Ma Z, Wang Y, Shen Q, et al. Key processes of silicon-on-glass MEMS fabrication technology for gyroscope application sensors. Sensors, 2018, 18, 1240 doi: 10.3390/s18041240[12] Townsend K, Durston M. Rate sensor with quadrature rejection. USA Patent, US13698339, 2013[13] Li Y, Yang Z, Yan G. An improved method to remove anti-footing Al layer after DRIE. 2009 4th IEEE International Conference on Nano/Micro Engineered and Molecular Systems, 2009, 868 doi: 10.1109/NEMS.2009.5068712[14] Hu L, Xue Y, Shi F. Interfacial investigation and mechanical properties of glass-Al-glass anodic bonding process. J Micromech Microeng, 2017, 27, 105004 doi: 10.1088/1361-6439/aa83c7[15] Hu Y Q, Zhao Y P, Yu T X. Fractal pattern formation in anodic bonding of pyrex glass/Al/Si. Int J Nonlinear Sci Numerical Simul, 2008, 9, 315 doi: 10.1515/IJNSNS.2008.9.4.315[16] Zhang J, Huang Q A, Li W H. Simulations for surface evolvement and footing effect in ICP DRIE fabrications. J Phys: Conf Ser, 2006, 34, 522 doi: 10.1088/1742-6596/34/1/086[17] Nomura K, Okada A, Shoji S, et al. Application of I-structure though-glass interconnect filled with submicron gold particles to a hermetic sealing device. J Micromech Microeng, 2016, 26, 105018 doi: 10.1088/0960-1317/26/10/105018[18] Yang F, Han G, Yang J, et al. Research on wafer-level MEMS packaging with through-glass vias micromachines. Micromachines, 2018, 10, 15 doi: 10.3390/mi10010015[19] Gu J, Xia X, Zhang W, et al. A modified MEMS-casting based TSV filling method with universal nozzle piece that uses surface trenches as nozzles. 2018 19th International Conference on Electronic Packaging Technology, 2018, 536 doi: 10.1109/ICEPT.2018.8480697[20] Cai M, Si C, Han G, et al. Deep silicon etching of bonded wafer based on ITO mask. J Micronanoelectron Technol, 2020, 57, 11 -

Proportional views

DownLoad:

DownLoad:

Chaowei Si:got his Ph.D. degree in 2014 at Tsinghua University. Then he joined the Institute of Semiconductors, Chinese Academy of Sciences. His research focuses on MEMS inertial devices and RF devices

Chaowei Si:got his Ph.D. degree in 2014 at Tsinghua University. Then he joined the Institute of Semiconductors, Chinese Academy of Sciences. His research focuses on MEMS inertial devices and RF devices