| Citation: |

Guang Yang, Lingbo Xu, Can Cui, Xiaodong Pi, Deren Yang, Rong Wang. Anisotropic etching mechanisms of 4H-SiC: Experimental and first-principles insights[J]. Journal of Semiconductors, 2024, 45(1): 012502. doi: 10.1088/1674-4926/45/1/012502

****

G Yang, L B Xu, C Cui, X D Pi, D R Yang, R Wang. Anisotropic etching mechanisms of 4H-SiC: Experimental and first-principles insights[J]. J. Semicond, 2024, 45(1): 012502. doi: 10.1088/1674-4926/45/1/012502

|

Anisotropic etching mechanisms of 4H-SiC: Experimental and first-principles insights

DOI: 10.1088/1674-4926/45/1/012502

More Information

-

Abstract

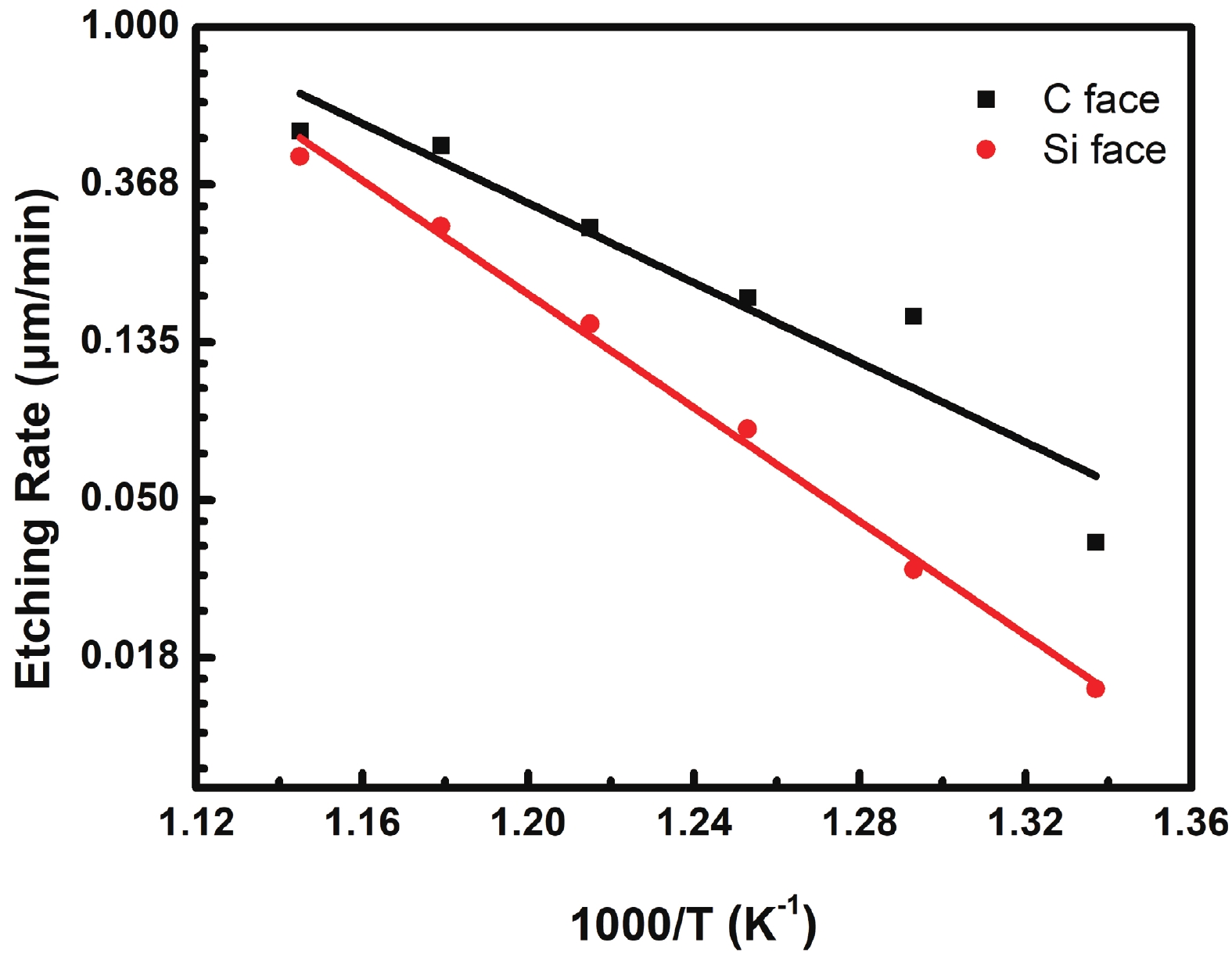

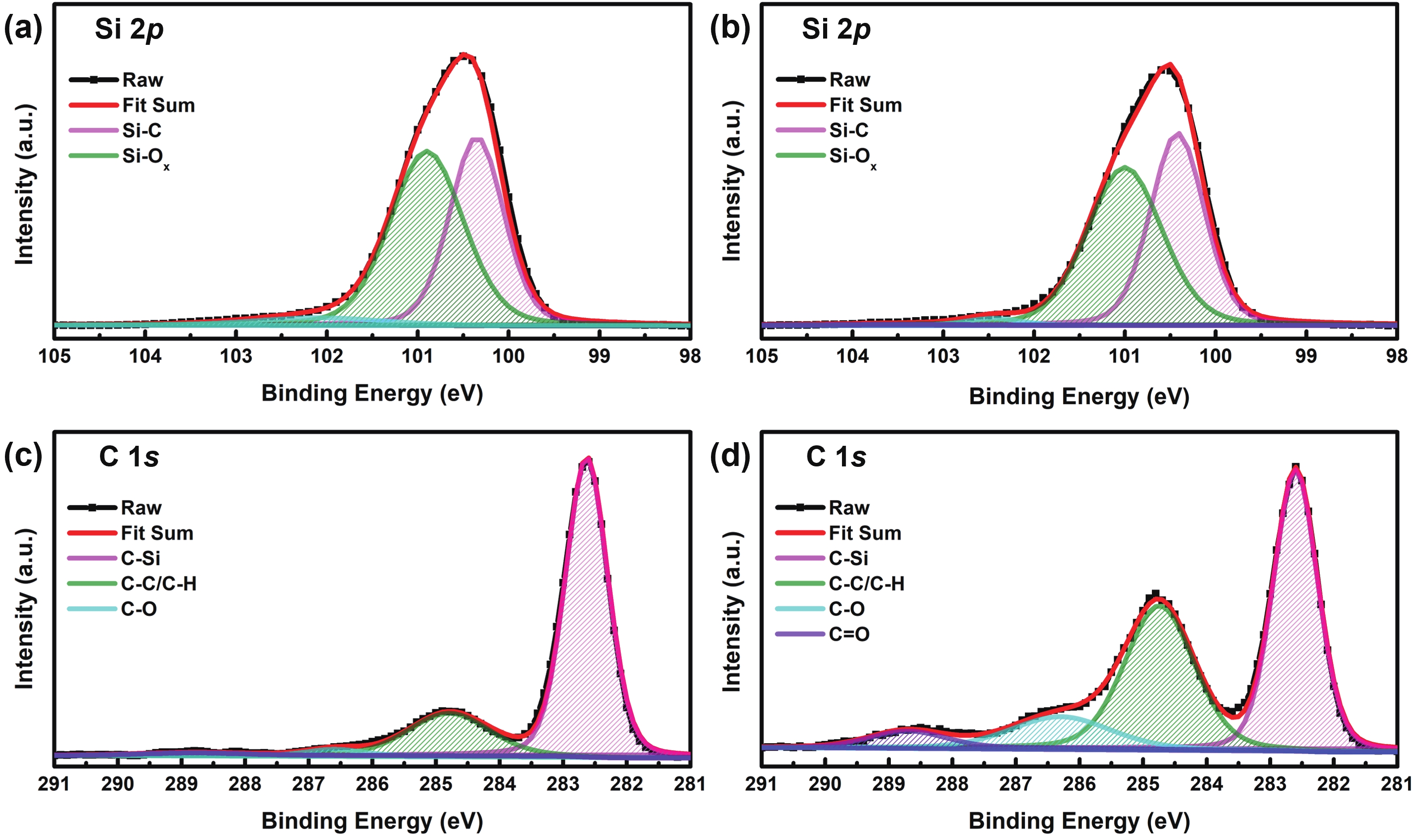

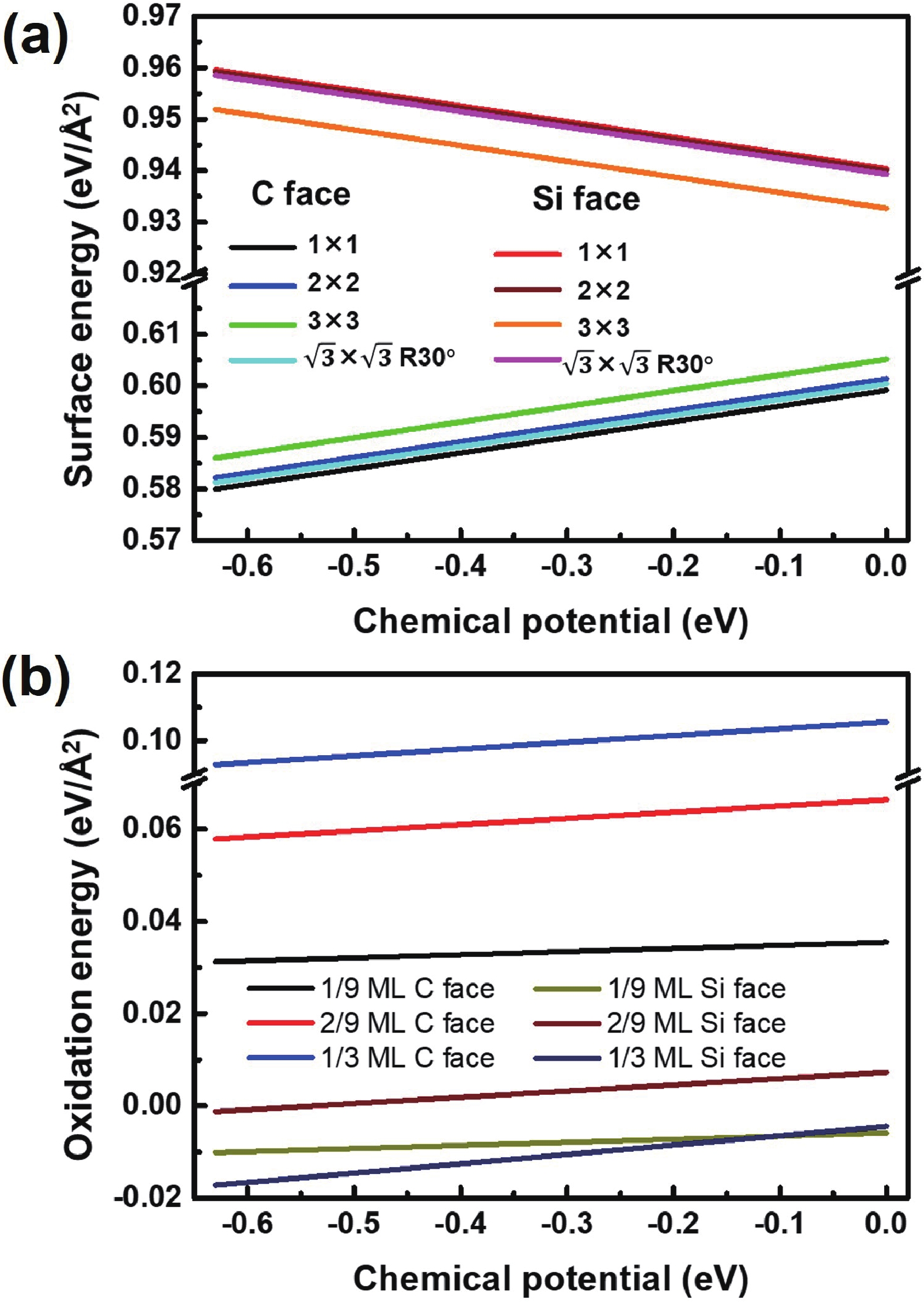

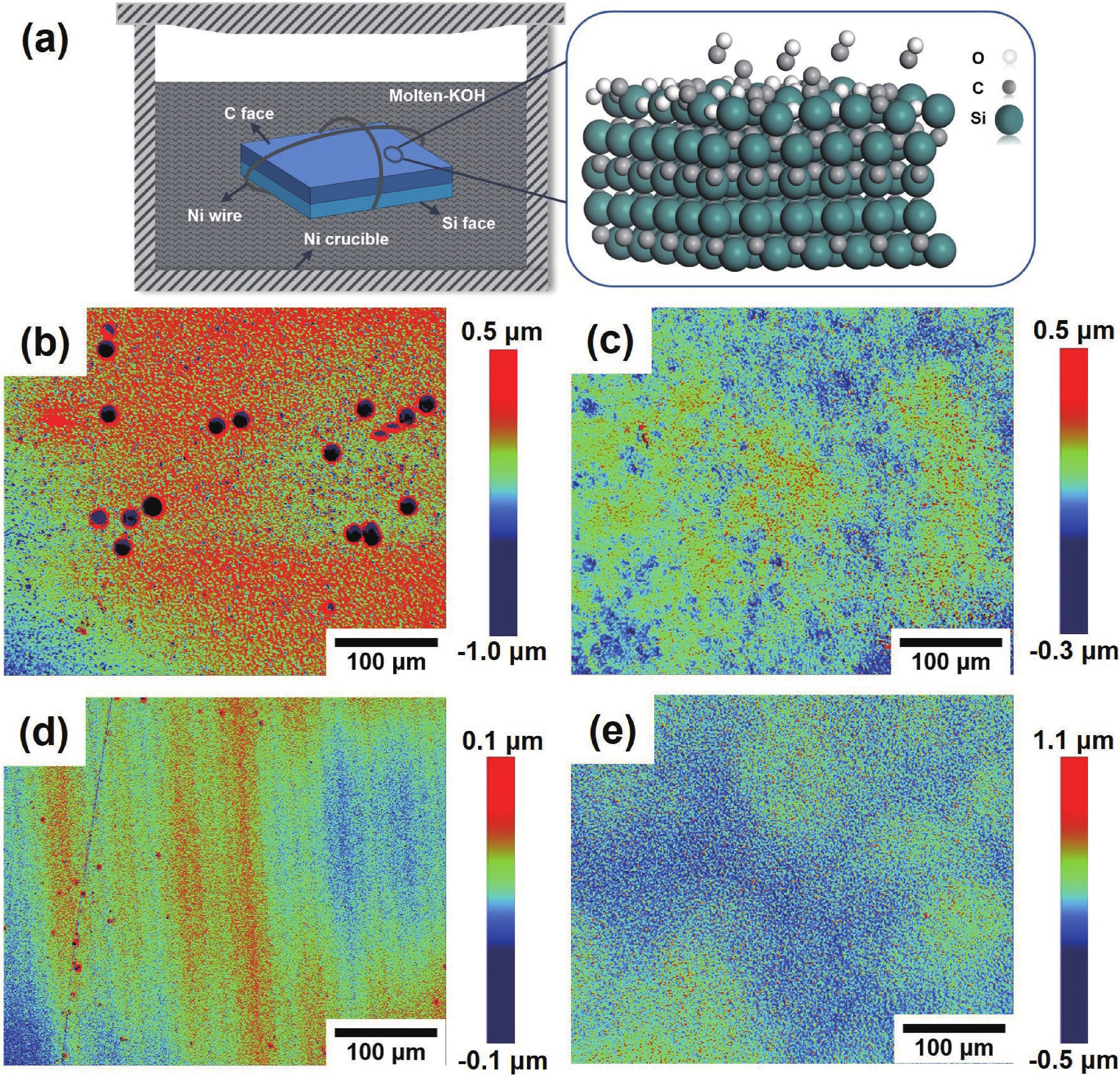

Molten-alkali etching has been widely used to reveal dislocations in 4H silicon carbide (4H-SiC), which has promoted the identification and statistics of dislocation density in 4H-SiC single crystals. However, the etching mechanism of 4H-SiC is limited misunderstood. In this letter, we reveal the anisotropic etching mechanism of the Si face and C face of 4H-SiC by combining molten-KOH etching, X-ray photoelectron spectroscopy (XPS) and first-principles investigations. The activation energies for the molten-KOH etching of the C face and Si face of 4H-SiC are calculated to be 25.09 and 35.75 kcal/mol, respectively. The molten-KOH etching rate of the C face is higher than the Si face. Combining XPS analysis and first-principles calculations, we find that the molten-KOH etching of 4H-SiC is proceeded by the cycling of the oxidation of 4H-SiC by the dissolved oxygen and the removal of oxides by molten KOH. The faster etching rate of the C face is caused by the fact that the oxides on the C face are unstable, and easier to be removed with molten alkali, rather than the C face being easier to be oxidized. -

References

[1] Itoh A, Matsunami H. Single crystal growth of SiC and electronic devices. Crit Rev Solid State Mater Sci, 1997, 22, 111 doi: 10.1080/10408439708241260[2] Li J J, Yang G, Liu X S, et al. Dislocations in 4H silicon carbide. J Phys D:Appl Phys, 2022, 55, 463001 doi: 10.1088/1361-6463/ac8a58[3] Yang S, Liang X W, Cui J W, et al. Impact of switching frequencies on the TID response of SiC power MOSFETs. J Semicond, 2021, 42, 082802 doi: 10.1088/1674-4926/42/8/082802[4] Lebedev A A, Oganesyan G A, Kozlovski V V, et al. Radiation defects in heterostructures 3C-SiC/4H-SiC. Crystals, 2019, 9, 115 doi: 10.3390/cryst9020115[5] Casady J B, Johnson R W. Status of silicon carbide (SiC) as a wide-bandgap semiconductor for high-temperature applications: A review. Solid State Electron, 1996, 39, 1409 doi: 10.1016/0038-1101(96)00045-7[6] Kimoto T, Watanabe H. Defect engineering in SiC technology for high-voltage power devices. Appl Phys Express, 2020, 13, 120101 doi: 10.35848/1882-0786/abc787[7] Grekov A, Zhang Q C, Fatima H, et al. Effect of crystallographic defects on the reverse performance of 4H–SiC JBS diodes. Microelectron Reliab, 2008, 48, 1664 doi: 10.1016/j.microrel.2008.05.001[8] Gao W D, Yang G, Qian Y X, et al. Dislocation-related leakage-current paths of 4H silicon carbide. Front Mater, 2023, 10, 1022878 doi: 10.3389/fmats.2023.1022878[9] Skowronski M. Degradation of hexagonal silicon carbide-based bipolar devices. 2005 International Semiconductor Device Research Symposium, 2006, 138 doi: 10.1063/1.2159578[10] Song H Z, Sudarshan T S. Basal plane dislocation conversion near the epilayer/substrate interface in epitaxial growth of 4° off-axis 4H–SiC. J Cryst Growth, 2013, 371, 94 doi: 10.1016/j.jcrysgro.2013.02.011[11] Yang G, Luo H, Li J J, et al. Discrimination of dislocations in 4H-SiC by inclination angles of molten-alkali etched pits. J Semicond, 2022, 43, 122801 doi: 10.1088/1674-4926/43/12/122801[12] Luo H, Li J J, Yang G, et al. Electronic and optical properties of threading dislocations in n-type 4H-SiC. ACS Appl Electron Mater, 2022, 4, 1678 doi: 10.1021/acsaelm.1c01330[13] Yu J Y, Yang X L, Peng Y, et al. Revelation of the dislocations in the C-face of 4H-SiC substrates using a microwave plasma etching treatment. CrystEngComm, 2021, 23, 353 doi: 10.1039/D0CE01489C[14] Yao Y Z, Ishikawa Y, Sato K, et al. Dislocation revelation from (0001) carbon-face of 4H-SiC by using vaporized KOH at high temperature. Appl Phys Express, 2012, 5, 075601 doi: 10.1143/APEX.5.075601[15] Syväjärvi M, Yakimova R, Janzén E. Anisotropic etching of SiC. J Electrochem Soc, 2000, 147, 3519 doi: 10.1149/1.1393930[16] Katsuno M, Ohtani N, Takahashi J, et al. Mechanism of molten KOH etching of SiC single crystals: Comparative study with thermal oxidation. Jpn J Appl Phys, 1999, 38, 4661 doi: 10.1143/JJAP.38.4661[17] Hatayama T, Shimizu T, Yano H, et al. Anisotropic etching of SiC in the mixed gas of chlorine and oxygen. Mater Sci Forum, 2008, 600/601/602/603, 659 doi: 10.4028/www.scientific.net/MSF.600-603.659[18] Segovia J J, Lozano-Martín D, Martín M C, et al. Updated determination of the molar gas constantRby acoustic measurements in argon at UVa-CEM. Metrologia, 2017, 54, 663 doi: 10.1088/1681-7575/aa7c47[19] Fukunaga K, Jun S D, Kimoto T. Anisotropic etching of single crystalline SiC using molten KOH for SiC bulk micromachining. Proceedings of SPIE - The International Society for Optical Engineering, San Jose, CA, US, 2006, 6109, 6109 doi: 10.1117/12.647116[20] Tengeler S, Kaiser B, Chaussende D, et al. (001) 3C SiC/Ni contact interface: in situ XPS observation of annealing induced Ni2Si formation and the resulting barrier height changes. Appl Surf Sci, 2017, 400, 6 doi: 10.1016/j.apsusc.2016.12.136[21] Wang B J, Yin J H, Chen D H, et al. Optical and surface properties of 3C–SiC thin epitaxial films grown at different temperatures on 4H–SiC substrates. Superlattices Microstruct, 2021, 156, 106960 doi: 10.1016/j.spmi.2021.106960[22] Wee A T S, Feng Z C, Hng H H, et al. Surface chemical states on 3C-SiC/Si epilayers. Appl Surf Sci, 1994, 81, 377 doi: 10.1016/0169-4332(94)90041-8[23] Cui Y X, Hu X B, Xie X J, et al. Threading dislocation classification for 4H-SiC substrates using the KOH etching method. CrystEngComm, 2018, 20, 978 doi: 10.1039/C7CE01855J[24] Kresse G, Furthmüller J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys Rev B Condens Matter, 1996, 54, 11169 doi: 10.1103/PhysRevB.54.11169[25] Kresse G, Furthmüller J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comput Mater Sci, 1996, 6, 15 doi: 10.1016/0927-0256(96)00008-0[26] Blöchl P E. Projector augmented-wave method. Phys Rev B Condens Matter, 1994, 50, 17953 doi: 10.1103/PhysRevB.50.17953[27] Perdew J P, Burke K, Ernzerhof M. Generalized gradient approximation made simple. Phys Rev Lett, 1996, 77, 3865 doi: 10.1103/PhysRevLett.77.3865[28] Heyd J, Scuseria G E, Ernzerhof M. Hybrid functionals based on a screened Coulomb potential. J Chem Phys, 2003, 118, 8207 doi: 10.1063/1.1564060[29] Zhang J Z, Zhang Y O, Tse K, et al. New approaches for calculating absolute surface energies of wurtzite (0001)/ $ (000\bar{1}) $: A study of ZnO and GaN. J Appl Phys, 2016, 119, 205302 doi: 10.1063/1.4952395[30] Zhang Y O, Zhang J Z, Tse K, et al. Pseudo-hydrogen passivation: A novel way to calculate absolute surface energy of zinc blende (111)/ $ (\bar{1}\bar{1}\bar{1}) $ surface. Sci Rep, 2016, 6, 20055 doi: 10.1038/srep20055[31] Li W B, Zhao J J, Zhu Q Z, et al. Insight into the initial oxidation of 4H-SiC from first-principles thermodynamics. Phys Rev B, 2013, 87, 085320 doi: 10.1103/PhysRevB.87.085320 -

Proportional views

Guang Yang is a master’s degree student of the School of Science, Zhejiang Sci-Tech University, class of 2020. His research focuses on dislocations in 4H-SiC.

Guang Yang is a master’s degree student of the School of Science, Zhejiang Sci-Tech University, class of 2020. His research focuses on dislocations in 4H-SiC. Can Cui received his PhD degree at Zhejiang University in 2006. He then carried out research at Tohoku University and National Institute for Materials Science. He is now a professor in Zhejiang Sci-Tech University. His research mainly focuses on crystal growth and optoelectronic devices.

Can Cui received his PhD degree at Zhejiang University in 2006. He then carried out research at Tohoku University and National Institute for Materials Science. He is now a professor in Zhejiang Sci-Tech University. His research mainly focuses on crystal growth and optoelectronic devices. Xiaodong Pi received his PhD degree at the University of Bath in 2004. He then carried out research at McMaster University and the University of Minnesota at Twin Cities. He joined Zhejiang University as an associate professor in 2008. He is now a professor in the State Key Laboratory of Silicon Materials, the School of Materials Science and Engineering and Zhejiang University-Hangzhou Global Scientific and Technological Innovation Center. His research mainly concerns group IV semiconductor materials and devices.

Xiaodong Pi received his PhD degree at the University of Bath in 2004. He then carried out research at McMaster University and the University of Minnesota at Twin Cities. He joined Zhejiang University as an associate professor in 2008. He is now a professor in the State Key Laboratory of Silicon Materials, the School of Materials Science and Engineering and Zhejiang University-Hangzhou Global Scientific and Technological Innovation Center. His research mainly concerns group IV semiconductor materials and devices. Deren Yang is an academician of the Chinese Academy of Science, presently of NingboTech University, director of the Faculty of Engineering at Zhejiang University and chief scientist of Zhejiang University-Hangzhou Global Scientific and Technological Innovation Center. He received his PhD in 1991, at Zhejiang University. In the 1990s, he worked in Japan, Germany, and Sweden for several years as a visiting researcher. He has been engaged in research on silicon materials for microelectronic devices, solar cells, and nanodevices.

Deren Yang is an academician of the Chinese Academy of Science, presently of NingboTech University, director of the Faculty of Engineering at Zhejiang University and chief scientist of Zhejiang University-Hangzhou Global Scientific and Technological Innovation Center. He received his PhD in 1991, at Zhejiang University. In the 1990s, he worked in Japan, Germany, and Sweden for several years as a visiting researcher. He has been engaged in research on silicon materials for microelectronic devices, solar cells, and nanodevices. Rong Wang received her PhD degree at Zhejiang University in 2014. She then carried out research at Taiyuan University of Technology and China Academy of Engineering Physics. She joined the Zhejiang University-Hangzhou Global Scientific and Technological Innovation Center in 2020. Her research mainly focuses on wide-bandgap semiconductor physics.

Rong Wang received her PhD degree at Zhejiang University in 2014. She then carried out research at Taiyuan University of Technology and China Academy of Engineering Physics. She joined the Zhejiang University-Hangzhou Global Scientific and Technological Innovation Center in 2020. Her research mainly focuses on wide-bandgap semiconductor physics.

DownLoad:

DownLoad: