| Citation: |

Huiqiao Liu, Jiakun Zhang, Jinjin Fu, Chao Li, Yang Fan, Kangzhe Cao. Functional nanolayers favor the stability of solid-electrolyte-interphase in rechargeable batteries[J]. Journal of Semiconductors, 2024, 45(2): 020201. doi: 10.1088/1674-4926/45/2/020201

****

H Q Liu, J K Zhang, J J Fu, C Li, Y Fan, K Z Cao. Functional nanolayers favor the stability of solid-electrolyte-interphase in rechargeable batteries[J]. J. Semicond, 2024, 45(2): 020201. doi: 10.1088/1674-4926/45/2/020201

|

Functional nanolayers favor the stability of solid-electrolyte-interphase in rechargeable batteries

DOI: 10.1088/1674-4926/45/2/020201

More Information

-

References

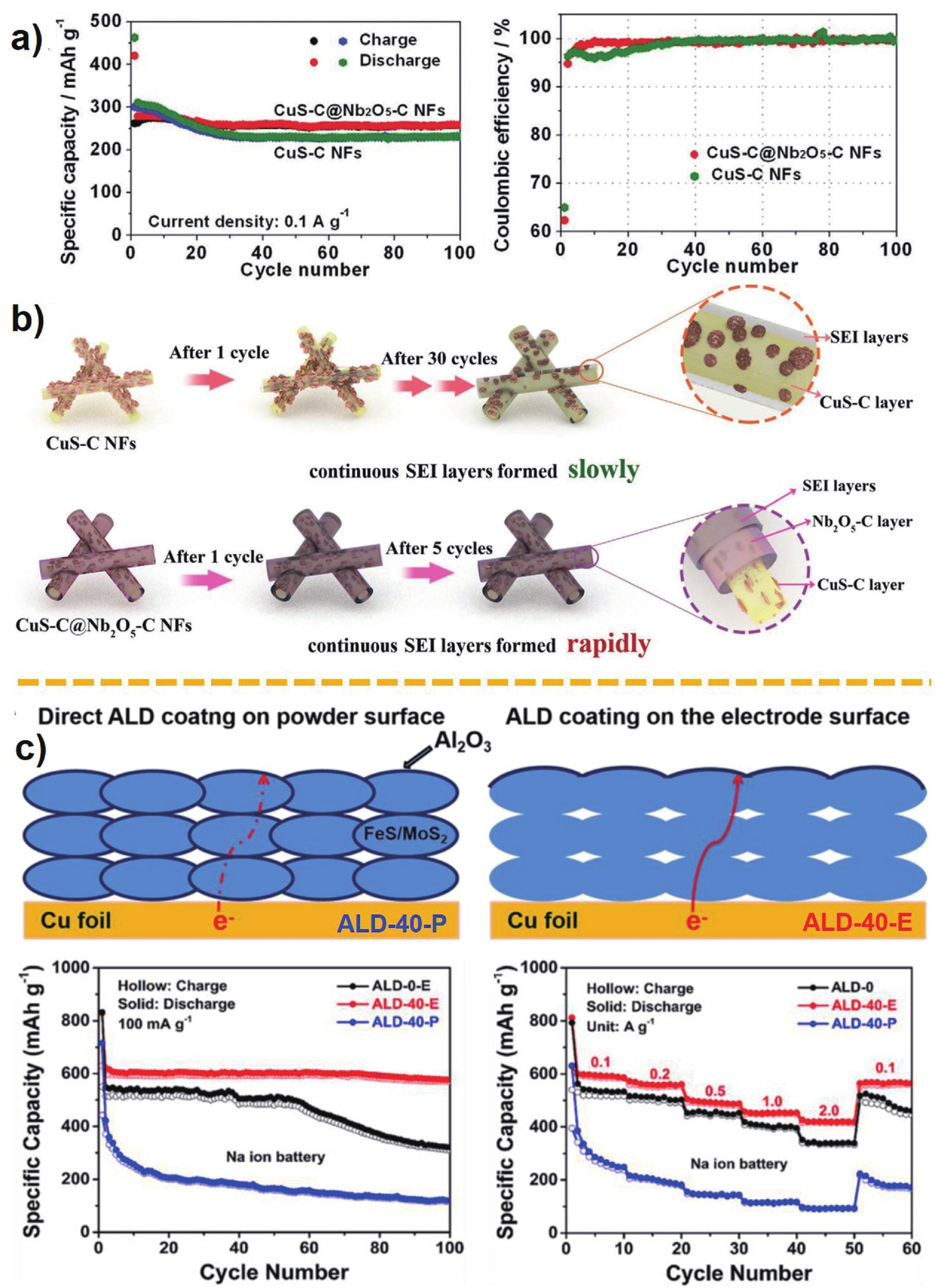

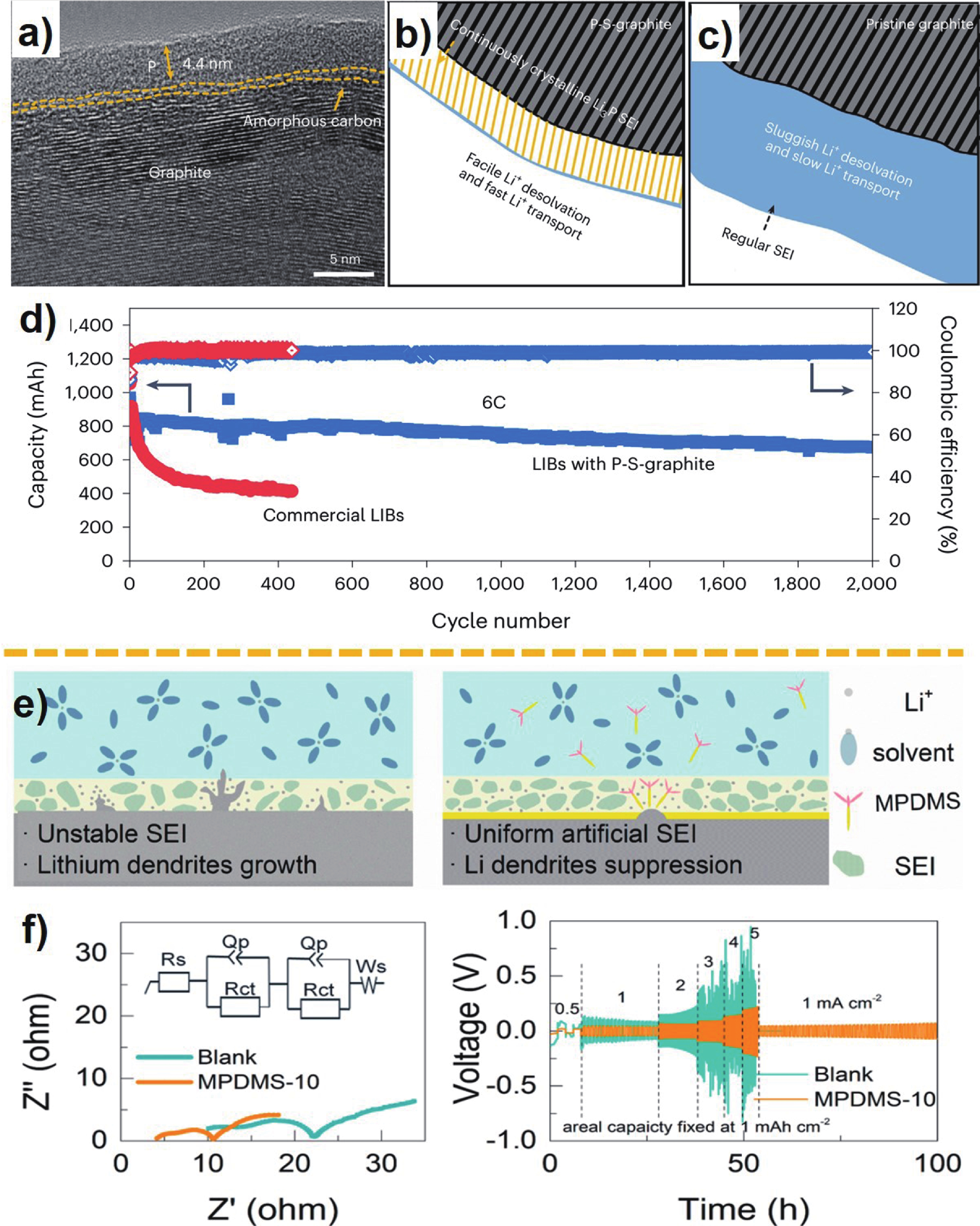

[1] Liu Y Y, Shi H D, Wu Z S. Recent status, key strategies and challenging perspectives of fast-charging graphite anodes for lithium-ion batteries. Energy Environ Sci, 2023, 16, 4834 doi: 10.1039/D3EE02213G[2] Chao X, Yan C Z, Zhao H P, et al. Micro-nano structural electrode architecture for high power energy storage. J Semicond, 2023, 44, 050201 doi: 10.1088/1674-4926/44/5/050201[3] Wang H W, Zhai D Y, Kang F Y. Solid electrolyte interphase (SEI) in potassium ion batteries. Energy Environ Sci, 2020, 13, 4583 doi: 10.1039/D0EE01638A[4] Xu Y B, Jia H, Gao P Y, et al. Direct in situ measurements of electrical properties of solid–electrolyte interphase on lithium metal anodes. Nat Energy, 2023, 8, 1345 doi: 10.1038/s41560-023-01361-1[5] Hou M J, Zhou Y J, Liang F, et al. Research progress of solid electrolyte interphase for sodium metal anodes. Chem Eng J, 2023, 475, 146227 doi: 10.1016/j.cej.2023.146227[6] Single F, Latz A, Horstmann B. Identifying the mechanism of continued growth of the solid-electrolyte interphase. ChemSusChem, 2018, 11, 1950 doi: 10.1002/cssc.201800077[7] Feng G X, Jia H, Shi Y P, et al. Imaging solid-electrolyte interphase dynamics using operando reflection interference microscopy. Nat Nanotechnol, 2023, 18, 780 doi: 10.1038/s41565-023-01316-3[8] Lodico J J, Mecklenburg M, Chan H L, et al. Operando spectral imaging of the lithium ion battery’s solid-electrolyte interphase. Sci Adv, 2023, 9, eadg5135 doi: 10.1126/sciadv.adg5135[9] Qian G Y, Li Y W, Chen H B, et al. Revealing the aging process of solid electrolyte interphase on SiO x anode. Nat Commun, 2023, 14, 6048 doi: 10.1038/s41467-023-41867-6[10] Chen Y, Wu W K, Gonzalez-Munoz S, et al. Nanoarchitecture factors of solid electrolyte interphase formation via 3D nano-rheology microscopy and surface force-distance spectroscopy. Nat Commun, 2023, 14, 1321 doi: 10.1038/s41467-023-37033-7[11] Cao C C, Zhong Y J, Shao Z P. Electrolyte engineering for safer lithium-ion batteries: A review. Chin J Chem, 2023, 41, 1119 doi: 10.1002/cjoc.202200588[12] Zheng J, Hu C, Nie L J, et al. Recent advances in potassium-ion batteries: From material design to electrolyte engineering. Adv Mater Technol, 2023, 8, 2201591 doi: 10.1002/admt.202201591[13] Yang Y, Yang W H, Yang H J, et al. Electrolyte design principles for low-temperature lithium-ion batteries. eScience, 2023, 3, 100170 doi: 10.1016/j.esci.2023.100170[14] Liu H Q, He Y N, Cao K Z, et al. Activating commercial Al pellets by replacing the passivation layer for high-performance half/full Li-ion batteries. Chem Eng J, 2022, 433, 133572 doi: 10.1016/j.cej.2021.133572[15] Liu H Q, He Y N, Zhang H, et al. Lowering the voltage-hysteresis of CuS anode for Li-ion batteries via constructing heterostructure. Chem Eng J, 2021, 425, 130548 doi: 10.1016/j.cej.2021.130548[16] Ye M H, Zhao W G, Li J H, et al. Integration of localized electric-field redistribution and interfacial tin nanocoating of lithium microparticles toward long-life lithium metal batteries. ACS Appl Mater Interfaces, 2021, 13, 650 doi: 10.1021/acsami.0c18831[17] Zhou J H, Ma K N, Lian X Y, et al. Eliminating graphite exfoliation with an artificial solid electrolyte interphase for stable lithium-ion batteries. Small, 2022, 18, e2107460 doi: 10.1002/smll.202107460[18] Tu S B, Zhang B, Zhang Y, et al. Fast-charging capability of graphite-based lithium-ion batteries enabled by Li3P-based crystalline solid–electrolyte interphase. Nat Energy, 2023, 8, 1365 doi: 10.1038/s41560-023-01387-5[19] He Y, Jiang L, Chen T W, et al. Progressive growth of the solid-electrolyte interphase towards the Si anode interior causes capacity fading. Nat Nanotechnol, 2021, 16, 1113 doi: 10.1038/s41565-021-00947-8[20] Wang H, Miao M R, Li H, et al. In situ-formed artificial solid electrolyte interphase for boosting the cycle stability of Si-based anodes for Li-ion batteries. ACS Appl Mater Interfaces, 2021, 13, 22505 doi: 10.1021/acsami.1c03902[21] Pan S Y, Han J W, Wang Y Q, et al. Integrating SEI into layered conductive polymer coatings for ultrastable silicon anodes. Adv Mater, 2022, 34, e2203617 doi: 10.1002/adma.202203617[22] Yu Z A, Cui Y, Bao Z N. Design principles of artificial solid electrolyte interphases for lithium-metal anodes. Cell Rep Phys Sci, 2020, 1, 100119 doi: 10.1016/j.xcrp.2020.100119[23] Chen A L, Shang N, Ouyang Y, et al. Electroactive polymeric nanofibrous composite to drive in situ construction of lithiophilic SEI for stable lithium metal anodes. eScience, 2022, 2, 192 doi: 10.1016/j.esci.2022.02.003[24] Li C, Liang Z Y, Li Z Z, et al. Self-assembly monolayer inspired stable artificial solid electrolyte interphase design for next-generation lithium metal batteries. Nano Lett, 2023, 23, 4014 doi: 10.1021/acs.nanolett.3c00783[25] Ding H B, Wang J, Zhou J, et al. Building electrode skins for ultra-stable potassium metal batteries. Nat Commun, 2023, 14, 2305 doi: 10.1038/s41467-023-38065-9[26] Wang B, Yuan F, Li W, et al. Rational formation of solid electrolyte interface for high-rate potassium ion batteries. Nano Energy, 2020, 75, 104979 doi: 10.1016/j.nanoen.2020.104979[27] Zhou H, Cui C, Cheng R F, et al. MXene enables stable solid-electrolyte interphase for Si@MXene composite with enhanced cycling stability. ChemElectroChem, 2021, 8, 3089 doi: 10.1002/celc.202100878[28] Hou L, Cui R W, Xiong S S, et al. A multilayered sturdy shell protects silicon nanoparticle Si@void C@TiO2 as an advanced lithium ion battery anode. Phys Chem Chem Phys, 2021, 23, 3934 doi: 10.1039/D0CP05434H[29] Liu H Q, He Y N, Cao K Z, et al. Stimulating the reversibility of Sb2S3 anode for high-performance potassium-ion batteries. Small, 2021, 17, 2008133 doi: 10.1002/smll.202008133[30] Chen C, Hu Q L, Xue H Y, et al. Ultrafast and ultrastable FeSe2 embedded in nitrogen-doped carbon nanofibers anode for sodium-ion half/full batteries. Nanotechnology, 2024, 35, 055404 doi: 10.1088/1361-6528/ad06d7[31] Wei Z N, Wang L N, Chen P L, et al. Constructing layered vanadium disulfide nanosheets via wet-chemistry: A superior anode material for sodium ion batteries. J Xinyang Norm Univ Nat Sci Ed, 2020, 33, 612 doi: 10.3969/j.issn.1003-0972.2020.04.016[32] Xu J, Dong Z, Li Y J, et al. Freestanding wide layer spacing MoS2@WS2@CC ternary structure with fast diffusion path for a highly activity zinc-ion batteries. Appl Surf Sci, 2023, 613, 156146 doi: 10.1016/j.apsusc.2022.156146[33] Yang G W, Yan C Z, Hu P, et al. Synthesis of CoSe2 reinforced nitrogen-doped carbon composites as advanced anodes for potassium-ion batteries. Inorg Chem Front, 2022, 9, 3719 doi: 10.1039/D2QI00848C[34] Cao K Z, Zheng R T, Wang S D, et al. Boosting coulombic efficiency of conversion-reaction anodes for potassium-ion batteries via confinement effect. Adv Funct Mater, 2020, 30, 2007712 doi: 10.1002/adfm.202007712[35] Han B, Chen S Q, Guo C F, et al. Atomic layer deposition of alumina onto yolk-shell FeS/MoS2 as universal anodes for Li/Na/K-Ion batteries. Electrochim Acta, 2022, 402, 139471 doi: 10.1016/j.electacta.2021.139471 -

Proportional views

Huiqiao Liu received her Ph.D. degree from the College of Chemistry at Nankai University in 2017. Currently, she is an Associate Professor at School of Chemistry and Chemical Engineering, Xinyang Normal University. Her current research focuses on applying electrochemical surface-enhanced Raman spectroscopy to study the interface in rechargeable battery and biochemical sensing.

Huiqiao Liu received her Ph.D. degree from the College of Chemistry at Nankai University in 2017. Currently, she is an Associate Professor at School of Chemistry and Chemical Engineering, Xinyang Normal University. Her current research focuses on applying electrochemical surface-enhanced Raman spectroscopy to study the interface in rechargeable battery and biochemical sensing. Jiakun Zhang is currently studying for a master’s degree at Xinyang Normal University. His research interests focus on the flexible wearable EC-SERS substrate for biosensors and electrochemical analysis.

Jiakun Zhang is currently studying for a master’s degree at Xinyang Normal University. His research interests focus on the flexible wearable EC-SERS substrate for biosensors and electrochemical analysis. Kangzhe Cao is an Associated Professor at Xinyang Normal Universityand the director of Xinyang Key Laboratory of Low-Carbon EnergyMaterials. He received his Ph.D. degree (2017) from the College of Chemistry at Nankai University, and then joined Xinyang Normal University. His research interests include materials design for electrochemical energy storage (Li/Na/K-ion batteries, capacitors) and electrochemical Raman analysis.

Kangzhe Cao is an Associated Professor at Xinyang Normal Universityand the director of Xinyang Key Laboratory of Low-Carbon EnergyMaterials. He received his Ph.D. degree (2017) from the College of Chemistry at Nankai University, and then joined Xinyang Normal University. His research interests include materials design for electrochemical energy storage (Li/Na/K-ion batteries, capacitors) and electrochemical Raman analysis.

DownLoad:

DownLoad: