| Citation: |

Daryoosh Vashaee. Thermoelectric infrared detectors: Design, fabrication, and performance assessment[J]. Journal of Semiconductors, 2024, 45(12): 122304. doi: 10.1088/1674-4926/24060011

****

D Vashaee, Thermoelectric infrared detectors: Design, fabrication, and performance assessment[J]. J. Semicond., 2024, 45(12), 122304 doi: 10.1088/1674-4926/24060011

|

Thermoelectric infrared detectors: Design, fabrication, and performance assessment

DOI: 10.1088/1674-4926/24060011

More Information

-

Abstract

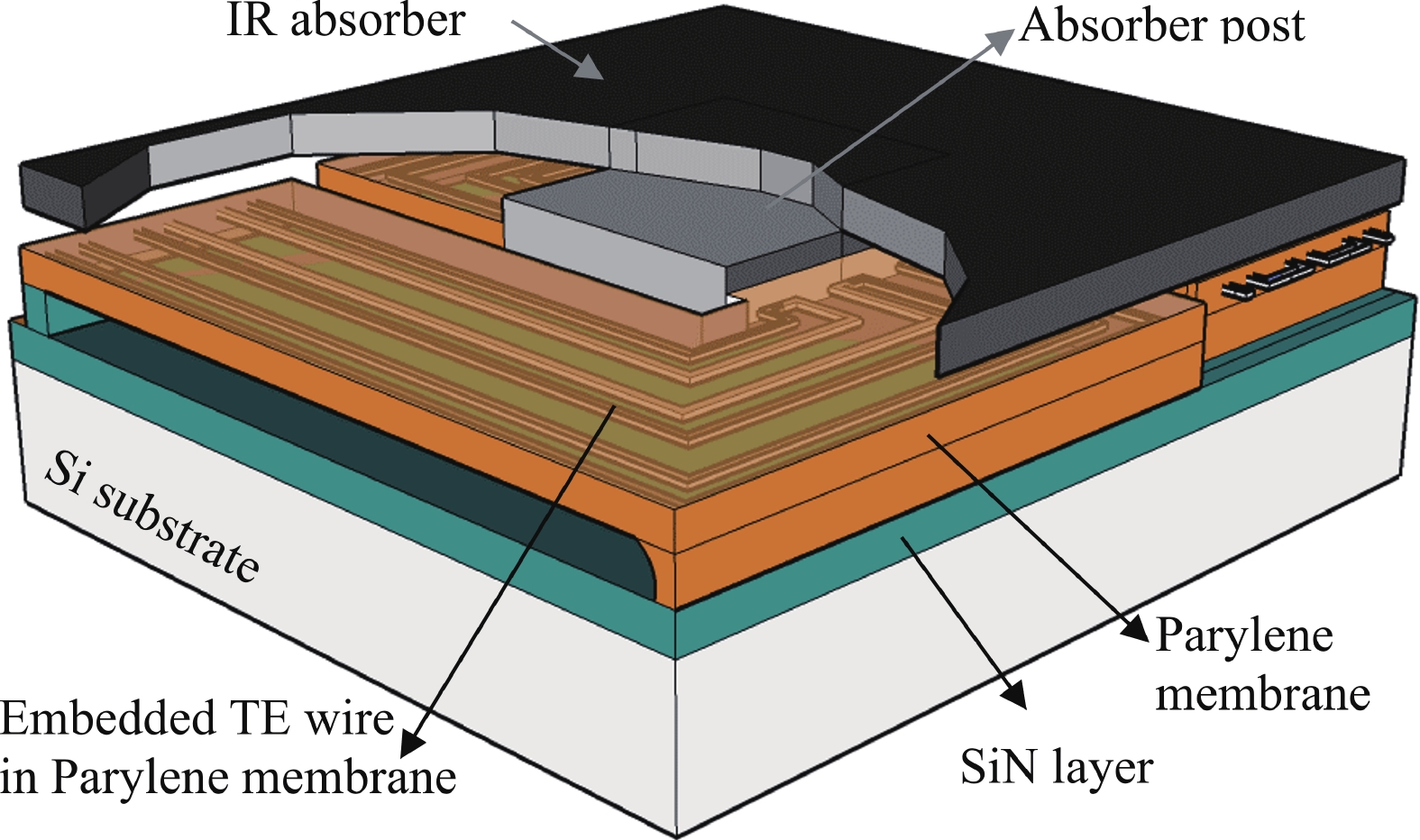

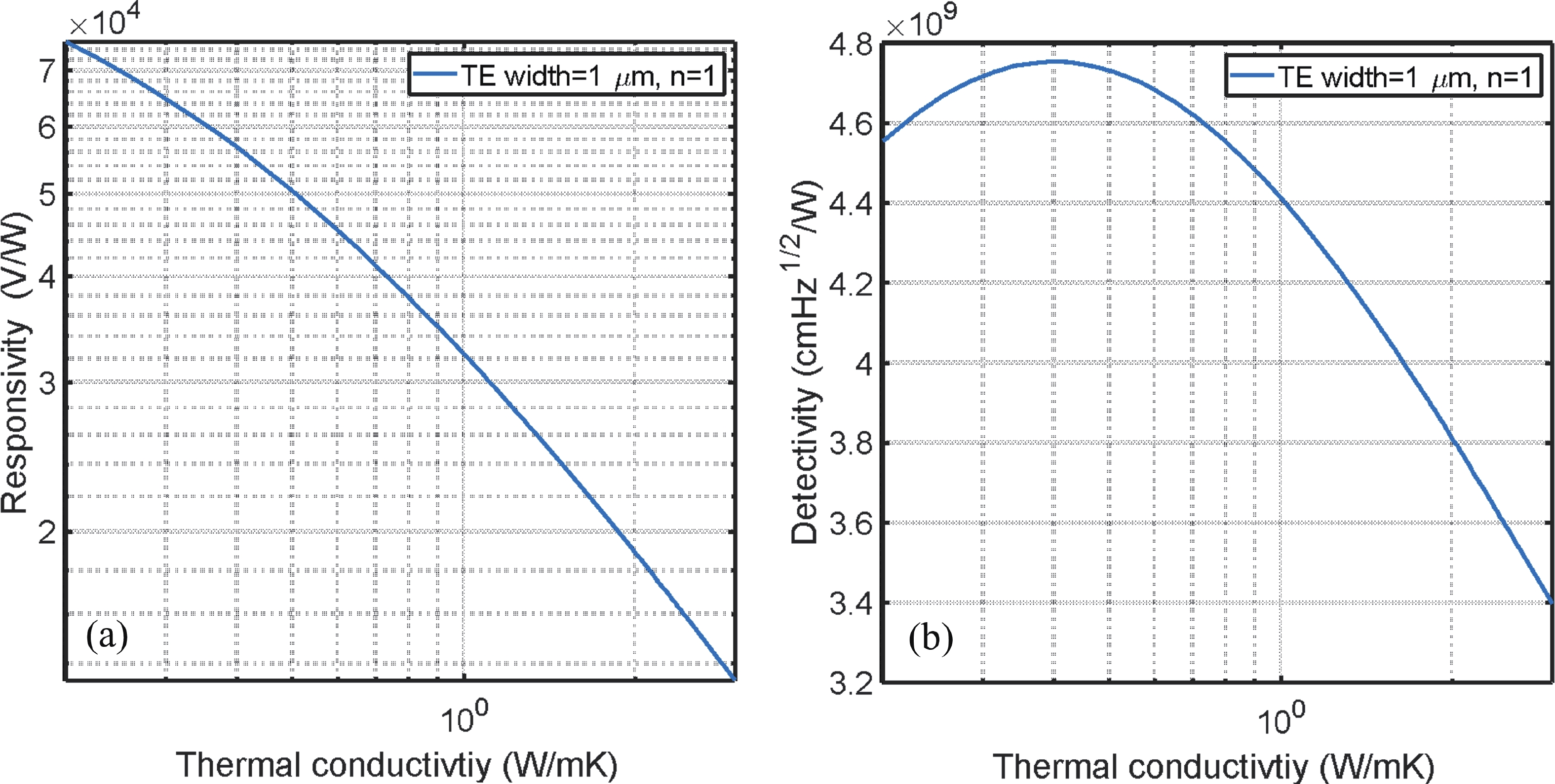

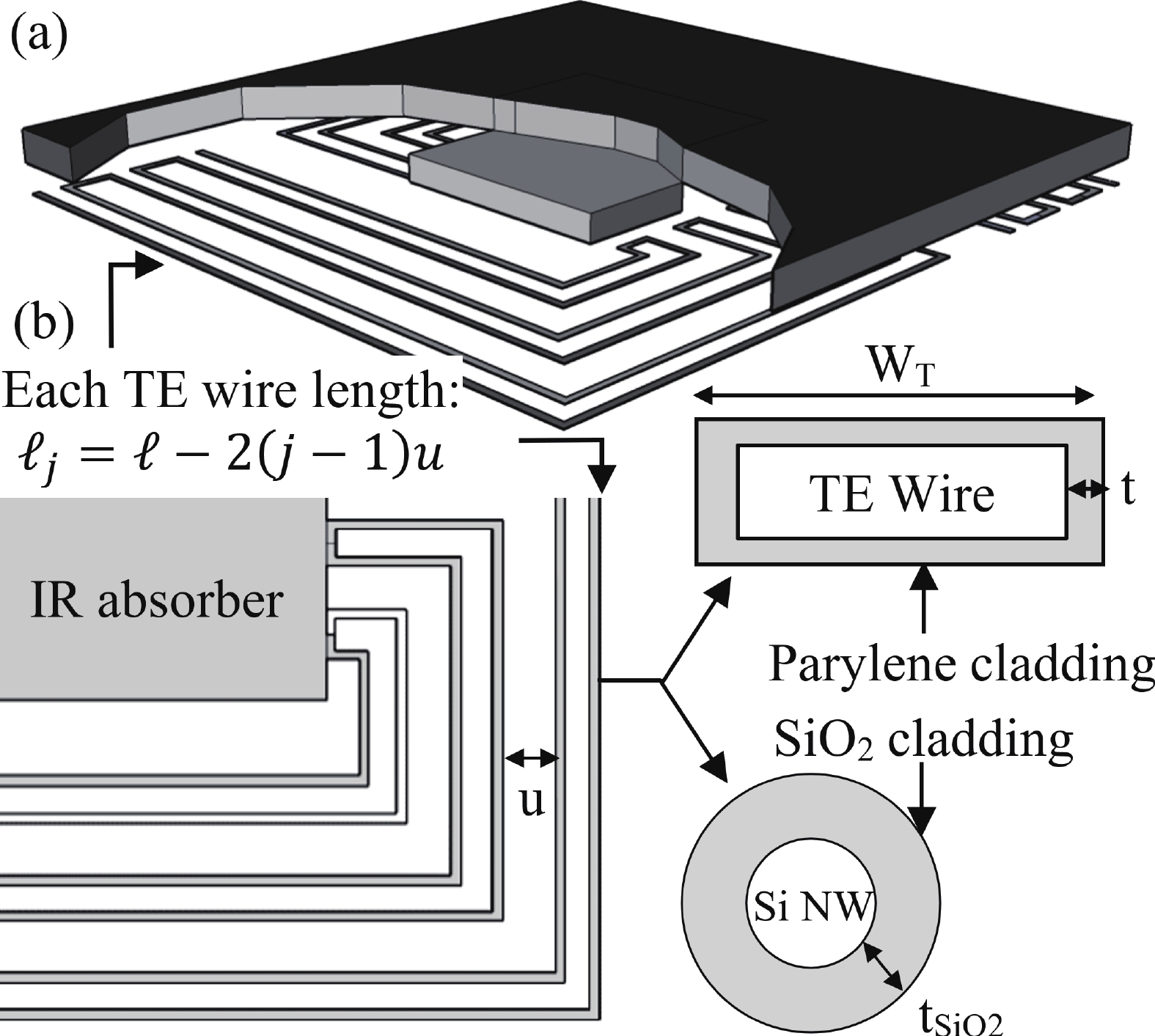

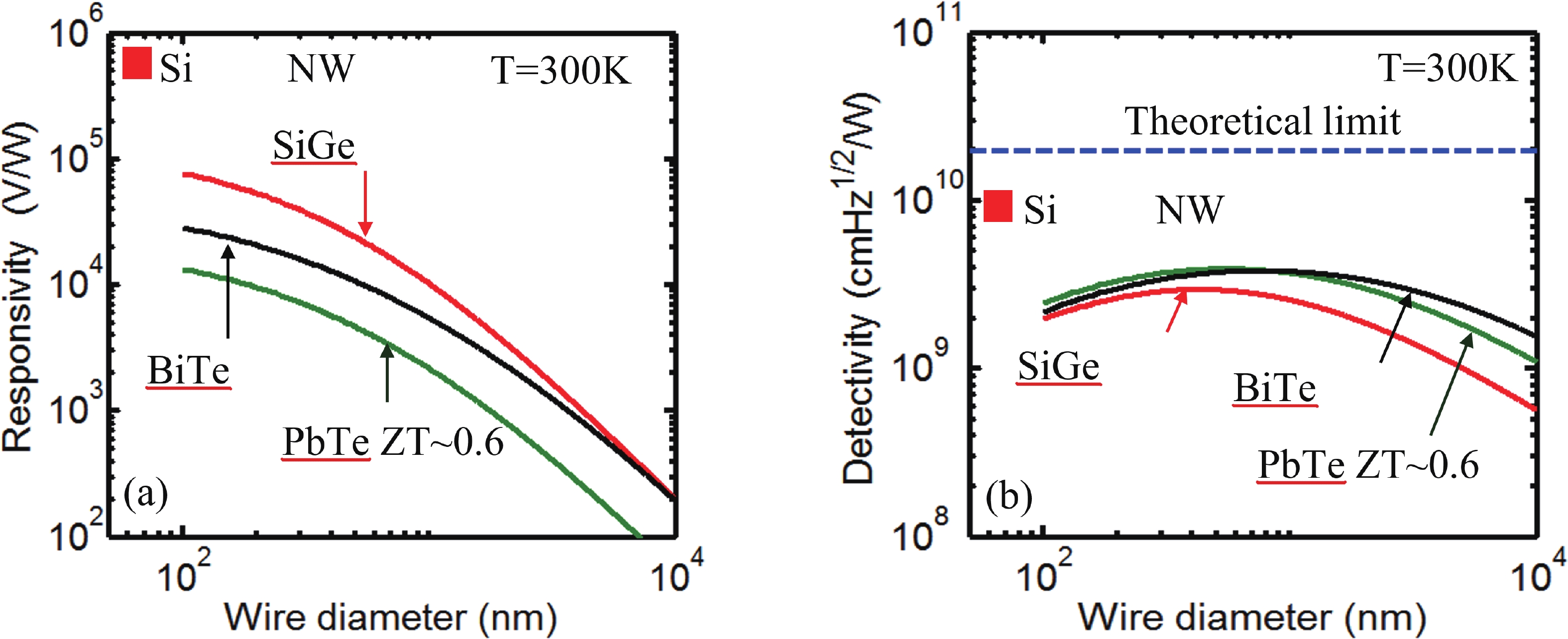

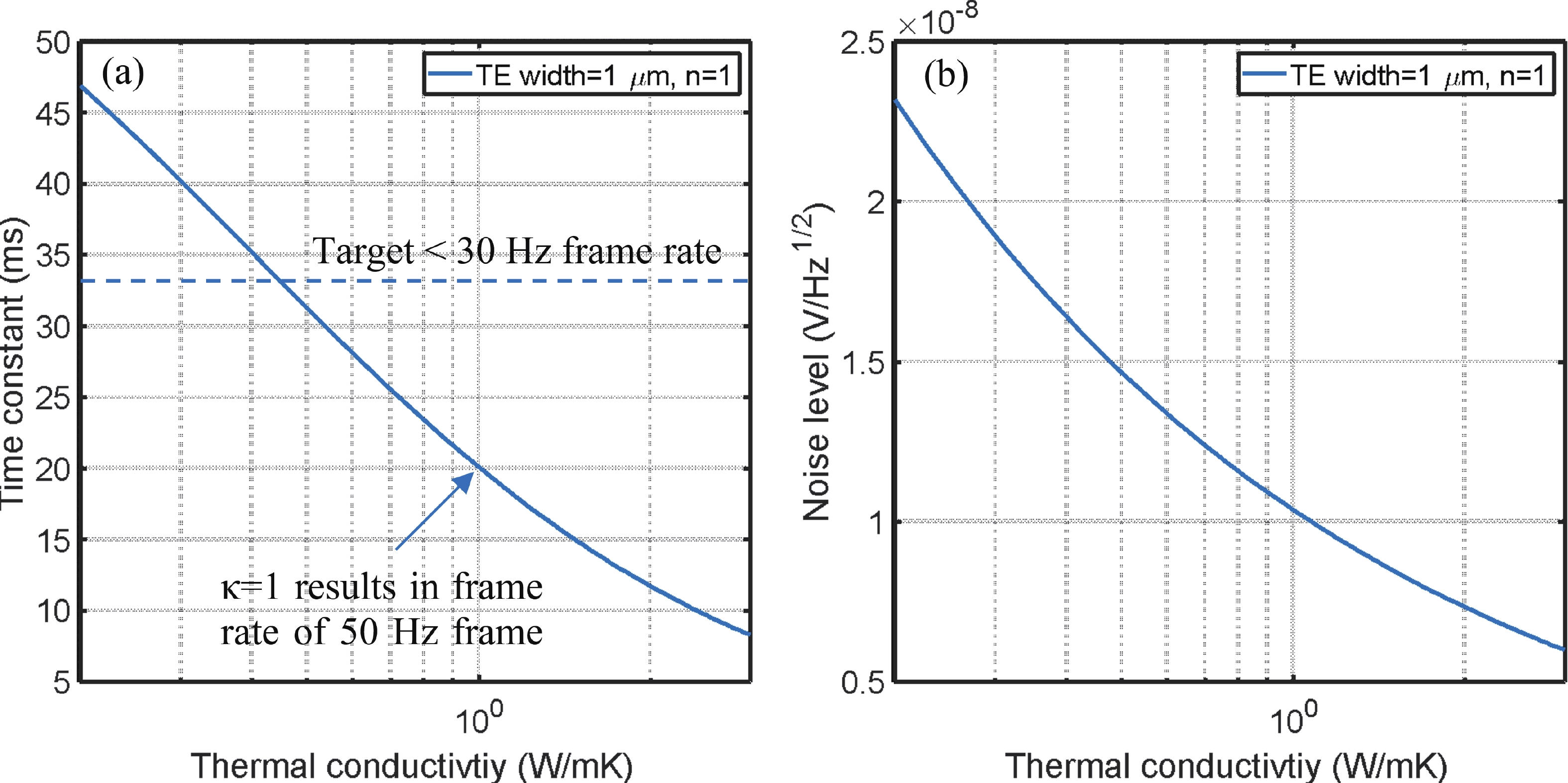

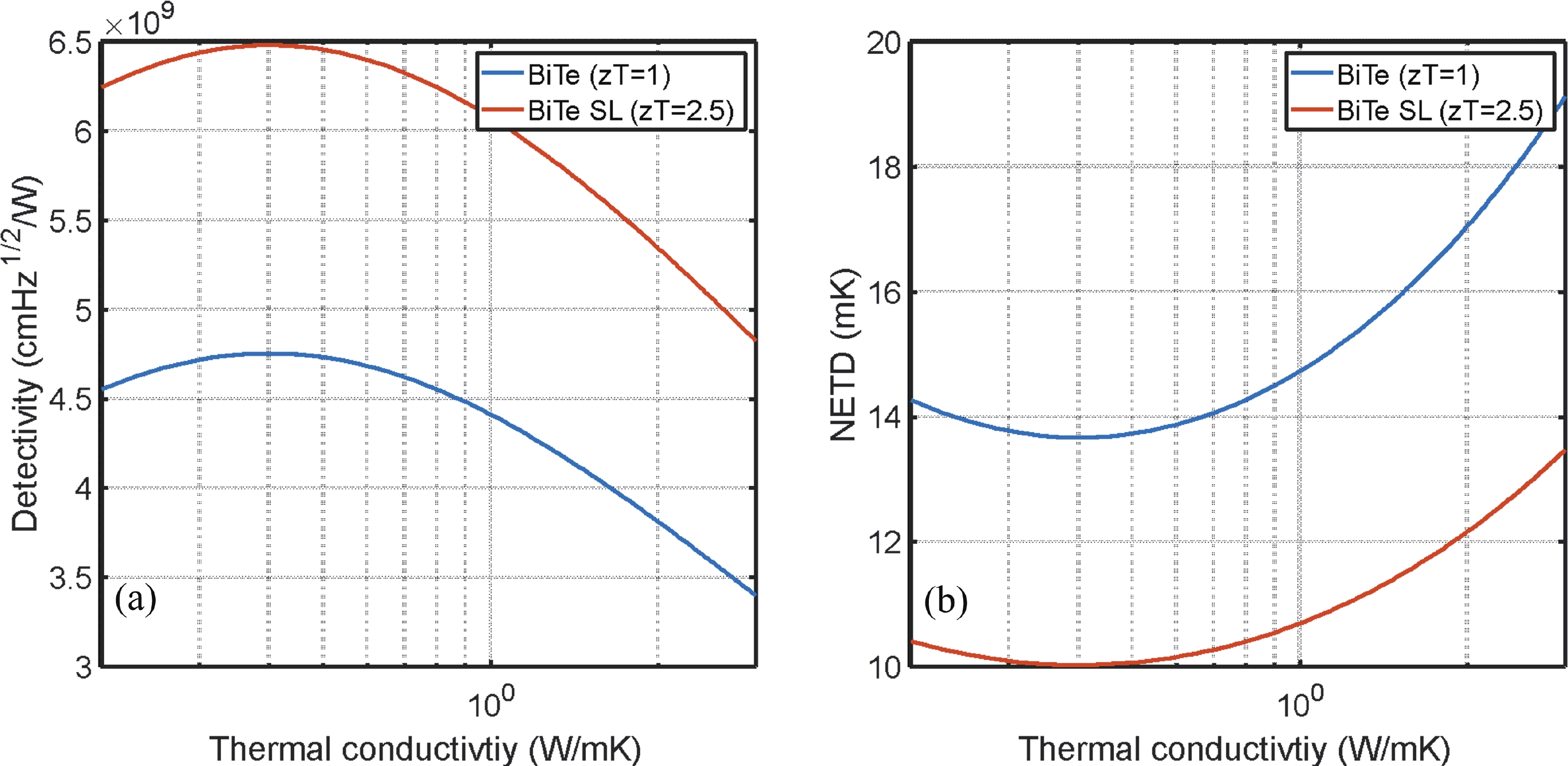

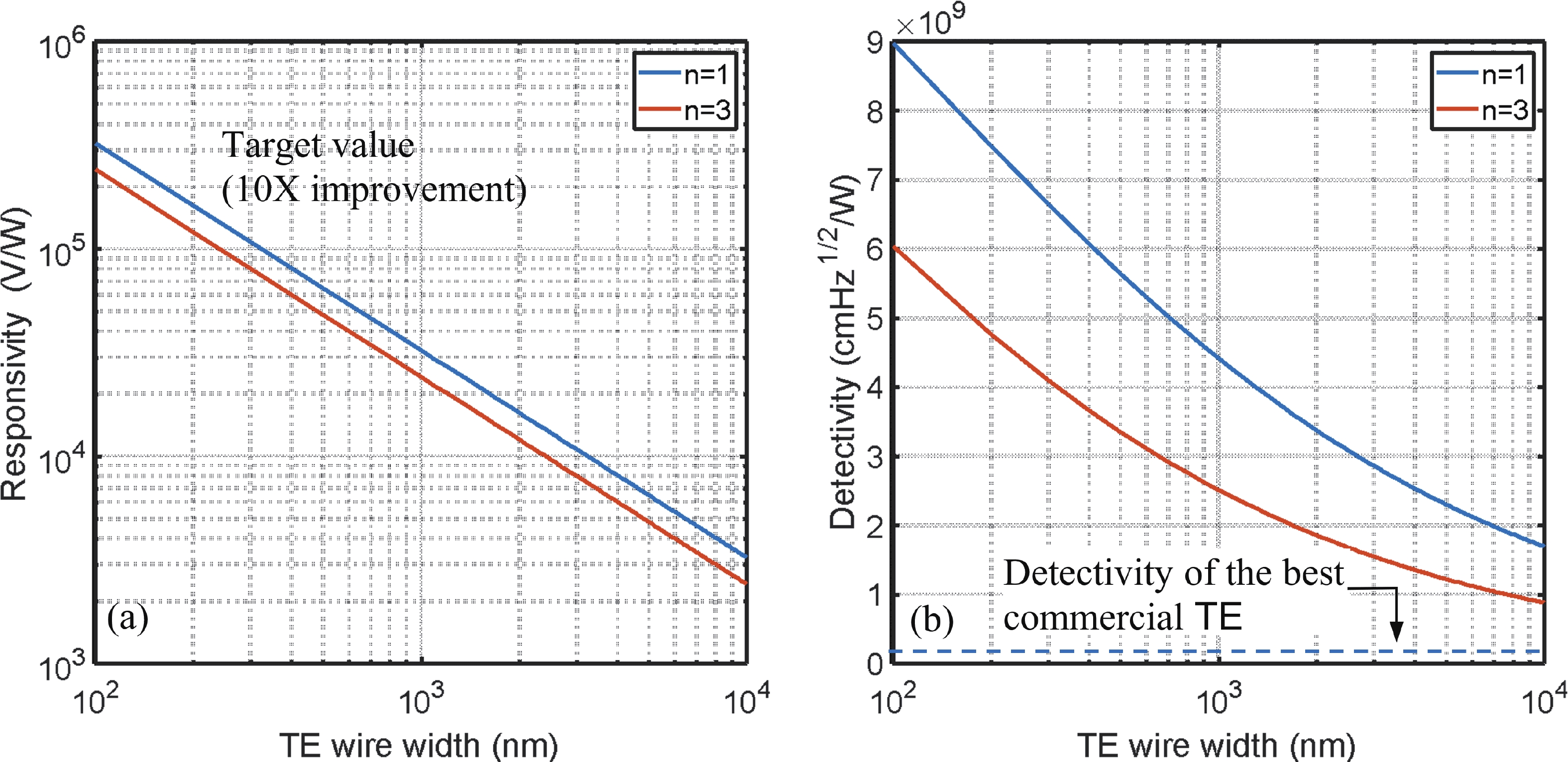

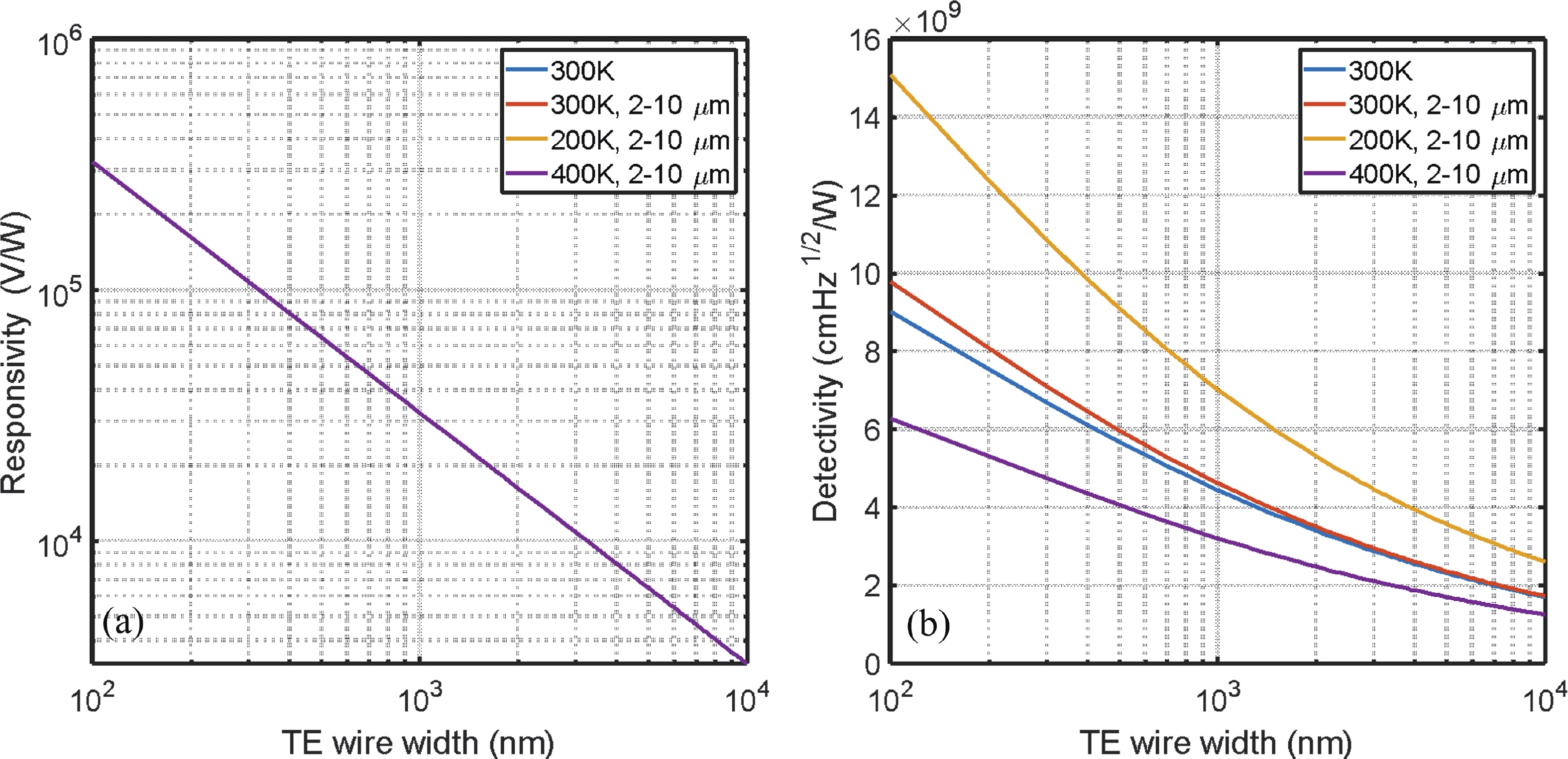

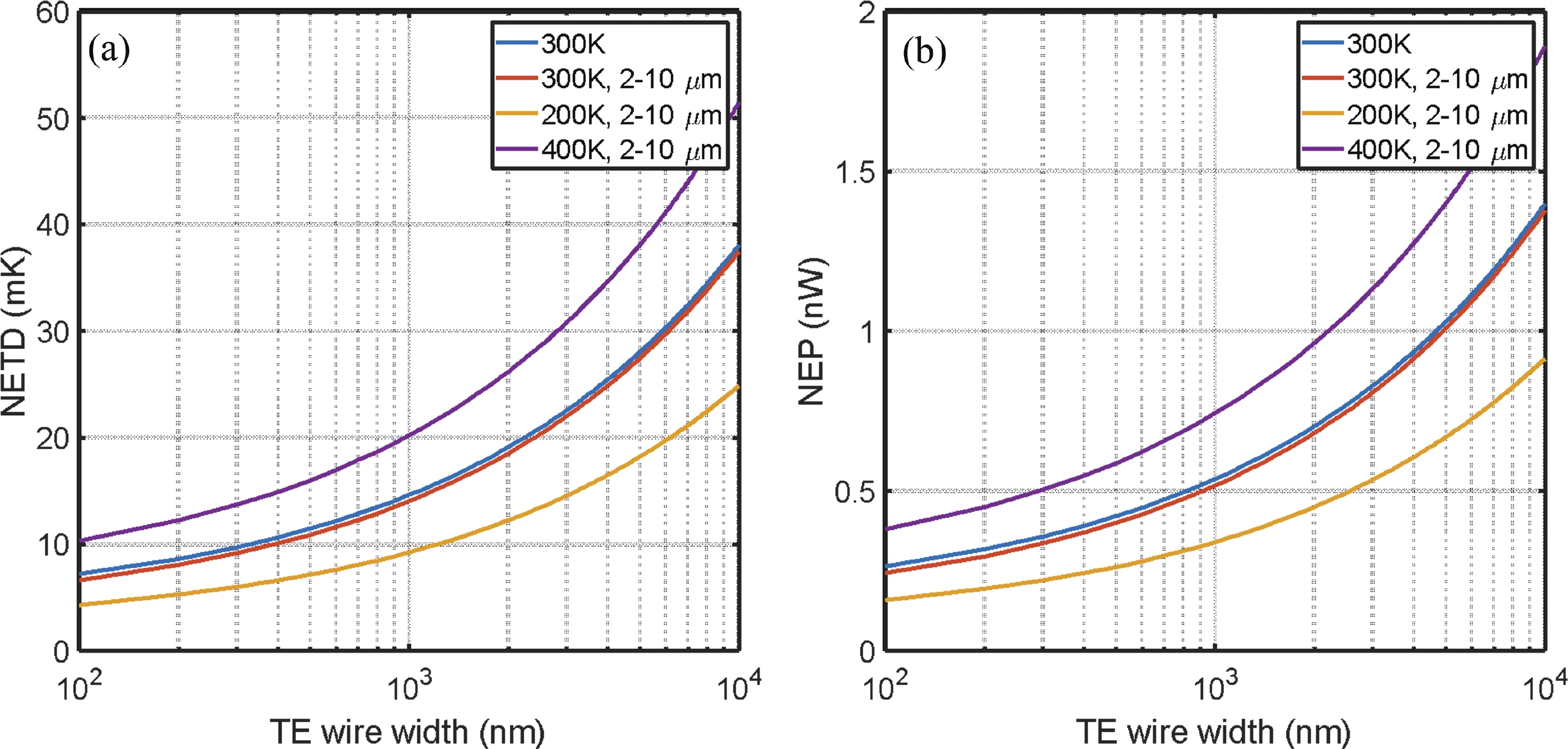

This study presents a comprehensive optimization and comparative analysis of thermoelectric (TE) infrared (IR) detectors using Bi2Te3 and Si materials. Through theoretical modeling and numerical simulations, we explored the impact of TE material properties, device structure, and operating conditions on responsivity, detectivity, noise equivalent temperature difference (NETD), and noise equivalent power (NEP). Our study offers an optimally designed IR detector with responsivity and detectivity approaching 2 × 105 V/W and 6 × 109 cm∙Hz1/2/W, respectively. This enhancement is attributed to unique design features, including raised thermal collectors and long suspended thin thermoelectric wire sensing elements embedded in low thermal conductivity organic materials like parylene. Moreover, we demonstrate the compatibility of Bi2Te3-based detector fabrication processes with existing MEMS foundry processes, facilitating scalability and manufacturability. Importantly, for TE IR detectors, zT/κ emerges as a critical parameter contrary to conventional TE material selection based solely on zT (where zT is the thermoelectric figure of merit and κ is the thermal conductivity).-

Keywords:

- thermoelectric,

- infrared focal plane arrays,

- micromachining,

- Bi2Te3

-

References

[1] Vashaee D, Abdolvand R. Nano-wire thermoelectric infra-red detector, USA Patent, US20130248712A1, 2013[2] Bhatnagar P, Zaferani S H, Rafiefard N, et al. Advancing personalized healthcare and entertainment: Progress in energy harvesting materials and techniques of self-powered wearable devices. Prog Mater Sci, 2023, 139, 101184 doi: 10.1016/j.pmatsci.2023.101184[3] Bhatnagar P, Vashaee D. Development of MEMS process compatible (Bi, Sb)2(Se, Te)3-based thin films for scalable fabrication of planar micro-thermoelectric generators. Micromachines, 2022, 13(9), 1459 doi: 10.3390/mi13091459[4] Nozariasbmarz A, Krasinski J S, Vashaee D. N-type bismuth telluride nanocomposite materials optimization for thermoelectric generators in wearable applications. Materials (Basel), 2019, 12(9), 1529 doi: 10.3390/ma12091529[5] Tayebi L, Zamanipour Z, Vashaee D. Design optimization of micro-fabricated thermoelectric devices for solar power generation. Renew Energy, 2014, 69, 166 doi: 10.1016/j.renene.2014.02.055[6] Bhatnagar P, Vashaee D. Process considerations for selective doping of poly-Si thin films with spin-on dopants and nickel silicide formation for planar thermoelectric devices. Mater Sci Semicond Process, 2022, 150, 106941 doi: 10.1016/j.mssp.2022.106941[7] Nozariasbmarz A, Tahmasbi Rad A, Zamanipour Z, et al. Enhancement of thermoelectric power factor of silicon germanium films grown by electrophoresis deposition. Scr Mater, 2013, 69(7), 549 doi: 10.1016/j.scriptamat.2013.06.025[8] Kruse P W, Blue M D, Garfunkel J H, et al. Long wavelength photoeffects in mercury selenide, mercury telluride, and mercury telluride-cadmium telluride. Infrared Phys, 1962, 2(1), 53 doi: 10.1016/0020-0891(62)90043-X[9] Rogalski A, Piotrowski J. Intrinsic infrared detectors. Prog Quantum Electron, 1988, 12(2/3), 87 doi: 10.1016/0079-6727(88)90001-8[10] Levine B F. Quantum-well infrared photodetectors. J Appl Phys, 1993, 74(8), R1 doi: 10.1063/1.354252[11] Wood AR. Foss NA Micromachined bolometer arrays achieve low-cost imaging. Laser Focus World, 1993, 29(6), 101[12] Hanson C M. Chapter 4 hybrid pyroelectric-ferroelectric bolometer arrays. Semiconductors and Semimetals. Amsterdam: Elsevier, 1997, 123 doi: 10.1016/S0080-8784(08)62690-3[13] Kanno T, Saga M, Matsumoto S, et al. Uncooled infrared focal plane array having 128 × 128 thermopile detector elements. Infrared Technology XX, 1994, 450 doi: 10.1117/12.188660[14] Jerominek H, Pope T D, Renaud M, et al. 64 × 64, 128 × 128, 240 × 320 pixel uncooled IR bolometric detector arrays. Infrared Technology and Applications XXIII, 1997, 236 doi: 10.1117/12.280342[15] Kruse P W. Uncooled thermal imaging arrays, systems, and applications. SPIE, 2001, 51[16] Beratan H R, Hanson C M, Meissner E G. Low-cost uncooled ferroelectric detector. Infrared Detectors: State of the Art II, 1994, 2274, 147 doi: 10.1117/12.189240[17] Hamamatsu Photonics. Available: https://www.hamamatsu.com/eu/en.html [accessed May 28, 2024][18] Ioffe AF. Poluprovodnikovye termoelementy. Semi-Cp CV–ACp, 1960, 2[19] Hicks L D, Dresselhaus M S. Effect of quantum-well structures on the thermoelectric figure of merit. Phys Rev B Condens Matter, 1993, 47(19), 12727 doi: 10.1103/PhysRevB.47.12727[20] Zamanipour Z, Shi X H, Dehkordi A M, et al. The effect of synthesis parameters on transport properties of nanostructured bulk thermoelectric p-type silicon germanium alloy. Phys Status Solidi A, 2012, 209(10), 2049 doi: 10.1002/pssa.201228102[21] Zamanipour Z, Shi X H, Mozafari M, et al. Synthesis, characterization, and thermoelectric properties of nanostructured bulk p-type MnSi1.73, MnSi1.75, and MnSi1.77. Ceram Int, 2013, 39(3), 2353 doi: 10.1016/j.ceramint.2012.08.086[22] Dresselhaus M S, Chen G, Ren Z F, et al. Nanocomposites to enhance zt in thermoelectrics. MRS Online Proc Libr, 2008, 1044(1), 204 doi: 10.1557/PROC-1044-U02-04[23] Satyala N, Tahmasbi Rad A, Zamanipour Z, et al. Reduction of thermal conductivity of bulk nanostructured bismuth telluride composites embedded with silicon nano-inclusions. J Appl Phys, 2014, 115, 044304 doi: 10.1063/1.4861727[24] Satyala N, Krasinski J S, Vashaee D. Simultaneous enhancement of mechanical and thermoelectric properties of polycrystalline magnesium silicide with conductive glass inclusion. Acta Mater, 2014, 74, 141 doi: 10.1016/j.actamat.2014.04.007[25] Nozariasbmarz A, Zamanipour Z, Norouzzadeh P, et al. Enhanced thermoelectric performance in a metal/semiconductor nanocomposite of iron silicide/silicon germanium. RSC Adv, 2016, 6(55), 49643 doi: 10.1039/C6RA01947A[26] Zamanipour Z, Vashaee D. Comparison of thermoelectric properties of p-type nanostructured bulk Si0.8Ge0.2 alloy with Si0.8Ge0.2 composites embedded with CrSi2 nano-inclusisons. J Appl Phys, 2012, 112(9), 093714 doi: 10.1063/1.4764919[27] Norouzzadeh P, Vashaee D. Classification of valleytronics in thermoelectricity. Sci Rep, 2016, 6, 22724 doi: 10.1038/srep22724[28] Hooshmand Zaferani S, Ghomashchi R, Vashaee D. Strategies for engineering phonon transport in Heusler thermoelectric compounds. Renew Sustain Energy Rev, 2019, 112, 158 doi: 10.1016/j.rser.2019.05.051[29] Norouzzadeh P, Myles C W, Vashaee D. Prediction of giant thermoelectric power factor in type-VIII clathrate Si46. Sci Rep, 2014, 4, 7028 doi: 10.1038/srep07028[30] Norouzzadeh P, Myles C W, Vashaee D. Prediction of a large number of electron pockets near the band edges in type-VIII clathrate Si46 and its physical properties from first principles. J Phys: Condens Matter, 2013, 25(47), 475502 doi: 10.1088/0953-8984/25/47/475502[31] Heremans J P, Jovovic V, Toberer E S, et al. Enhancement of thermoelectric efficiency in PbTe by distortion of the electronic density of states. Science, 2008, 321(5888), 554 doi: 10.1126/science.1159725[32] Vashaee D, Zhang Y, Shakouri A, et al. Cross-plane Seebeck coefficient in superlattice structures in the miniband conduction regime. Phys Rev B, 2006, 74(19), 195315 doi: 10.1103/PhysRevB.74.195315[33] Vashaee D, Shakouri A. Nonequilibrium electrons and phonons in thin film thermionic coolers. Microscale Thermophys Eng, 2004, 8(2), 91 doi: 10.1080/10893950490445225[34] Vashaee D, Shakouri A. HgCdTe superlattices for solid-state cryogenic refrigeration. Appl Phys Lett, 2006, 88(13), 132110 doi: 10.1063/1.2191094[35] Polash M M H, Mohaddes F, Rasoulianboroujeni M, et al. Magnon-drag thermopower in antiferromagnets versus ferromagnets. J Mater Chem C, 2020, 8(12), 4049 doi: 10.1039/C9TC06330G[36] Polash M M H, Vashaee D. Magnon-bipolar carrier drag thermopower in antiferromagnetic/ferromagnetic semiconductors: Theoretical formulation and experimental evidence. Phys Rev B, 2020, 102(4), 045202 doi: 10.1103/PhysRevB.102.045202[37] Polash M M H, Rasoulianboroujeni M, Vashaee D. Magnon and spin transition contribution in heat capacity of ferromagnetic Cr-doped MnTe: Experimental evidence for a paramagnetic spin-caloritronic effect. Appl Phys Lett, 2020, 117(4), 03043903 doi: 10.1063/5.0011887[38] Polash M M H, Yalameha S, Zhou H H, et al. Topological quantum matter to topological phase conversion: Fundamentals, materials, physical systems for phase conversions, and device applications. Mater Sci Eng R Rep, 2021, 145, 100620 doi: 10.1016/j.mser.2021.100620[39] Polash M M H, Vashaee D. Anomalous thermoelectric transport properties of Fe-rich magnetic FeTe. Phys Status Solidi Rapid Res Lett, 2021, 15(10), 2100231 doi: 10.1002/pssr.202100231[40] Polash M M H, Moseley D, Zhang J J, et al. Understanding and design of spin-driven thermoelectrics. Cell Rep Phys Sci, 2021, 2(11), 100614 doi: 10.1016/j.xcrp.2021.100614[41] Polash M M H, Vashaee D. Spin fluctuations yield zT enhancement in ferromagnets. iScience, 2021, 24(11), 103356 doi: 10.1016/j.isci.2021.103356[42] Heydarinasab F, Jazandari M, Polash M M H, et al. Paramagnon heat capacity and anomalous thermopower in anisotropic magnetic systems: Understanding interlayer spin correlations in a magnetically disordered phase. Phys Rev B, 2024, 109(5), 054418 doi: 10.1103/PhysRevB.109.054418[43] Polash M M H, Smirnov A I, Vashaee D. Electron spin resonance in emerging spin-driven applications: Fundamentals and future perspectives. Appl Phys Rev, 2023, 10(4), 041301 doi: 10.1063/5.0072564[44] Norouzzadeh P, Ede K F, Vashaee D. The effect of nanostructuring on the spectral population of electrons and phonons. J Alloys Compd, 2018, 753, 234 doi: 10.1016/j.jallcom.2018.04.243[45] Norouzzadeh P, Zamanipour Z, Krasinski J S, et al. The effect of nanostructuring on thermoelectric transport properties of p-type higher manganese silicide MnSi1.73. J Appl Phys, 2012, 112(12), 124308 doi: 10.1063/1.4769884[46] Satyala N, Vashaee D. Detrimental influence of nanostructuring on the thermoelectric properties of magnesium silicide. J Appl Phys, 2012, 112(9), 093716 doi: 10.1063/1.4764872[47] Nozariasbmarz A, Roy P, Zamanipour Z, et al. Comparison of thermoelectric properties of nanostructured Mg2Si, FeSi2, SiGe, and nanocomposites of SiGe–Mg2Si, SiGe–FeSi2. APL Mater, 2016, 4(10), 104814 doi: 10.1063/1.4966138[48] Mohebali M, Liu Y, Tayebi L, et al. Thermoelectric figure of merit of bulk FeSi2–Si0.8Ge0.2 nanocomposite and a comparison with β-FeSi2. Renew Energy, 2015, 74, 940 doi: 10.1016/j.renene.2014.08.059[49] Satyala N, Vashaee D. Modeling of thermoelectric properties of MagnesiumSilicide (Mg2Si). J Electron Mater, 2012, 41(6), 1785 doi: 10.1007/s11664-012-2024-7[50] Keppens V, Mandrus D, Sales B C, et al. Localized vibrational modes in metallic solids. Nature, 1998, 395(6705), 876 doi: 10.1038/27625[51] Hermann R P, Jin R Y, Schweika W, et al. Einstein oscillators in thallium filled antimony skutterudites. Phys Rev Lett, 2003, 90(13), 135505 doi: 10.1103/PhysRevLett.90.135505[52] Koza M M, Johnson M R, Viennois R, et al. Breakdown of phonon glass paradigm in La- and Ce-filled Fe4Sb12 skutterudites. Nat Mater, 2008, 7(10), 805 doi: 10.1038/nmat2260[53] Norouzzadeh P, Myles C W, Vashaee D. Phonon dynamics in type-VIII silicon clathrates: Beyond the rattler concept. Phys Rev B, 2017, 95(19), 195206 doi: 10.1103/PhysRevB.95.195206[54] Norouzzadeh P, Myles C W, Vashaee D. Electronic, elastic, vibrational, and thermodynamic properties of type-VIII clathrates Ba8Ga16Sn30 and Ba8Al16Sn30 by first principles. J Appl Phys, 2013, 114(16), 163509 doi: 10.1063/1.4826213[55] Norouzzadeh P, Norouzzadeh P, Myles C W, Vashaee D. Structural, electronic, phonon and thermodynamic properties of hypothetical type-VIII clathrates Ba8Si46 and Ba8Al16Si30 investigated by first principles. J Alloys Compd, 2014, 587, 474 doi: 10.1016/j.jallcom.2013.10.190[56] Kruse P W. Uncooled IR focal plane arrays. Opto-Electronics Review, 1999, 7(4), 253[57] Murphy D F, Ray M, Wyles R, et al. High-sensitivity (25-μm pitch) microbolometer FPAs and application development. Infrared Technology and Applications XXVII, 2001, 4369, 222 doi: 10.1117/12.445290[58] Anderson J S, Bradley D, Chen C W, et al. Low-cost microsensors program. Infrared Technology and Applications XXVII, 2001, 4369, 559 doi: 10.1117/12.445315[59] McEwen K R, Manning P A. European uncooled thermal imaging sensors. Infrared Technology and Applications XXV, 1999, 368, 322[60] Murphy D, Ray M, Kennedy A, et al. Expanded applications for high performance VOx microbolometer FPAs. Infrared Technology and Applications XXXI, 2005, 5783, 448 doi: 10.1117/12.609462[61] Oliver A D, Baer W G, Wise K D. A bulk-micromachined 1024-element uncooled infrared imager. Proceedings of the International Solid-State Sensors and Actuators Conference-TRANSDUCERS '95, 2002, 636 doi: 10.1109/SENSOR.1995.721912[62] Hirota M, Nakajima Y, Saito M, et al. 120×90 element thermopile array fabricated with CMOS technologyInfrared Technology and Applications XXVIII. SPIE, 2003, 4820, 239 doi: 10.1117/12.457719[63] Schaufelbuchl A, Munich U, Menolfi C, et al. 256-pixel CMOS-integrated thermoelectric infrared sensor array. Technical Digest. MEMS 2001.14th IEEE International Conference on Micro Electro Mechanical Systems, 2001, 200 doi: 10.1109/MEMSYS.2001.906513[64] Foote M C, Gaalema S D. Progress toward high-performance thermopile imaging arrays. Infrared Technology and Applications XXVII, 2001, 4369, 350 doi: 10.1117/12.445337[65] Foote M C, Krueger T R, Schofield J T, et al. Space science applications of thermopile detector arrays. Quantum Sensing: Evolution and Revolution from Past to Future, 2003, 4999, 443 doi: 10.1117/12.482474[66] Hirota M, Nakajima Y, Saito M, et al. 120 × 90 element thermoelectric infrared focal plane array with precisely patterned Au-black absorber. Sens Actuat A Phys, 2007, 135(1), 146 doi: 10.1016/j.sna.2006.06.058[67] Shih C Y, Chen Y, Tai Y C. Parylene-strengthened thermal isolation technology for microfluidic system-on-chip applications. Sens Actuat A Phys, 2006, 126(1), 270 doi: 10.1016/j.sna.2005.09.024[68] Vashaee D, LaBounty C J, Fang X, et al. P-type InGaAsP coolers for integrated optic devices. Proc SPIE, 2001, 4284, 139 doi: 10.1117/12.426867[69] Osterman D P, Patt R, Hunt R, et al. Uncooled micromachined thermopile arrays and readout circuits. Infrared Technology and Applications XXV, 1999, 3698, 376 doi: 10.1117/12.354539[70] Hochbaum A I, Chen R K, Delgado R D, et al. Enhanced thermoelectric performance of rough silicon nanowires. Nature, 2008, 451(7175), 163 doi: 10.1038/nature06381 -

Proportional views

Daryoosh Vashaee is a full Professor of Electrical and Computer Engineering and Materials Science and Engineering at North Carolina State University. He is the director of the Nanoscience and Quantum Engineering Research Laboratory. His research interests include quantum and nanostructured materials for energy conversion and information technologies. In the past, he has contributed to the development of several critical thermoelectric structures, including heterostructure thermionic devices, bulk nanocomposite, and paramagnetic thermoelectric materials. He received his Ph.D. at the University of California at Santa Cruz and worked at MIT as a postdoctoral scholar.

Daryoosh Vashaee is a full Professor of Electrical and Computer Engineering and Materials Science and Engineering at North Carolina State University. He is the director of the Nanoscience and Quantum Engineering Research Laboratory. His research interests include quantum and nanostructured materials for energy conversion and information technologies. In the past, he has contributed to the development of several critical thermoelectric structures, including heterostructure thermionic devices, bulk nanocomposite, and paramagnetic thermoelectric materials. He received his Ph.D. at the University of California at Santa Cruz and worked at MIT as a postdoctoral scholar.

DownLoad:

DownLoad: