| Citation: |

Di Chen, Rui Li, Chunxue Liu, Kai Jiang. Electrospraying Si/SiOx/C and Sn/C nanosphere arrays on carbon cloth for high-performance flexible lithium-ion batteries[J]. Journal of Semiconductors, 2025, 46(1): 012605. doi: 10.1088/1674-4926/24080030

****

D Chen, R Li, C X Liu, and K Jiang, Electrospraying Si/SiOx/C and Sn/C nanosphere arrays on carbon cloth for high-performance flexible lithium-ion batteries[J]. J. Semicond., 2025, 46(1), 012605 doi: 10.1088/1674-4926/24080030

|

Electrospraying Si/SiOx/C and Sn/C nanosphere arrays on carbon cloth for high-performance flexible lithium-ion batteries

DOI: 10.1088/1674-4926/24080030

CSTR: 32376.14.1674-4926.24080030

More Information-

Abstract

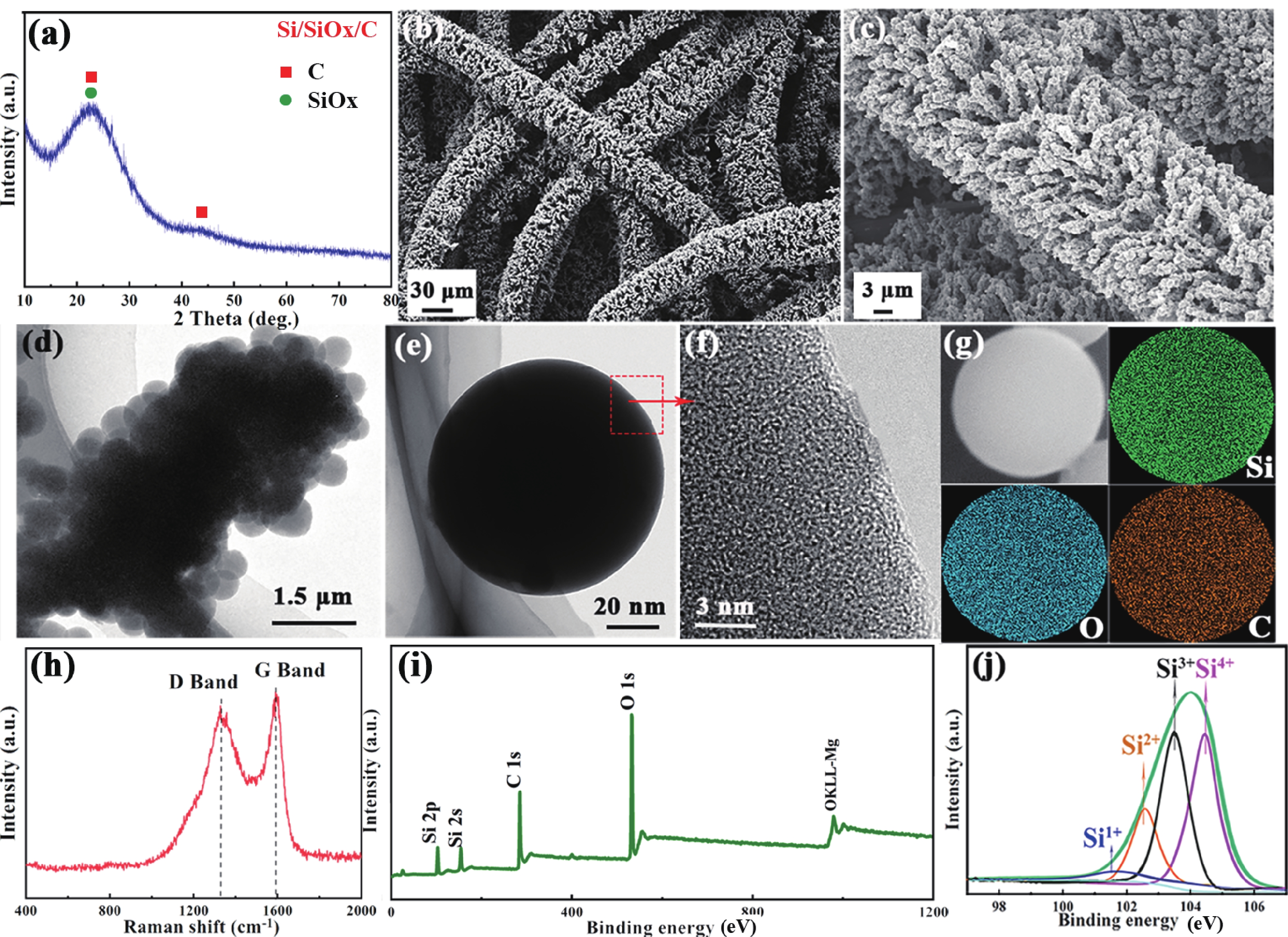

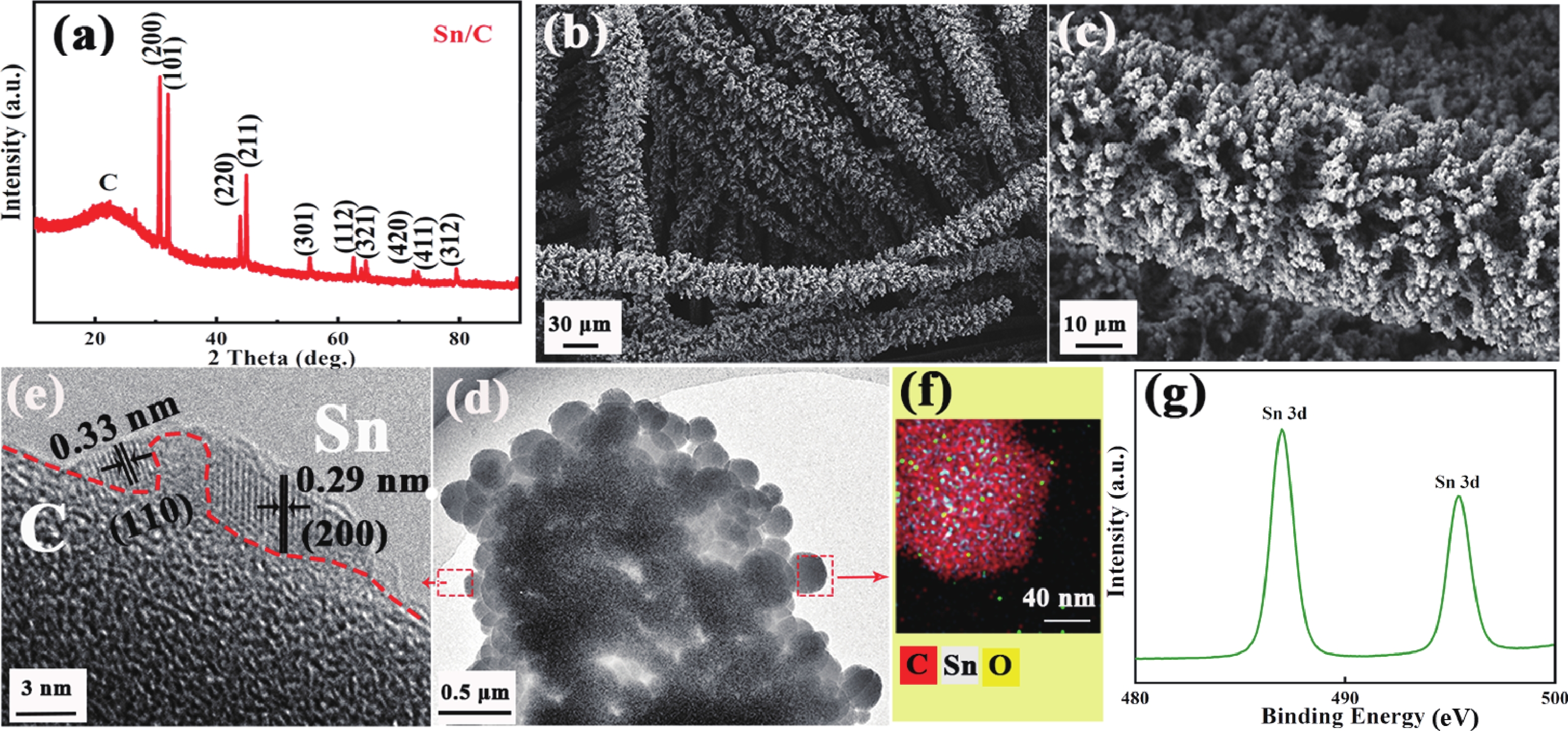

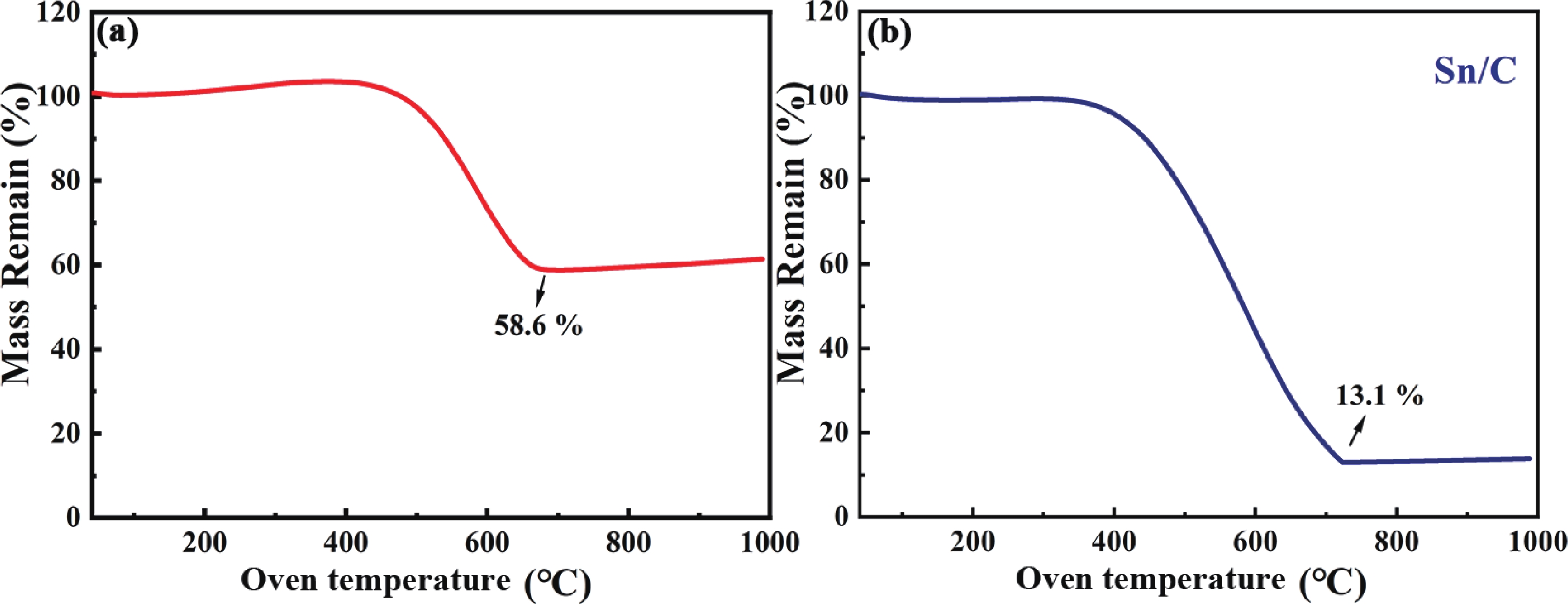

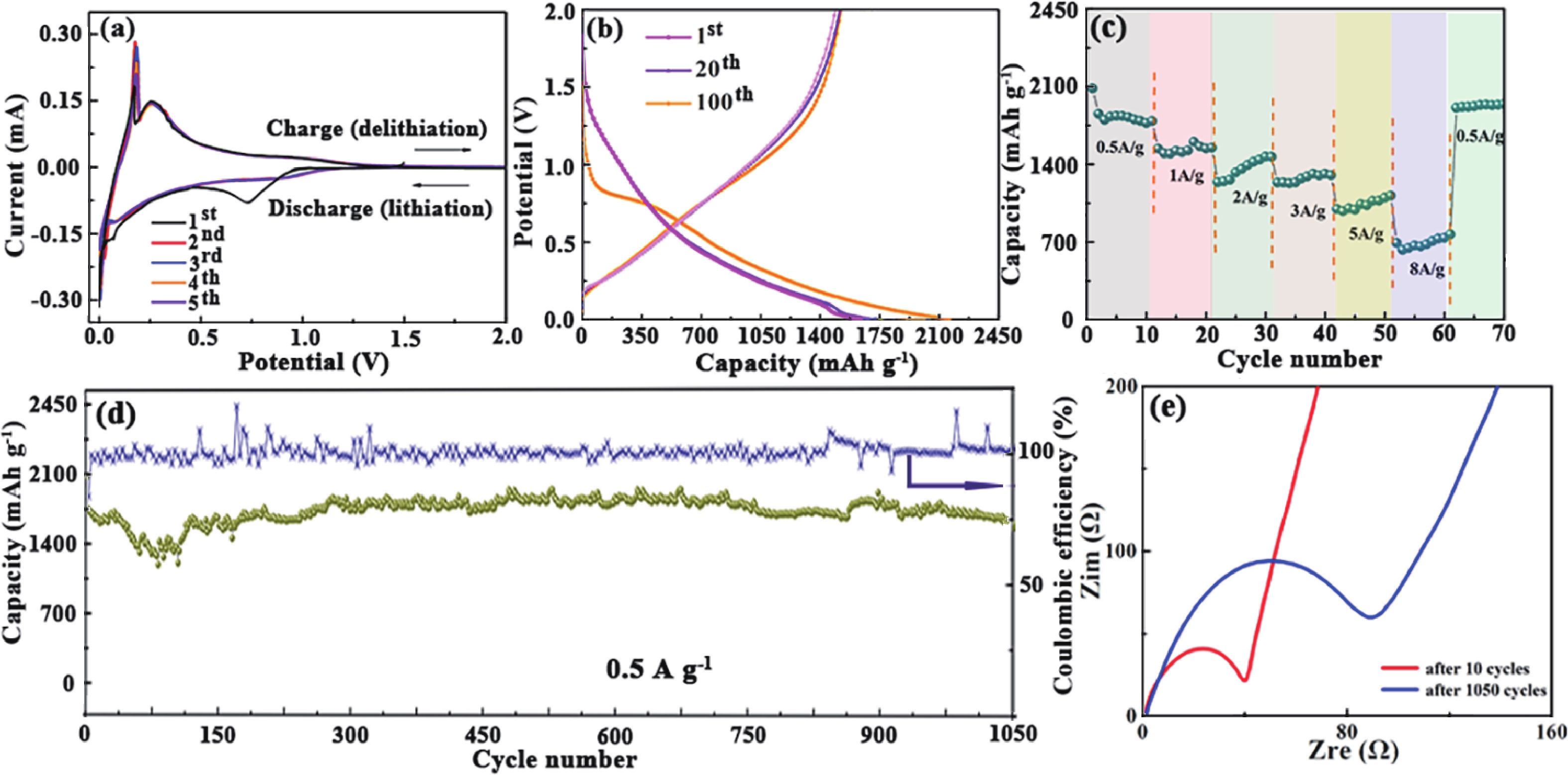

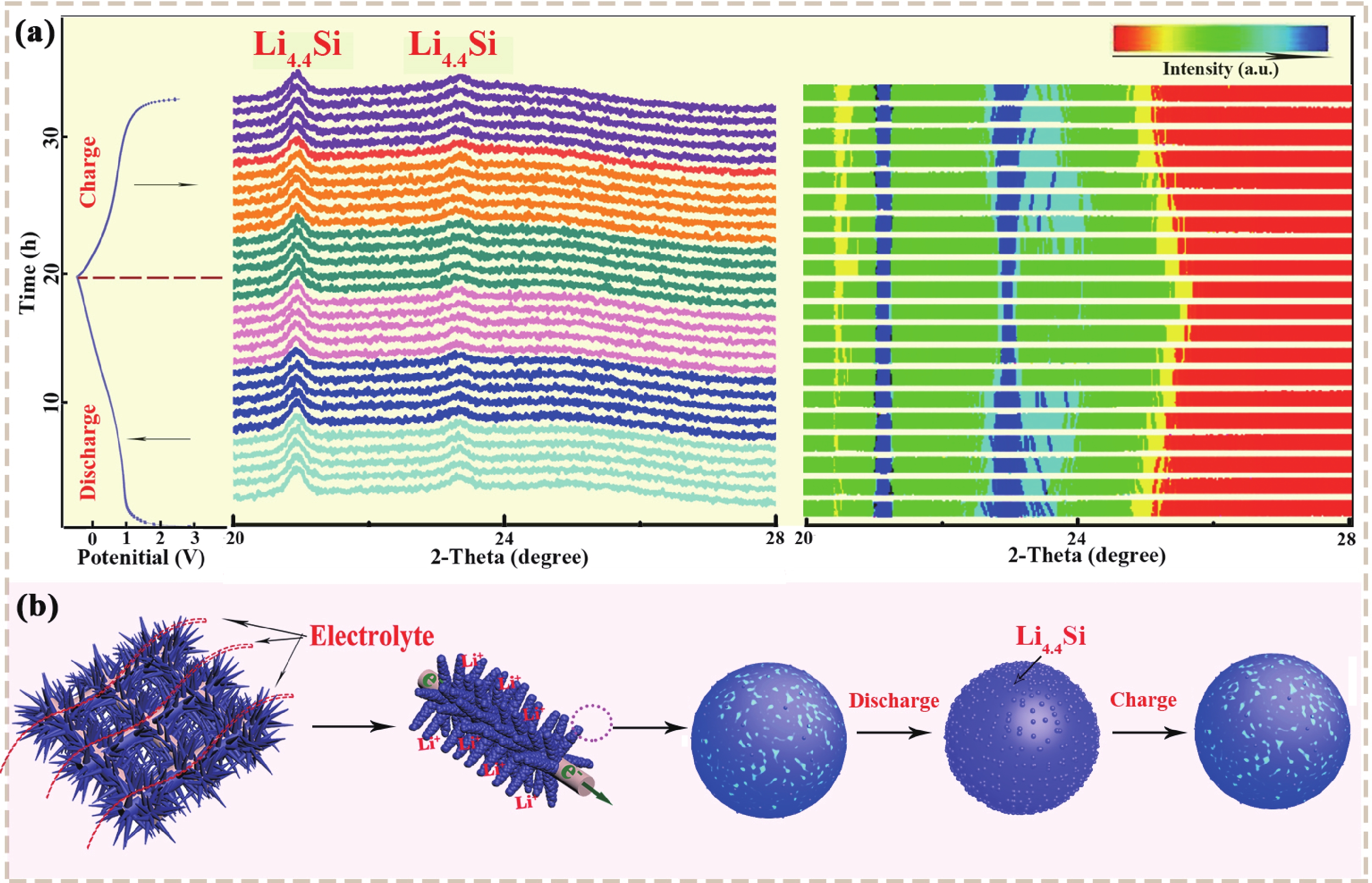

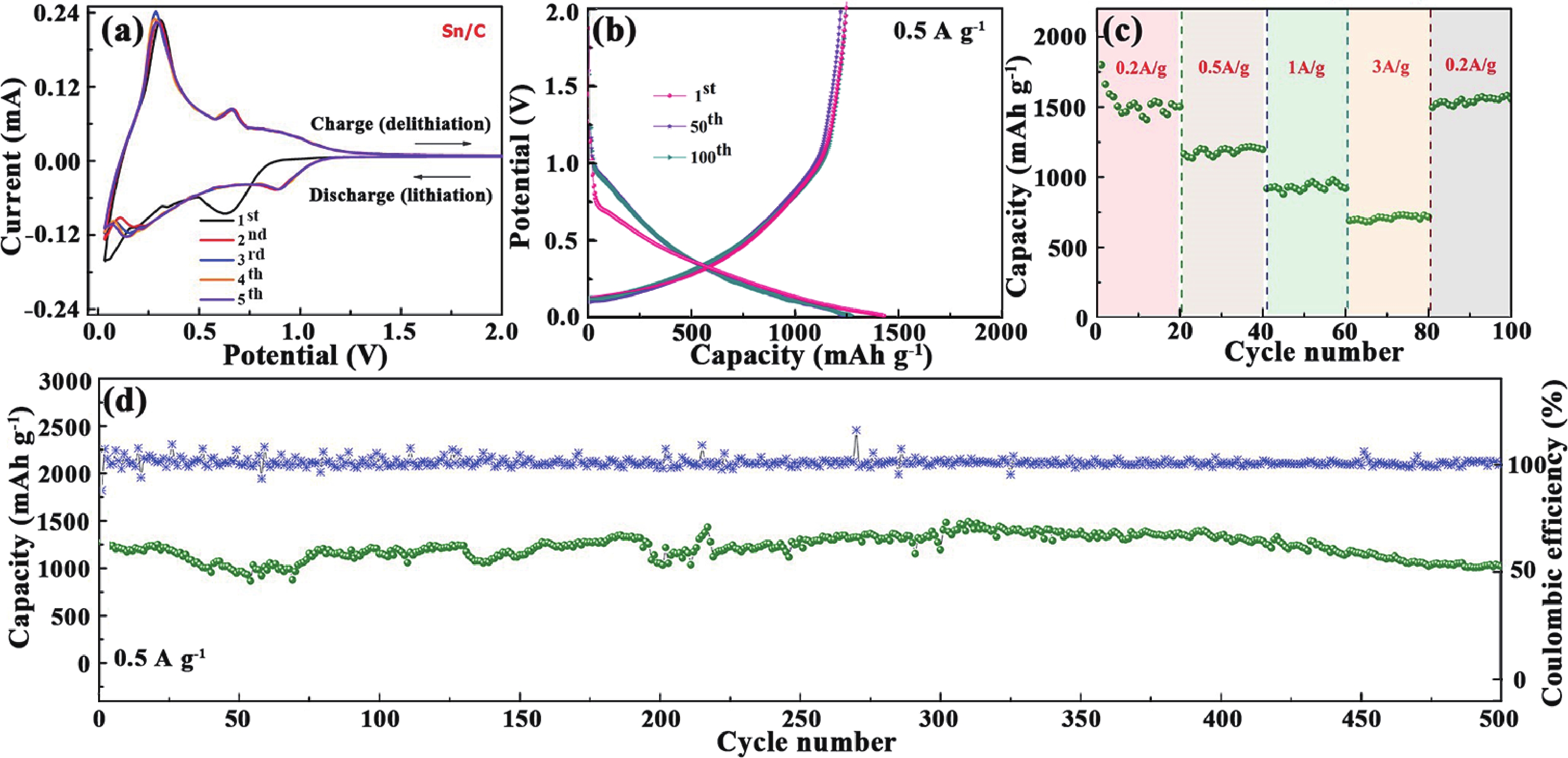

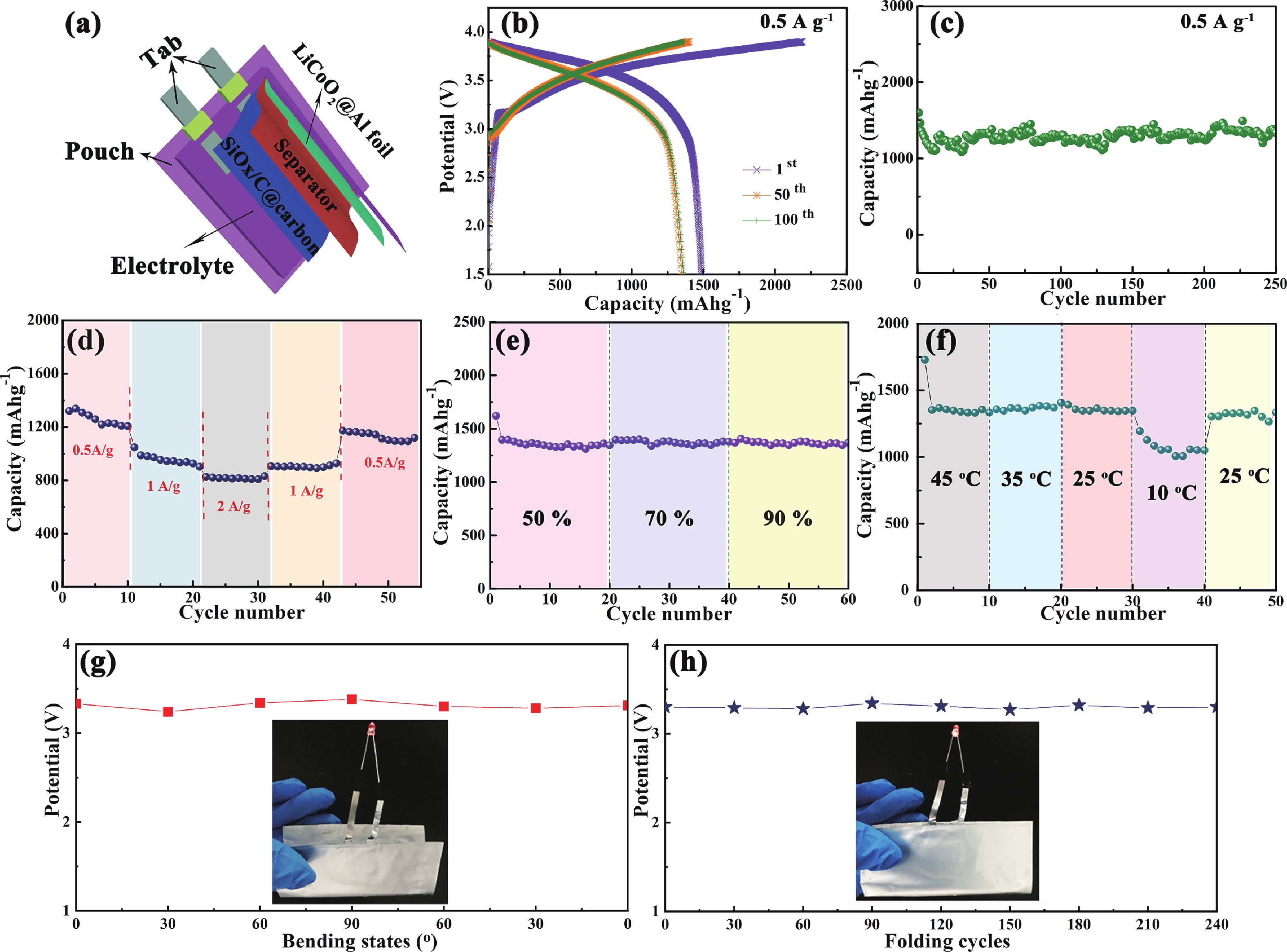

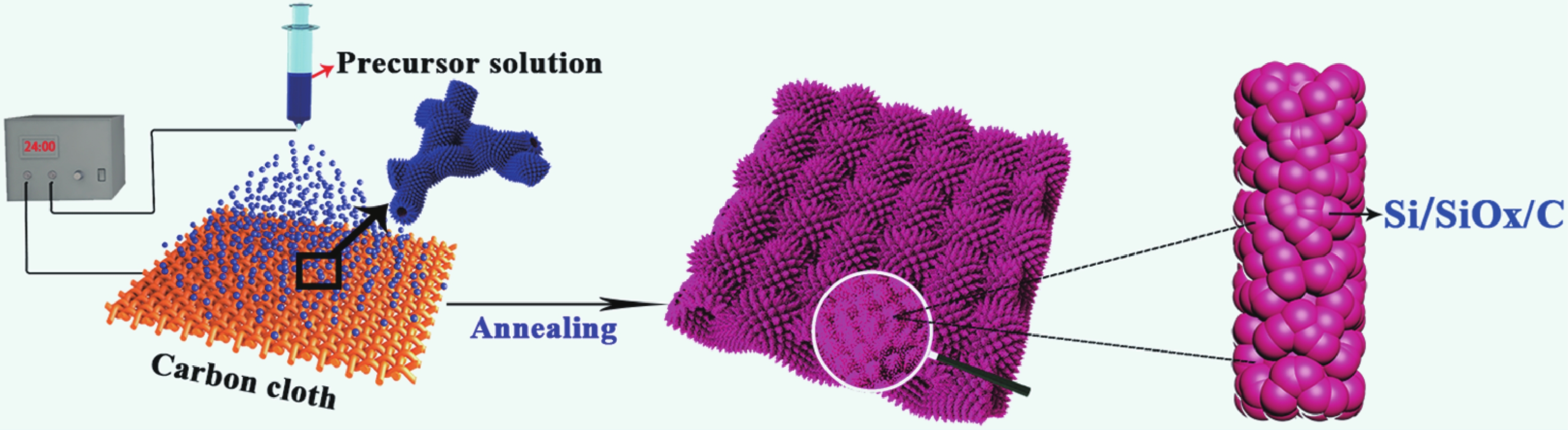

Exploring electrode materials with larger capacity, higher power density and longer cycle life was critical for developing advanced flexible lithium-ion batteries (LIBs). Herein, we used a controlled two-step method including electrospraying followed with calcination treatment by CVD furnace to design novel electrodes of Si/Six/C and Sn/C microrods array consisting of nanospheres on flexible carbon cloth substrate (denoted as Si/Six/C@CC, Sn/C@CC). Microrods composed of cumulated nanospheres (the diameter was approximately 120 nm) had a mean diameter of approximately 1.5 µm and a length of around 4.0 µm, distributing uniformly along the entire woven carbon fibers. Both of Si/Si/Six/C@CC and Sn/C@CC products were synthesized as binder-free anodes for Li-ion battery with the features of high reversible capacity and excellent cycling. Especially Si/Six/C electrode exhibited high specific capacity of about 1750 mA∙h∙g−1 at 0.5 A∙g−1 and excellent cycling ability even after 1050 cycles with a capacity of 1388 mA∙h∙g−1. Highly flexible Si/Six/C@CC//LiCoO2 batteries based on liquid and solid electrolytes were also fabricated, exhibiting high flexibility, excellent electrical stability and potential applications in flexible wearable electronics.-

Keywords:

- electrospraying,

- Si/SiOx/C,

- Sn/C,

- lithium-ion batteries

-

References

[1] Liu Z, Xu J, Chen D, et al. Flexible electronics based on inorganic nanowires. Chem Soc Rev, 2015, 44, 161 doi: 10.1039/C4CS00116H[2] Chen D, Lou Z, Jiang K, et al. Device configurations and future prospects of flexible/stretchable lithium-ion batteries. Adv Funct Mater, 2018, 28, 1805596 doi: 10.1002/adfm.201805596[3] Liu B, Zhang J, Wang X, et at. Hierarchical three-dimensional ZnCo2O4 nanowire arrays/carbon cloth anodes for a novel class of high-performance flexible lithium-ion batteries. Nano Lett, 2012, 12, 3005 doi: 10.1021/nl300794f[4] Amine R, Daali A, Zhou X W, et al. A practical phosphorus-based anode material for high-energy lithium-ion batteries. Nano Energy, 2020, 74 doi: 10.1016/j.nanoen.2020.104849[5] Zhou K K, Zhao Y, Sun X P, et al. Ultra-stretchable triboelectric nanogenerator as high-sensitive and self-powered electronic skins for energy harvesting and tactile sensing. Nano Energy, 2020, 70, 104546 doi: 10.1016/j.nanoen.2020.104546[6] Zhong G K, Qu K, Ren C L, et al. Epitaxial array of Fe3O4 nanodots for high rate high capacity conversion type lithium ion batteries electrode with long cycling life. Nano Energy, 2020, 74, 104876 doi: 10.1016/j.nanoen.2020.104876[7] Kwon H J, Hwang J Y, Shin H J, et al. Nano/microstructured silicon–carbon hybrid composite particles fabricated with corn starch biowaste as anode materials for Li-ion batteries. Nano Lett, 2019, 20, 625 doi: 10.1021/acs.nanolett.9b04395[8] Shen L F, Yuan C Z, Luo H J, et al. In situ synthesis of high-loading Li4Ti5O12-graphene hybrid nanostructures for high rate lithium ion batteries. Nanoscale, 2011, 3, 572 doi: 10.1039/C0NR00639D[9] Liu H, Liu X X, Li W, et al. Porous carbon composites for next generation rechargeable lithium batteries. Adv Energy Mater, 2017, 7, 1700283 doi: 10.1002/aenm.201700283[10] Pan Q C, Wu Y N, Zhong W T, et al. Carbon nanosheets encapsulated nisb nanoparticles as advanced anode materials for lithium-ion batteries. Energy & Environ Mater, 2020, 3, 186 doi: 10.1002/eem2.12070[11] Wan L J, Chua D H C, Sun H C, et al. Construction of two-dimensional bimetal (Fe-Ti) oxide/carbon/MXene architecture from titanium carbide MXene for ultrahigh-rate lithium-ion storage. J Colloid Interface Sci, 2021, 588, 147 doi: 10.1016/j.jcis.2020.12.071[12] Zhang Y X, Wu B R, Mu G, et al. Recent progress and perspectives on silicon anode: Synthesis and prelithiation for LIBs energy storage. J Energy Chem, 2022, 64, 615 doi: 10.1016/j.jechem.2021.04.013[13] Zhang L Q, Zhu C X, Yu S C, et al. Status and challenges facing representative anode materials for rechargeable lithium batteries. J Energy Chem, 2022, 66, 260 doi: 10.1016/j.jechem.2021.08.001[14] Liu X L, Gao Y F, Jin R H, et al. Scalable synthesis of Si nanostructures by low-temperature magnesiothermic reduction of silica for application in lithium ion batteries. Nano Energy, 2014, 4, 31 doi: 10.1016/j.nanoen.2013.12.002[15] Shang H, Zuo Z C, Yu L, et al. Low-temperature growth of all-carbon graphdiyne on a silicon anode for high-performance lithium-ion batteries. Adv Mater, 2018, 30, 1801459 doi: 10.1002/adma.201801459[16] Wang B, Ryu J, Choi S, et al. Ultrafast-charging silicon-based coral-like network anodes for lithium-ion batteries with high energy and power densities. ACS Nano, 2019, 13, 2307 doi: 10.1021/acsnano.8b09034[17] Lee J H, Oh S H, Jeong S Y, et al. Rattle-type porous Sn/C composite fibers with uniformly distributed nanovoids containing metallic Sn nanoparticles for high-performance anode materials in lithium-ion batteries. Nanoscale, 2018, 10, 21483 doi: 10.1039/C8NR06075D[18] Sung J, Ma J, Choi S H, et al. Fabrication of lamellar nanosphere structure for effective stress-management in large-volume-variation anodes of high-energy lithium-ion batteries. Adv Mater, 2019, 31, 1900970 doi: 10.1002/adma.201900970[19] Lim K W, Lee J I, Yang J, et al. Catalyst-free synthesis of Si-Six core-shell nanowire anodes for high-rate and high-capacity lithium-ion batteries. ACS Appl Mater Interfaces, 2014, 6, 6340 doi: 10.1021/am405618m[20] Choi I, Lee M J, Oh S M, et al. Fading mechanisms of carbon-coated and disproportionated Si/SiO negative electrode (Si/SiO/C) in Li-ion secondary batteries: Dynamics and component analysis by TEM. Electrochim Acta, 2012, 85, 369 doi: 10.1016/j.electacta.2012.08.098[21] Liang J W, Li X N, Hou Z G, et al. A deep reduction and partial oxidation strategy for fabrication of mesoporous Si anode for lithium ion batteries. ACS Nano, 2016, 10, 2295 doi: 10.1021/acsnano.5b06995[22] Liu Z H, Zhao Y L, He R H, et al. Yolk@Shell SiO/C microspheres with semi-graphitic carbon coating on the exterior and interior surfaces for durable lithium storage. Energy Storage Mater, 2019, 19, 299 doi: 10.1016/j.ensm.2018.10.011[23] Guo C F, Wang D L, Liu T F, et al. A three dimensional SiOx/C@RGO nanocomposite as a high energy anode material for lithium-ion batteries. J Mater Chem A, 2014, 2, 3521 doi: 10.1039/C3TA13746E[24] Tao J M, Yan Z R, Yang J S, et al. Boosting the cell performance of the Six@C anode material via rational design of a Si-valence gradient. Carbon Energy, 2021, 4, 129 doi: 10.1002/cey2.141[25] Li Z L, Zhao H L, Wang J, et al. Rational structure design to realize high-performance Six@C anode material for lithium ion batteries. Nano Res, 2020, 13, 527 doi: 10.1007/s12274-020-2644-9[26] Yu Q, Ge P P, Liu Z H, et al. Ultrafine Six/C nanospheres and their pomegranate-like assemblies for high-performance lithium storage. J Mater Chem A, 2018, 6, 14903 doi: 10.1039/C8TA03987A[27] Wang B, Qiu T F, Li X L, et al. Synergistically engineered self-standing silicon/carbon composite arrays as high performance lithium battery anodes. J Mater Chem A, 2015, 3, 494 doi: 10.1039/C4TA06088A[28] Huang T T, Lou Z, Lu Y, et al. Metal-organic-framework-derived MCo2O4 (M = Mn and Zn) nanosheet arrays on carbon cloth as integrated anodes for energy storage applications. ChemElectroChem, 2019, 6, 5836 doi: 10.1002/celc.201901445[29] Zhang J, Gu J W, He H Y, et al. High-capacity nano-Si@Six@C anode composites for lithium-ion batteries with good cyclic stability. J Solid State Electrochem, 2017, 21, 2259 doi: 10.1007/s10008-017-3578-3[30] Zhang J Y, Hou Z L, Zhang X M, et al. Delicate construction of Si@Six composite materials by microwave hydrothermal for lithium-ion battery anodes. Ionics, 2020, 26, 69 doi: 10.1007/s11581-019-03204-0[31] Liu S F, Kuo C H, Lin C C, et al. Biowaste-derived Si@Six/C anodes for sustainable lithium-ion batteries. Electrochim Acta, 2022, 403, 139580 doi: 10.1016/j.electacta.2021.139580[32] Jiang B L, Zeng S, Wang H, et al. Dual core−shell structured Si@Six@C nanocomposite synthesized via a one-step pyrolysis method as a highly stable anode material for lithium-ion batteries. ACS Appl Mater nterfaces, 2016, 8, 31611 doi: 10.1021/acsami.6b09775[33] Xu Y H, Liu Q, Zhu Y J, et al. Uniform nano-Sn/C composite anodes for lithium ion batteries. Nano Lett, 2013, 13, 470 doi: 10.1021/nl303823k[34] Chen L, Li Y T, Li S P, et al. PEO/garnet composite electrolytes for solid-state lithium batteries: From "ceramic-in-polymer" to "polymer-in-ceramic". Nano Energy, 2018, 46, 176 doi: 10.1016/j.nanoen.2017.12.037 -

Supplements

24080030Supporting_information.pdf

24080030Supporting_information.pdf

-

Proportional views

Di Chen received her BSc degree (1999) in chemistry from Anhui Normal University and PhD degree (2005) in chemistry from the University of Science and Technology of China. She has worked as a professor at Huazhong University of Science and Technology and University of Science and Technology Beijing. In 2022, she joined the School of Integrated Circuit at Beijing Institute of Technology. Her current research focuses on flexible energy storage device and flexible sensors for health monitoring.

Di Chen received her BSc degree (1999) in chemistry from Anhui Normal University and PhD degree (2005) in chemistry from the University of Science and Technology of China. She has worked as a professor at Huazhong University of Science and Technology and University of Science and Technology Beijing. In 2022, she joined the School of Integrated Circuit at Beijing Institute of Technology. Her current research focuses on flexible energy storage device and flexible sensors for health monitoring. Kai Jiang received his MB/BS degree from Second Military Medical College, Shanghai, China, in 1991, and MD/PhD degrees from Chinese PLA Postgraduate Medical College, Beijing, China, in 1998. He further studied at the Queen Mary Hospital of University of Hong Kong in 2002, and Universitat de Barcelona, Spain, in 2008. He has been with the Department of Hepatobiliary Surgery, Chinese PLA General Hospital since 1991, where he is currently a Professor of surgery and vice Dean of the Department. His current research interests focus on surgical operation and applications of nanotechnology in clinical medicine.

Kai Jiang received his MB/BS degree from Second Military Medical College, Shanghai, China, in 1991, and MD/PhD degrees from Chinese PLA Postgraduate Medical College, Beijing, China, in 1998. He further studied at the Queen Mary Hospital of University of Hong Kong in 2002, and Universitat de Barcelona, Spain, in 2008. He has been with the Department of Hepatobiliary Surgery, Chinese PLA General Hospital since 1991, where he is currently a Professor of surgery and vice Dean of the Department. His current research interests focus on surgical operation and applications of nanotechnology in clinical medicine.

DownLoad:

DownLoad: