| Citation: |

Jingyan Li, Xiangbo Zeng, Hao Li, Xiaobing Xie, Ping Yang, Haibo Xiao, Xiaodong Zhang, Qiming Wang. Reduced defect density in microcrystalline silicon by hydrogen plasma treatment[J]. Journal of Semiconductors, 2013, 34(10): 103006. doi: 10.1088/1674-4926/34/10/103006

****

J Y Li, X B Zeng, H Li, X B Xie, P Yang, H B Xiao, X D Zhang, Q M Wang. Reduced defect density in microcrystalline silicon by hydrogen plasma treatment[J]. J. Semicond., 2013, 34(10): 103006. doi: 10.1088/1674-4926/34/10/103006.

|

Reduced defect density in microcrystalline silicon by hydrogen plasma treatment

DOI: 10.1088/1674-4926/34/10/103006

More Information

-

Abstract

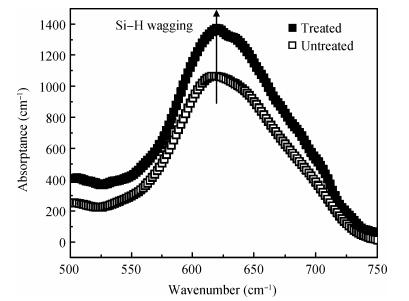

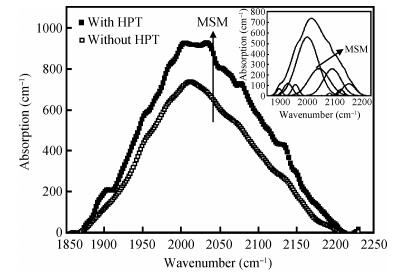

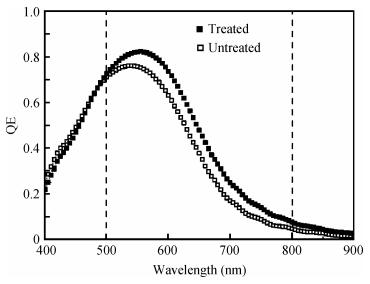

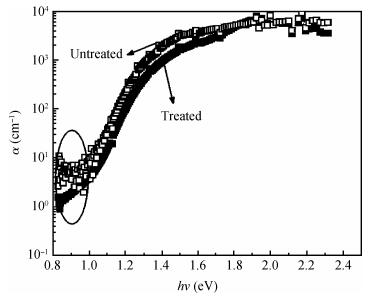

The effect of hydrogen plasma treatment (HPT) during the initial stage of microcrystalline silicon (μc-Si) growth on the defect density of μc-Si has been investigated. Lower absorption coefficient in the 0.8-1.0 eV indicated less defect density compared to its counterpart without HPT. The infrared spectroscopy of μc-Si with HPT shows an increase in 2040 cm-1, which reveals more Si-H in the amorphous/crystalline interfaces. We ascribe the decrease of defect density to hydrogen passivation of the dangling bonds. Improved performance of μc-Si solar cell with HPT is due to the reduced defect density. -

References

[1] Klein S, Finger F, Carius R. Intrinsic microcrystalline silicon prepared by hot-wire chemical vapour deposition for thin film solar cells. Thin Solid Films, 2003, 430(1/2):202 http://www.sciencedirect.com/science/article/pii/S0040609003001111[2] Bugnon G, Feltrin A, Meillaud F. Influence of pressure and silane depletion on microcrystalline silicon material quality and solar cell performance. J Appl Phys, 2009, 105(6):064507 doi: 10.1063/1.3095488[3] Poortmans J, Vladimir. Thin film solar cells fabrication, characterization and applications. England: John Wiley & Sons, 2006[4] Smets A H M, Matsui T, Kondo M. High-rate deposition of microcrystalline silicon p-i-n solar cells in the high pressure depletion regime. J Appl Phys, 2008, 104(3):034508 doi: 10.1063/1.2961334[5] Chen Y S, Wang J H. The effect of transient depletion of source gases on the properties of microcrystalline silicon solar cells. Sol Energy, 2009, 83(9):1454 doi: 10.1016/j.solener.2009.03.015[6] Ide Y, Saito Y, Yamada A, et al. 2-step growth method and microcrystalline silicon thin film solar cells prepared by hot wire cell method. Jpn J Appl Phys, 2004, 43(5A):2419 doi: 10.1143/JJAP.43.2419[7] Chantana J, Tsutsui Y, Sobajima Y. Importance of starting procedure for film growth in substrate-type microcrystalline-silicon solar cells. Jpn J Appl Phys, 2011, 50(4):045806 doi: 10.1143/JJAP.50.045806[8] Ihara H, Nozaki H. Improvement of hydrogenated amorphous silicon n-i-p diode performance by H2 plasma treatment for i/p interface. Jpn J Appl Phys, 1990, 29(12):2159 http://www.academia.edu/1811567/Amorphous_Silicon_Nanocone_Array_Solar_Cell[9] Ambrico M, Schiavulli L, Ligonzo T. Optical absorption and electrical conductivity measurements of microcrystalline silicon layers grown by SiF4/H plasma on glass substrates. Thin Solid Films, 2001, 383(1/2):200 http://www.academia.edu/14105049/Optical_absorption_and_electrical_conductivity_measurements_of_microcrystalline_silicon_layers_grown_by_SiF_rH_plasma_on_glass_4_2[10] Langford A A, Fleet M L, Nelson B P. Infrared absorption strength and hydrogen content of hydrogenated amorphous silicon. Phys Rev B, 1992, 45(23):13367 doi: 10.1103/PhysRevB.45.13367[11] Kaneko T, Wakagi M, Onisawa K. Change in crystalline morphologies of polycrystalline silicon films prepared by radiofrequency plasmaenhanced chemical vapor deposition using SiF4 + H2 gas mixture at 350℃. Appl Phys Lett, 1994, 64(14):1865 doi: 10.1063/1.111781[12] Han D, Wang K, Owens J M. Hydrogen structures and the optoelectronic properties in transition films from amorphous to microcrystalline silicon prepared by hot-wire chemical vapor deposition. J Appl Phys, 2003, 93(7):3776 doi: 10.1063/1.1555680[13] Bronneberg A C, Cankoy N, Sanden M C M. Ion-induced effects on grain boundaries and a-Si:H tissue quality in microcrystalline silicon films. J Vac Sci Technol A, 2012, 30(6):061512 doi: 10.1116/1.4766193[14] Keudell A V, Abelson J R. The interaction of atomic hydrogen with very thin amorphous hydrogenated silicon films analyzed using in situ real time infrared spectroscopy:reaction rates and the formation of hydrogen platelets. J Appl Phys, 1998, 84(1):489 doi: 10.1063/1.368082[15] Marra D C, Edelberg E A, Naone R L. Silicon hydride composition of plasma-deposited hydrogenated amorphous and nanocrystalline silicon films and surfaces. J Vac Sci Technol A, 1998, 16(6):3199 doi: 10.1116/1.581520[16] Xu L, Li Z P, Wen C. Bonded hydrogen in nanocrystalline silicon photovoltaic materials:impact on structure and defect density. J Appl Phys, 2011, 110(6):064315 doi: 10.1063/1.3638712 -

Proportional views

DownLoad:

DownLoad: