| Citation: |

Mengting Jiang, Yuling Liu. Reducing the mechanical action of polishing pressure and abrasive during copper chemical mechanical planarization[J]. Journal of Semiconductors, 2014, 35(12): 126001. doi: 10.1088/1674-4926/35/12/126001

****

M T Jiang, Y L Liu. Reducing the mechanical action of polishing pressure and abrasive during copper chemical mechanical planarization[J]. J. Semicond., 2014, 35(12): 126001. doi: 10.1088/1674-4926/35/12/126001.

|

Reducing the mechanical action of polishing pressure and abrasive during copper chemical mechanical planarization

DOI: 10.1088/1674-4926/35/12/126001

More Information

-

Abstract

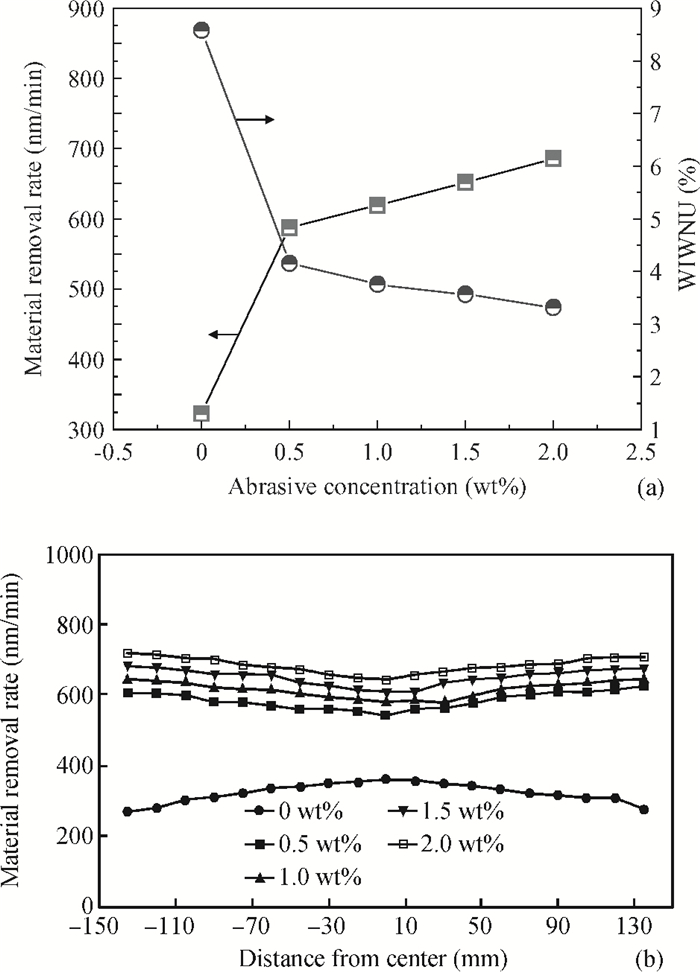

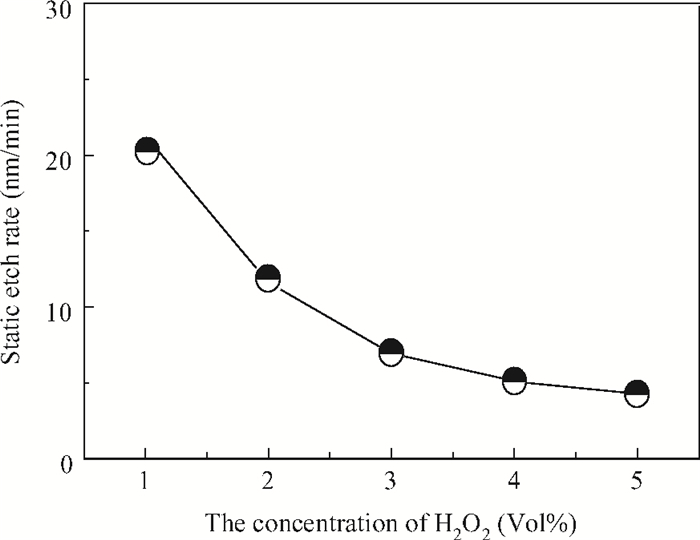

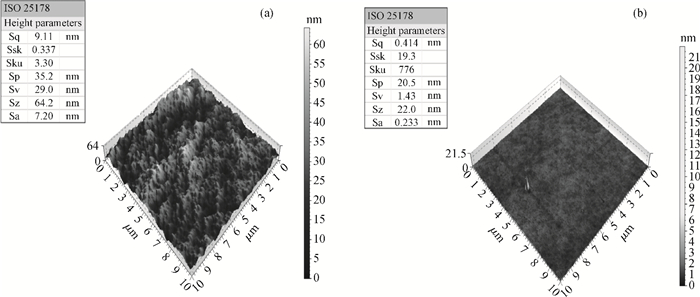

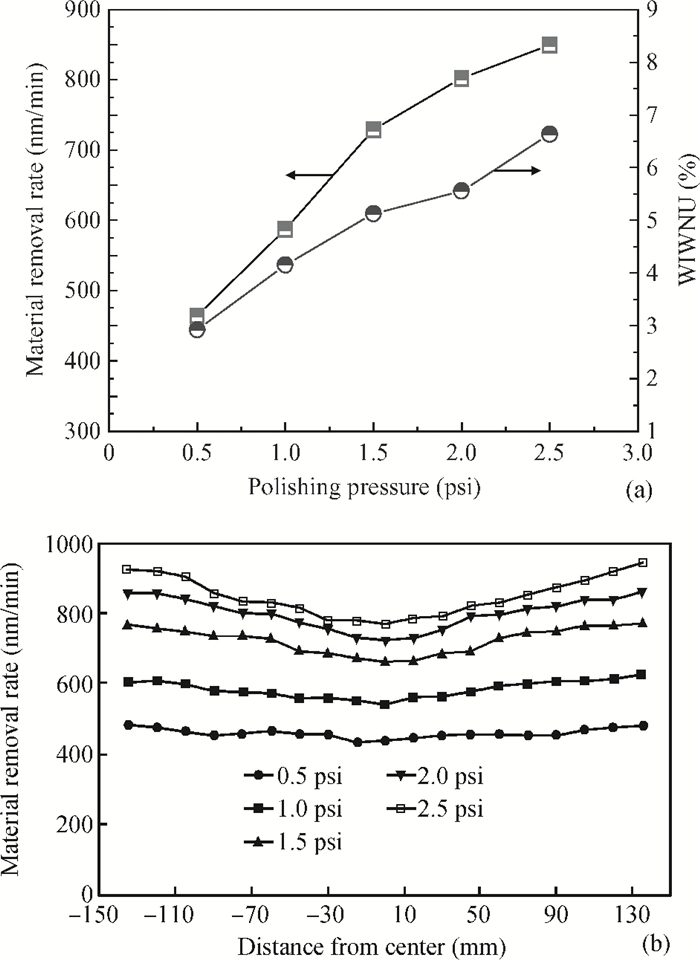

Chemical mechanical planarization (CMP) is a critical process in deep sub-micron integrated circuit manufacturing. This study aims to improve the planarization capability of slurry, while minimizing the mechanical action of the pressure and silica abrasive. Through conducting a series of single-factor experiments, the appropriate pressure and the optimum abrasive concentration for the alkaline slurry were confirmed. However, the reduced mechanical action may bring about a decline of the polishing rate, and further resulting in the decrease of throughput. Therefore, we take an approach to compensating for the loss of mechanical action by optimizing the composition of the slurry to enhance the chemical action in the CMP process. So 0.5 wt% abrasive concentration of alkaline slurry for copper polishing was developed, it can achieve planarization efficiently and obtain a wafer surface with no corrosion defect at a reduced pressure of 1.0 psi. The results presented here will contribute to the development of a "softer gentler polishing" technique in the future. -

References

[1] Fayolle M, Romagna F. Copper CMP evaluation:planarization issues. Microelectron Eng, 1997, 37/38:135 doi: 10.1016/S0167-9317(97)00104-4[2] Zantye P B, Kumar A, Sikdar A K. Chemical mechanical planarization for microelectronics applications. Mater Sci Eng, 2004, 45(3):89 http://www.worldcat.org/title/chemical-mechanical-planarization-for-microelectronics-applications/oclc/491603826[3] Chiu S Y, Wang Y L, Liu C P, et al. High-selectivity damascene chemical mechanical polishing. Thin Solid Films, 2006, 498(1/2):60 http://web.mit.edu/cmp/publications/papers/electrochemical2.pdf[4] Lakshminarayanan S, Steigerwald J, Price D T, et al. Contact and via structures with copper interconnects fabricated using dual damascene technology. IEEE Electron Device Lett, 1994, 15(8):307 doi: 10.1109/55.296225[5] Wu L X, Yan C F. An analytical model for step height reduction in CMP with different pattern densities. J Electrochem Soc, 2007, 154(7):H596 doi: 10.1149/1.2735932[6] Ruan W B, Chen L, Li Z G, et al. Effects of pattern characteristics on copper CMP. Journal of Semiconductors, 2009, 30(4):046001 doi: 10.1088/1674-4926/30/4/046001[7] Yin K D, Wang S L, Liu Y L, et al. Evaluation of planarization capability of copper slurry in the CMP process. Journal of Semiconductors, 2013, 34(3):036002 doi: 10.1088/1674-4926/34/3/036002[8] Pandija S, Roy D, Babu S V. Achievement of high planarization efficiency in CMP of copper at a reduced down pressure. Microelectron Eng, 2009, 86(3):367 doi: 10.1016/j.mee.2008.11.047[9] Li Y, Liu Y L, Niu X H, et al. Application of a macromolecular chelating agent in chemical mechanical polishing of copper film under the condition of low pressure and low abrasive concentration. Journal of Semiconductors, 2014, 35(1):016001 doi: 10.1088/1674-4926/35/1/016001[10] Kim N H, Lim J H, Kim S Y, et al. Semi-abrasive free slurry with acid colloidal silica for copper chemical mechanical planarization. J Mater Sci, 2005, 16(9):629 doi: 10.1007/s10854-005-3241-0[11] Lee H, Park B, Jeong H. Mechanical effect of process condition and abrasive concentration on material removal rate profile in copper chemical mechanical planarization. J Mater Processing Technol, 2009, 209(4):1729 doi: 10.1016/j.jmatprotec.2008.04.021[12] Lee H, Park B, Jeong H. Influence of slurry components on uniformity in copper chemical mechanical planarization. Microelectron Eng, 2008, 85(4):689 doi: 10.1016/j.mee.2007.12.044 -

Proportional views

DownLoad:

DownLoad: