| Citation: |

Huamao Huang, Jinyong Hu, Hong Wang. GaN-based light-emitting diodes with hybrid micro/nano-textured indium-tin-oxide layer[J]. Journal of Semiconductors, 2014, 35(8): 084006. doi: 10.1088/1674-4926/35/8/084006

****

H M Huang, J Y Hu, H Wang. GaN-based light-emitting diodes with hybrid micro/nano-textured indium-tin-oxide layer[J]. J. Semicond., 2014, 35(8): 084006. doi: 10.1088/1674-4926/35/8/084006.

|

GaN-based light-emitting diodes with hybrid micro/nano-textured indium-tin-oxide layer

DOI: 10.1088/1674-4926/35/8/084006

More Information

-

Abstract

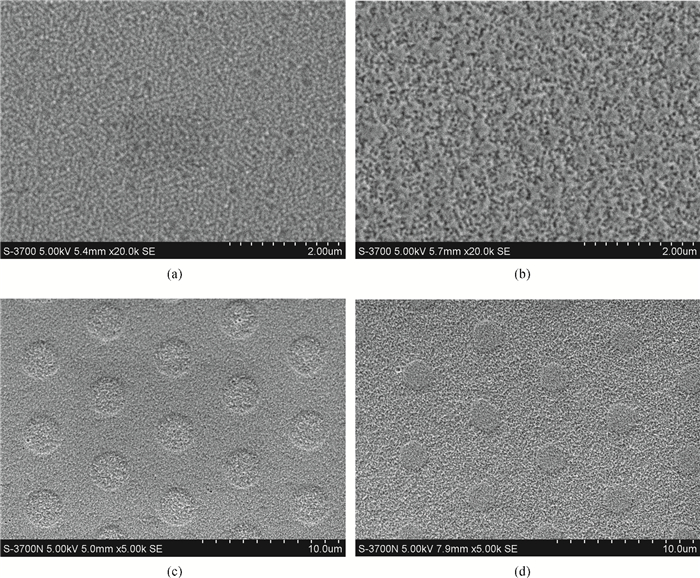

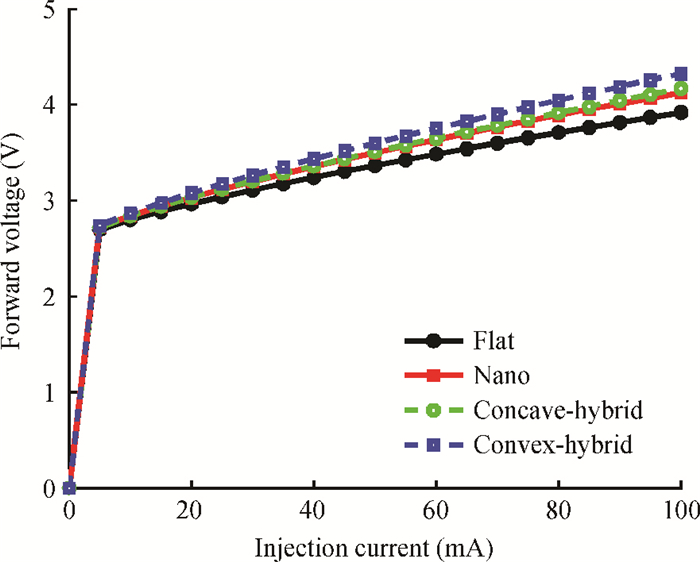

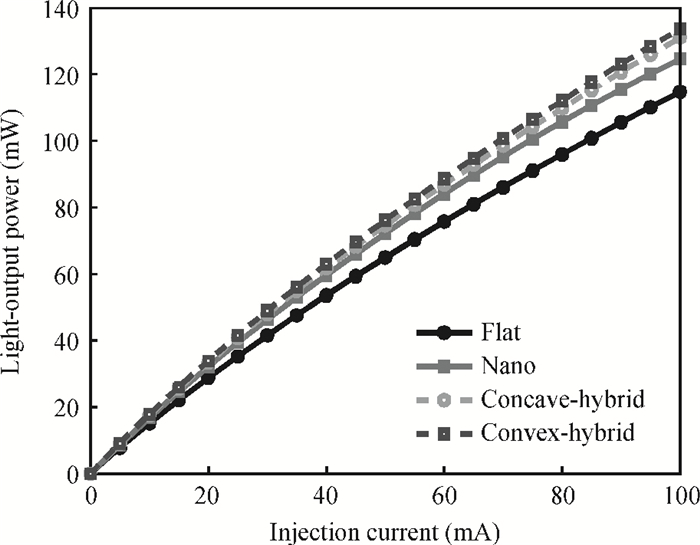

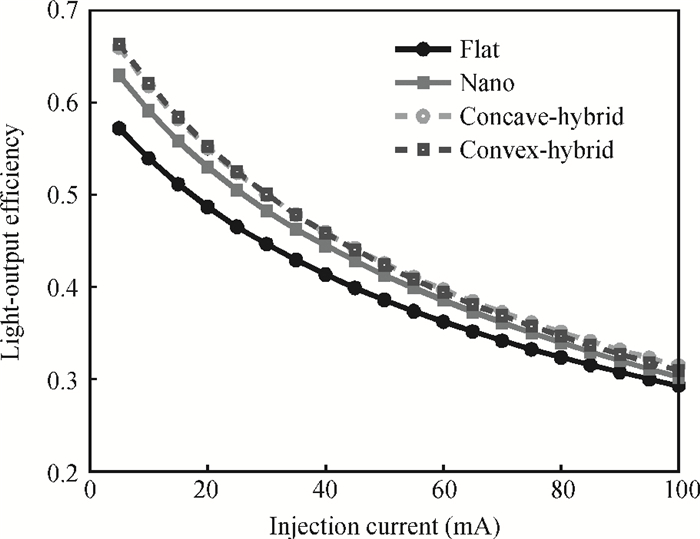

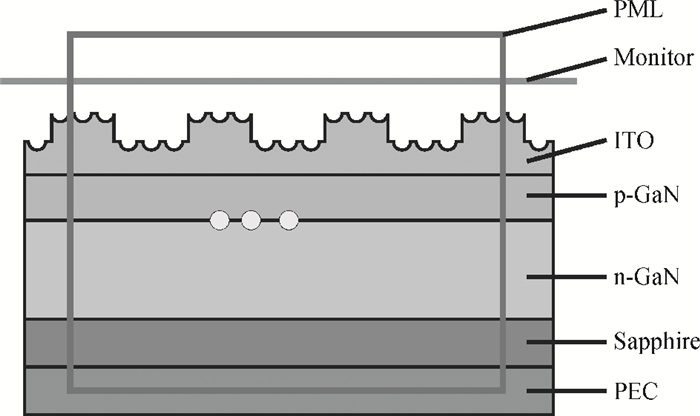

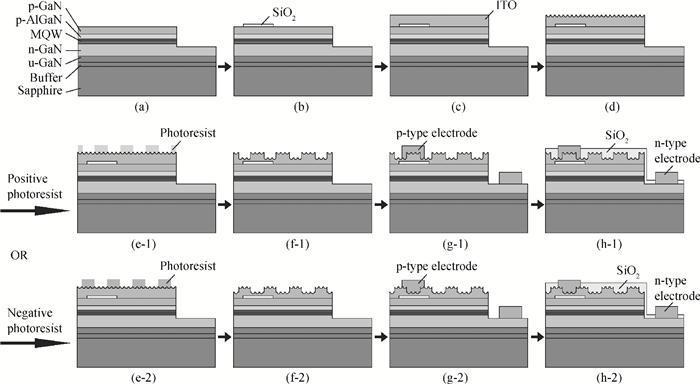

Three types of textured indium-tin-oxide (ITO) surface, including nano-texturing and hybrid micro/nano-texturing with micro-holes (concave-hybrid-pattern) or micro-pillars (convex-hybrid-pattern), were applied to GaN-based light-emitting diodes (LEDs). The nano-texturing was realized by maskless wet-etching, and the micro-texturing was achieved by standard photolithography and wet-etching. Compared to LED chips with flat ITO surface, those with nano-pattern, concave-hybrid-pattern, and convex-hybrid-pattern exhibit enhancement of 11.3%, 15.8%, and 17.9%, respectively, for the light-output powers at 20 mA. The electrical performance has no degradation. Moreover, the convex-hybrid-pattern show higher light-output efficiency under small injection current, while the concave-hybrid-pattern exhibit better light-output efficiency at large injection current. The light-extraction efficiency is simulated by use of two-dimensional finite difference time domain method, and the numerical results are consistent with the experiments. -

References

[1] Zhmakin A I. Enhancement of light extraction from light emitting diodes. Phys Rep, 2011, 498:189 doi: 10.1016/j.physrep.2010.11.001[2] Pan S M, Tu R C, Fan Y M, et al. Improvement of InGaN-GaN light-emitting diodes with surface-textured indium-tin-oxide transparent ohmic contacts. IEEE Photon Tech Lett, 2003, 15(5):649 doi: 10.1109/LPT.2003.809985[3] Wang P, Cao B, Wei W, et al. Improved light extraction of GaN-based light-emitting diodes by ITO patterning with optimization design. Solid-State Electron, 2010, 54:283 doi: 10.1016/j.sse.2009.10.005[4] Tsai C F, Su Y K, Lin C L. Improvement in external quantum efficiency of InGaN-based LEDs by micro-textured surface with different geometric patterns. J Electrochem Soc, 2012, 159(2):H151 doi: 10.1149/2.055202jes[5] Chang S J, Shen C F, Chen W S, et al. Nitride-based light emitting diodes with indium tin oxide electrode patterned by imprint lithography. Appl Phys Lett, 2007, 91:013504 doi: 10.1063/1.2753726[6] Leem D S, Cho J, Sone C, et al. Light-output enhancement of GaN-based light-emitting diodes by using hole-patterned transparent indium tin oxide electrodes. J Appl Phys, 2005, 98:076107. doi: 10.1063/1.2081117[7] Horng R H, Yang C C, Wu J Y, et al. GaN-based light-emitting diodes with indium tin oxide texturing window layers using natural lithography. Appl Phys Lett, 2005, 86:221101 doi: 10.1063/1.1940723[8] He Anhe, Zhang Yong, Zhu Xuehui, et al. Improved light extraction of GaN-based light-emitting diodes with surface-textured indium tin oxide electrodes by nickel nanoparticle mask dry-etching. Chin Phys B, 2010, 19(6):068101 doi: 10.1088/1674-1056/19/6/068101[9] Liao C, Wu Y S. InGaN-GaN light emitting diode performance improved by roughening indium tin oxide window layer via natural lithography. Electrochem Solid State Lett, 2010, 13(1):J8 doi: 10.1149/1.3257601[10] Leem D S, Lee T, Seong T Y. Enhancement of the light output of GaN-based light-emitting diodes with surface-patterned ITO electrodes by maskless wet-etching. Solid-State Electron, 2007, 51:793 doi: 10.1016/j.sse.2007.02.038[11] Kang J H, Kim H G, Ryu J H, et al. Enhancement of light output power in InGaN/GaN LEDs with nanoroughed hemispherical indium tin oxide transparent ohmic contacts. Electrochem Solid State Lett, 2010, 13(2):D1 doi: 10.1149/1.3261741[12] Kang J H, Ryu J H, Kim H K, et al. Comparison of various surface textured layer in InGaN LEDs for high light extraction efficiency. Opt Express, 2011, 19(4):3637 doi: 10.1364/OE.19.003637[13] Kang J H, Kim H G, Kim H K, et al. Improvement of light output power in InGaN/GaN light-emitting diodes with a nanotextured GaN surface using indium tin oxide nanospheres. Jpn J Appl Phys, 2009, 48:102104 doi: 10.1143/JJAP.48.102104[14] Li S, Kuo D S, Liu C H, et al. Efficiency improvement of GaN-based light-emitting diodes by direct wet etching of indium-tin-oxide layer. IET Optoelectron, 2012, 6(6):303 doi: 10.1049/iet-opt.2012.0019[15] Huh C, Lee J M, Kim D J, et al. Improvement in light-output efficiency of InGaN/GaN multiple-quantum well light-emitting diodes by current blocking layer. J Appl Phys, 2002, 92(5):2248 doi: 10.1063/1.1497467[16] Pan J W, Tsai P J, Chang K D, et al. Light extraction efficiency analysis of GaN-based light-emitting diodes with nanopatterned sapphire substrates. Appl Opt, 2013, 52(7):1358 doi: 10.1364/AO.52.001358 -

Proportional views

DownLoad:

DownLoad: