| Citation: |

Xueqin Gong, Shiwei Feng, Yuan Yue, Junwei Yang, Jingwei Li. Thermal analysis in high power GaAs-based laser diodes[J]. Journal of Semiconductors, 2016, 37(4): 044011. doi: 10.1088/1674-4926/37/4/044011

****

X Q Gong, S W Feng, Y Yue, J W Yang, J W Li. Thermal analysis in high power GaAs-based laser diodes[J]. J. Semicond., 2016, 37(4): 044011. doi: 10.1088/1674-4926/37/4/044011.

|

Thermal analysis in high power GaAs-based laser diodes

DOI: 10.1088/1674-4926/37/4/044011

More Information

-

Abstract

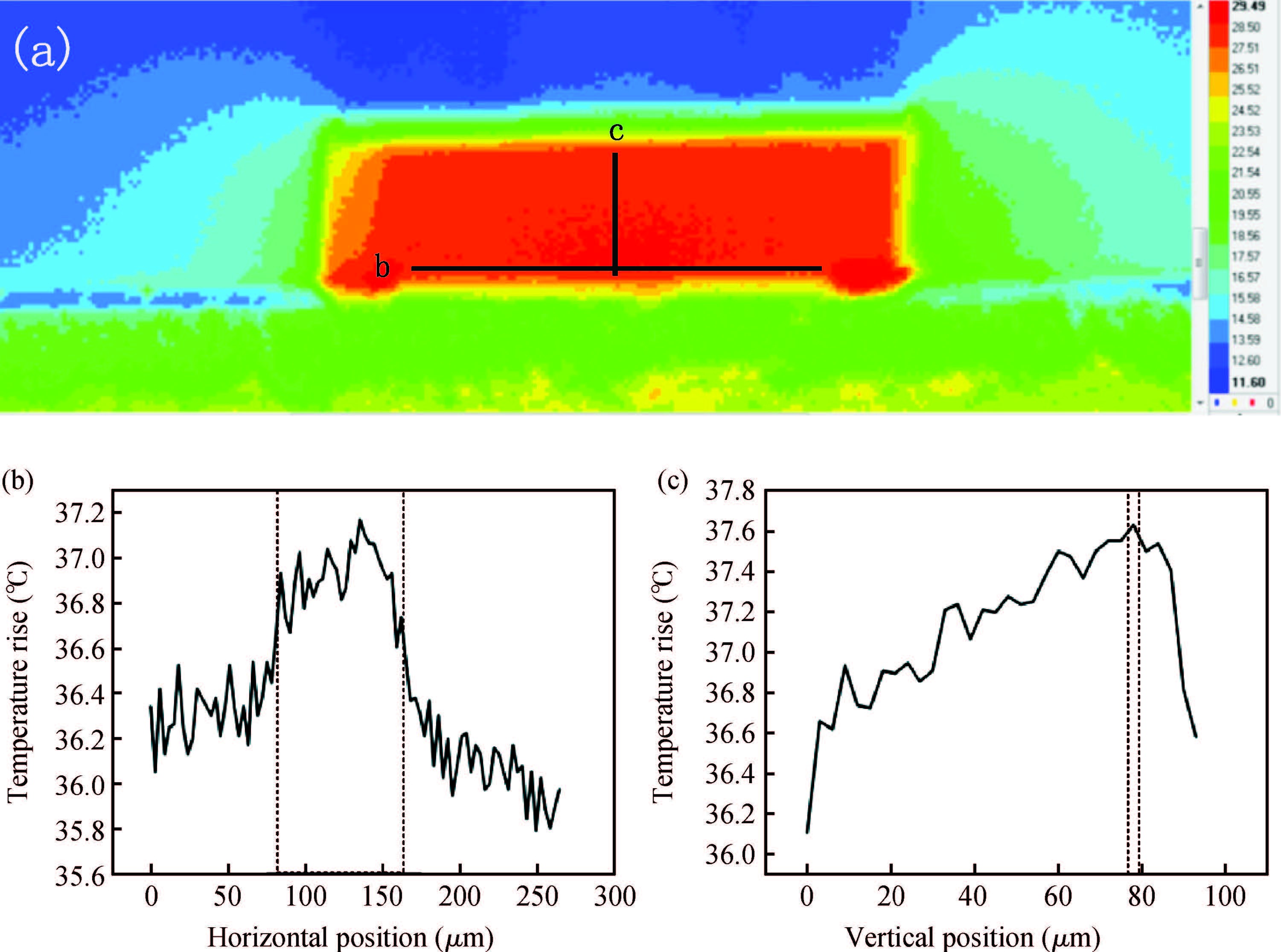

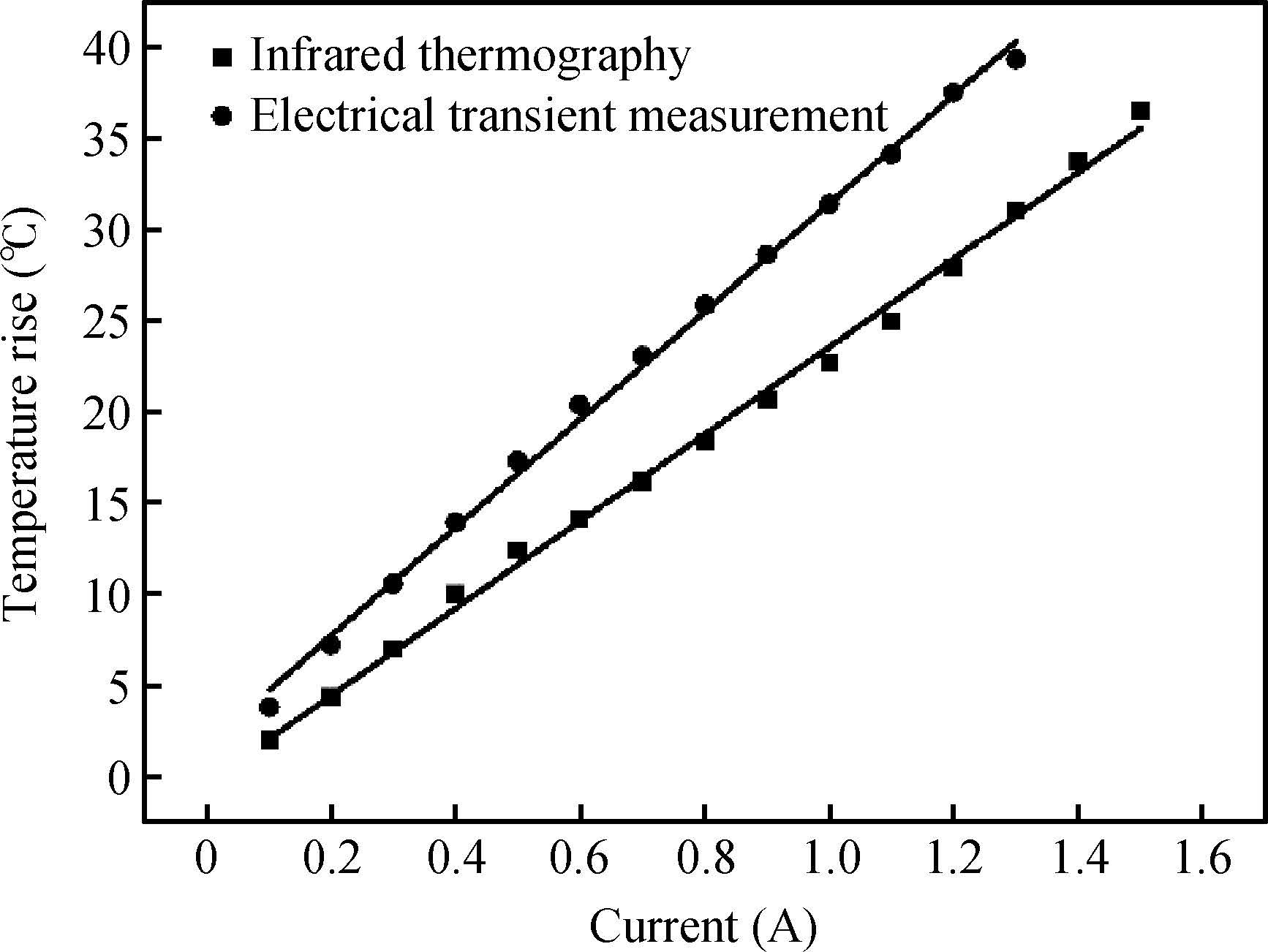

The thermal characteristics of 808 nm AlGaAs/GaAs laser diodes (LDs) are analyzed via electrical transient measurements and infrared thermography. The temperature rise and thermal resistance are measured at various input currents and powers. From the electrical transient measurements, it is found that there is a significant reduction in thermal resistance with increasing power because of the device power conversion efficiency. The component thermal resistance that was obtained from the structure function showed that the total thermal resistance is mainly composed of the thermal resistance of the sub-mount rather than that of the LD chip, and the thermal resistance of the sub-mount decreases with increasing current. The temperature rise values are also measured by infrared thermography and are calibrated based on a reference image, with results that are lower than those determined by electrical transient measurements. The difference in the results is caused by the limited spatial resolution of the measurements and by the signal being captured from the facet rather than from the junction of the laser diode. -

References

[1] [2] [3] [4] [5] [6] [7] [8] [9] [10] [11] [12] [13] [14] [15] [16] [17] [18] [19] [20] [21] -

Proportional views

DownLoad:

DownLoad: