| Citation: |

Kesheng Wang, Jia Cheng, Yin Zhong, Linhong Ji. A novel measuring method of clamping force for electrostatic chuck in semiconductor devices[J]. Journal of Semiconductors, 2016, 37(4): 044012. doi: 10.1088/1674-4926/37/4/044012

****

K S Wang, J Cheng, Y Zhong, L H Ji. A novel measuring method of clamping force for electrostatic chuck in semiconductor devices[J]. J. Semicond., 2016, 37(4): 044012. doi: 10.1088/1674-4926/37/4/044012.

|

A novel measuring method of clamping force for electrostatic chuck in semiconductor devices

DOI: 10.1088/1674-4926/37/4/044012

More Information

-

Abstract

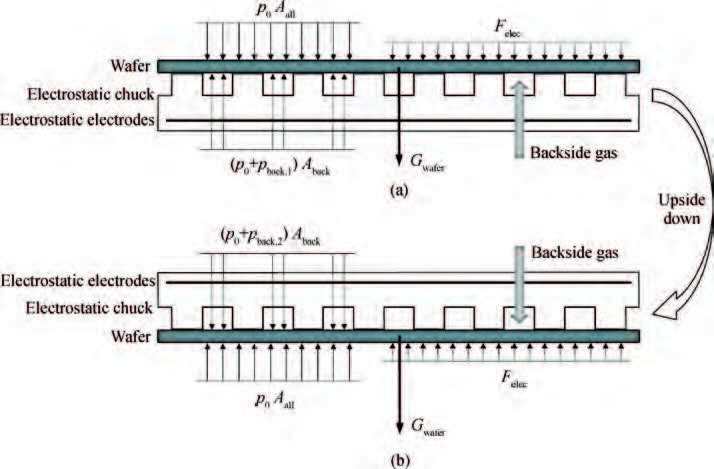

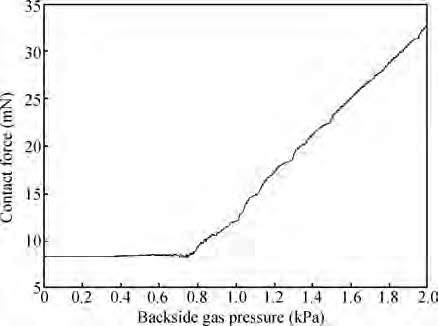

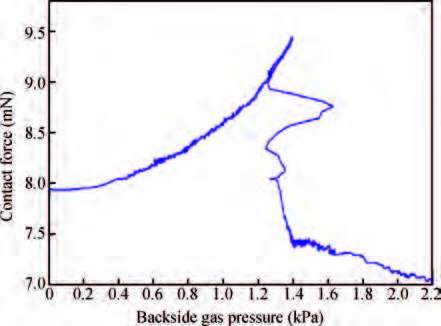

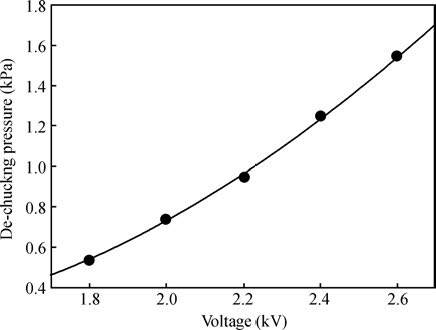

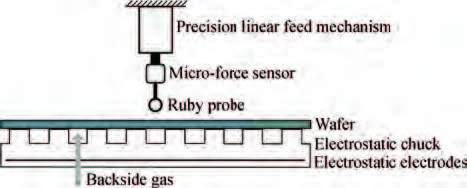

Electrostatic chucks are one of the core components of semiconductor devices. As a key index of electrostatic chucks, the clamping force must be controlled within a reasonable range. Therefore, it is essential to accurately measure the clamping force. To reduce the negative factors influencing measurement precision and repeatability, this article presents a novel method to measure the clamping force and we elaborate both the principle and the key procedure. A micro-force probe component is introduced to monitor, adjust, and eliminate the gap between the wafer and the electrostatic chuck. The contact force between the ruby probe and the wafer is selected as an important parameter to characterize de-chucking, and we have found that the moment of de-chucking can be exactly judged. Moreover, this article derives the formula calibrating equivalent action area of backside gas pressure under real working conditions, which can effectively connect the backside gas pressure at the moment of de-chucking and the clamping force. The experiments were then performed on a self-designed measuring platform. The de-chucking mechanism is discussed in light of our analysis of the experimental data. Determination criteria for de-chucking point are summed up. It is found that the relationship between de-chucking pressure and applied voltage conforms well to quadratic equation. Meanwhile, the result reveals that actual de-chucking behavior is much more complicated than the description given in the classical empirical formula.-

Keywords:

- electrostatic chuck,

- wafer,

- clamping force,

- de-chucking,

- measuring method

-

References

[1] [2] [3] [4] [5] [6] [7] [8] [9] [10] [11] [12] [13] -

Proportional views

DownLoad:

DownLoad: