| Citation: |

R. Bansen, C. Ehlers, Th. Teubner, T. Boeck. Steady-state solution growth of microcrystalline silicon on nanocrystalline seed layers on glass[J]. Journal of Semiconductors, 2016, 37(9): 093001. doi: 10.1088/1674-4926/37/9/093001

****

R. Bansen, C. Ehlers, Th. Teubner, T. Boeck. Steady-state solution growth of microcrystalline silicon on nanocrystalline seedlayers on glass[J]. J. Semicond., 2016, 37(9): 093001. doi: 10.1088/1674-4926/37/9/093001.

|

Steady-state solution growth of microcrystalline silicon on nanocrystalline seed layers on glass

DOI: 10.1088/1674-4926/37/9/093001

More Information

-

Abstract

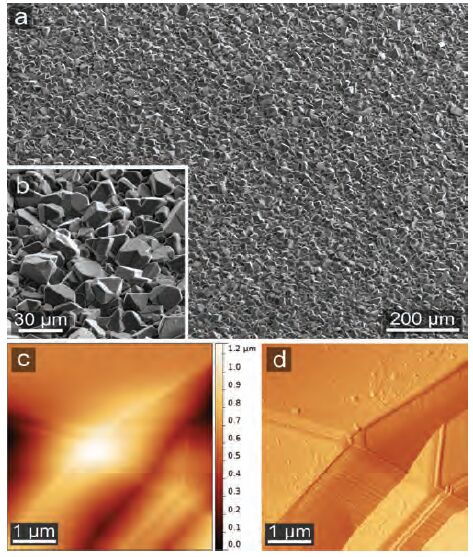

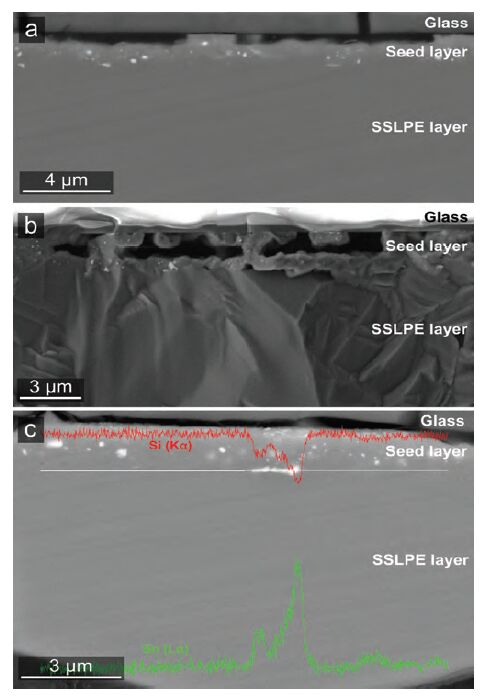

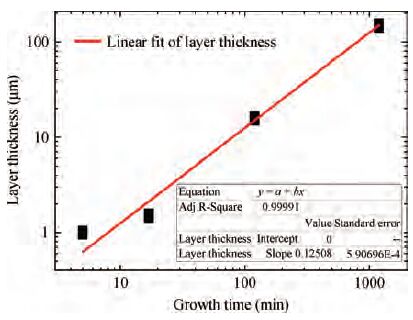

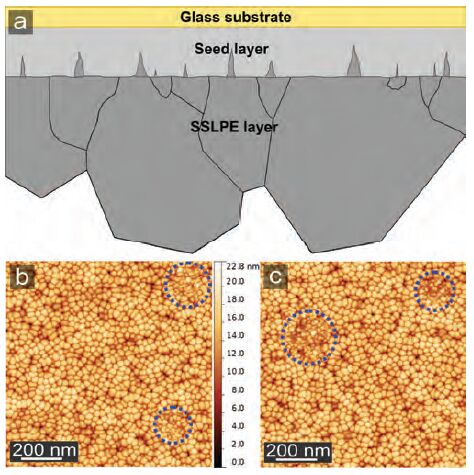

The growth of polycrystalline silicon layers on glass from tin solutions at low temperatures is presented. This approach is based on the steady-state solution growth of Si crystallites on nanocrystalline seed layers, which are prepared in a preceding process step. Scanning electron microscopy and atomic force microscopy investigations reveal details about the seed layer surfaces, which consist of small hillocks, as well as about Sn inclusions and gaps along the glass substrate after solution growth. The successful growth of continuous microcrystalline Si layers with grain sizes up to several ten micrometers shows the feasibility of the process and makes it interesting for photovoltaics. -

References

[1] Sonntag P, Haschke J, Kühnapfel S, et al. Interdigitated back-contact heterojunction solar cell concept for liquid phase crystallized thin-film silicon on glass. Prog Photovoltaics Res, 2016, 24: 716 doi: 10.1002/pip.v24.5[2] Huang J, Varlamov S, Dore J, et al. Micro-structural defects in polycrystalline silicon thin-film solar cells on glass by solid-phase crystallisation and laser-induced liquid-phase crystallization. Sol Energy Mater Sol Cells, 2015, 132: 282 doi: 10.1016/j.solmat.2014.09.021[3] Gawlik A, Plentz J, Höger I, et al. Multicrystalline silicon thin film solar cells on glass with epitaxially grown emitter prepared by a two-step laser crystallization process. Phys Status Solidi, 2014, 212: 162 http://cn.bing.com/academic/profile?id=1529485619&encoded=0&v=paper_preview&mkt=zh-cn[4] Amkreutz D, Haschke J, Häring T, et al. Conversion efficiency and process stability improvement of electron beam crystallized thin film silicon solar cells on glass. Sol Energy Mater Sol Cells, 2014, 123: 13 doi: 10.1016/j.solmat.2013.12.021[5] Bronger T, Wöbkenberg P H, Wördenweber J, et al. Solution-based silicon in thin-film solar cells. Adv Energy Mater, 2014, 4: 1301871 doi: 10.1002/aenm.201301871[6] Orhan J B, Monnard R, Vallat-Sauvain E, et al. Nano-textured superstrates for thin film silicon solar cells: status and industrial challenges. Sol Energy Mater Sol Cells, 2015, 140: 344 doi: 10.1016/j.solmat.2015.04.027[7] Bansen R, Heimburger R, Schmidtbauer J, et al. Crystalline silicon on glass by steady-state solution growth using indium as solvent. Appl Phys A, 2015, 119: 1577 doi: 10.1007/s00339-015-9141-0[8] Bansen R, Heimburger R, Schmidtbauer J, et al. Solution growth of crystalline Si on glass. 29th European Photovoltaic Solar Energy Conference and Exhibition, Amsterdam, 2014: 1908 http://cn.bing.com/academic/profile?id=2311065638&encoded=0&v=paper_preview&mkt=zh-cn[9] McNeely J B, Hall R B, Barnett A M, et al. Thin-film silicon crystal growth on low cost substrates. J Cryst Growth, 1984, 70: 420 doi: 10.1016/0022-0248(84)90297-5[10] Teubner T, Heimburger R, Böttcher K, et al. Equipment for low temperature steady-state growth of silicon from metallic solutions. Cryst Growth Des, 2008, 8: 2484 doi: 10.1021/cg800120q[11] Klapper H, Rudolph P. Defect generation and interaction during crystal growth. Handbook of Crystal Growth. Volume Ⅱ, ed T Nishinaga, Elsevier, 2015: 1093[12] Capper P, Mauk M. Liquid phase epitaxy of electronic, optical and optoelectronic materials. Wiley, 2007: 114 http://cn.bing.com/academic/profile?id=652837748&encoded=0&v=paper_preview&mkt=zh-cn[13] Haberl B. Structural characterization of amorphous silicon. PhD Dissertation, The Australian National University, 2010 -

Proportional views

DownLoad:

DownLoad: