| Citation: |

Fan Tang, Zhenning Guo. Design of a cylindrical LED substrate without radiator[J]. Journal of Semiconductors, 2017, 38(12): 124005. doi: 10.1088/1674-4926/38/12/124005

****

F Tang, Z N Guo. Design of a cylindrical LED substrate without radiator[J]. J. Semicond., 2017, 38(12): 124005. doi: 10.1088/1674-4926/38/12/124005.

|

Design of a cylindrical LED substrate without radiator

DOI: 10.1088/1674-4926/38/12/124005

More Information

-

Abstract

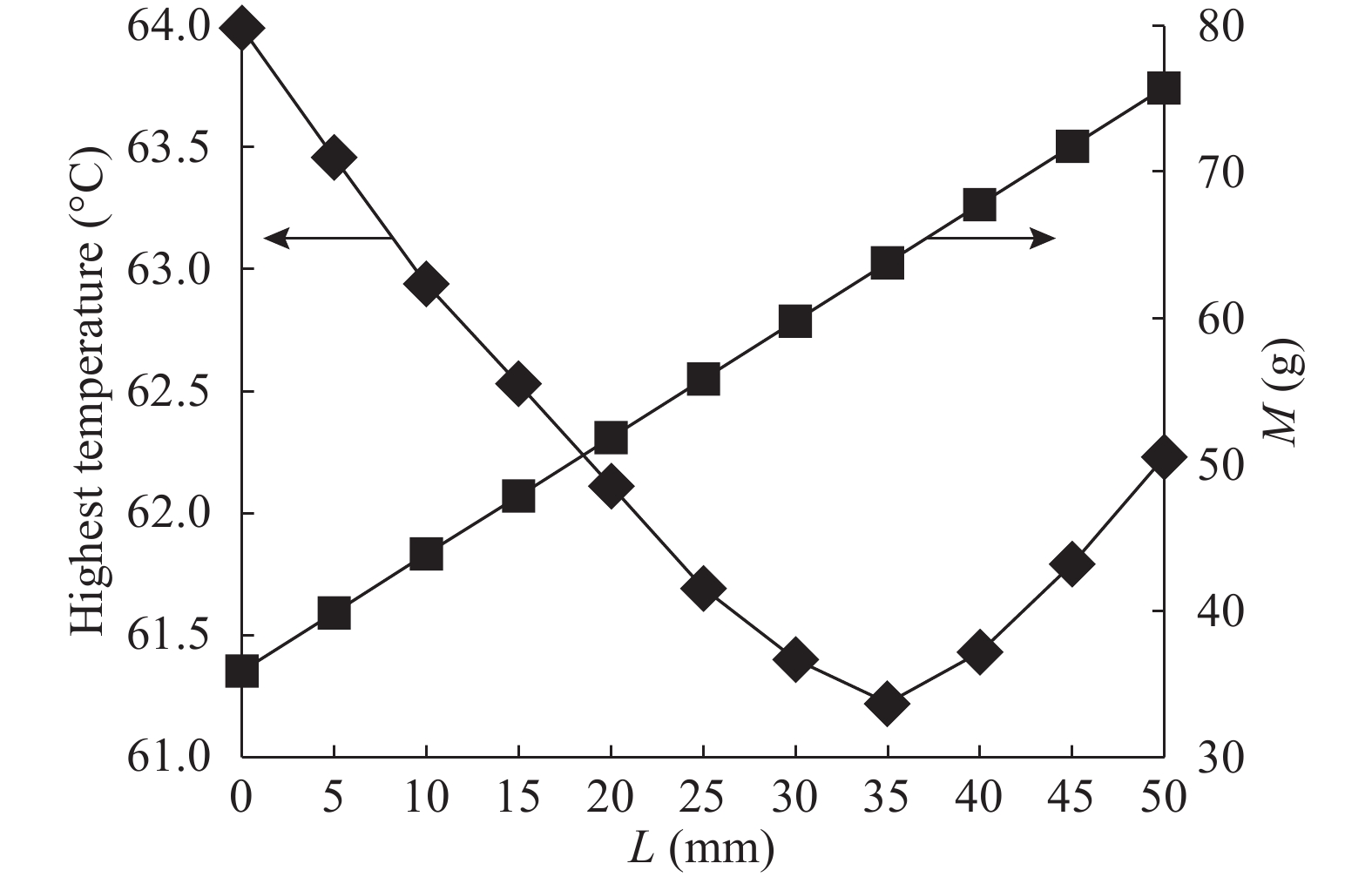

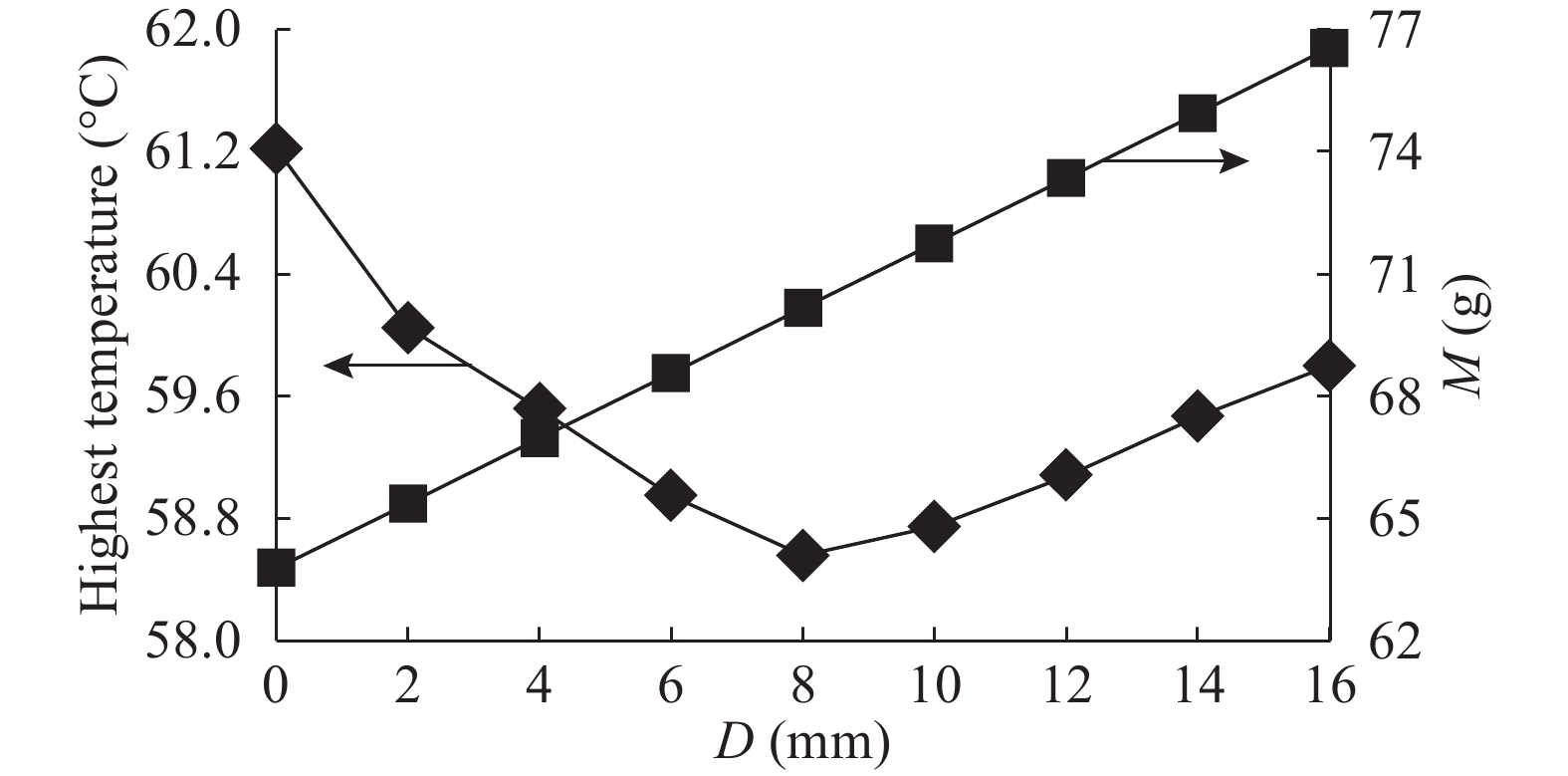

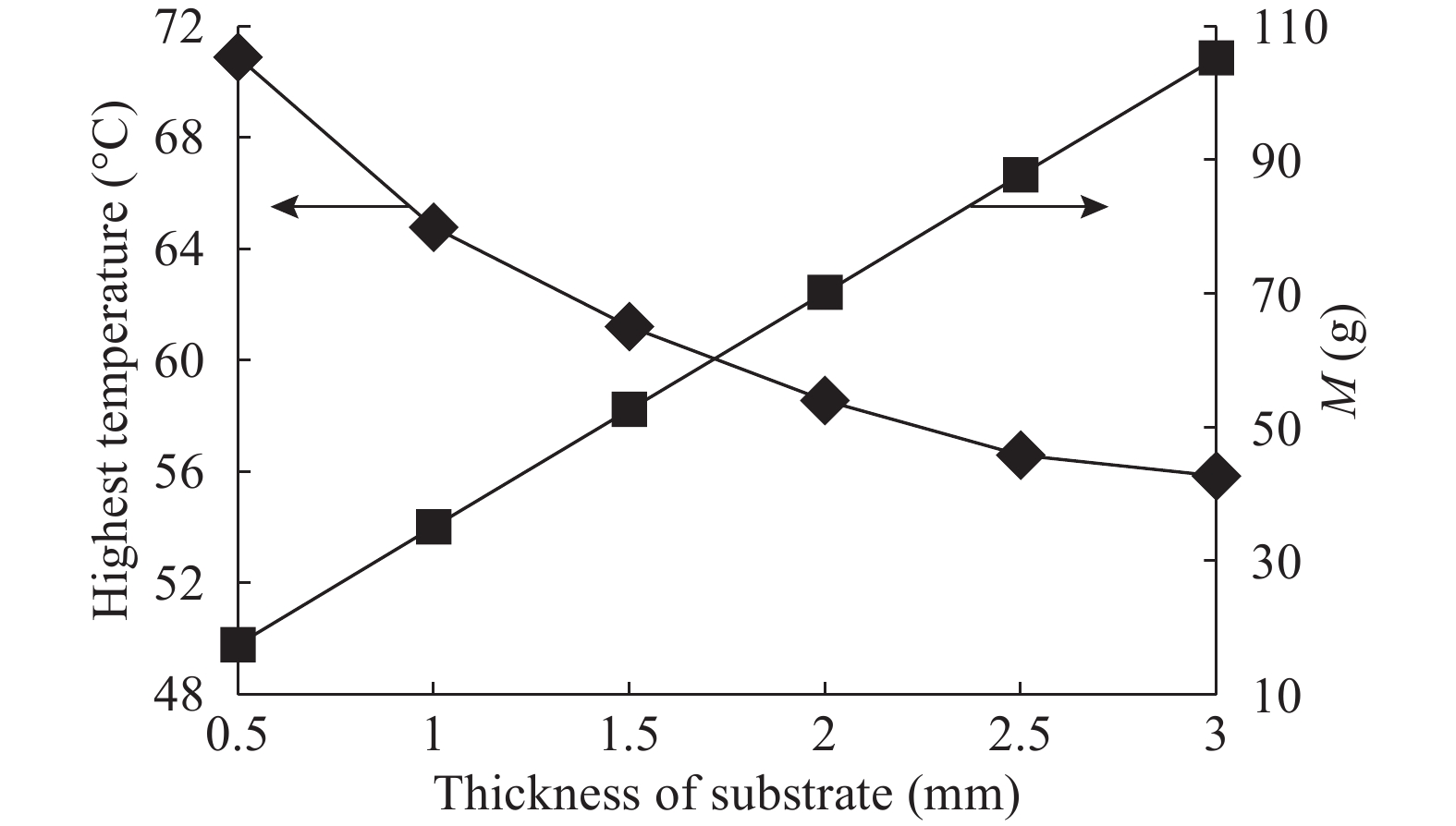

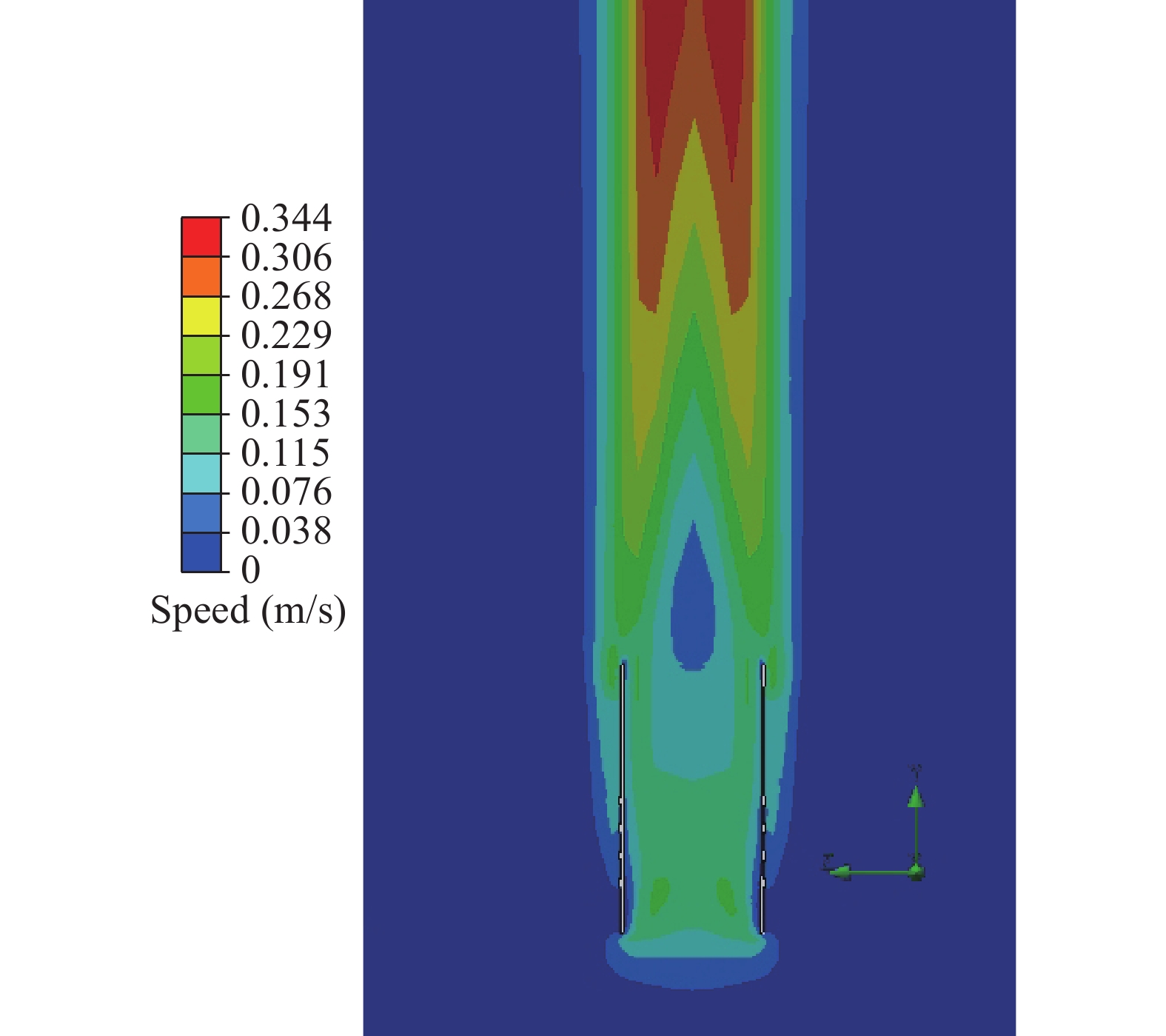

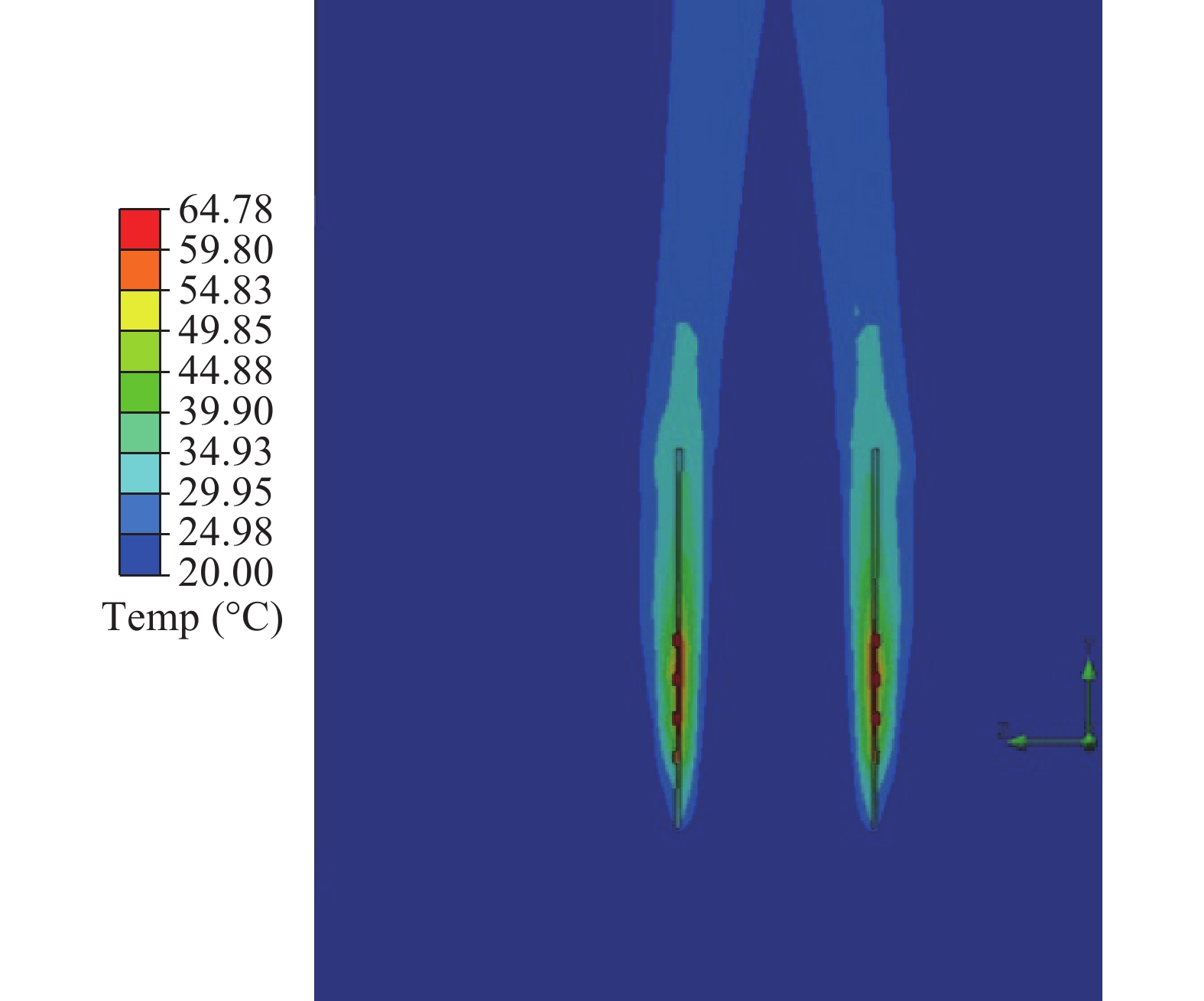

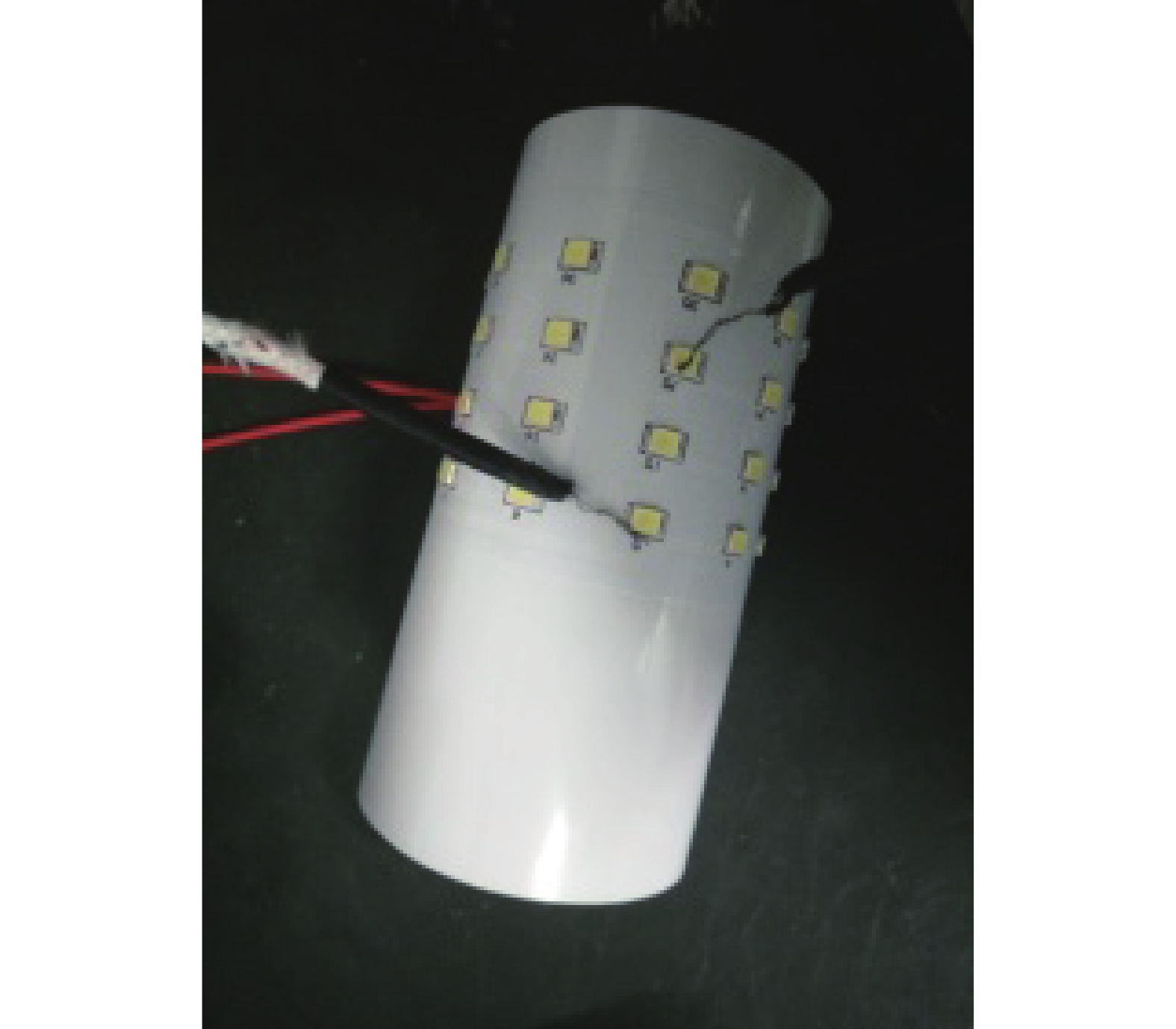

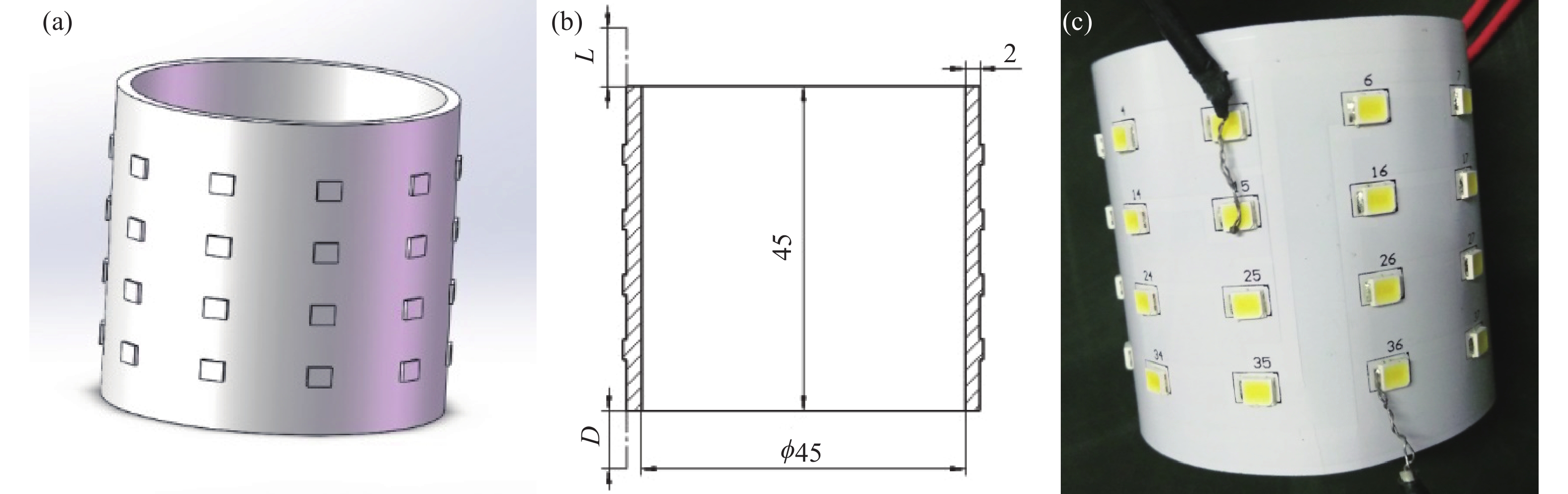

To reduce the weight and production costs of light-emitting diode (LED) lamps, we applied the principle of the chimney effect to design a cylindrical LED substrate without a radiator. We built a 3D model by using Solidworks software and applied the flow simulation plug-in to conduct model simulation, thereby optimizing the heat source distribution and substrate thickness. The results indicate that the design achieved optimal cooling with a substrate with an upper extension length of 35 mm, a lower extension length of 8 mm, and a thickness of 1 mm. For a substrate of those dimensions, the highest LED chip temperature was 64.78 °C, the weight of the substrate was 35.09 g, and Rjb = 7.00 K/W. If the substrate is powered at 8, 10, and 12 W, its temperature meets LED safety requirements. In physical tests, the highest temperature for a physical 8 W cylindrical LED substrate was 66 °C, which differed by only 1.22 °C from the simulation results, verifying the validity of the simulation. The designed cylindrical LED substrate can be used in high-power LED lamps that do not require radiators. This design is not only excellent for heat dissipation, but also for its low weight, low cost, and simplicity of manufacture. -

References

[1] Lin Y C, Nguyen T, Zhou Y. Materials challenges and solutions for the packaging of high power LEDs. International Microsystems, Packing, Assembly Conference, Taiwan, China, 2006: 177[2] Arik M, Petroski J, Weaver S. Thermal challenges in the future generation solid state lighting applications: light emitting diodes. IEEE Intersociety Conf, Thermal Phenomena, Hawaii, 2002: 113[3] Li J H. Thermal design and simulation of LED lamps. Zhejiang: Hangzhou Dianzi University, 2011[4] He F, Chen Q H, Liu J F. Thermal analysis of high mast integrated LED Lamp with new heatsink structure of laminated pure aluminum plate. Chin J Lumin, 2014, 35: 743[5] Wang L, Wu K, Yu Y B. Study on LED array heat radiator improvement under natural convection. J Optoelectron•Laser, 2011, 22: 338[6] Xiang J H, Zhang C L, Chen S. Numerical optimization of phase-change radiator for high-power LED. J Guangzhou Univ (Nat Sci Ed), 2015, 14: 61[7] Zhu P. The enhancement of heat dissipation of high power LED lamp with chimney effect. Dalian Univ Technol, 2014: 20[8] Hu M Y, Wu Y P, Yang Z R. Thermal design of high power plate LED COB lighting source. Electron Process Technol, 2015, 36: 63[9] Li J, Ji S T, Liu Y. Analysis on the stack effect of cooling device of electronic components. Electron Pack, 2011, 11: 36[10] Liu J, Liu J F, Chen Q H. Thermal management of novel 12W LED bulb for the substitution of 100 W incandescent bulb. Chin J Lumin, 2014, 35: 86 -

Proportional views

DownLoad:

DownLoad: