| Citation: |

Fengxiang Wang, Quan Yuan, Xiao Kan, Jicong Zhao, Zeji Chen, Jinling Yang, Fuhua Yang. Reliability testing of a 3D encapsulated VHF MEMS resonator[J]. Journal of Semiconductors, 2018, 39(10): 104008. doi: 10.1088/1674-4926/39/10/104008

****

F X Wang, Q Yuan, X Kan, J C Zhao, Z J Chen, J L Yang, F H Yang, Reliability testing of a 3D encapsulated VHF MEMS resonator[J]. J. Semicond., 2018, 39(10): 104008. doi: 10.1088/1674-4926/39/10/104008.

|

Reliability testing of a 3D encapsulated VHF MEMS resonator

DOI: 10.1088/1674-4926/39/10/104008

More Information

-

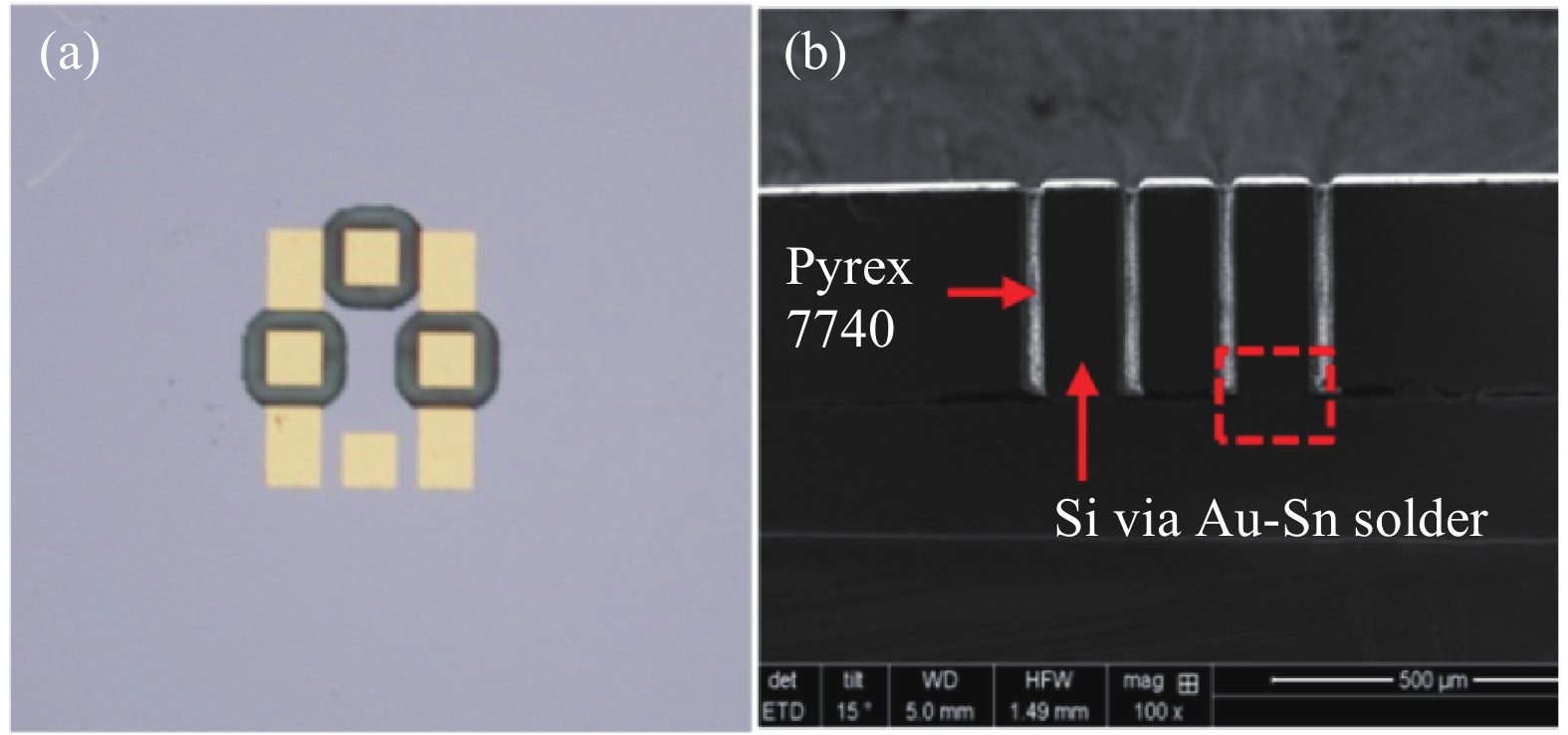

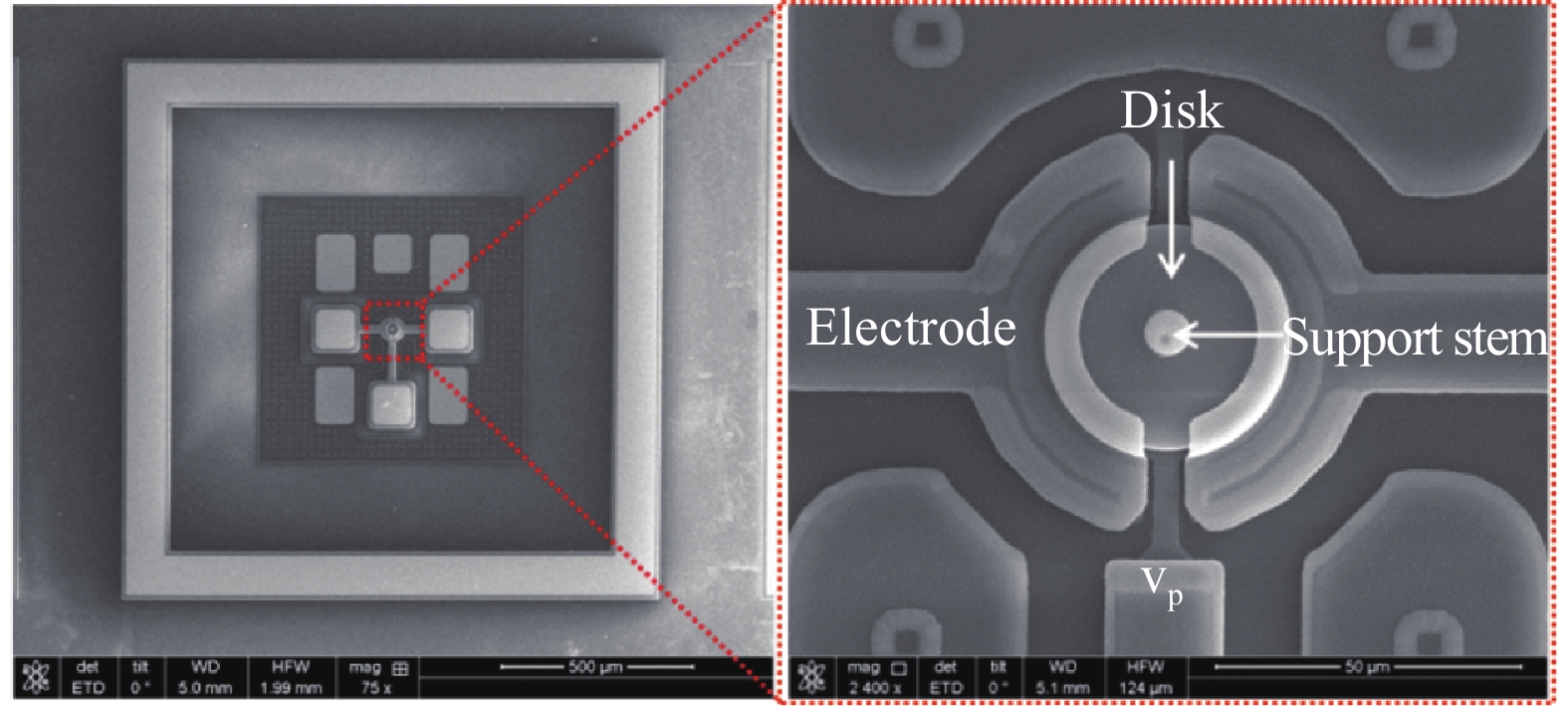

Abstract

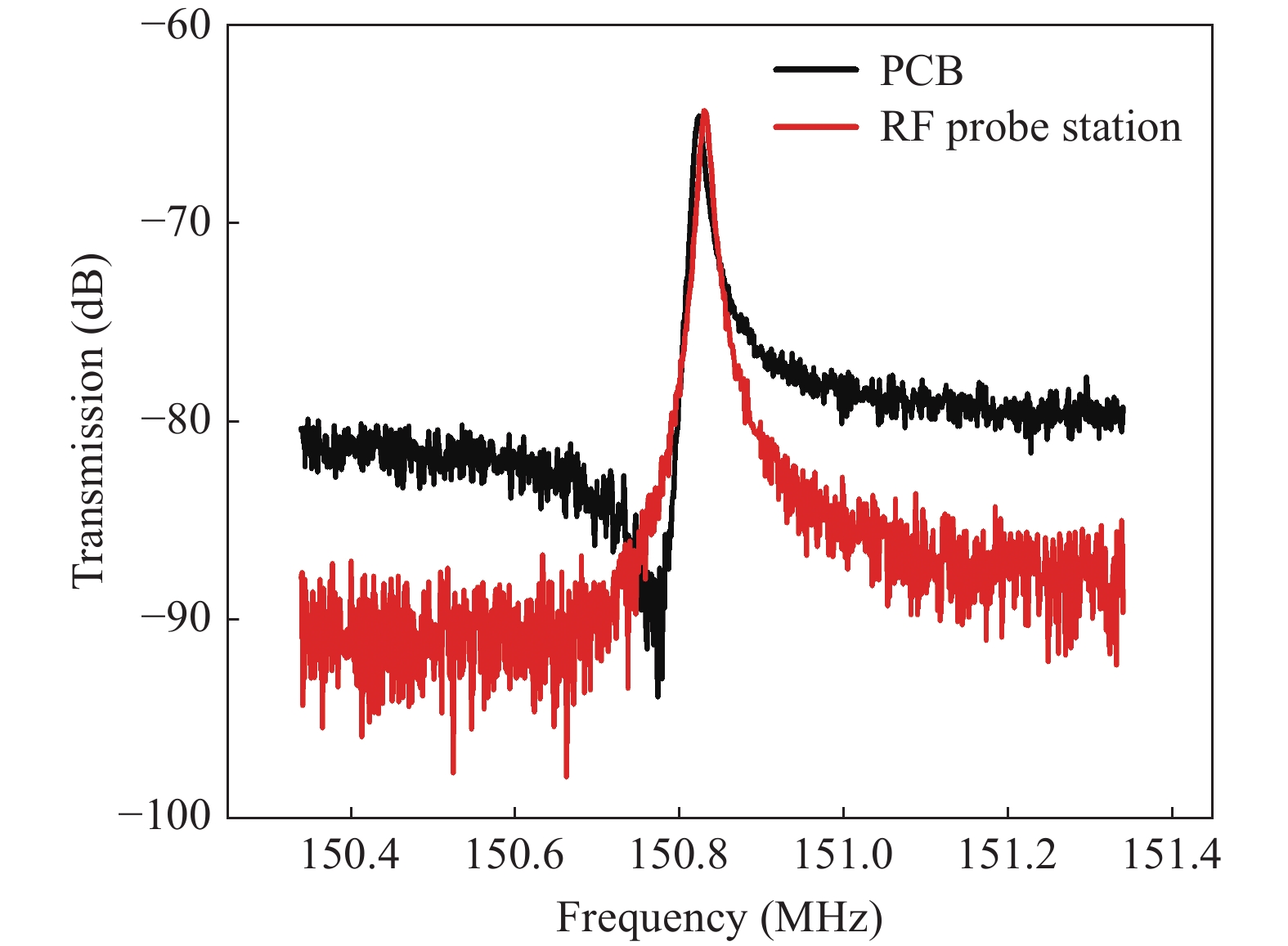

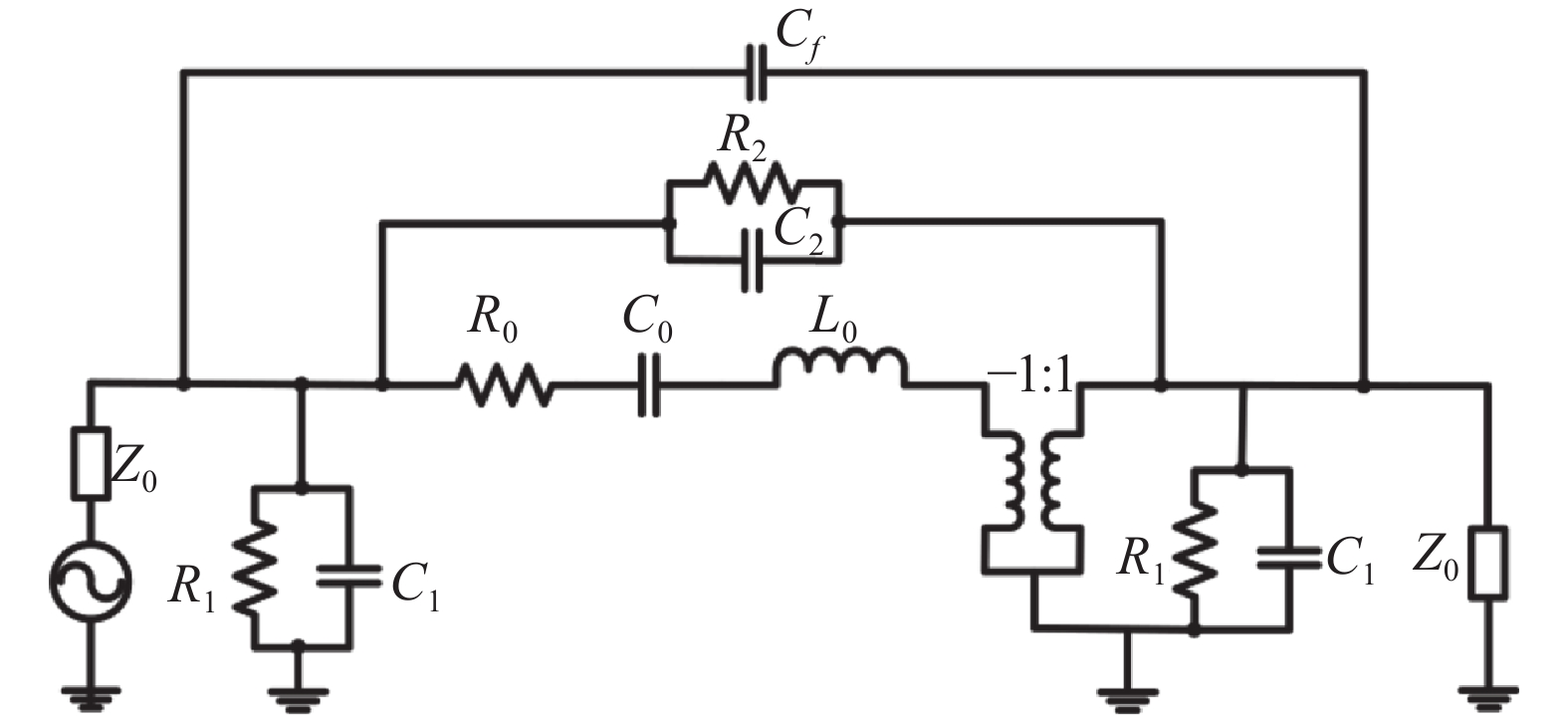

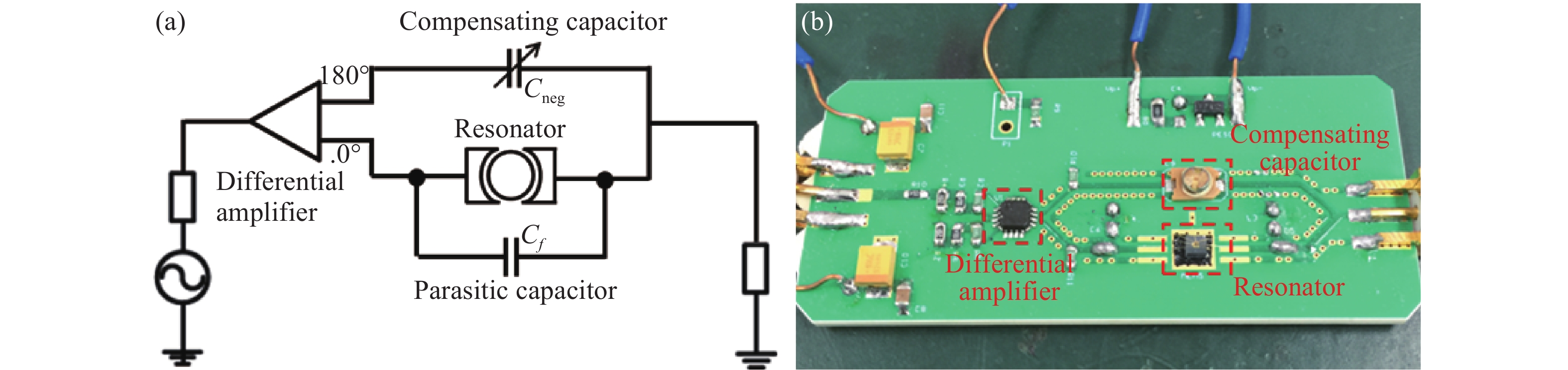

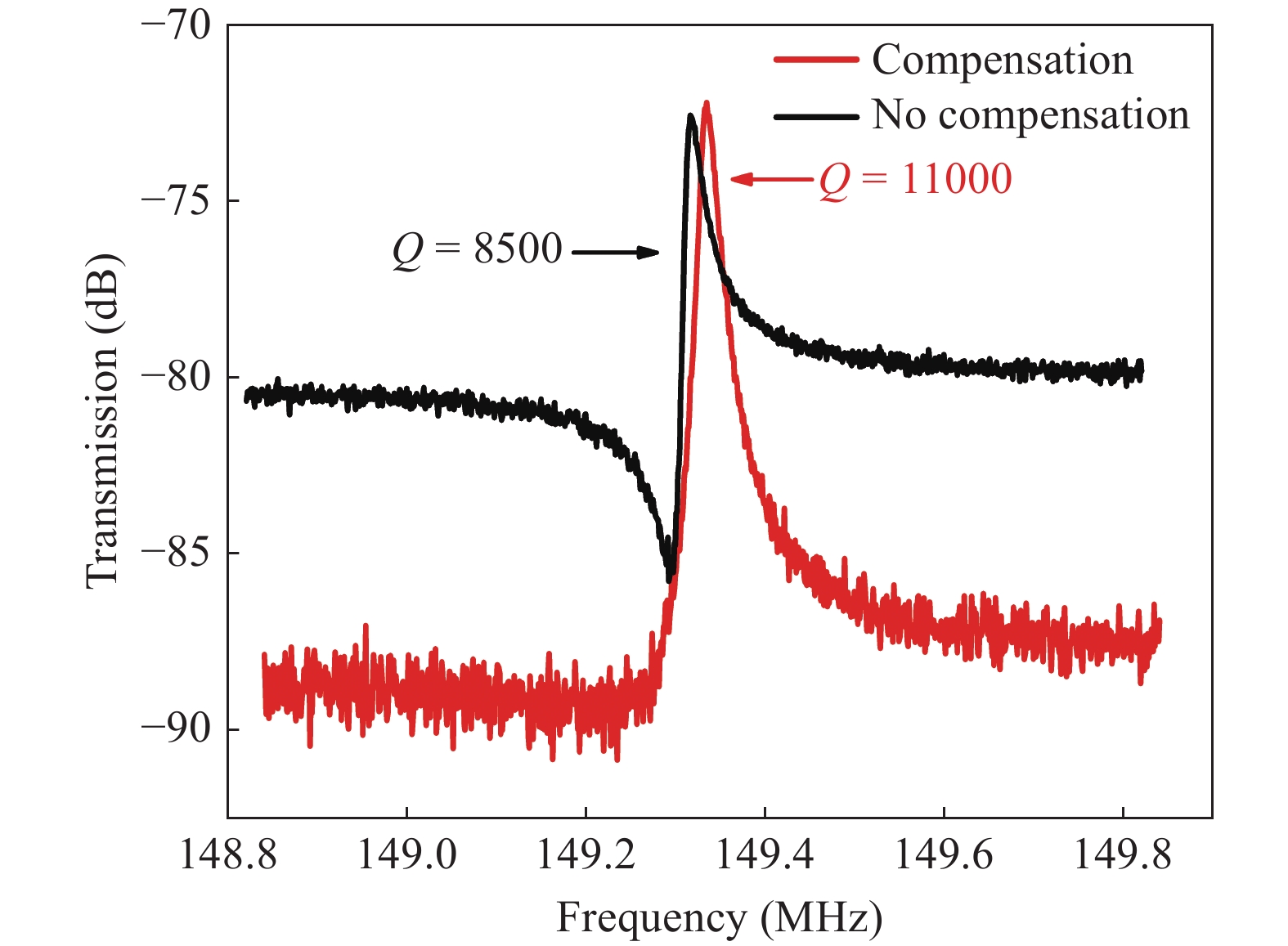

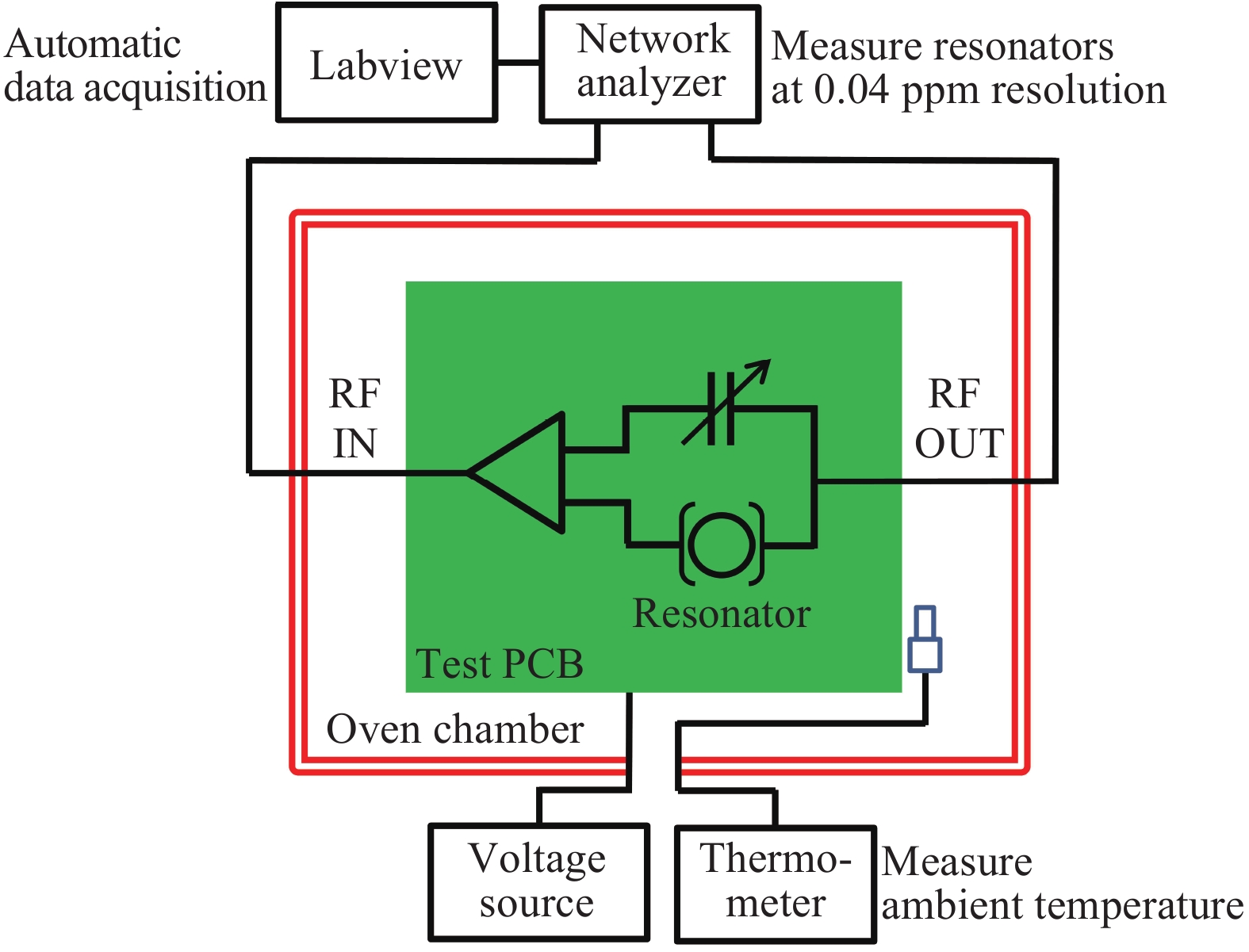

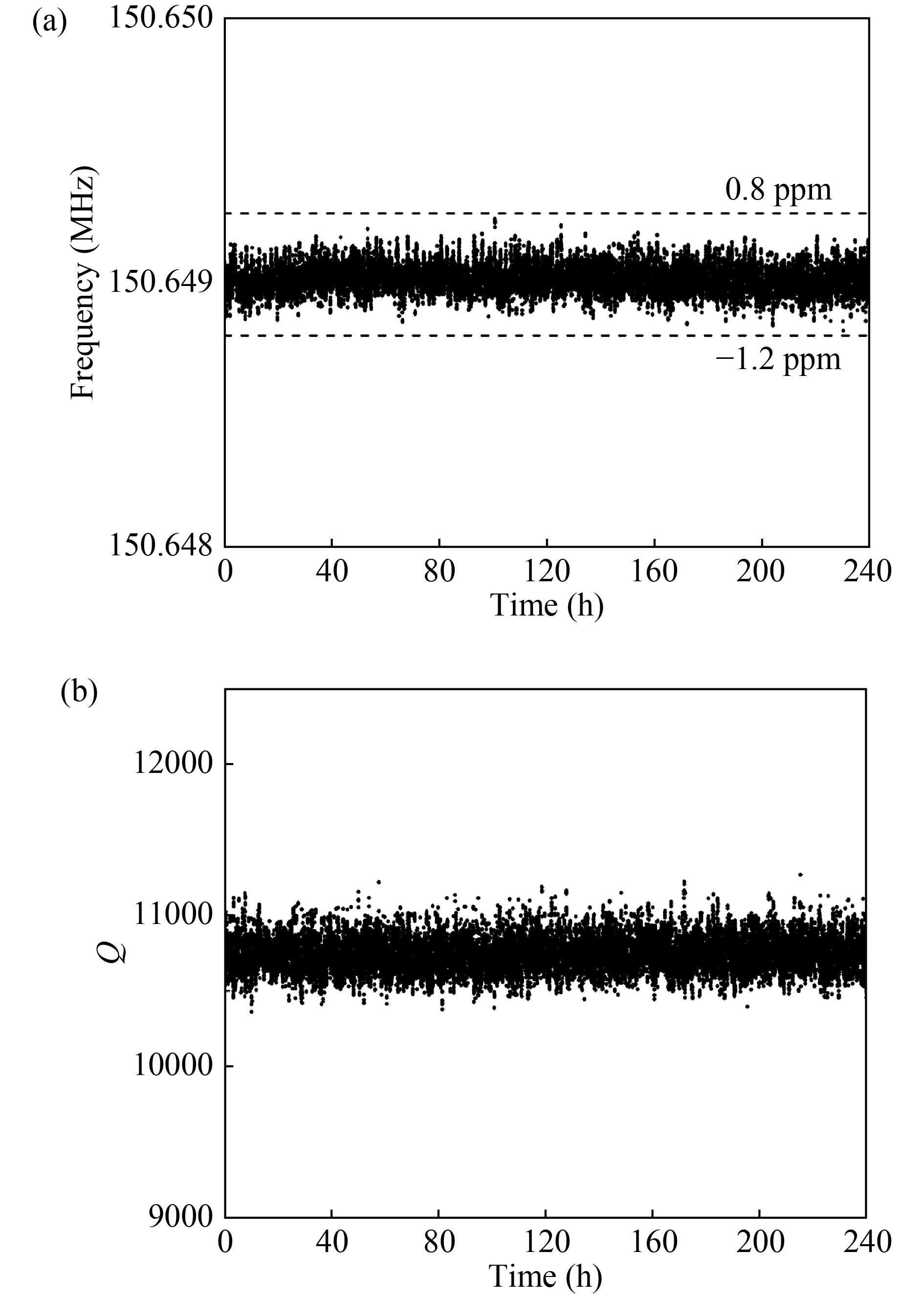

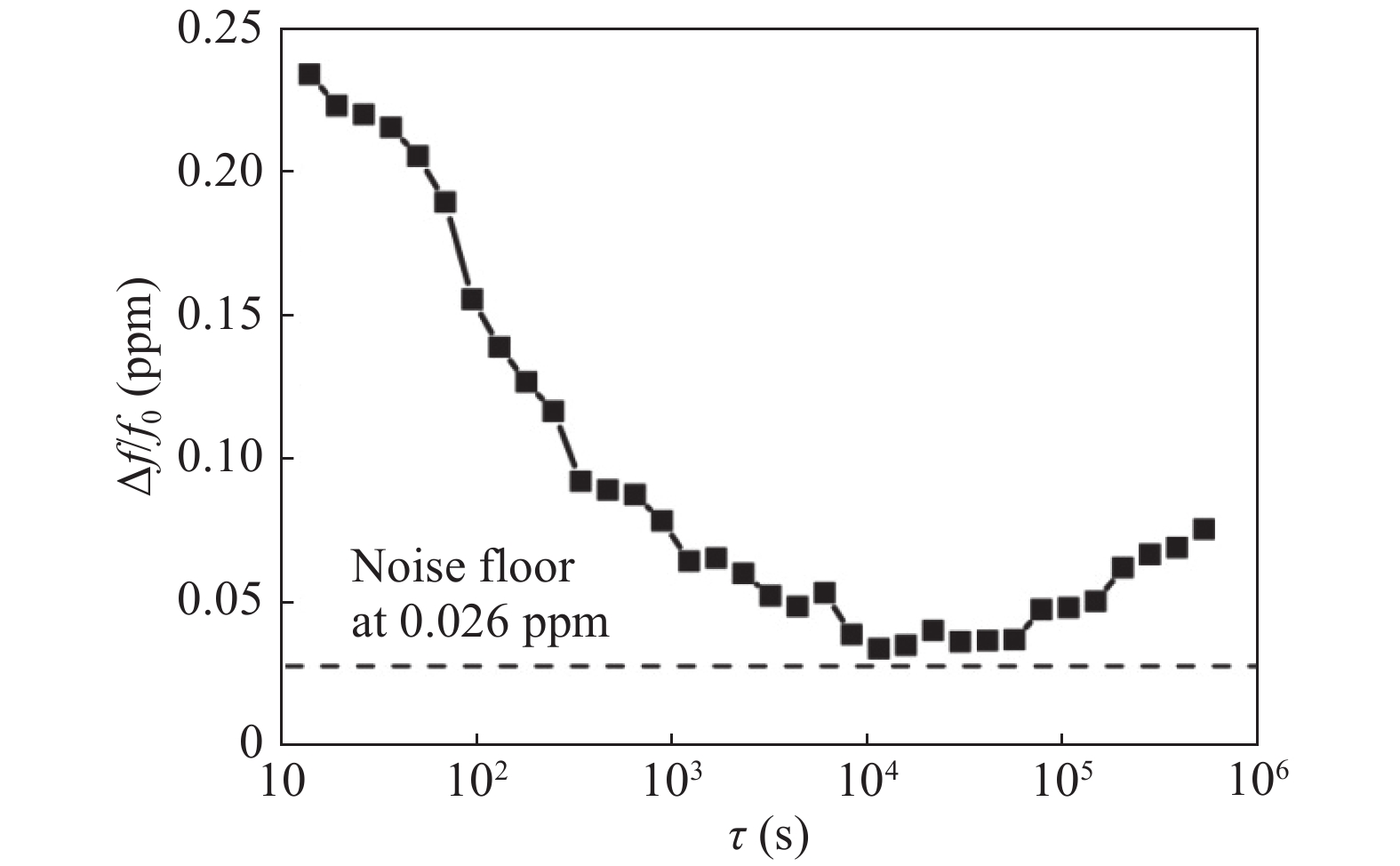

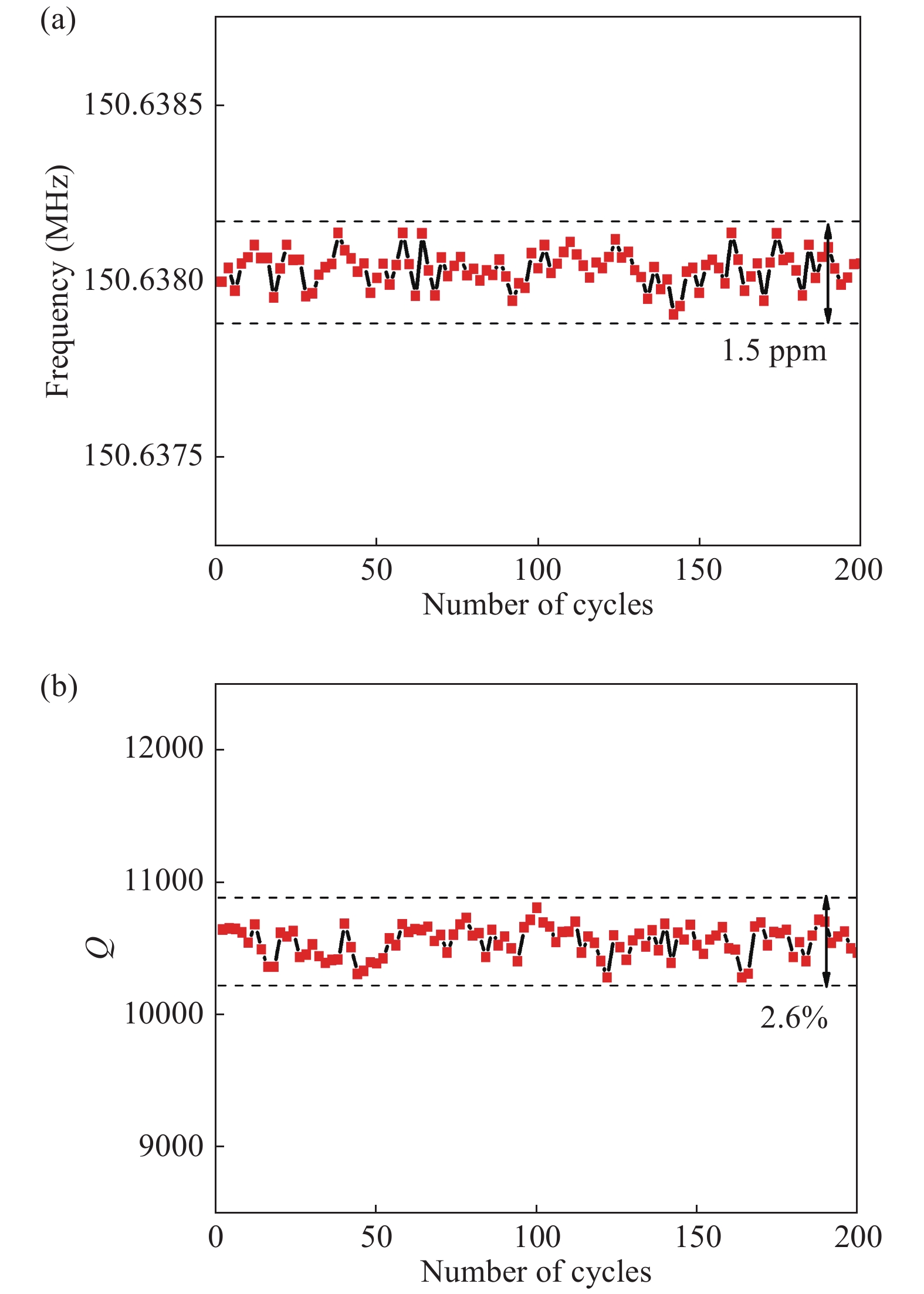

The frequency stability of a three-dimensional (3D) vacuum encapsulated very high frequency (VHF) disk resonator is systematically investigated. For eliminating the parasitic effect caused by the parasitic capacitance of the printed circuit board (PCB), a negating capacitive compensation method was developed. The testing results implemented at 25 °C for 240 h for the long-term stability indicates that the resonant frequency variation remained within ±1 ppm and the noise floor derived from Allan Deviation was 26 ppb, which is competitive with the conventional quartz resonators. The resonant frequency fluctuation of 1.5 ppm was obtained during 200 temperature cycling between −40 and 85 °C. -

References

[1] Vig J, Ballato A. Ultrasonic instruments and devices. New York: Academic, 1999[2] Rocheleau T O, Naing T L, Nguyen T C. Long-term stability of a hermetically packaged MEMS disk oscillator. IEEE European Frequency and Time Forum & International Frequency Control Symposium, 2014: 209[3] Kim B, Candler R N, Hopcroft M A, et al. Frequency stability of wafer-scale film encapsulated silicon based MEMS resonators. Sens Actuators A, 2007, 136(1): 125 doi: 10.1016/j.sna.2006.10.040[4] Koskenvuori M, Mattila T, Häärä A, et al. Long-term stability of single-crystal silicon microresonators. Sens Actuators A, 2004, 115(1): 23 doi: 10.1016/j.sna.2004.03.013[5] Tabrizian R, Casinovi G, Ayazi F. Temperature-stable silicon oxide (SilOx) micromechanical resonators. IEEE Trans Electron Devices, 2013, 60(8): 2656 doi: 10.1109/TED.2013.2270434[6] Kaajakari V, Kiihamäki J, Oja A, et al. Stability of wafer level vacuum encapsulated single-crystal silicon resonators. Sens Actuators A, 2006, 130/131(2): 42[7] Jin X, Y F Liu, H Zhao, et al. Reliable low-cost fabrication and characterization methods for micromechanical disk resonators. 16th International Solid-State Sensors, Actuators and Microsystems Conference (TRANSDUCERS), 2011: 2462[8] Yuan Q, Luo W, Zhao H, et al. Frequency stability of RF-MEMS disk resonators. IEEE Trans Electron Devices, 2015, 62(5): 1603 doi: 10.1109/TED.2015.2415199[9] Zhao J C, Yuan Q, Wang F X, et al. Design and characterization of a 3D encapsulation with silicon vias for radio frequency micro-electromechanical system resonator. Chin Phys B, 2017, 26(6): 119[10] Zhao J C, Yuan Q, Kan X, et al. A low feed-through 3D vacuum packaging technique with silicon vias for RF MEMS resonators. J Micromechan Microeng, 2016, 27(1): 014003[11] Vig J R, Meeker T R. The aging of bulk acoustic wave resonators, filters and oscillators. Proceedings of the Symposium on Frequency Control, 1991: 77[12] Antonio D, Zanette D H, López D. Frequency stabilization in nonlinear micromechanical oscillators. Nat Commun, 2012, 3(3): 806 -

Proportional views

DownLoad:

DownLoad: