| Citation: |

Bang Li, Xin Yan, Xia Zhang, Xiaomin Ren. Growth and characteristics of p-type doped GaAs nanowire[J]. Journal of Semiconductors, 2018, 39(5): 053004. doi: 10.1088/1674-4926/39/5/053004

****

B Li, X Yan, X Zhang, X M Ren. Growth and characteristics of p-type doped GaAs nanowire[J]. J. Semicond., 2018, 39(5): 053004. doi: 10.1088/1674-4926/39/5/053004.

|

Growth and characteristics of p-type doped GaAs nanowire

DOI: 10.1088/1674-4926/39/5/053004

More Information

-

Abstract

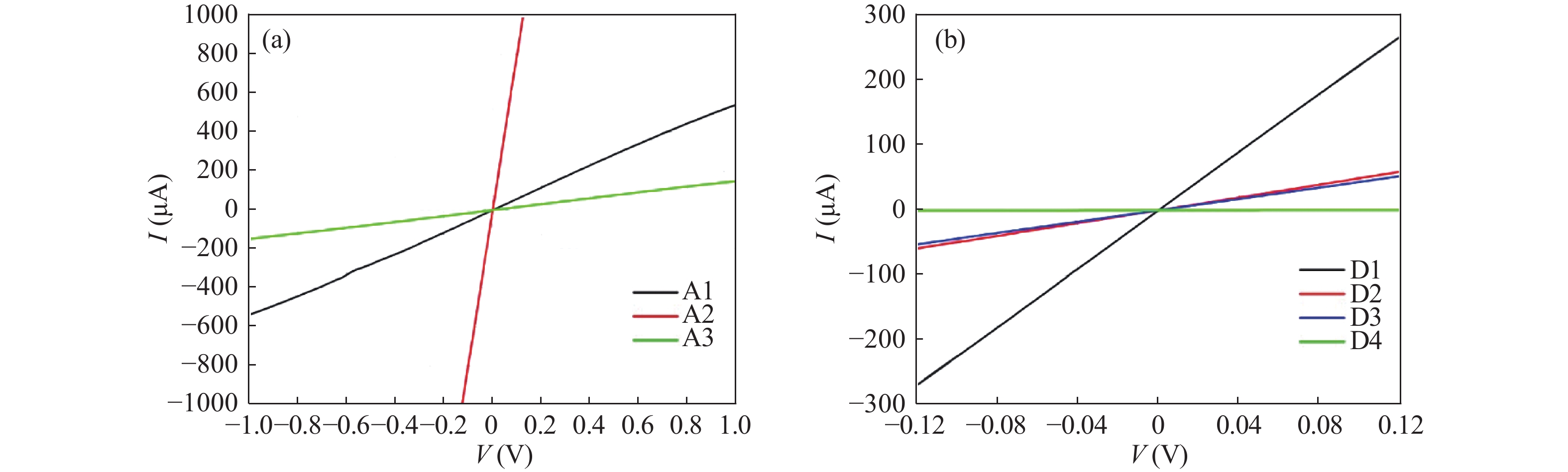

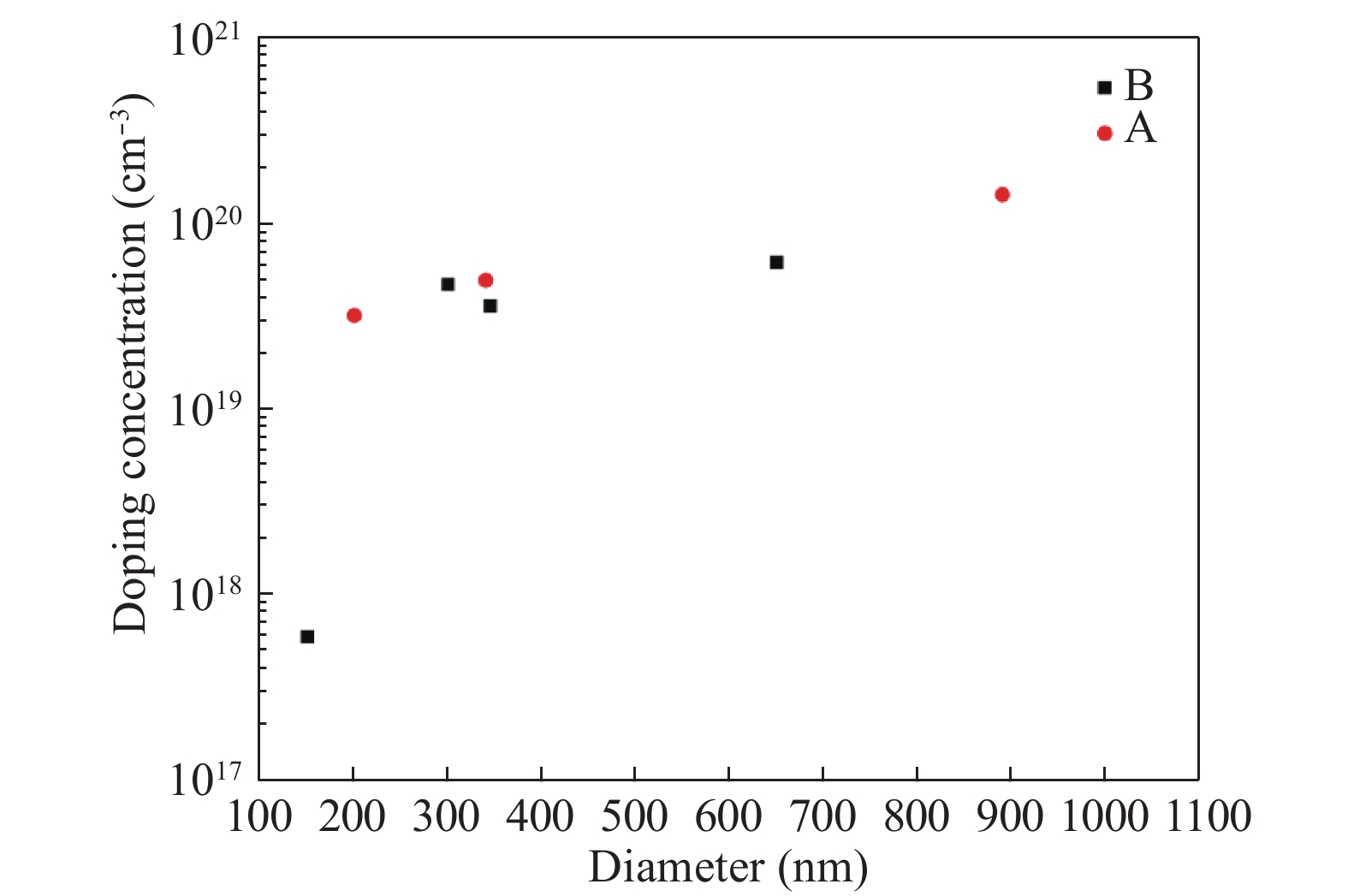

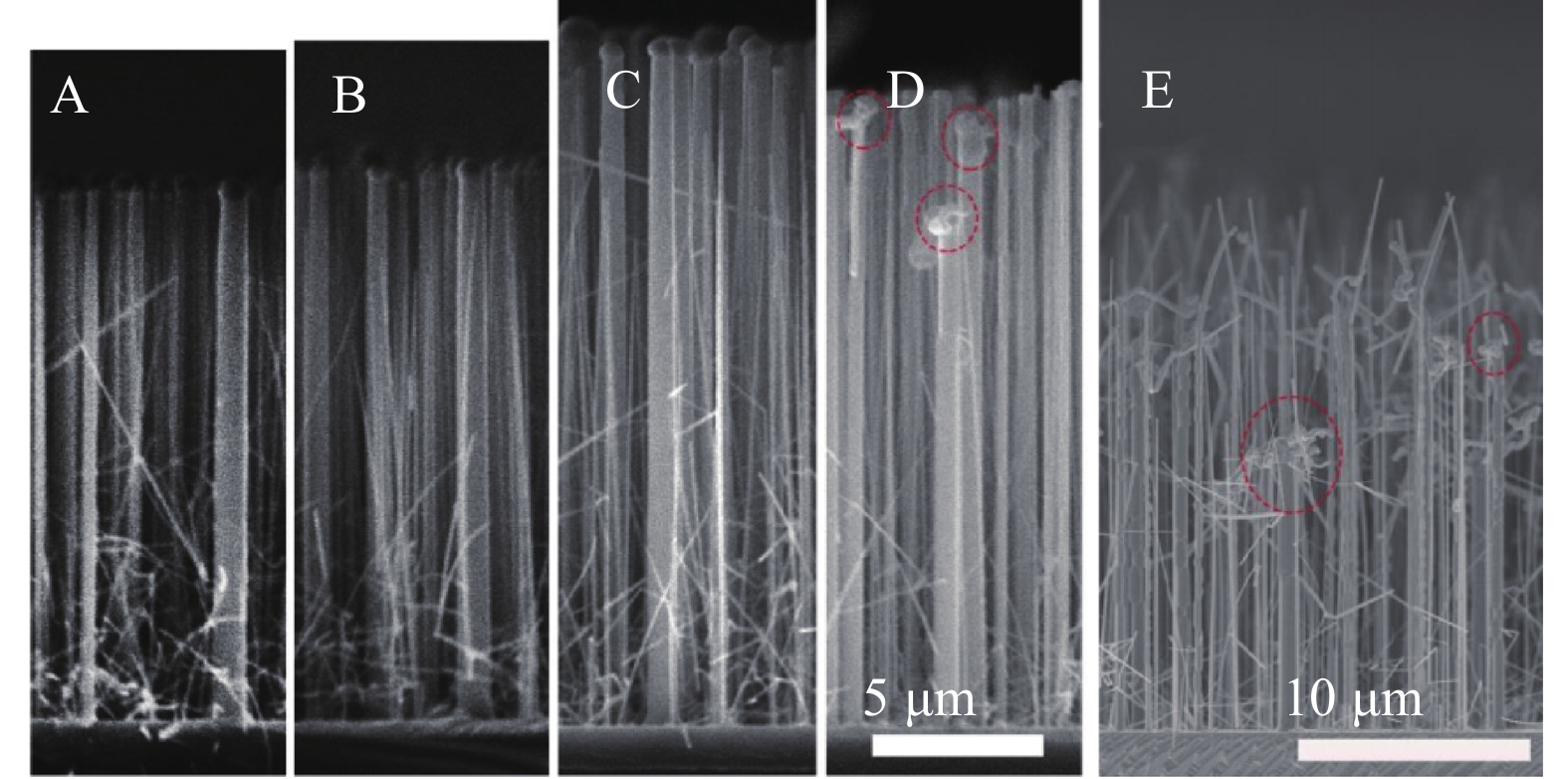

The growth of p-type GaAs nanowires (NWs) on GaAs (111) B substrates by metal-organic chemical vapor deposition (MOCVD) has been systematically investigated as a function of diethyl zinc (DEZn) flow. The growth rate of GaAs NWs was slightly improved by Zn-doping and kink is observed under high DEZn flow. In addition, the I–V curves of GaAs NWs has been measured and the p-type dope concentration under the II/III ratio of 0.013 and 0.038 approximated to 1019–1020 cm−3. -

References

[1] Dai X, Zhang S, Wang Z, et al. GaAs/AlGaAs nanowire photodetector. Nano Lett, 2014, 14(5): 2688 doi: 10.1021/nl5006004[2] Tsakalakos L, Balch J, Fronheiser J, et al. Silicon nanowire solar cells. Appl Phys Lett, 2007, 91(23): 233117 doi: 10.1063/1.2821113[3] Piccione B, Cho C, Vugt L K, et al. All-optical active switching in individual semiconductor nanowires. Nat Nanotechnol, 2012, 7: 640 doi: 10.1038/nnano.2012.144[4] Pan C, Dong L, Zhu G, et al. High-resolution electroluminescent imaging of pressure distribution using a piezoelectric nanowire LED array. Nat Photonics, 2013, 7(9): 752 doi: 10.1038/nphoton.2013.191[5] Hoa N D, Le D T T, Tam P D, et al. On-chip fabrication of SnO2-nanowire gas sensor: The effect of growth time on sensor performance. Sens Actuator B, 2010, 146(1): 361 doi: 10.1016/j.snb.2010.02.054[6] Vitiello M S, Coquillat D, Viti L, et al. Room-temperature terahertz detectors based on semiconductor nanowire field-effect transistors. Nano Lett, 2011, 12(1): 96[7] Patolsky F, Zheng G, Lieber C M. Nanowire sensors for medicine and the life sciences. Future Medicine, 2006, 1(1): 51[8] Haraguchi K, Katsuyama T, Hiruma K, et al. GaAs p‐n junction formed in quantum wire crystals. Appl Phys Lett, 1992, 60(6): 745 doi: 10.1063/1.106556[9] Wagner R S, Ellis W C. Vapor-Liquid-Solid mechanism of single crystal growth. Appl Phys Lett, 1964, 4(5): 89 doi: 10.1063/1.1753975[10] Li H Y, Wunnicke O, Borgström M T, et al. Remote p-doping of InAs nanowires. Nano Lett, 2007, 7(5): 1144 doi: 10.1021/nl0627487[11] Franke D, Reier F W, Grote N. Post-growth Zn diffusion into InGaAs/InP in a LP-MOVPE reactor. J Cryst Growth, 1998, 195(1–4): 112 doi: 10.1016/S0022-0248(98)00681-2[12] Stichtenoth D, Wegener K, Gutsche C, et al. P-type doping of GaAs nanowires. Appl Phys Lett, 2008, 92(16): 163107 doi: 10.1063/1.2912129[13] Gutsche C, Niepelt R, Gnauck M, et al. Direct determination of minority carrier diffusion lengths at axial GaAs nanowire p–n junctions. Nano Lett, 2012, 12(3): 1453 doi: 10.1021/nl204126n[14] Chang C C, Chi C Y, Yao M, et al. Electrical and optical characterization of surface passivation in GaAs nanowires. Nano Lett, 2012, 12(9): 4484 doi: 10.1021/nl301391h[15] Sager D, Gutsche C, Prost W, et al. Recombination dynamics in single GaAs-nanowires with an axial heterojunction: n-versus p-doped areas. J Appl Phys, 2013, 113(17): 174303 doi: 10.1063/1.4803488[16] Borgström M T, Norberg E, Wickert P, et al. Precursor evaluation for in situ InP nanowire doping. Nanotechnology, 2008, 19(44): 445602 doi: 10.1088/0957-4484/19/44/445602[17] Gutsche C, Lysov A, Regolin I, et al. n-type doping of vapor–liquid–solid grown GaAs nanowires. Nanoscale Res Lett, 2011, 6(1): 65[18] Salehzadeh O, Kavanagh K L, Watkins S P. Controlled axial and radial Te-doping of GaAs nanowires. J Appl Phys, 2012, 112(5): 054324 doi: 10.1063/1.4751988[19] Joyce H J, Docherty C J, Gao Q, et al. Electronic properties of GaAs, InAs and InP nanowires studied by terahertz spectroscopy. Nanotechnology, 2013, 24(21): 214006 doi: 10.1088/0957-4484/24/21/214006[20] Boland J L, Conesa-Boj S, Parkinson P, et al. Modulation doping of GaAs/AlGaAs core–shell nanowires with effective defect passivation and high electron mobility. Nano Lett, 2015, 15(2): 1336 doi: 10.1021/nl504566t[21] Sladek K, Klinger V, Wensorra J, et al. MOVPE of n-doped GaAs and modulation doped GaAs/AlGaAs nanowires. J Cryst Growth, 2010, 312(5): 635 doi: 10.1016/j.jcrysgro.2009.11.026[22] Sourribes M J L, Isakov I, Panfilova M, et al. Minimization of the contact resistance between InAs nanowires and metallic contacts. Nanotechnology, 2013, 24(4): 045703 doi: 10.1088/0957-4484/24/4/045703[23] Gutsche C, Regolin I, Blekker K, et al. Controllable p-type doping of GaAs nanowires during vapor-liquid-solid growth. J Appl Phys, 2009, 105(2): 024305 doi: 10.1063/1.3065536[24] Ketterer B, Uccelli E, i Morral A F. Mobility and carrier density in p-type GaAs nanowires measured by transmission Raman spectroscopy. Nanoscale, 2012, 4(5): 1789 doi: 10.1039/c2nr11910b -

Proportional views

DownLoad:

DownLoad: