| Citation: |

Lei Jin, Hongjuan Cheng, Jianli Chen, Song Zhang, Yongkuan Xu, Zhanping Lai. Controlling morphology evolution of AlN nanostructures: influence of growth conditions in physical vapor transport[J]. Journal of Semiconductors, 2018, 39(7): 073001. doi: 10.1088/1674-4926/39/7/073001

****

L Jin, H J Cheng, J L Chen, S Zhang, Y K Xu, Z P Lai, Controlling morphology evolution of AlN nanostructures: influence of growth conditions in physical vapor transport[J]. J. Semicond., 2018, 39(7): 073001. doi: 10.1088/1674-4926/39/7/073001.

|

Controlling morphology evolution of AlN nanostructures: influence of growth conditions in physical vapor transport

DOI: 10.1088/1674-4926/39/7/073001

More Information

-

Abstract

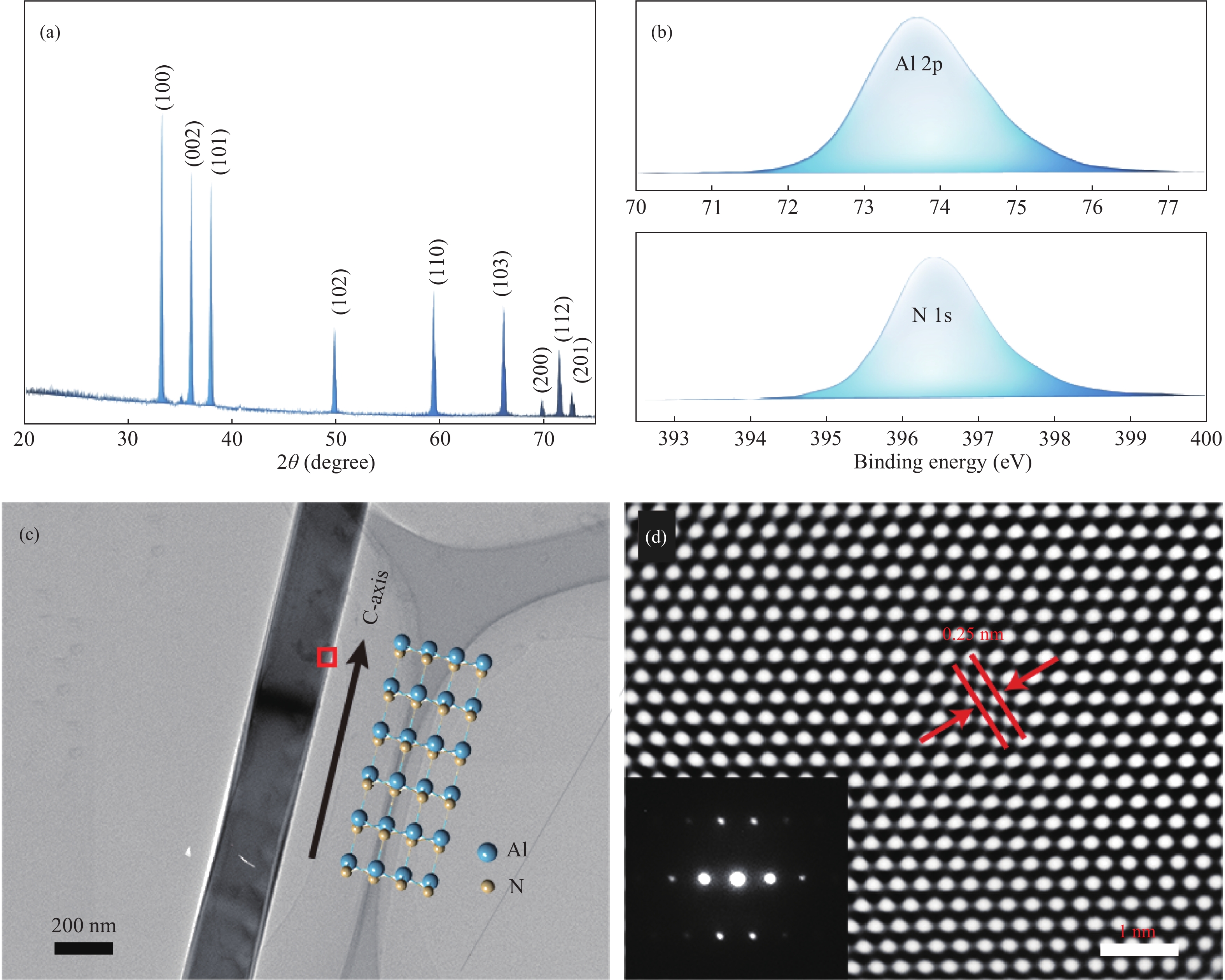

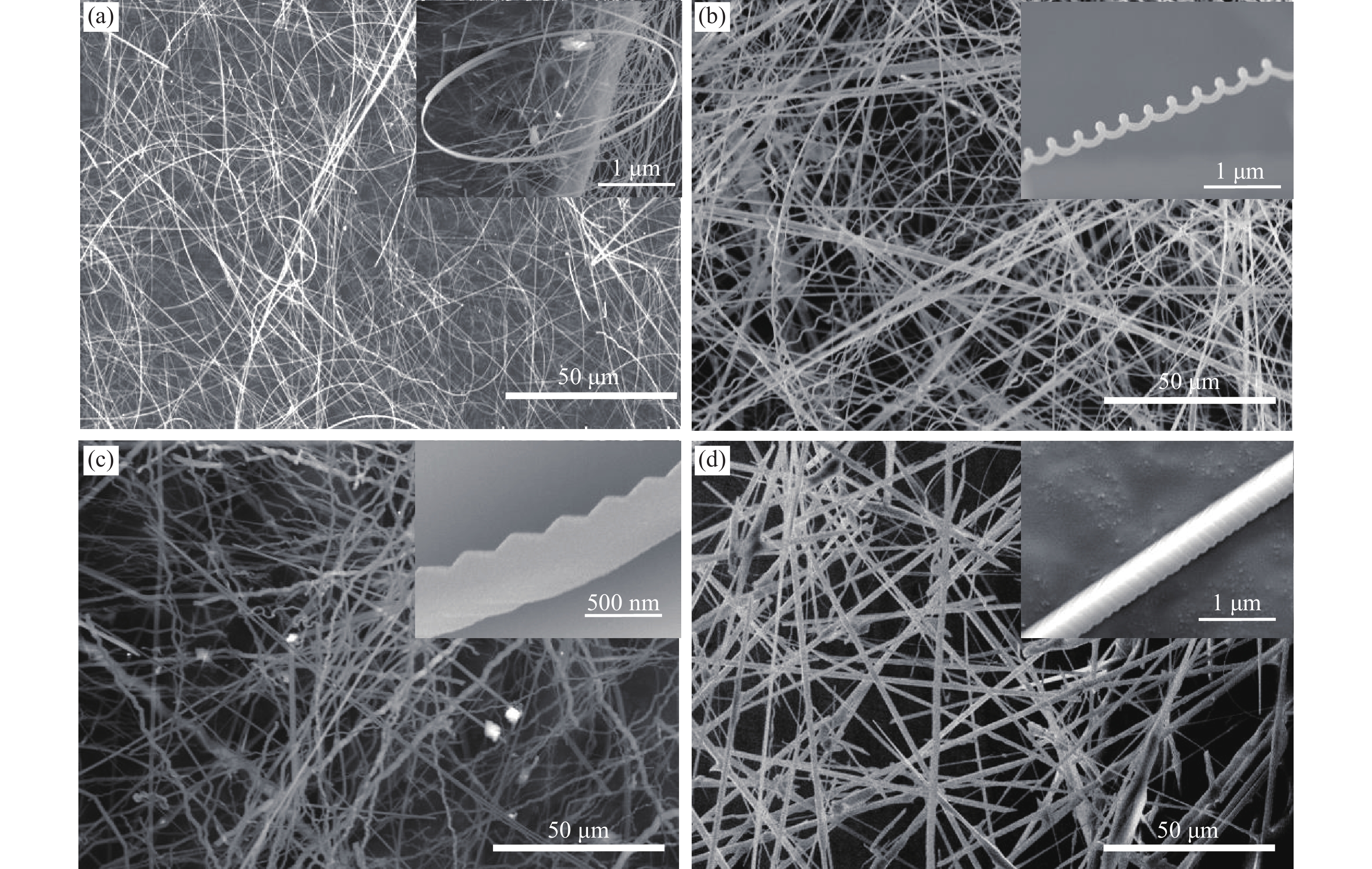

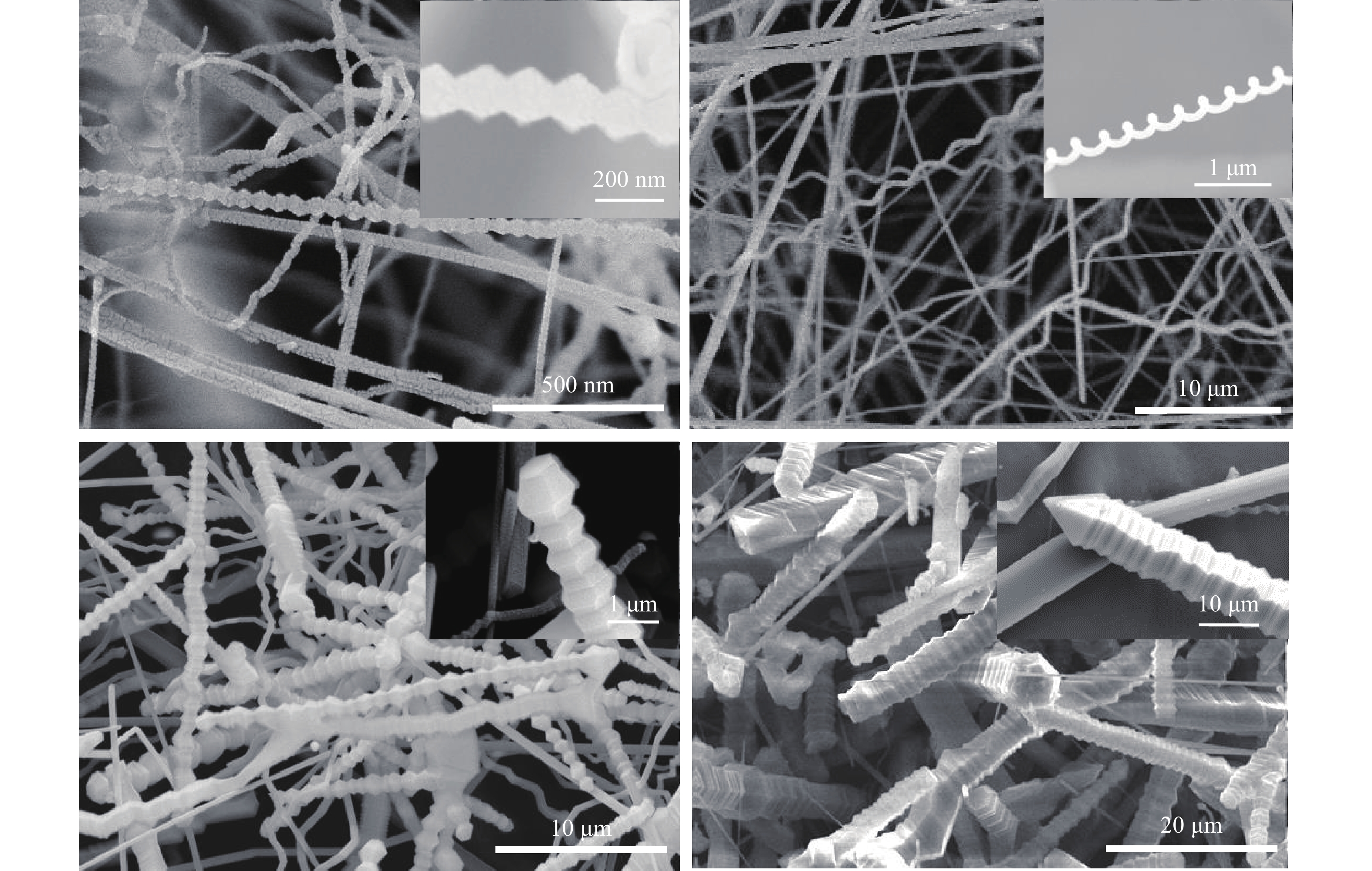

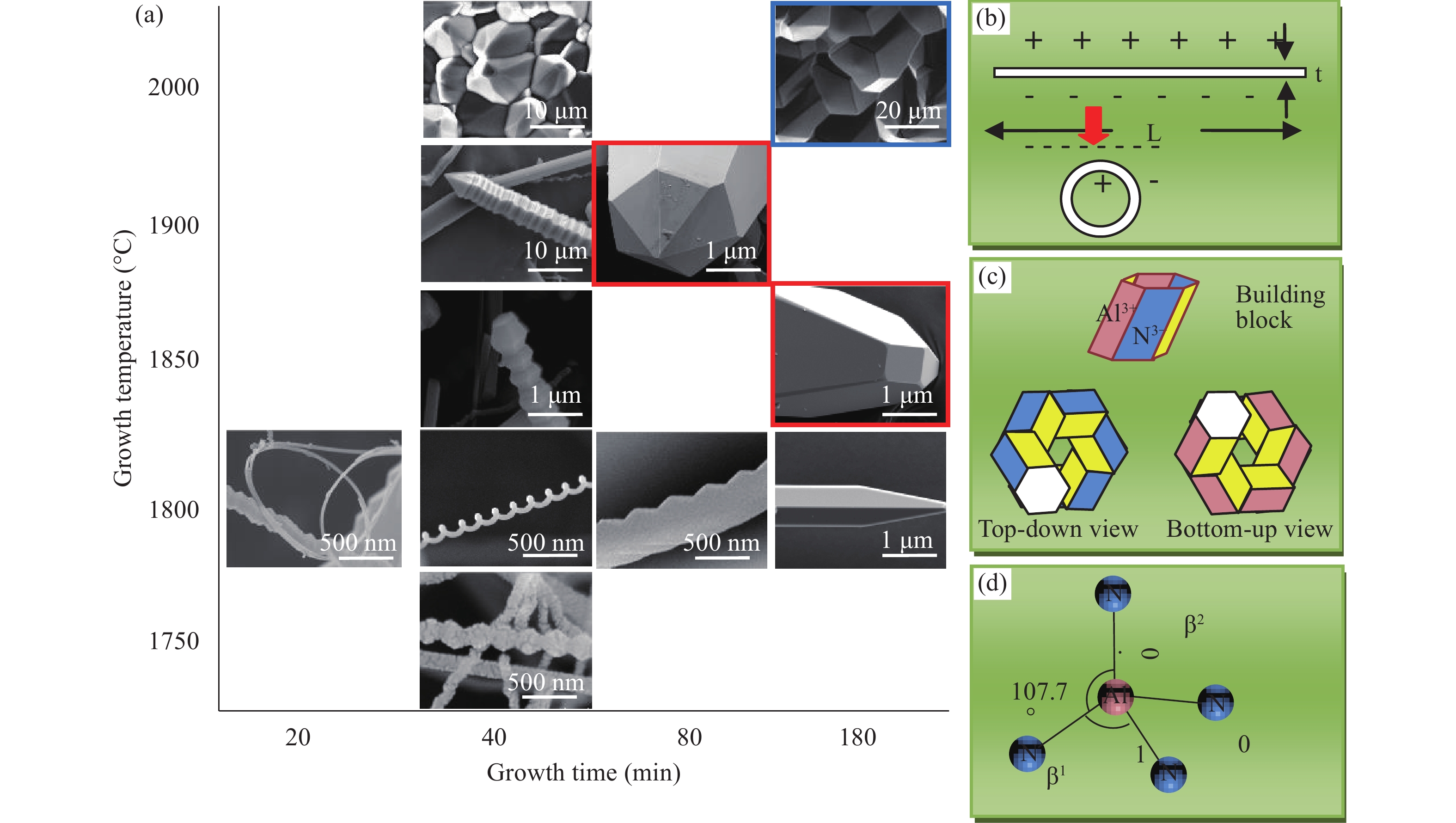

A series of AlN nanostructures were synthesized by an ultrahigh-temperature, catalyst-free, physical vapor transport (PVT) process. Energy dispersive X-ray spectroscopy (EDX), X-ray diffraction (XRD), X-Ray photoelectron spectroscopy (XPS), high resolution transmission electron microscopy (HRTEM) detection show that high quality AlN nanowires were prepared. Nanostructures including nanorings, nanosprings, nanohelices, chain-like nanowires, six-fold symmetric nanostructure and rod-like structure were successfully obtained by controlling the growth duration and temperature. The morphology evolution was attributed to electrostatic polar charge model and the crystalline lattice structure of AlN.-

Keywords:

- AlN nanowire,

- ultrahigh-temperature,

- catalyst-free,

- PVT,

- morphology evolution

-

References

[1] Zhou C J, Yang Y, Shu Y, et al. Visible-light photoresponse of AlN-based film bulk acoustic wave resonator. Appl Phys Lett, 2013, 102: 191914 doi: 10.1063/1.4807135[2] Sorokin B P, Kvashnin G M, Volkov A P, et al. AlN/single crystalline diamond piezoelectric structure as a high overtone bulk acoustic resonator. Appl Phys Lett, 2013, 102: 113507 doi: 10.1063/1.4798333[3] Liu G, Zhou G G, Qin Z Y, et al. Luminescence characterizations of freestanding bulk single crystalline aluminum nitride towards optoelectronic application. Crystengcomm, 2017, 19(37): 5522 doi: 10.1039/C7CE01239J[4] He J H, Yang R S, Chueh Y L, et al. Aligned AlN nanorods with multi-tipped surfaces-growth, field-emission, and cathodoluminescence properties. Adv Mater, 2006, 18: 650 doi: 10.1002/(ISSN)1521-4095[5] Sheppard L M. Aluminum nitride: a versatile but challenging material. Am Ceram Soc Bull, 1990, 69: 1801[6] Yang J, Liu T W, Hsu C W, et al. Controlled growth of aluminium nitride nanorod arrays via chemical vapour deposition. Nanotechnology, 2006, 17: S321 doi: 10.1088/0957-4484/17/11/S15[7] Li J J, Song B, Wu R, et al. Preparation and optical properties of free-standing transparent aluminum nitride film assembled by aligned nanorods. J Am Ceram Soc, 2012, 95: 870[8] Zheng J, Yang Y, Yu B, et al. [0001] oriented aluminum nitride one-dimensional nanostructures: synthesis, structure evolution, and electrical properties. ACS Nano, 2007, 2: 134[9] Tondare V N, Balasubramanian C, Shende S V, et al. Field emission from open ended aluminum nitride nanotubes. Appl Phys Lett, 2002, 80: 4813 doi: 10.1063/1.1482137[10] Lei W W, Liu D, Zhu P W, et al. One-step synthesis of AlN branched nanostructures by an improved DC arc discharge plasma method. CrystEngComm, 2010, 12: 511 doi: 10.1039/B910735E[11] Lei M, Yang H, Guo Y F, et al. Synthesis and optical property of high purity AlN nanowires. Mater Sci Eng B, 2007, 143: 85 doi: 10.1016/j.mseb.2007.07.068[12] Liu F, Su Z J, Mo F Y, et al. Controlled synthesis of ultra-long AlN nanowires in different densities and in situ investigation of the physical properties of an individual AlN nanowire. Nanoscale, 2011, 3: 610 doi: 10.1039/C0NR00586J[13] Meng F, Estruga M, Forticaux A, et al. Formation of stacking faults and the screw dislocation-driven growth: a case study of aluminum nitride nanowires. ACS Nano, 2013, 7: 11369 doi: 10.1021/nn4052293[14] Iwata M, Adachi K, Furukawa S, et al. Synthesis of purified AlN nano powder by transferred type arc plasma. J Phys D, 2004, 37: 1041 doi: 10.1088/0022-3727/37/7/014[15] Duan J H, Yang S G, Liu H W, et al. AlN nanorings. J Cryst Growth, 2005, 283: 291 doi: 10.1016/j.jcrysgro.2005.06.015[16] Wang H, Liu G, Yang W, et al. Bicrystal AlN zigzag nanowires. J Phys Chem C, 2007, 111: 17169 doi: 10.1021/jp077435u[17] Cimalla V, Foerster C, Cengher D, et al. Growth of AlN nanowires by metal organic chemical vapour deposition. Phys Status Solid B, 2006, 243: 1476 doi: 10.1002/(ISSN)1521-3951[18] Zhang X H, Shao R W, Jin L, et al. Helical growth of aluminum nitride: new insights into its growth habit from nanostructures to single crystals. Sci Rep, 2015, 5: 10087 doi: 10.1038/srep10087[19] Epelbaum B M, Seitz C, Magerl A, et al. Natural growth habit of bulk AlN crystals. J Cryst Growth, 2004, 265: 577 doi: 10.1016/j.jcrysgro.2004.02.100[20] Liu Y, Jiang L B, Wang G, et al. Adjustable nitrogen-vacancy induced magnetism in AlN. Appl Phys Lett, 2012, 100: 122401 doi: 10.1063/1.3696023[21] Lei M, Song B, Guo X, et al. Large-scale AlN nanowires synthesized by direct sublimation method. J Eur Ceram Soc, 2009, 29: 195-200 doi: 10.1016/j.jeurceramsoc.2008.06.002[22] Kong X Y, Wang Z L. Spontaneous polarization-induced nanohelixes, nanosprings, and nanorings of piezoelectric nanobelts. Nano Lett, 2003, 3: 1625 doi: 10.1021/nl034463p[23] Yang R, Ding Y, Wang Z L, et al. Deformation-free single-crystal nanohelixes of polar nanowires. Nano Lett, 2004, 4: 1309 doi: 10.1021/nl049317d[24] Wang X Q, Xi G C, Xiong S L, et al. Solution-phase synthesis of single-crystal CuO nanoribbons and nanorings. Cryst Growth Des, 2007, 7: 930 doi: 10.1021/cg060798j[25] Jian J K, Zhang Z H, Sun Y P. GaN nanorings: another example of spontaneous polarization-induced nanostructure. J Cryst Growth, 2007, 303: 427 doi: 10.1016/j.jcrysgro.2006.11.209[26] Kuang X P, Zhang H Y, Wang G G, et al. Effect of deposition temperature on the microstructure and surface morphology of c-axis oriented AlN films deposited on sapphire substrate by RF reactive magnetron sputtering. Superlattice Microstruct, 2012, 52: 931 doi: 10.1016/j.spmi.2012.08.003[27] Ishihara M, Li S J, Yumoto H, et al. Control of preferential orientation of AlN films prepared by the reactive sputtering method. Thin Solid Films, 1998, 316: 152 doi: 10.1016/S0040-6090(98)00406-4[28] Xu X H, Wu H S, Zhang C J, et al. Morphological properties of AlN piezoelectric thin films deposited by DC reactive magnetron sputtering. Thin Solid Films, 2001, 388: 62 doi: 10.1016/S0040-6090(00)01914-3[29] Bickermann M, Epelbaum B M, Filip O, et al. Growth of AlN bulk crystals on SiC seeds: chemical analysis and crystal properties. Phys Status Solidi C, 2012, 9: 449 doi: 10.1002/pssc.v9.3/4[30] Noveski V, Schlesser R, Raghothamachar B, et al. Seeded growth of bulk AlN crystals and grain evolution in polycrystalline AlN boules. J Cryst Growth, 2005, 279: 13 doi: 10.1016/j.jcrysgro.2004.12.027[31] Hartmann C, Wollweber J, Dittmar A, et al. Preparation of bulk AlN seeds by spontaneous nucleation of freestanding crystals. Jpn J Appl Phys, 2013, 52: 08JA06 doi: 10.7567/JJAP.52.08JA06 -

Proportional views

DownLoad:

DownLoad: