| Citation: |

Jiaqi Wei, Kumsong Kim, Fang Liu, Ping Wang, Xiantong Zheng, Zhaoying Chen, Ding Wang, Ali Imran, Xin Rong, Xuelin Yang, Fujun Xu, Jing Yang, Bo Shen, Xinqiang Wang. β-Ga2O3 thin film grown on sapphire substrate by plasma-assisted molecular beam epitaxy[J]. Journal of Semiconductors, 2019, 40(1): 012802. doi: 10.1088/1674-4926/40/1/012802

****

J Q Wei, K Kim, F Liu, P Wang, X T Zheng, Z Y Chen, D Wang, A Imran, X Rong, X L Yang, F J Xu, J Yang, B Shen, X Q Wang, β-Ga2O3 thin film grown on sapphire substrate by plasma-assisted molecular beam epitaxy[J]. J. Semicond., 2019, 40(1): 012802. doi: 10.1088/1674-4926/40/1/012802.

|

β-Ga2O3 thin film grown on sapphire substrate by plasma-assisted molecular beam epitaxy

DOI: 10.1088/1674-4926/40/1/012802

More Information

-

Abstract

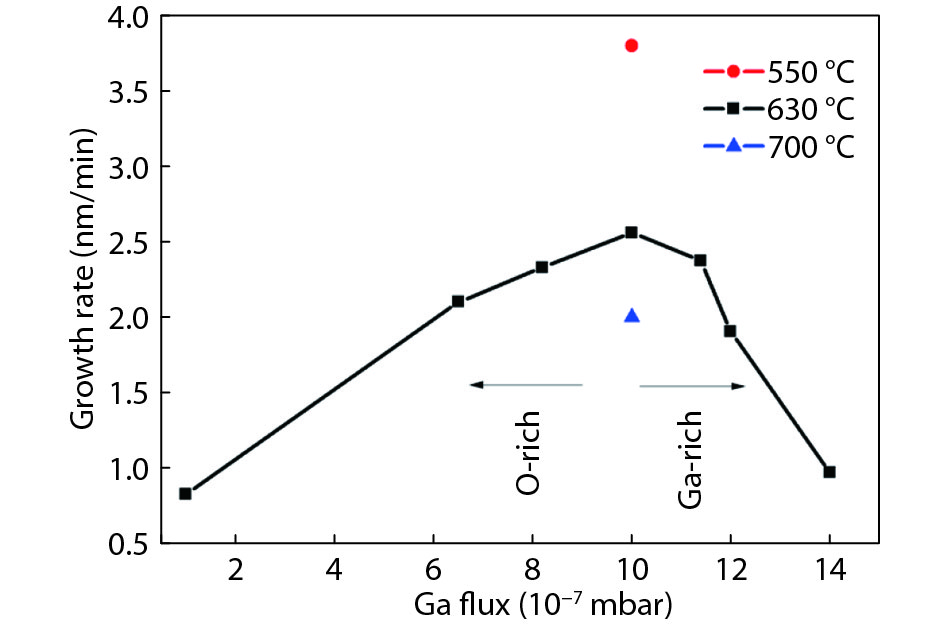

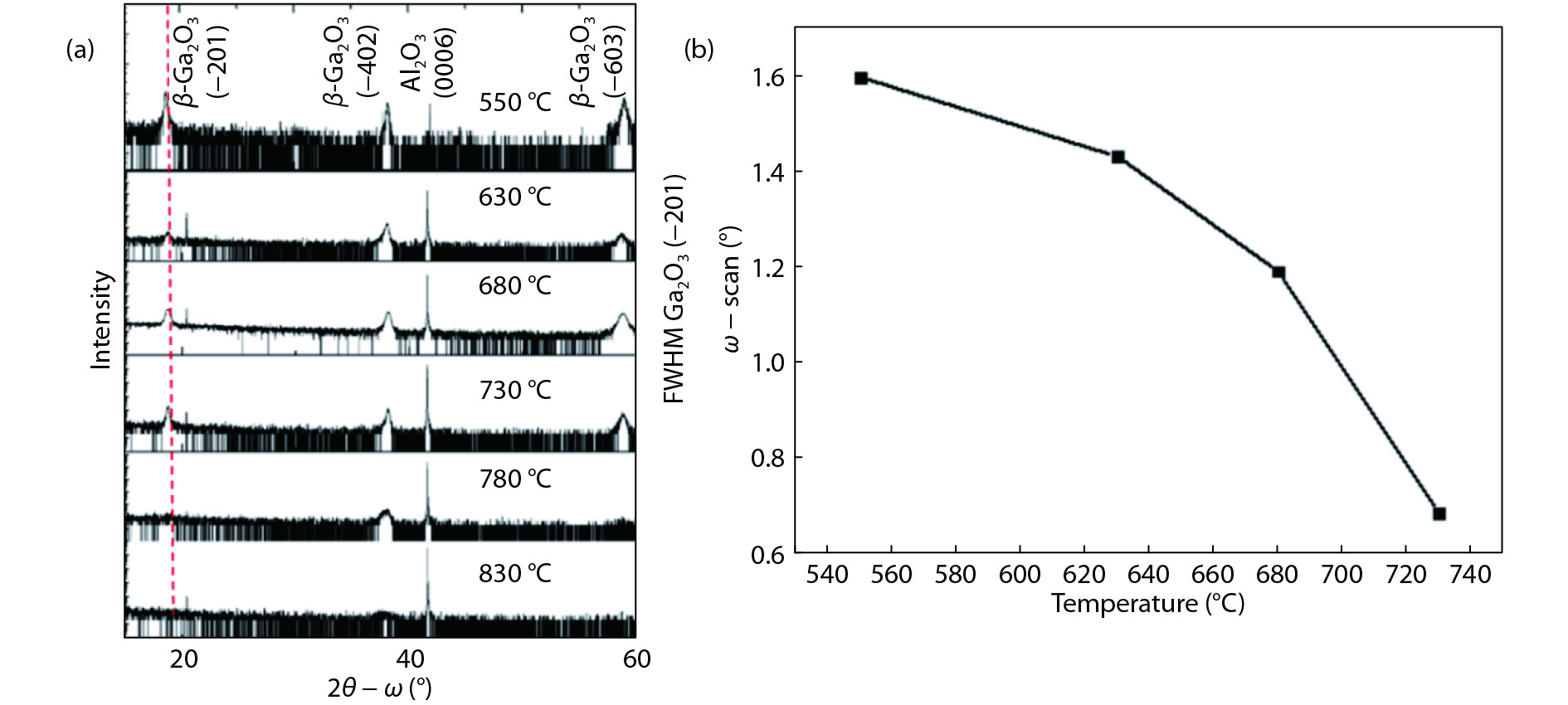

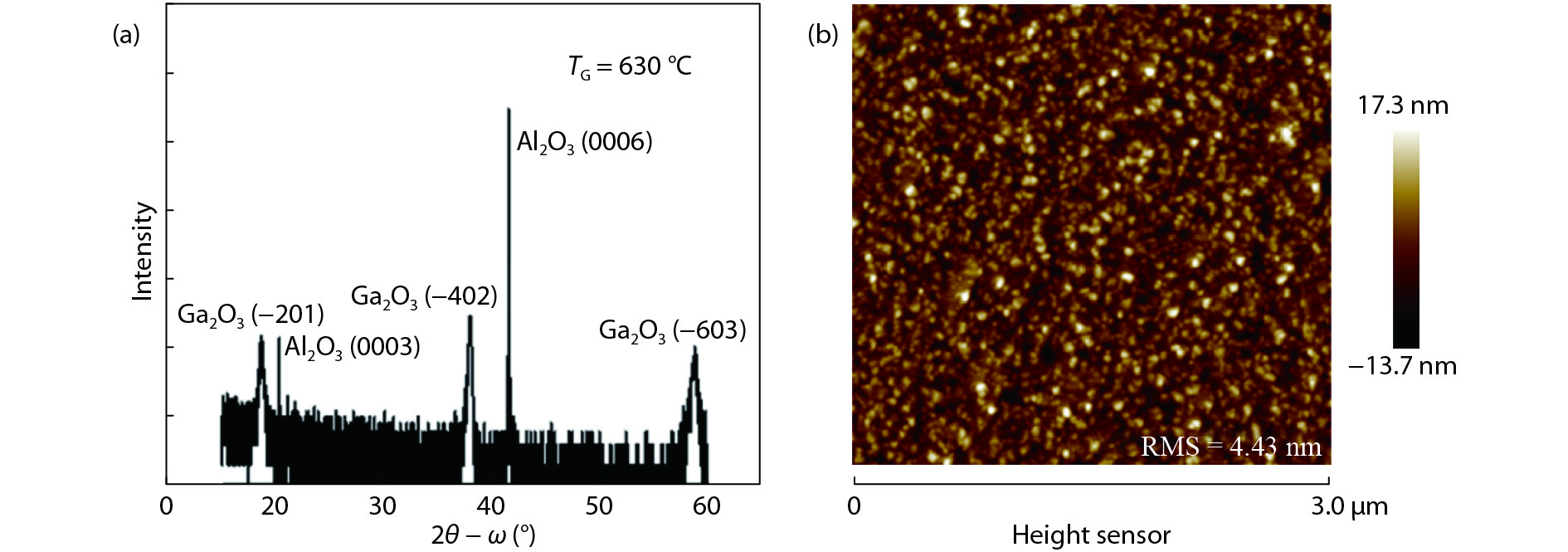

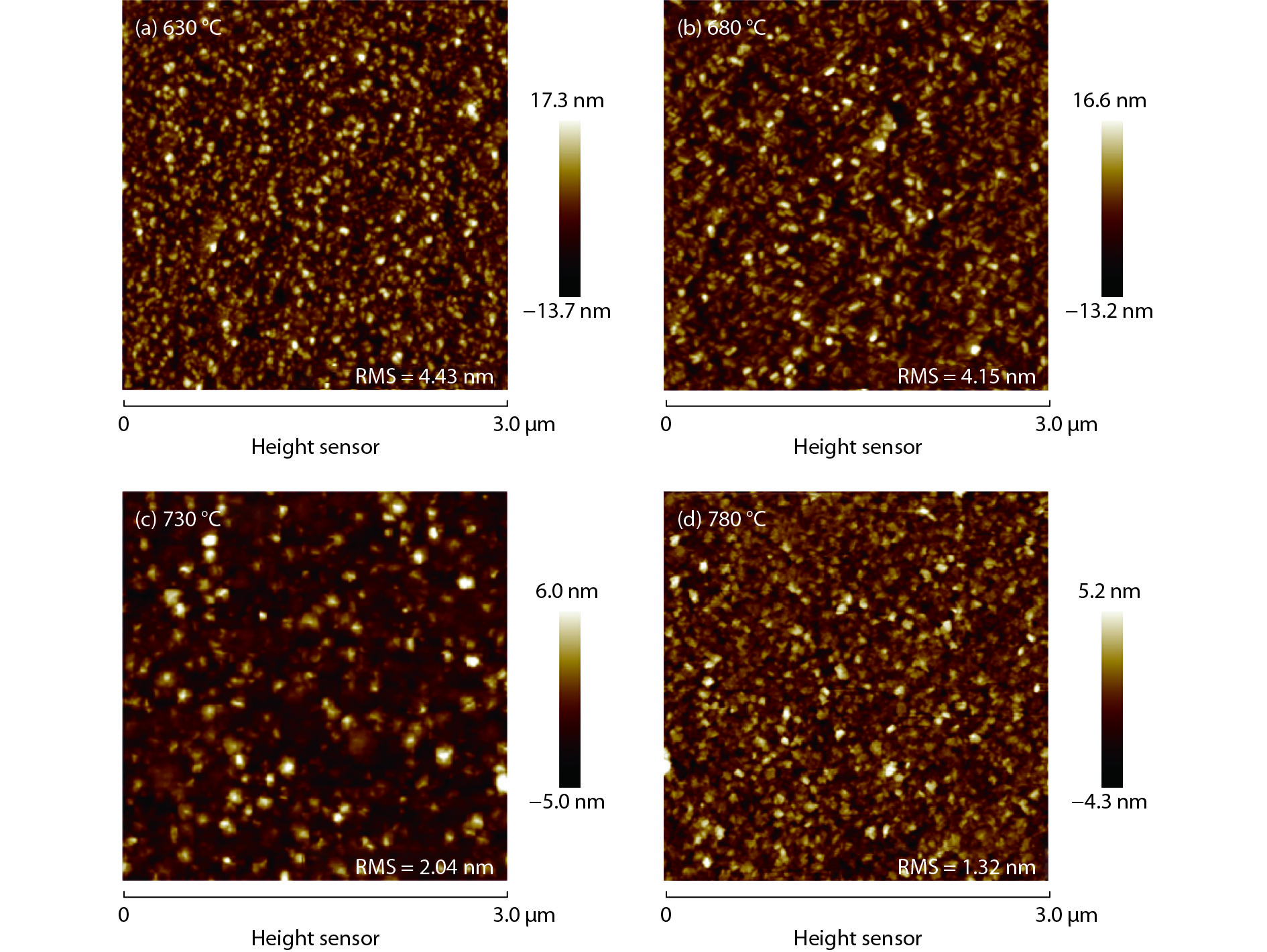

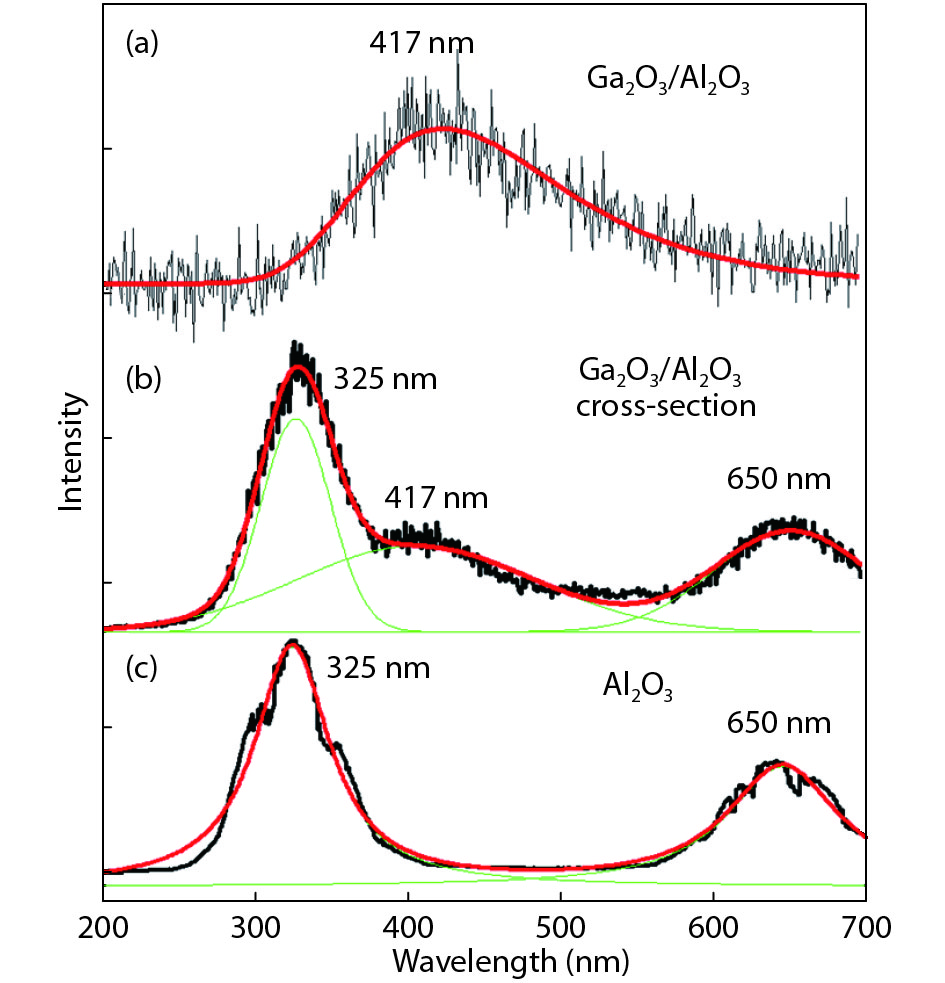

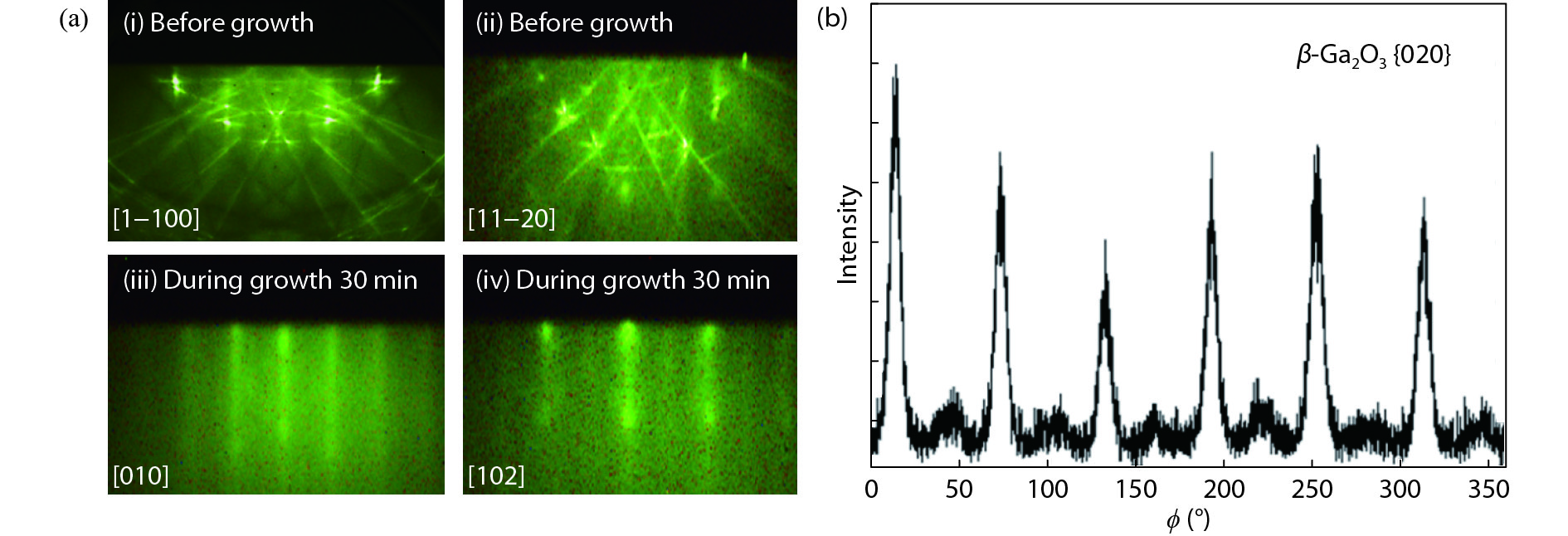

Monoclinic gallium oxide (Ga2O3) has been grown on (0001) sapphire (Al2O3) substrate by plasma-assisted molecular beam epitaxy (PA-MBE). The epitaxial relationship has been confirmed to be [010]($\bar{2}01$ ) β-Ga2O3||[$01\bar{1}0$ ](0001)Al2O3 via in-situ reflection high energy electron diffraction (RHEED) monitoring and ex-situ X-ray diffraction (XRD) measurement. Crystalline quality is improved and surface becomes flatter with increasing growth temperature, with a best full width at half maximum (FWHM) of XRD ω-rocking curve of ($\bar{2}01$ ) plane and root mean square (RMS) roughness of 0.68° and 2.04 nm for the sample grown at 730 °C, respectively. Room temperature cathodoluminescence measurement shows an emission at ~417 nm, which is most likely originated from recombination of donor–acceptor pair (DAP).-

Keywords:

- β-Ga2O3,

- sapphire substrate,

- PA-MBE,

- crystalline quality,

- CL measurement

-

References

[1] Guo D, Wu Z, Li P, et al. Fabrication of β-Ga2O3 thin films and solar-blind photodetectors by laser MBE technology. Opt Mater Express, 2014, 4(5): 1067 doi: 10.1364/OME.4.001067[2] Mu W, Jia Z, Yin Y, et al. High quality crystal growth and anisotropic physical characterization of β-Ga2O3 single crystals grown by EFG method. J Alloys Compd, 2017, 714: 453 doi: 10.1016/j.jallcom.2017.04.185[3] Pearton S J, Yang J, Patrick C, et al. A review of Ga2O3 materials, processing, and devices. Appl Phys Rev, 2018, 5(1): 011301 doi: 10.1063/1.5006941[4] Xue H, He Q, Jian G, et al. An overview of the ultrawide bandgap Ga2O3 semiconductor-based schottky barrier diode for power electronics application. Nanoscale Res Lett, 2018 13: 290 doi: 10.1186/s11671-018-2712-1[5] Zhao X, Cui W, Wu Z, et al. Growth and characterization of Sn doped β-Ga2O3 thin films and enhanced performance in a solar-blind photodetector. J Electron Mater, 2017, 46(4): 2366 doi: 10.1007/s11664-017-5291-5[6] Kumar S S, Rubio E J, Noor-A-Alam M, et al. Structure, morphology, and optical properties of amorphous and nanocrystalline gallium oxide thin films. J Phys Chem C, 2013, 117(8): 4194 doi: 10.1021/jp311300e[7] Farzana E, Ahmadi E, Speck J S, et al. Deep level defects in Ge-doped (010) β-Ga2O3 layers grown by plasma-assisted molecular beam epitaxy. J Appl Phys, 2018, 123(16): 1[8] Hu Z, Zhou H, Feng Q, et al. Field-plated lateral β-Ga2O3 schottky barrier diode with high reverse blocking voltage of more than 3 kV and high DC power figure-of-merit of 500 MW/cm2. IEEE Electron Device Lett, 2018, 39(10): 1564[9] Higashiwaki M, Sasaki K, Kuramata A, et al. Development of gallium oxide power devices. Phys Status Solidi, 2014, 211(1): 21 doi: 10.1002/pssa.201330197[10] Galazka Z. β-Ga2O3 for wide-bandgap electronics and optoelectronics. Semicond Sci Technol, 2018, 33, 113001 doi: 10.1088/1361-6641/aadf78[11] Kumar S, Tessarek C, Christiansen S, et al. A comparative study of β-Ga2O3 nanowires grown on different substrates using CVD technique. J Alloys Compd, 2014, 587: 812 doi: 10.1016/j.jallcom.2013.10.165[12] Rafique S, Han L, Neal A T, et al. Towards high mobility heteroepitaxial β-Ga2O3 on sapphire-dependence on the substrate off-axis angle. Phys Status Solidi, 2018, 215(2): 1700467 doi: 10.1002/pssa.v215.2[13] E G Víllora, Shimamura K, Yoshikawa Y, et al. Large-size β-Ga2O3 single crystals and wafers. J Cryst Growth, 2004, 270(3/4): 420[14] Aida H, Nishiguchi K, Takeda H, et al. Growth of β-Ga2O3 single crystals by the edge-defined, film fed growth method. Jpn J Appl Phys, 2008, 47(11R): 8506[15] Higashiwaki M, Konishi K, Sasaki K, et al. Temperature-dependent capacitance-voltage and current-voltage characteristics of Pt/Ga2O3 (001) Schottky barrier diodes fabricated on n-Ga2O3 drift layers grown by halide vapor phase epitaxy. Appl Phys Lett, 2016, 108(13): 133503 doi: 10.1063/1.4945267[16] Sinha G, Adhikar K, Chaudhuri S, et al. Sol-gel derived phase pure α-Ga2O3 nanocrystalline thin film and its optical properties. J Cryst Growth, 2005, 276(1): 204[17] Kokubun Y, Miura K, Endo F, et al. Sol-gel prepared β-Ga2O3 thin films for ultraviolet photodetectors. Appl Phys Lett, 2007, 90(3): A316[18] Fleischer M, Hanrieder W, Meixner H. Stability of semiconducting gallium oxide thin films. Thin Solid Films, 1990, 190: 93 doi: 10.1016/0040-6090(90)90132-W[19] Liu J J, Yan J L, Shi L, et al. Electrical and optical properties of deep ultraviolet transparent conductive Ga2O3/ITO films by magnetron sputtering. J Semicond, 2010. 31: 103001. doi: 10.1088/1674-4926/31/10/103001[20] Ji Z, Du J, Fan J, et al. Gallium oxide films for filter and solar-blind UV detector. Opt Mater, 2006, 28(4): 415 doi: 10.1016/j.optmat.2005.03.006[21] Fleischer M, Hanrieder W, Meixner H. Stability of semiconducting gallium oxide thin films. Thin Solid Films, 2015, 190(1): 93[22] Lv Y, Ma J, Mi W, et al. Characterization of β-Ga2O3 thin films on sapphire (0001) using metal-organic chemical vapor deposition technique. Vacuum, 2012, 86(12): 1850 doi: 10.1016/j.vacuum.2012.04.019[23] Hayashi H, Huang R, Oba F, et al. Epitaxial growth of Mn-doped γ-Ga2O3 on spinel substrate. J Mater Res, 2011, 26(4): 578 doi: 10.1557/jmr.2010.32[24] Matsuzaki K, Hiramatsu H, Nomura K, et al. Growth, structure and carrier transport properties of Ga2O3 epitaxial film examined for transparent field-effect transistor. Thin Solid Films, 2006, 496(1): 37 doi: 10.1016/j.tsf.2005.08.187[25] Zhang F, Saito K, Tanaka T, et al. Electrical properties of Si doped Ga2O3 films grown by pulsed laser deposition. J Mater Sci: Mater Electron, 2015, 26(12): 9624 doi: 10.1007/s10854-015-3627-6[26] Oshima T, Okuno T, Fujita S. Ga2O3 thin film growth on c-plane sapphire substrates by molecular beam epitaxy for deep-ultraviolet photodetectors. Jpn J Appl Phys, 2007, 46(11): 7217 doi: 10.1143/JJAP.46.7217[27] Nakagomi S, Kokubun Y. Crystal orientation of β-Ga2O3 thin films formed on c-plane and a-plane sapphire substrate. J Cryst Growth, 2012, 349(1): 12 doi: 10.1016/j.jcrysgro.2012.04.006[28] Zhang Y, Joishi C, Xia Z, et al. Demonstration of β-(AlxGa1−x)2O3/Ga2O3 double heterostructure field effect transistors. Appl Phys Lett, 2018, 112(23): 233503 doi: 10.1063/1.5037095[29] Zhang F B, Saito K, Tanaka T, et al. Structural and optical properties of Ga2O3, films on sapphire substrates by pulsed laser deposition. J Cryst Growth, 2014, 387(2): 96[30] Huang L, Feng Q, Han G, et al. Comparison study of β-Ga2O3 photodetectors grown on sapphire at different oxygen pressures. IEEE Photonics J, 2017, 9(4): 1[31] Cheng Z, Hanke M, Vogt P, et al. Phase formation and strain relaxation of Ga2O3 on c-plane and a-plane sapphire substrates as studied by synchrotron-based x-ray diffraction. Appl Phys Lett, 2017, 111(16): 162104 doi: 10.1063/1.4998804[32] Villora E G, Shimamura K, Kitamura K, et al. Rf-plasma-assisted molecular-beam epitaxy of β-Ga2O3. Appl Phys Lett, 2006, 88(3): 841[33] Vogt P, Bierwagen O. Reaction kinetics and growth window for plasma-assisted molecular beam epitaxy of Ga2O3: Incorporation of Ga vs. Ga2O desorption. Appl Phys Lett, 2016, 108(7): 024001[34] Ravadgar P, Horng R H, Yao S D, et al. Effects of crystallinity and point defects on optoelectronic applications of β-Ga2O3 epilayers. Opt Express, 2013, 21(21): 24599 doi: 10.1364/OE.21.024599[35] Guzmán-Navarro G, Herrera-Zaldívar M, Valenzuela-Benavides J, et al. CL study of blue and UV emissions in β-Ga2O3 nanowires grown by thermal evaporation of GaN. J Appl Phys, 2011, 110(3): 033517 doi: 10.1063/1.3610386[36] Yu D P, Bubendorff J L, Zhou J F, et al. Localized cathodoluminescence investigation on single Ga2O3 nanoribbon/nanowire. Solid State Commun, 2002, 124(10/11): 417[37] Hao J, Cocivera M. Optical and luminescent properties of undoped and rare-earth-doped Ga2O3 thin films deposited by spray pyrolysis. J Phys D Appl Phys, 2002, 35(5): 433 doi: 10.1088/0022-3727/35/5/304 -

Proportional views

DownLoad:

DownLoad: